Sesamo ARIETE User manual

INSTALLATION MANUAL

Antipanic Breakaway System

ARIETE

2

Installation Manual

ARIETE

Installation Manual ARIETE

3

Contents

Operation typology of the ARIETE antipanic breakaway system ..........................page 4

Preparation of the sliding leaf ................................................................................page 9

Preparation of the semi-fixed leaf ..........................................................................page 11

Phases of assembly and installation of the ARIETE system..................................page 12

Leaf positioning ......................................................................................................page 21

Magnetic Reed Installation......................................................................................page 23

Installation of the safety photocell (Optional – partial Ariete) ................................page 24

Testing of the system..............................................................................................page 26

We would like to thank you for choosing this product.

In order to obtain the best performance of the ARIETE sys-

tem, the Sesamo Company recommends that you read and

carefully follow the installation and use instructions provided

in this manual. The installation of the ARIETE system must

be performed only by professionally qualified personnel to

whom this manual is directed. Any errors during the installa-

tion phase may be the source of danger for people or things.

The packaging materials (wood, plastic, cardboard, etc.)

should not be discarded in the environment or left within

reach of children since they are potentially dangerous. Each

individual phase of the installation must be performed in con-

formity with the current regulations and, in any case, accord-

ing to the dictates of general good practices. Ensure, before

beginning the installation, that the product is integral and has

not been damaged during transport or as a result of improp-

er storage. Before installing the product ensure that each

architectonic and structural element of the entrance (beam

fastening surfaces, fixtures, guide, etc.) is suitable and suffi-

ciently sturdy to be automated. Conduct a careful analysis of

the risks and make appropriate modifications to eliminate the

areas of dragging, crushing, shearing and of danger in gen-

eral.The manufacturer of the ARIETE system is not liable for

any unobservance of general good practices or specific reg-

ulations in the construction of the fixture to be motorised and

of any failures of the same. All of the protective safety

devices of the automatic door (photocells, active sensors,

etc.) must be installed in conformity with the regulations and

directives in force, the risk analysis, the system typology, the

use, the traffic, and the forces and inertias in play.Always pay

particular attention to the zones were there may occur:

crushing, shearing, dragging and any other danger in gener-

al, placing appropriate signs if necessary. Use only original

spare parts in maintenance or repair operations. Do not

tamper with or alter for any reason the internal parts of the

ARIETE system.The manufacturer declines any responsibil-

ity in the event that the internal parts of the ARIETE system

are tampered with or used improperly. The installer of the

ARIETE system is obligated to provide the person in charge

of the automatic door with the user’s manual and all the infor-

mation necessary for a correct use. Pay particular attention

to the messages in this manual marked by the danger sign.

These may either be warnings aimed at preventing potential

damage to the equipment or specific signals of potential dan-

ger for the safety of the installer or other people involved.

This system has been designed for the breakaway of auto-

matic sliding doors in case of emergency. Any other use will

be considered contrary to the use foreseen by the manufac-

turer who, consequently, cannot be held liable.

