SECTION 1 - INSTALLATION

1.2 SITING

The appliance m st be installed on a firm co nter or

table or alternatively on the special p rpose made

floor stand s pplied by Falcon.

If either appliance req ires to be installed in close

proximity to a wall, partition, etc. a clearance of 25mm

at the rear and sides is recommended.

A vertical clearance between the hotplates and any

overlying comb stible s rface of 900mm sho ld be

allowed and Fire Reg lations m st be complied with.

1.3 ELECTRICAL SUPPLY

The E350/32 is s itable for connection to a single

phase AC s pply only.

The E350/33 is designed for connection to either a

3 phase/4 wire AC s pply or to a single phase AC

s pply. (See note below.)

The cable entry is located at the rear of the appliance

and is s itable for 20mm cond it. The connection to

the mains electricity s pply m st be made thro gh a

s itable isolating switch with a contact separation of

at least 3mm in all poles. All wiring m st be exec ted

in accordance with the relevant reg lations listed on

the cover of this doc ment.

Warning

THESE APPLIANCES MUST BE EARTHED.

A s itable terminal is provided within compartment

which sho ld be sed for this p rpose.

No e

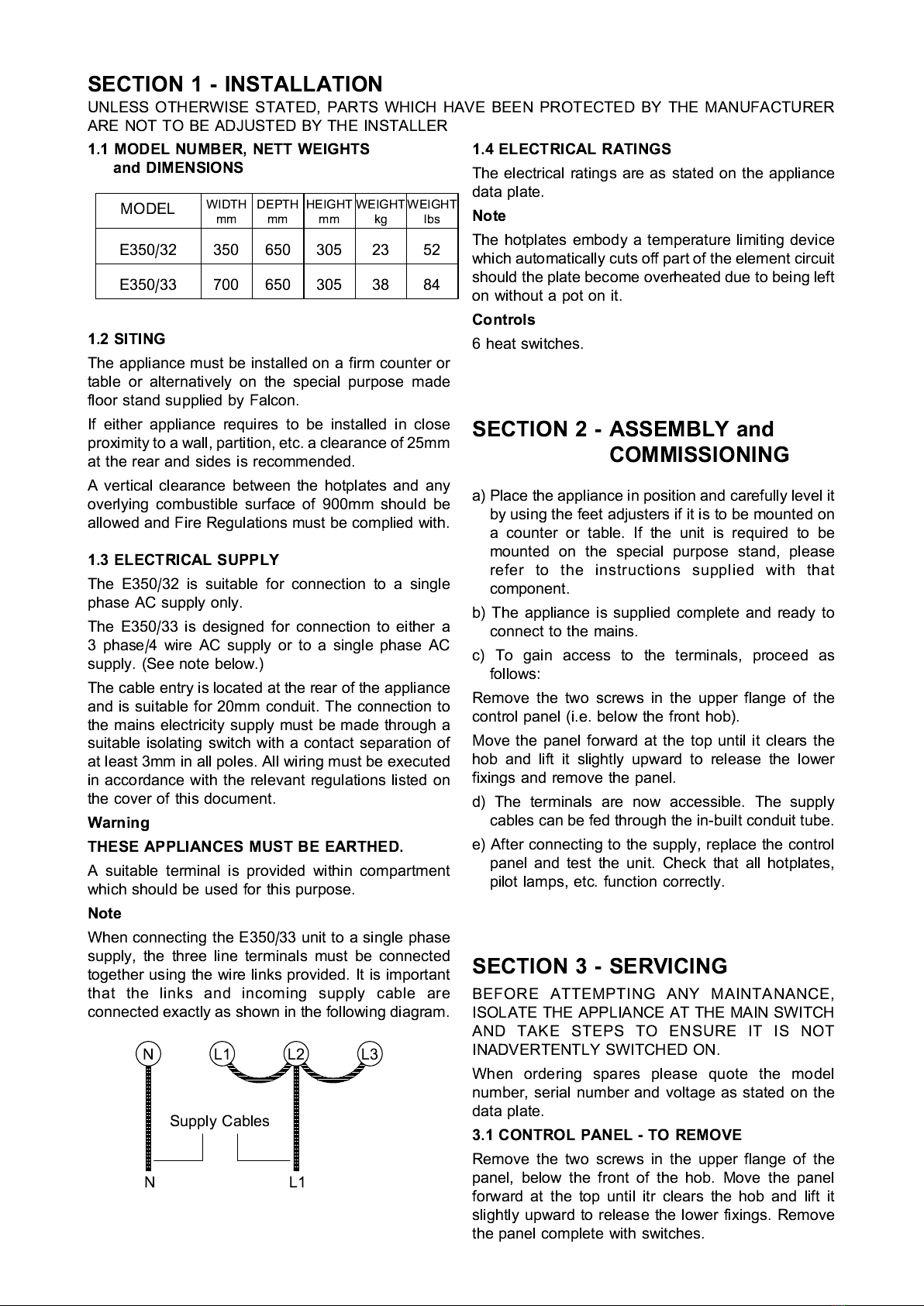

When connecting the E350/33 nit to a single phase

s pply, the three line terminals m st be connected

together sing the wire links provided. It is important

that the links and incoming s pply cable are

connected exactly as shown in the following diagram.

NL1L2L3

S pply Cables

NL1

1.4 ELECTRICAL RATINGS

The electrical ratings are as stated on the appliance

data plate.

No e

The hotplates embody a temperat re limiting device

which a tomatically c ts off part of the element circ it

sho ld the plate become overheated d e to being left

on witho t a pot on it.

Con rols

6 heat switches.

SECTION 2 - ASSEMBLY and

COMMISSIONING

a) Place the appliance in position and caref lly level it

by sing the feet adj sters if it is to be mo nted on

a co nter or table. If the nit is req ired to be

mo nted on the special p rpose stand, please

refer to the instr ctions s pplied with that

component.

b) The appliance is s pplied complete and ready to

connect to the mains.

c) To gain access to the terminals, proceed as

follows:

Remove the two screws in the pper flange of the

control panel (i.e. below the front hob).

Move the panel forward at the top ntil it clears the

hob and lift it slightly pward to release the lower

fixings and remove the panel.

d) The terminals are now accessible. The s pply

cables can be fed thro gh the in-b ilt cond it t be.

e) After connecting to the s pply, replace the control

panel and test the nit. Check that all hotplates,

pilot lamps, etc. f nction correctly.

SECTION 3 - SERVICING

BEFORE ATTEMPTING ANY MAINTANANCE,

ISOLATE THE APPLIANCE AT THE MAIN SWITCH

AND TAKE STEPS TO ENSURE IT IS NOT

INADVERTENTLY SWITCHED ON.

When ordering spares please q ote the model

n mber, serial n mber and voltage as stated on the

data plate.

3.1 CONTROL PANEL - TO REMOVE

Remove the two screws in the pper flange of the

panel, below the front of the hob. Move the panel

forward at the top ntil itr clears the hob and lift it

slightly pward to release the lower fixings. Remove

the panel complete with switches.

UNLESS OTHERWISE STATED, PARTS WHICH HAVE BEEN PROTECTED BY THE MANUFACTURER

ARE NOT TO BE ADJUSTED BY THE INSTALLER

MODEL WIDTH

mm DEPTH

mm HEIGHT

mm WEIGHT

kg WEIGHT

lbs

E350/32 350 650 305 23 52

E350/33 700 650 305 38 84

1.1 MODEL NUMBER, NETT WEIGHTS

and DIMENSIONS