4

ARIETE

Installation Manual

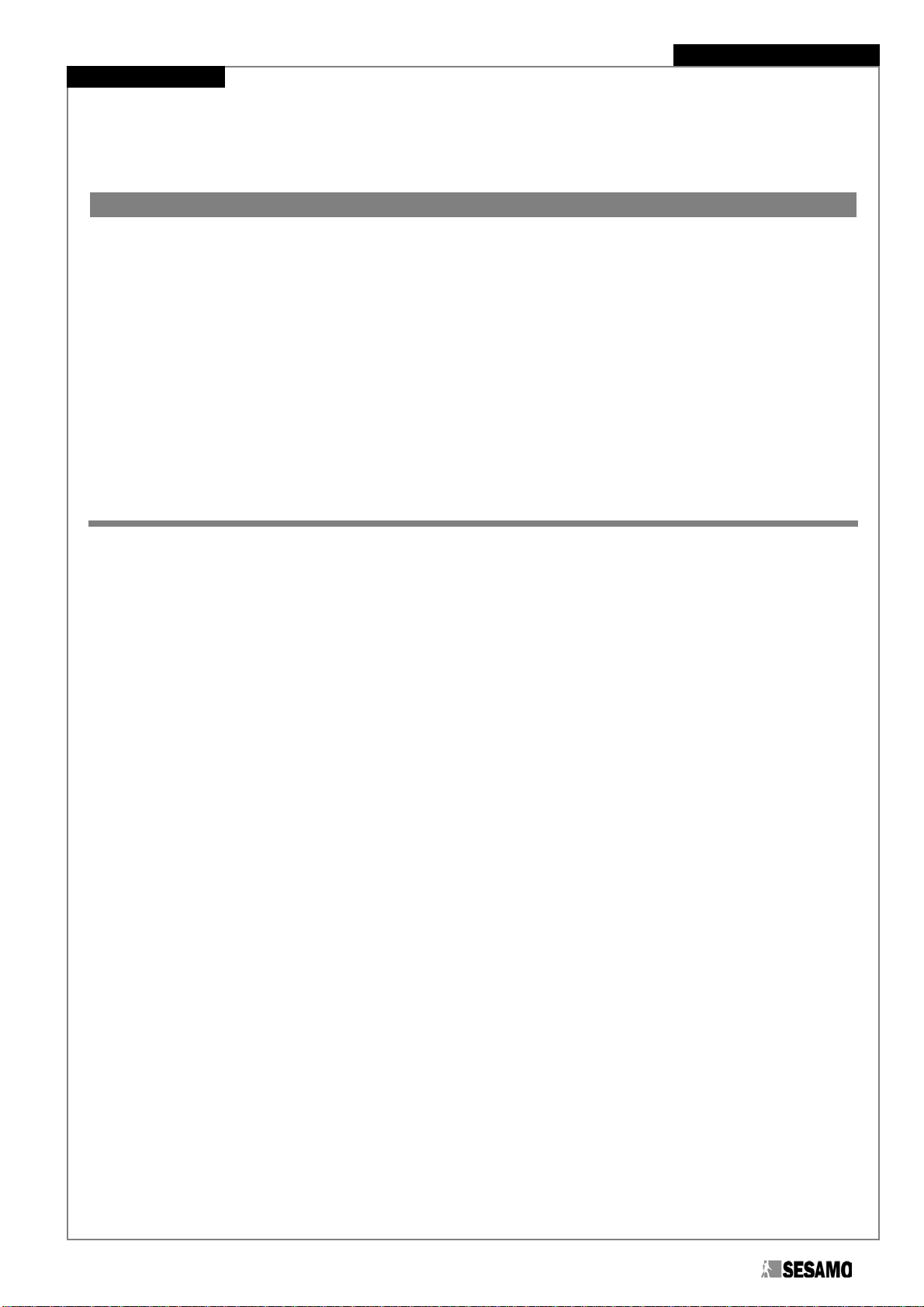

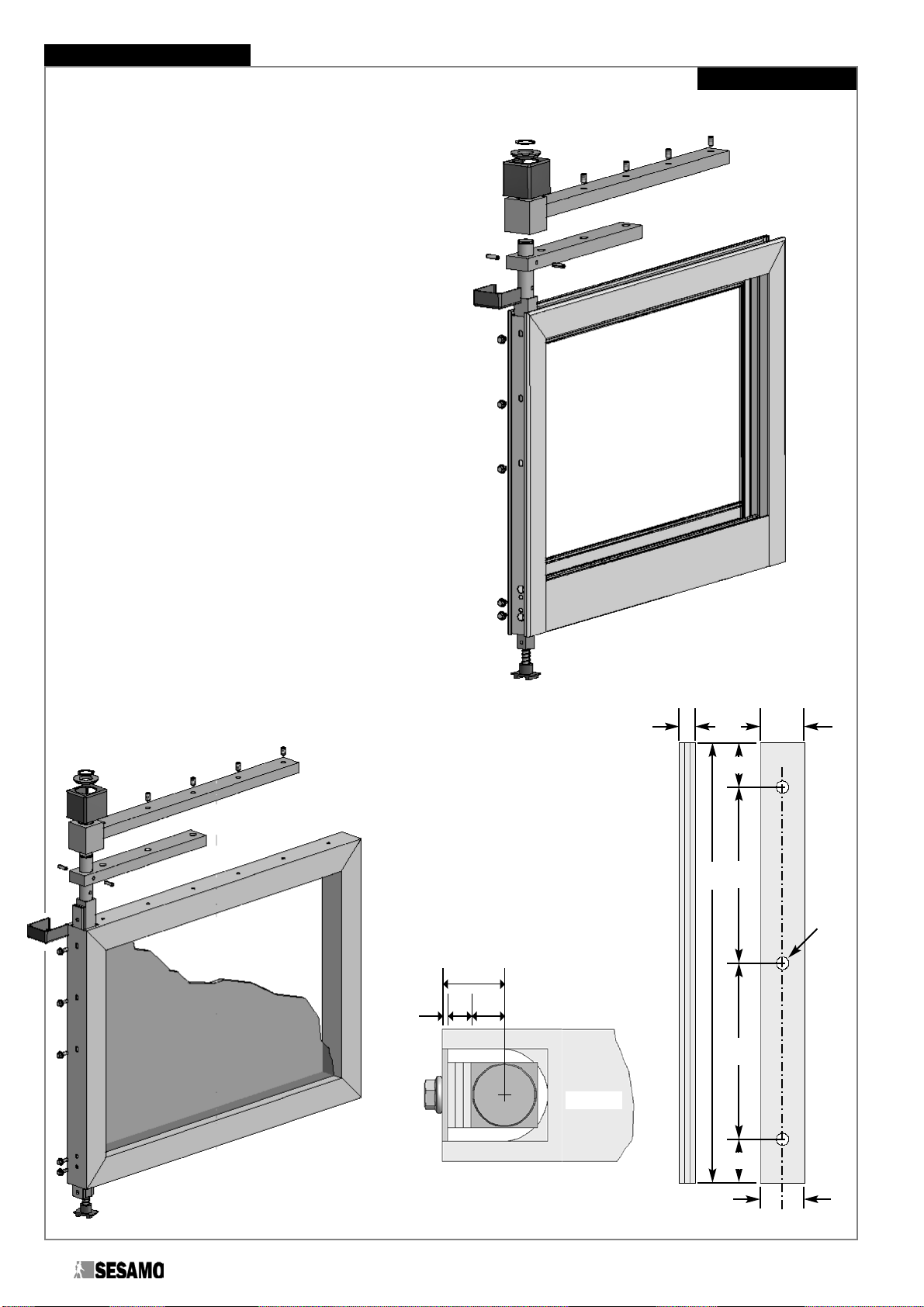

Operation typology of the ARIETE antipanic breakaway system

TOTAL ARIETE (T.A.)

Breakaway system for sliding and semi-

fixed door leaves (Fig. 1 and 2).

Fig. 1

I

E

I

E

I

E

I

E

Example: 2 sliding leaves

SA L.I.

SA

SA

SA

V

Fig. 2

IInterior

EExterior

SA Breakaway direction

LI Crossbeam inspection side

VEmergency passageway

ARIETE

Ariete is available in different models according to the characteristics of the leaf to which it must be coupled and on the

basis of the surface finish.

In particular, it is necessary to choose the type of system using the following stock table once the width and weight of the

leaf are known:

Ariete is available untreated or with silver-coloured

anodising treatment.

This manual does not make any distinction between

the different models available since the assembly

follows the same scheme.

ATTENTION:If the width of the leaf is greater

than 1200 mm, it is necessary to install a third

carriage to the leaf (element not provided in the KIT,

to be ordered separately).

Leaf width ARIETE

[mm]

PF04.01 - PF04.02 PF04.08 - PF04.09

(min.=570) Leaf weight with Ariete (12 Kg) included

600 From 0 to 135kg

700 From 0 to 115kg

800 From 0 to 115kg

900 From 0 to 90kg From 50 to 125kg

1000 From 0 to 80kg From 50 to 115kg

1100 From 0 to 70kg From 50 to 110kg

1200 From 50 to 100kg

1300 From 50 to 90kg

1400 From 50 to 80kg

Installation Manual ARIETE

5

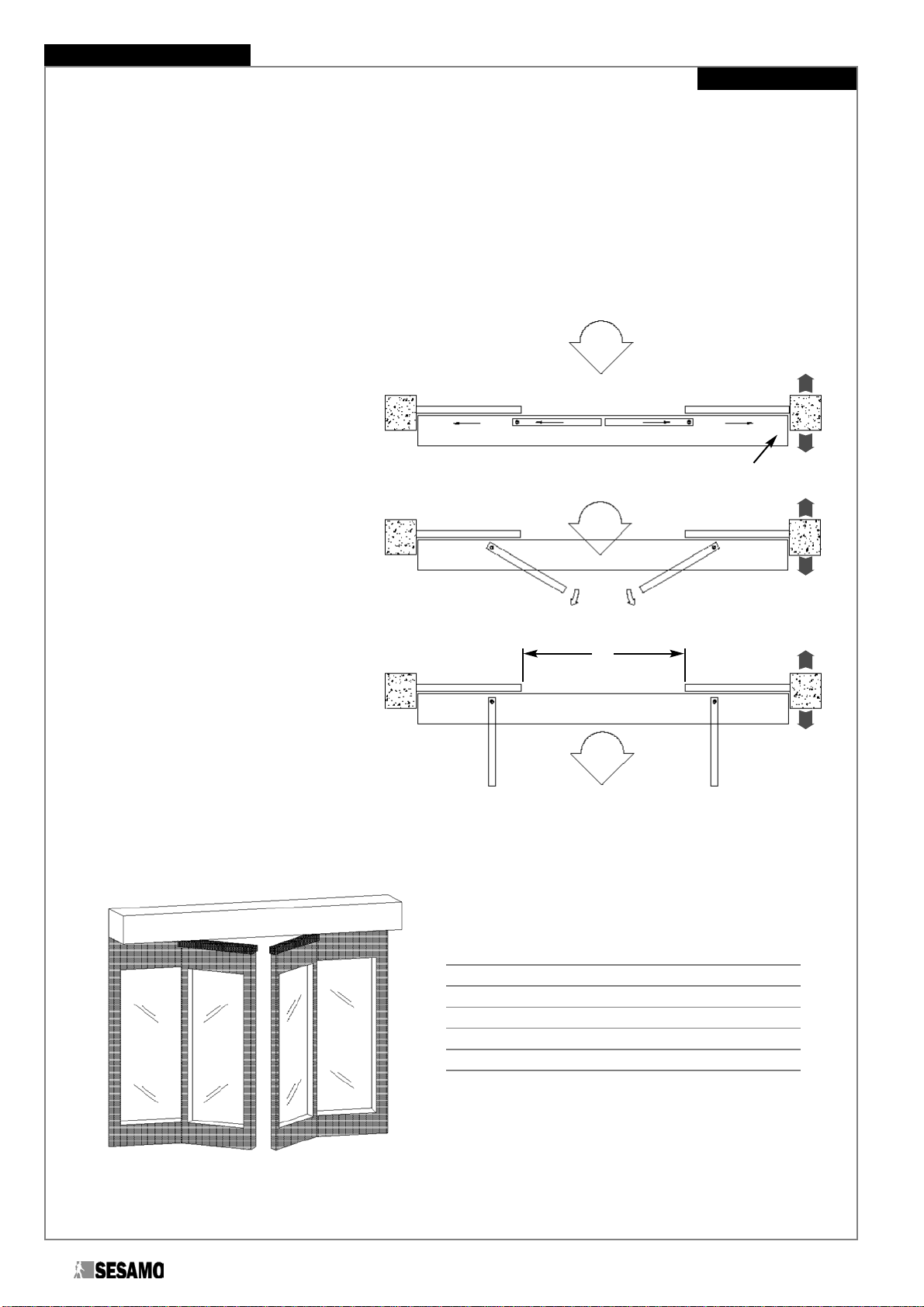

TOTAL ARIETE

Standard Doors (Fig.3a)SESAMO Magnum Doors (Fig.3b)

HCo Under-cover height

HAF Fixed leaf height

HAS Sliding leaf height HCo + HC –HAr - HT

HAr ARIETE system height 78,5mm

HC Under-cover – under-carriage distance

HT Under-sliding leaf – floor distance 13mm

IInterior

EExterior

For HC refer to the manuals of the automatism installed.

Fig. 3a Fig. 3b

ATTENTION: Keep the

minimum distance of 8mm

between the sash and the lower

ARIETE section shown in the

figure.

EIEI

6

ARIETE

Installation Manual

PARTIAL ARIETE

Breakaway system for sliding

leaves only (Fig. 4 and 5).

IInterior

EExterior

SA Breakaway direction

LI Crossbeam inspection side

VEmergency passageway

Fig. 5

Fig. 4

Example: 2 sliding leaves

I

E

I

E

I

E

SA

L.I.

SA

SA

V

Installation Manual ARIETE

7

PARTIAL ARIETE

Standard Doors (Fig.6a)SESAMO Magnum Doors (Fig.6b)

HCo Under-cover height HAF

HAF Fixed leaf height HCo

HAS Sliding leaf height HCo + HC –HAr - HT

HAr ARIETE system height 78,5mm

HC Under-cover – under-carriage distance

HT Under-sliding leaf – floor distance 13mm

IInterior

EExterior

For the value of HC refer to the manual of the automatism installed.

Fig. 6a Fig. 6b

EIEI

8

ARIETE

Installation Manual

TOTAL ARIETE

(sliding leaves and semi-fixed leaves)

A known LUP known T known

T4A-2SC+2Qmc 2LUP+2SC+2Qmc -

LUP 2A-2SC - T-2SC-2Qmc

2

A-LUP+2SC T+2SC-2Qmc

24

FORMULAS for crossbeams with the ARIETE system

SC End overlap

LUP Width of useful passageway

ALeaf width

XCasing thickness

YLeaf thickness

Qmc Machine quotient in rear

LUP SCSC

A

T

A

Standard Doors (Fig.13a)Magnum Door (Fig.13b, 13c)

Qmc

X

Y

10

Fig. 12

Fig. 13a Fig. 13b Fig. 13c

Partial ARIETE

Refer to the formulas provided in the manual of the automatism used without any modification.

Total ARIETE

Qmc

Qmc = 86 mm Qmc = 100 mm

Qmc

ARIETE

9

Installation Manual

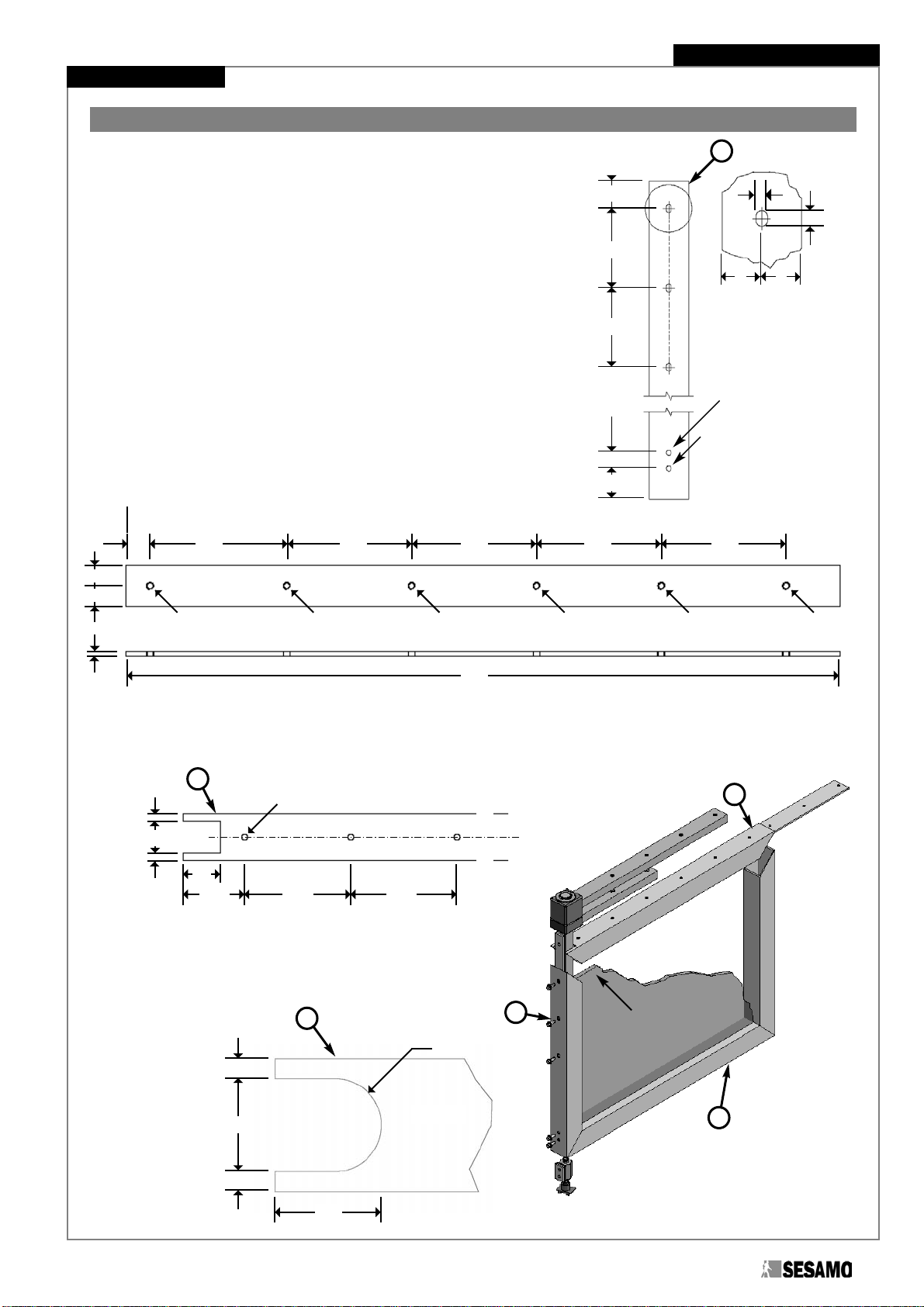

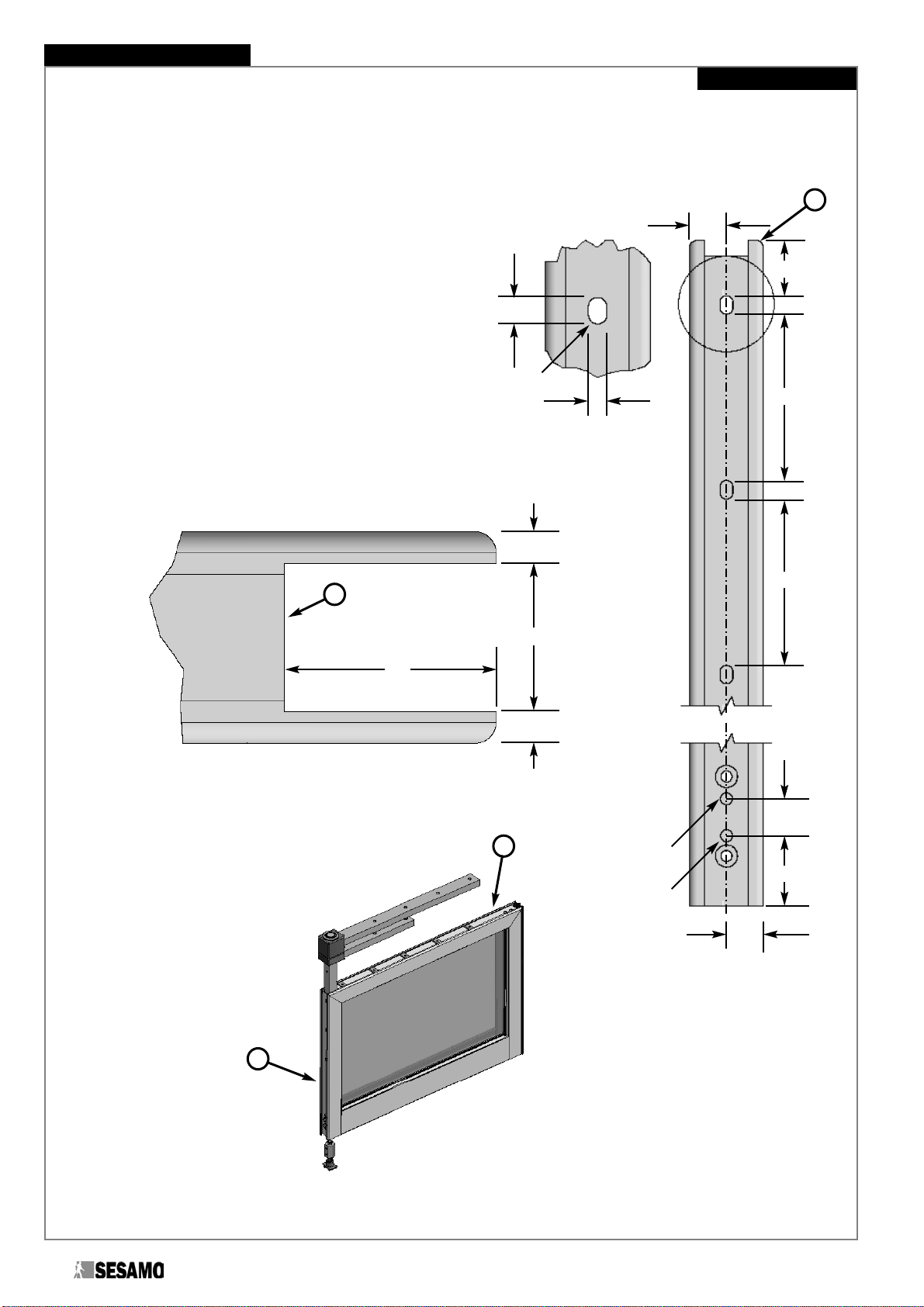

Preparation of the sliding leaf

Standard Doors

In the case of Standard doors:

- Perform the 3 slots and the 2 holes with diameter of 6.5mm on

the upright Athat will host the vertical rod of the ARIETE

system (Fig.14).

- Prepare a steel plate of minimum thickness 4mm with length

equal to L = Leaf Width – (2x50), and a width suitable to

guarantee a solid and secure fastening between the lower

ARIETE section and the upper crosspiece B.Drill and thread

the plate following the indications along the entire length (Fig.

15).

- Drill the upper crosspiece Bof the leaf following the indications

along the entire length of the crosspiece (Fig 16).

- Work the lower crosspiece Caccording to the scheme indicated

by the side of the strickle arm (Fig. 17).

- Insert the steel plate into the correct seat of the upper

crosspiece B(Fig. 18).

ATTENTION:Verify that the threaded holes of the plate are concentric with those present on the upper crosspiece B

and that they are spaced exactly according to the proportions of the drawing.

ATTENTION:Use appropriately sized doors suitable to

support the forces and the stresses caused by the breakaway of the

leaves, in the case of emergency, by means of the ARIETE system.

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

35

7

5

= =

100

100

20

38

Ø 6.5

Ø 6.5

4

28

40

Ø 6.5

66.5 115 115

20 115

M6X1

M6X1

M6X1

M6X1

M6X1

M6X1

115 115

L

115 115

=

=

=

=

Strickle Zone

=

=

35

40

Ø 35

A

BB

A

C

C

10

ARIETE

Installation Manual

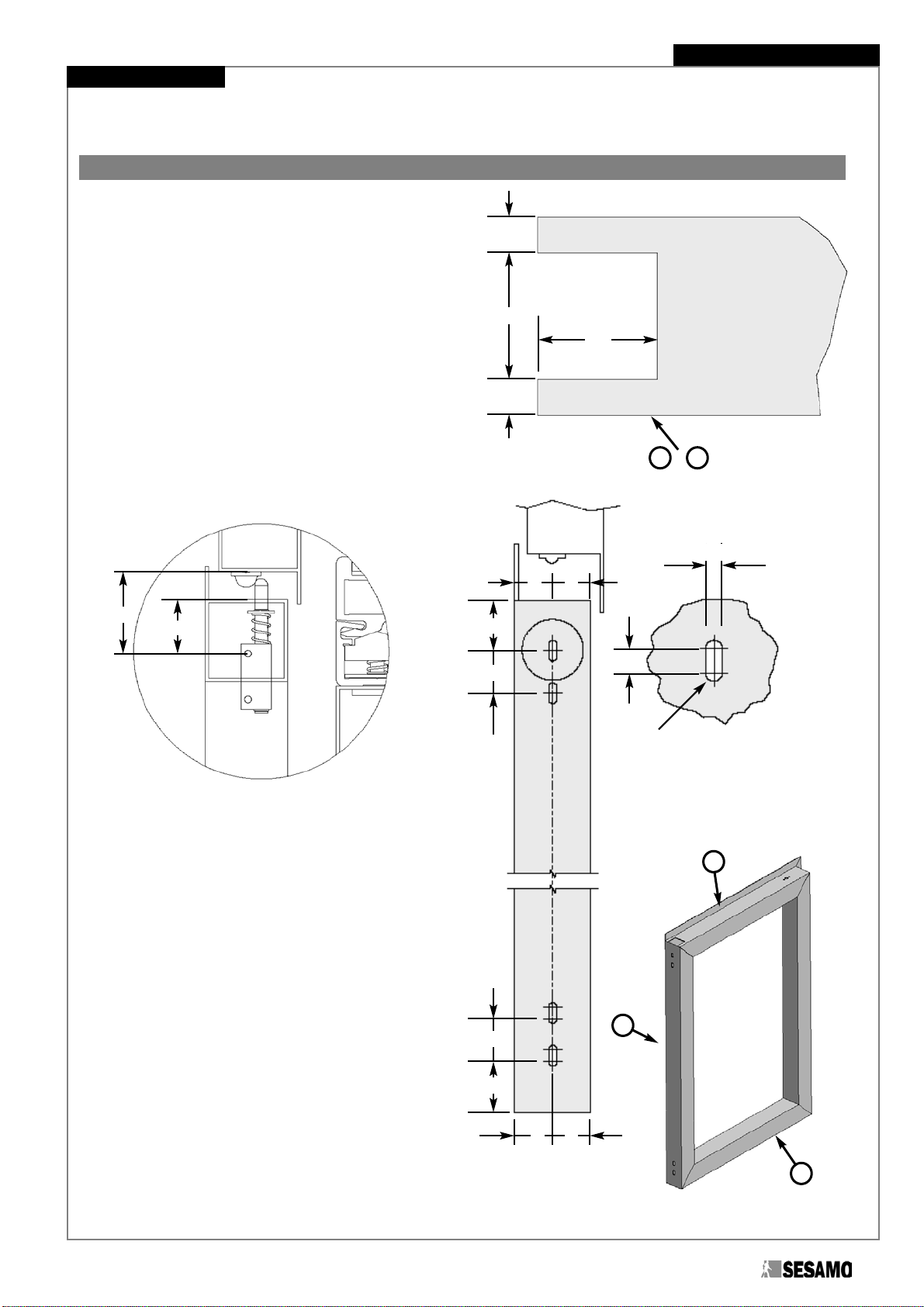

SESAMO Magnum Doors

In the case of SESAMO Magnum doors, position the lower

section/leaf fastening plaques into the correct seat on the

upper crosspiece and, as in the working of the Magnum

sections, perform:

- The 3 slots and the 2 holes of diameter 6.5mm on the

upright Athat will host the vertical rod of the ARIETE

system (Fig. 19).

- An opening on the upper crosspiece B(Fig. 20).

7

20

20

30

90

90

20

38

R=3.5

Ø 6.5

Ø 6.5

10

Fig. 19

40

=

=

28

Fig. 20

Fig. 21

A

B

B

A

Installation Manual ARIETE

11

Preparation of the semi-fixed leaf

Standard Doors

In the case of Standard doors:

- Perform an opening on the upper crosspiece Band on

the lower crosspiece C(Fig. 22).

- Calculate the centre of the top slot (quota X) so that the

distance between this and the supporting plane of the

coupling (see Fig. 57, 58) is equal to 50 mm (Fig. 23).

- perform the slots on the upright Aopposite of that which

will host the hinge (Fig. 24).

ATTENTION:Use

appropriately sized doors

suitable to support the forces

and the stresses caused by the

breakaway of the leaves, in the

case of emergency, by means

of the ARIETE system

=

X

24

28

30

=

= =

5.5

R=2.75

8

X

50

32

30

=

=

=

Fig. 22

Fig. 23

Fig. 24

Fig. 25

A

B

C

B C

HINGE SIDE

12

ARIETE

Installation Manual

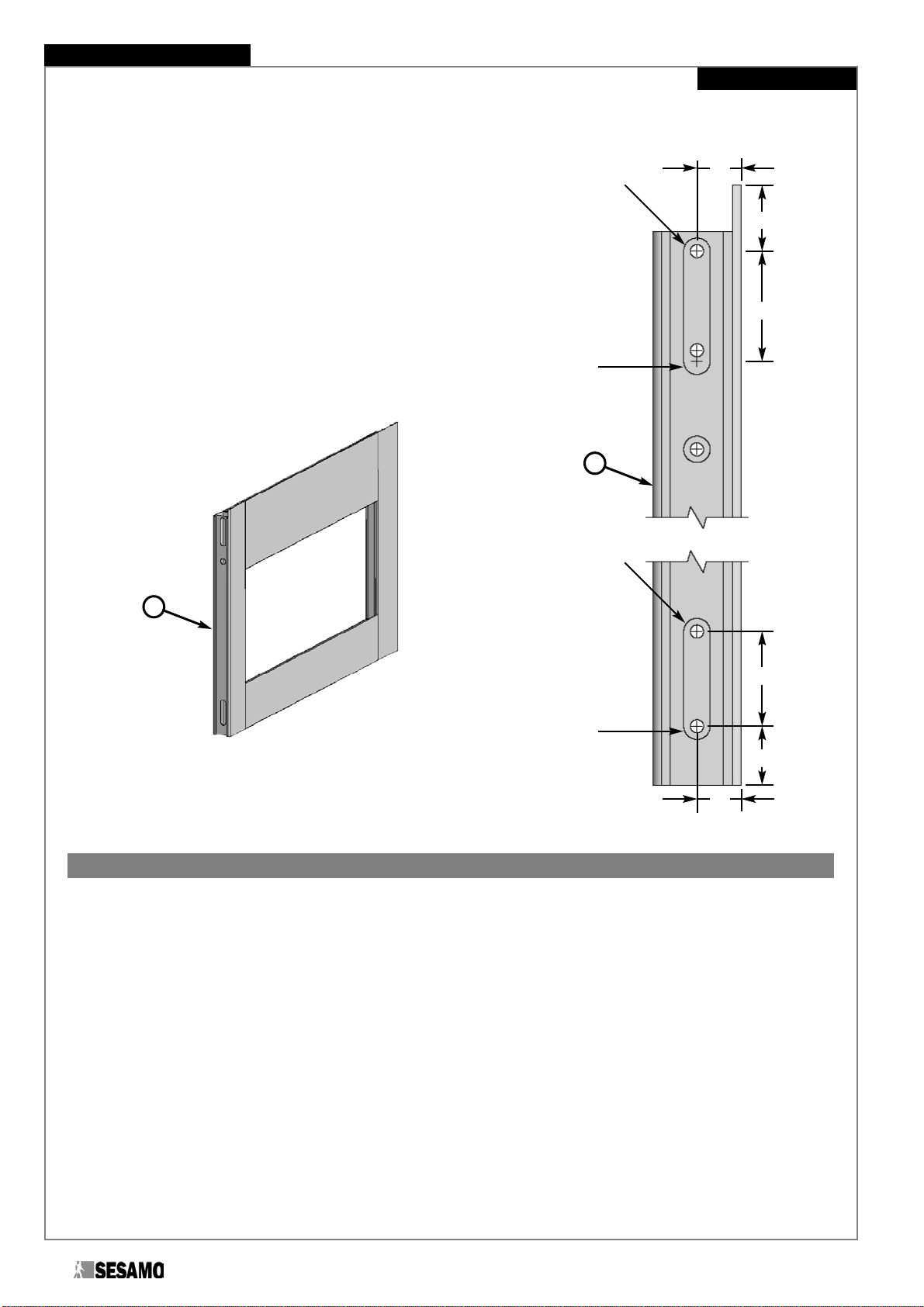

SESAMO Magnum Doors

In the case of SESAMO Magnum Doors perform:

- the slots on the upright Aopposite of that which will host the

hinge (Fig. 26).

Fig. 27

Phases of assembly and installation of the ARIETE system

Materials provided in the ARIETE Kit

- Upper worked section

- Lower worked section

- Worked guide section

- Vertical steel bar with rotation pin

- Lower steel bar

- Upper steel bar with pin seat

- Accessories box + screws + optionals

ATTENTION:Before installing the ARIETE system ensure that:

- All the architectonic and structural parts that support the automatism (beam fastening surfaces, etc.) and all the

elements that make up the installed automatism (carriages, guides, etc.) are suitable to support the forces and the

stresses caused by the breakaway of the leaves, in the case of emergency, by means of the ARIETE system.

20

30

50

20

30

27

Ø 12

Ø 12

Ø 12

Ø 12

Fig. 26

HINGE SIDE

A

A

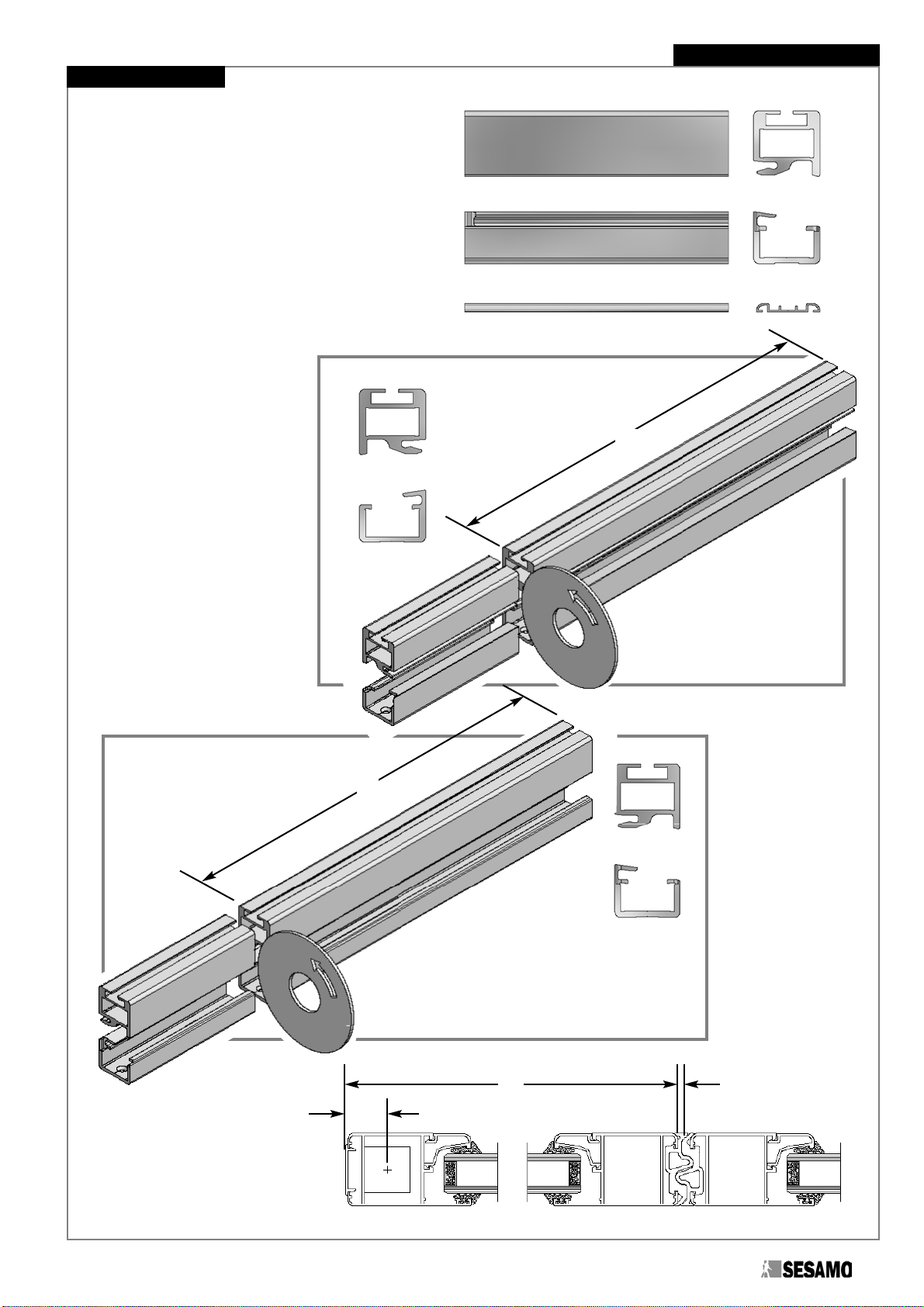

Cutting of the sections

Identify the correct case (Case A or Case B)

referring to the various operational typologies

listed below (Fig. 32-40).

ATTENTION:Be very

careful to cut the correct side.

Cut the upper section and the

lower section at the correct length

using the indicated formula (Fig.

29-31).

L = A + G - 60

A= Leaf width (aluminium only)

G= seal dimension (Magnum

Sections: G = 4 mm)

Installation Manual ARIETE

13

Fig. 28

Case A

Case B

L

L

Fig. 29

Fig. 30

Fig. 31

23.5

A G

14

ARIETE

Installation Manual

PARTIAL ARIETE

TOTAL ARIETE

1 Leaf opens LX P.A. 1 Leaf opens RX P.A.

2 Leaves P.A.

I

E

I

E

I

E

B A

B A

Fig. 32 Fig. 33

Fig. 36

1 Leaf opens RX T.A. 1 Leaf opens LX T.A.

2 Leaves T.A.

I

E

I

E

I

E

B A

B A

Fig. 38 Fig. 39

Fig. 40

Installation Manual ARIETE

15

Cut the floor guide

section at the correct

length using the

indicated formula (Fig.

41a-c).

Fig. 41a

Fig. 41b

Fig. 41c

L

A

79

HA HL

Lg

5

5

30

leaf in open

position

Lg = Leaf width + 30

13

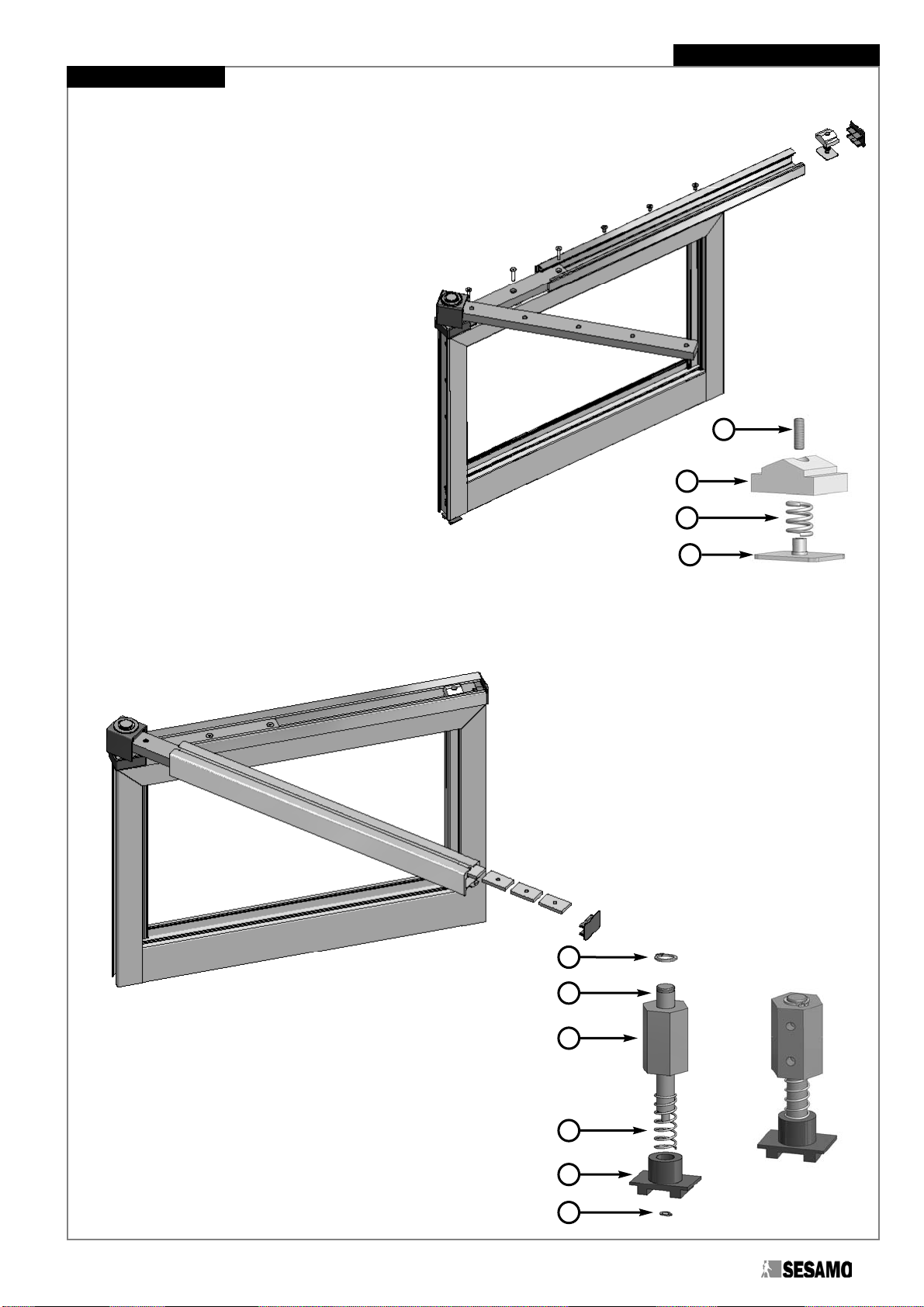

Assembly of the rotation pin complex (Fig. 42a)

Insert in sequence onto the vertical

rod (1) :

- lower blade (2) (with the two locking

holes turned downwards) blocked

with two elastic pegs 6x20 (3)

inserted into the hole on the vertical

rod

- the upper blade (5), respecting the

direction indicated in Fig. 42b

- 5 M8x16 conical point dowels (4)

(screw them in so that the head is

2mm under the surface of the the

upper blade (5))

- the cube cover (6)

- turned strickle fastening washer (7)

- the strickle fastening seeger Ø24 (8)

Fig. 42a

1

3

6

7

2

84

5

Fig. 42b

12.5

5

2

16

ARIETE

Installation Manual

Positioning of the (strickle) rotation pin complex onto the sliding leaf

SESAMO Magnum Sections

Thread the (strickle) rotation pin complex onto the vertical

section of the sliding leaf, inserting the lower blade cover into

the correct position (the 2 conical couplings of the cover

inserted into the 2 holes of the lower blade), fix the vertical

rod of the strickle by screwing the 3 M6x8 TE flanged screws

(Fig 43). Do not over-tighten the screws since the final

fastening will occur after having positioned the lower section

(Fig. 47 page 17 ).

Standard sections

Thread the (strickle) rotation pin complex onto the vertical

section of the sliding leaf, inserting the lower blade cover into

the correct position (the 2 conical couplings of the cover

inserted into the 2 holes of the lower blade), fix the vertical

rod of the strickle by screwing the 3 M6x8 TE flanged screws

(Fig. 44). Do not over-tighten the screws since the final

fastening will occur after having positioned the lower section (Fig. 47 page 17 ).

In the case of Standard sections place between

the internal upright and the strickle rotation pin

one or more steel or aluminium blades so that the

centre of the rotation axis is exactly at 23.5mm

from the external upright (Fig 45, 46).

A= 23,5 – 12,5 – S

A= distance between the internal

upright and the rotation pin

S= thickness of the upright section

ATTENTION:Be very careful about

the direction of breakthrough. Fig. 43

Fig. 44

Fig. 45

Fig. 46

ATTENTION:Be very careful about the

direction of breakthrough.

MIN.20

MAX

.25

A

==

25

25

Ø 7

100

100

250

SA12.5

23.5

Installation Manual ARIETE

17

Positioning and fastening of the lower and upper sections

Lower section (Fig. 47a):

Put the lower blade of the strickle onto the lower section until stopping it against

the lower blade cover.

The fastening occurs by screwing 3 M6x30 TS CEI screws in the

zone with the strickle and the M6x12 TS CEI screws in the

free zone suitably spaced (at least 1 screw every 2

holes). If necessary, loosen the fastening screws of

the strickle to the upright previously positioned (Fig.

43 and 44).

In the case of SESAMO Magnum doors the screws

are screwed to the lower section/leaf fastening

plaques.

In the case of SESAMO Standard doors the

screws are screwed to the lower section/leaf steel

plate (Fig. 15 page 9).

Insert inside the lower section the release force

regulator assembled as follows (Fig. 4b):

- put the spring (1) onto the release force regulator

plate (2)

- position the release force regulator slide (3)

- insert a M5x16 conical point dowel (4)

Tighten well the M6x8 TE flanged screws used for the vertical

fastening of the strickle onto the upright (Fig 43 and 44)

Position the section cap with the reference arrow turned upwards.

Upper section (Fig. 48):

- Put the upper blade of the strickle onto the upper

section and stop it against the cube cover

cube (Fig. 48).

- Screw in the 5 M8x16 conical point dowels

previously inserted into the holes of the upper

blade.

- Insert into the appropriate seat of the upper section

the 4 automatism adapter plaques. If 3 carriages

are mounted, 2 more plaques have to be

inserted.

- Position the section cap with the

reference arrow

turned upwards.

Assembly of the guide shoe complex (Fig. 49a, 49b)

Put the guide shoe pin (Fig 49a, part 1) inside the hole on the

guide shoe (Fig 49a, part 2)

Insert in sequence onto the guide shoe pin:

- the guide shoe spring (Fig. 49a, part 3)

- the guide shoe body (Fig. 49a, part 4)

- the 11mm seeger into the appropriate seat (Fig. 49a, part 5)

- the self-blocking 5mm seeger for the fastening of the guide

shoe onto the pin (Fig. 49a, part 6)

Fig. 47a

Fig. 48

Fig. 49a Fig. 49b

5

1

4

3

2

6

Fig. 47b

1

4

3

2

Fig. 52

18

ARIETE

Installation Manual

Positioning of the guide shoe complex onto the sliding leaf

Insert the guide shoe complex into the vertical section of the sliding leaf and

fasten it with two M6x8 TE flanged screws (Fig. 50).

In the case of Standard sections place between the internal upright and the

guide shoe rotation pin one or more steel or aluminium blades (Fig. 51) so that

the centre of the rotation axis is exactly at 23.5mm from the external upright

(see Fig. 45, 46), the fastening screws must be chosen according to the

thickness of the spacer so as to not obstruct the running of the guide shoe

pin (Fig 52).

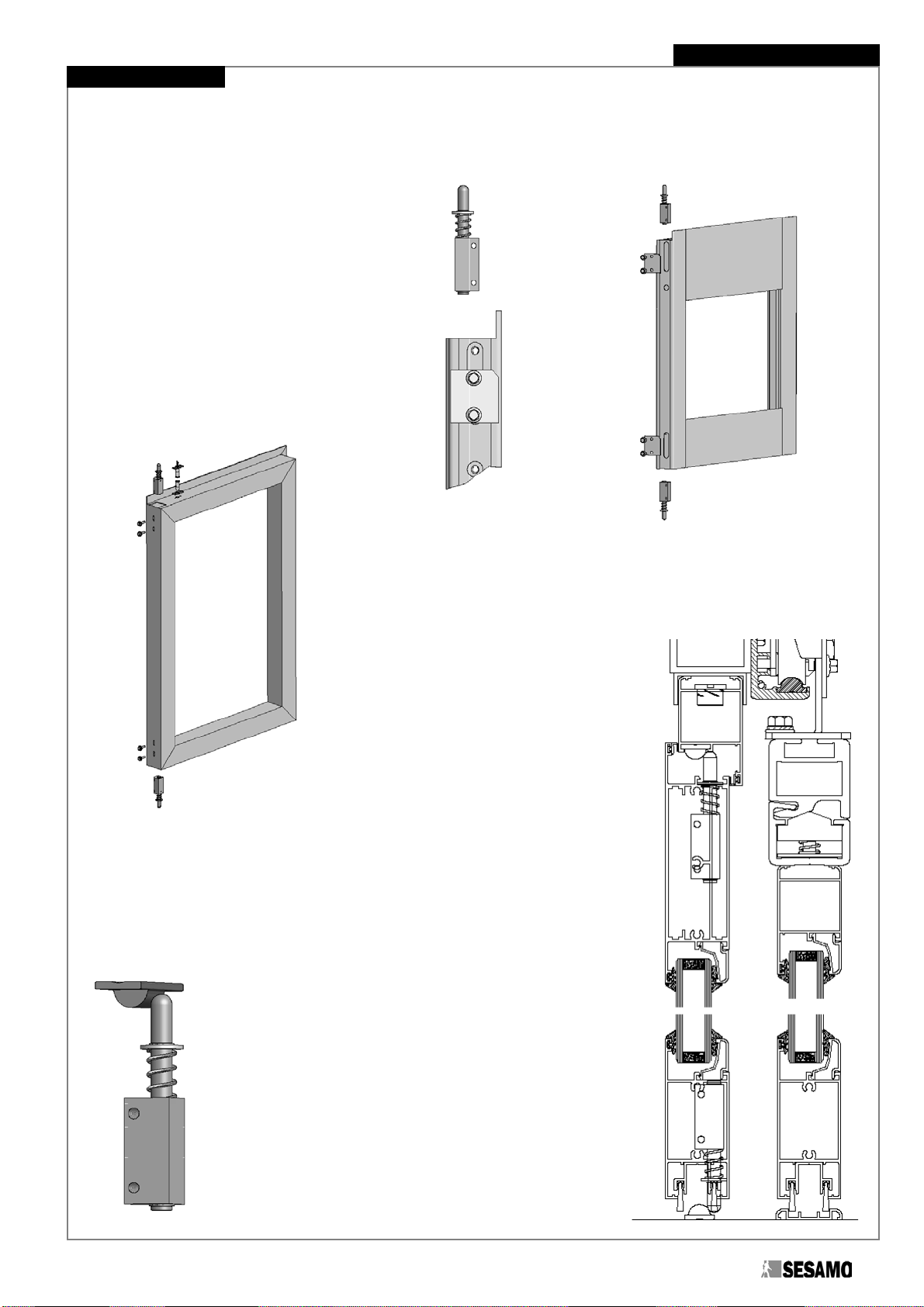

Assembly of the semi-fixed leaf release device complex (Fig. 53a, b)

Mount the 8mm seeger (Fig. 53a, part 2) into the appropriate seat on the semi-fixed release

device pin (Fig. 53a, part 1).

Insert in sequence onto the semi-fixed release device pin:

- one or more 8mm washers to obtain the desired preloading (Fig. 53a, part 3)

- the semi-fixed spring (Fig. 53a, part 4)

- the semi-fixed release device body (Fig. 53a, part 5)

Finish everything with the seeger 8mm (Fig. 53a, part 6)

in the appropriate seat.

ATTENTION:It is possible to vary the retention

force of the semi-fixed leaf exclusively by adding one

or more washers (Fig 53a, part 3).

Fig. 50

Fig. 51

A

40

Ø 7

20

= =

MIN.20 MAX.25

5

1

4

3

2

6

Fig. 53a

Fig. 53b

Installation Manual ARIETE

19

Positioning of the semi-fixed release complex onto the semi-fixed leaf (TOTAL ARIETE)

SESAMO Magnum Sections (Fig 54a)

In the case of the SESAMO Magnum

sections insert the 2 assembled semi-fixed

release groups into the vertical section of the

semi-fixed leaf, fix them with the M5x16 TE

flanged screws and appropriate plaques

(positioned as in Fig. 54b) inserted into the

external seat of the upright. Do not over-tighten

the fastening screws so as to allow for a later

adjustment of the height (Fig. 57).

Standard sections (Fig 55)

In the case of Standard sections, insert

the two assembled semi-fixed release

groups into the vertical section of the

semi-fixed leaf and fasten them with the

M5x16 TE flanged screws. Do not over-tighten

the fastening screws so as to allow for a later

adjustment of the height (Fig. 57).

Fastening of the semi-fixed release coupling (TOTAL ARIETE)

SESAMO Magnum Sections

In the case of SESAMO Magnum sections fasten the semi-fixed release coupling to

the floor, in a central position with respect to the semi-fixed leaf, with 2 6mm plugs and

2 AF 4x40 screws and work on the slots to move the coupling into contact with the

hemispherical zone of the release device (Fig 56, 57).

Insert the upper semi-fixed release coupling into the seat of the

“glassholder” of the rabbet frame before assembling it and

fastening it to the door with 2 AF 4.2x9.5 screws (Fig. 56).

Adjust the height of the release device so that its hemispherical

end touches the coupling at the middle of the curved ramp (Fig.

57).Tighten well the M5x16 TE flanged screws.

ATTENTION:Pay particular attention to the adjustment of

the device since any error may compromise the correct operation.

Do not use the slots to vary the preloading of the spring, for this

purpose action can be taken exclusively at the moment of the

device assembly (Fig.53a, b).

Fig. 54b

Fig. 54a

Fig. 57

Fig. 56

Fig. 55

HINGE SIDE

20

ARIETE

Installation Manual

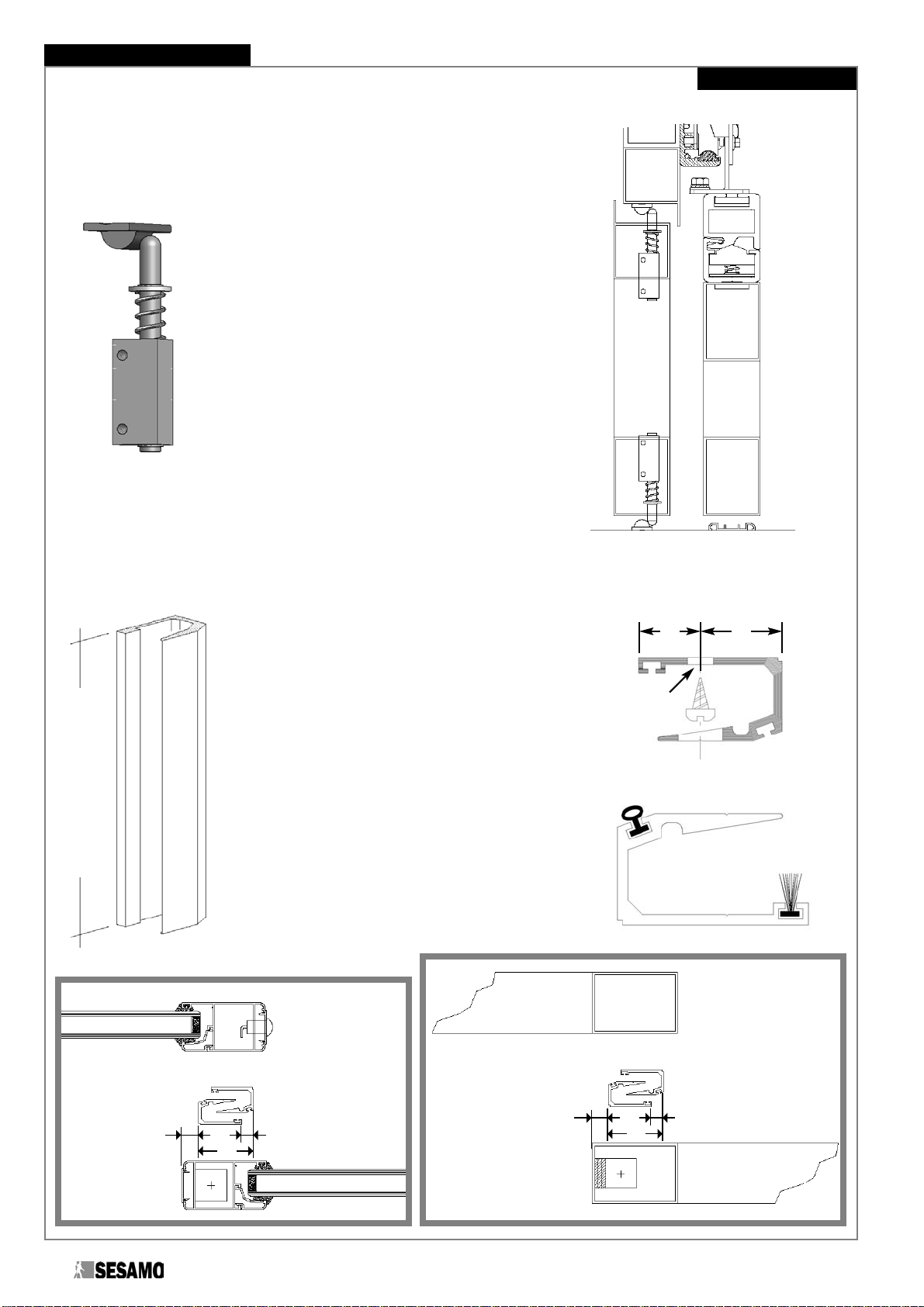

Standard sections

In the case of Standard sections fasten the semi-fixed release coupling to

the floor, in a central position with respect to the semi-fixed leaf, with 2

6mm plugs and 2 AF 4x40 screws.

Fasten the upper semi-fixed release coupling to

the door with 2 AF 4.2x9.5 screws in a central

position with respect to the semi-fixed leaf and

work on the slots to move the coupling into contact

with the hemispherical zone of the trigger device

(Fig. 57, 58).

Adjust the height of the release device so that its

hemispherical end touches the coupling at the

middle of the curved ramp (Fig. 57).Tighten well

the M5x16 TE flanged screws.

ATTENTION:Pay particular attention to the

adjustment of the device since any error may

compromise the correct operation. Do not use the

slots to vary the preloading of the spring, for this

purpose action can be taken exclusively at the

moment of the device assembly (Fig.53a, b).

Fig. 57

Fig. 58

Fastening of the sealing sections (TOTAL ARIETE)

- Cut the sealing section to the length HL = H

leaf – 78.5 mm (Fig. 41a, 59a).

- Drill the fixed and sliding leaves following the

scheme in Fig. 60a, b.Provide for at least 1

screw every 400mm, excluding the strickle zone

of the sliding leaf.

- Drill the sealing sections in the fastening zones

according to the scheme in Fig. 59b.The

position and the interaxis of the holes must

correspond with those performed on the sealing

sections.

- Fasten the sealing sections onto the fixed and

sliding leaves using appropriately sized self-

threading screws.

- Insert the brush and the rubber profile into the

appropriate channels of the sealing section

(Fig. 59c)

Fig. 59a

Fig. 60a Fig. 60b

Fig. 59b

Fig. 59c

15 20

Ø 5

H sealing section = HL

13 35

45 10 13 35

45 10

fixed leaf

sliding leaf

fixed leaf

sliding leaf

This manual suits for next models

4

Table of contents

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual