Setra Systems DPT267 Series User manual

This manual suits for next models

1

Other Setra Systems Transducer manuals

Setra Systems

Setra Systems 209 User manual

Setra Systems

Setra Systems 265 User manual

Setra Systems

Setra Systems AXD User manual

Setra Systems

Setra Systems 355X Series Product guide

Setra Systems

Setra Systems 209 User manual

Setra Systems

Setra Systems 540 Series User manual

Setra Systems

Setra Systems Multi-Sense 231RS User manual

Setra Systems

Setra Systems 267 User manual

Setra Systems

Setra Systems Multi-Sense 231RS User manual

Setra Systems

Setra Systems 526 User manual

Setra Systems

Setra Systems 204 User manual

Setra Systems

Setra Systems 550 User manual

Setra Systems

Setra Systems 223 User manual

Setra Systems

Setra Systems DPT264 Series User manual

Setra Systems

Setra Systems 264 User manual

Setra Systems

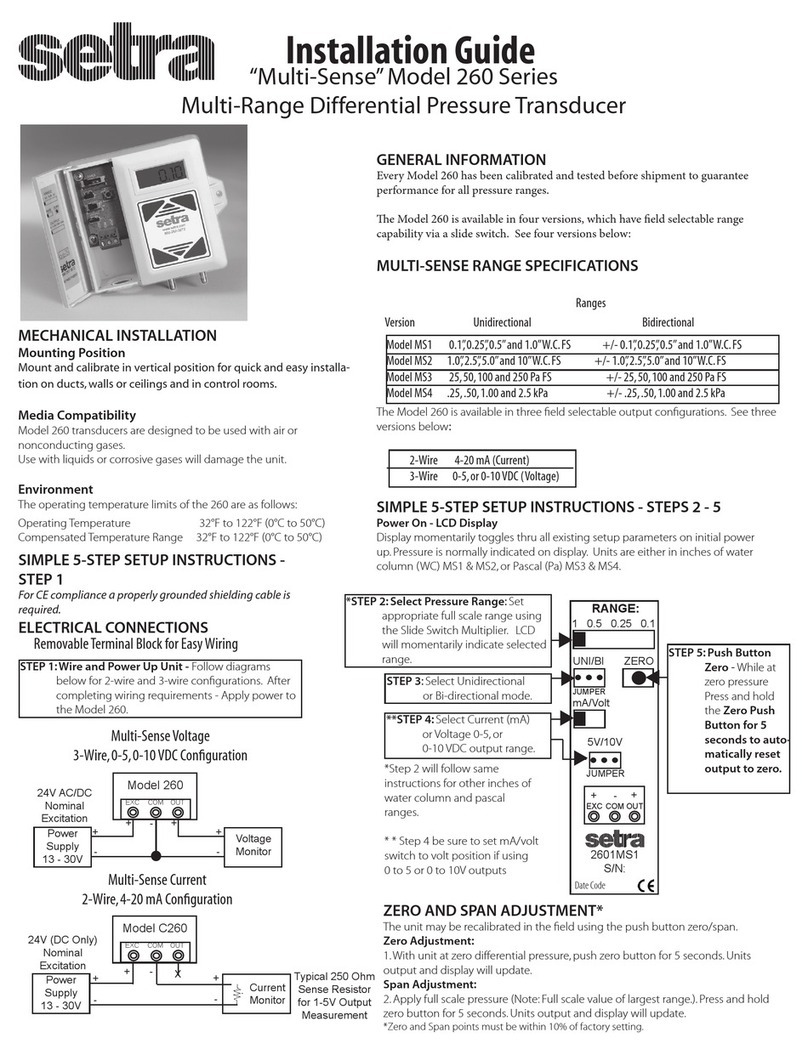

Setra Systems Multi-Sense 260 Series User manual

Setra Systems

Setra Systems MS1 User manual

Setra Systems

Setra Systems 567 User manual

Setra Systems

Setra Systems 224 User manual

Setra Systems

Setra Systems 267 User manual

Popular Transducer manuals by other brands

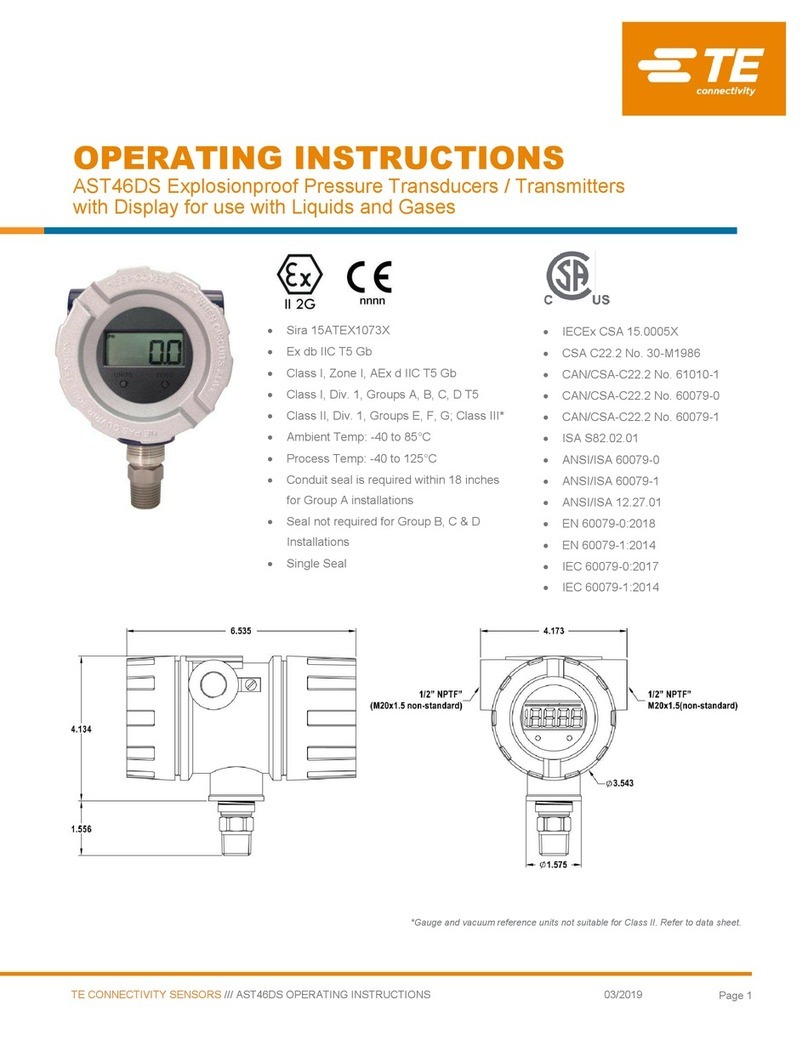

TE Connectivity

TE Connectivity AST46DS operating instructions

Siemens

Siemens SITRANS L 7ML1100 operating instructions

Balluff

Balluff BTL7-A Series user guide

Simrad

Simrad IS15 manual

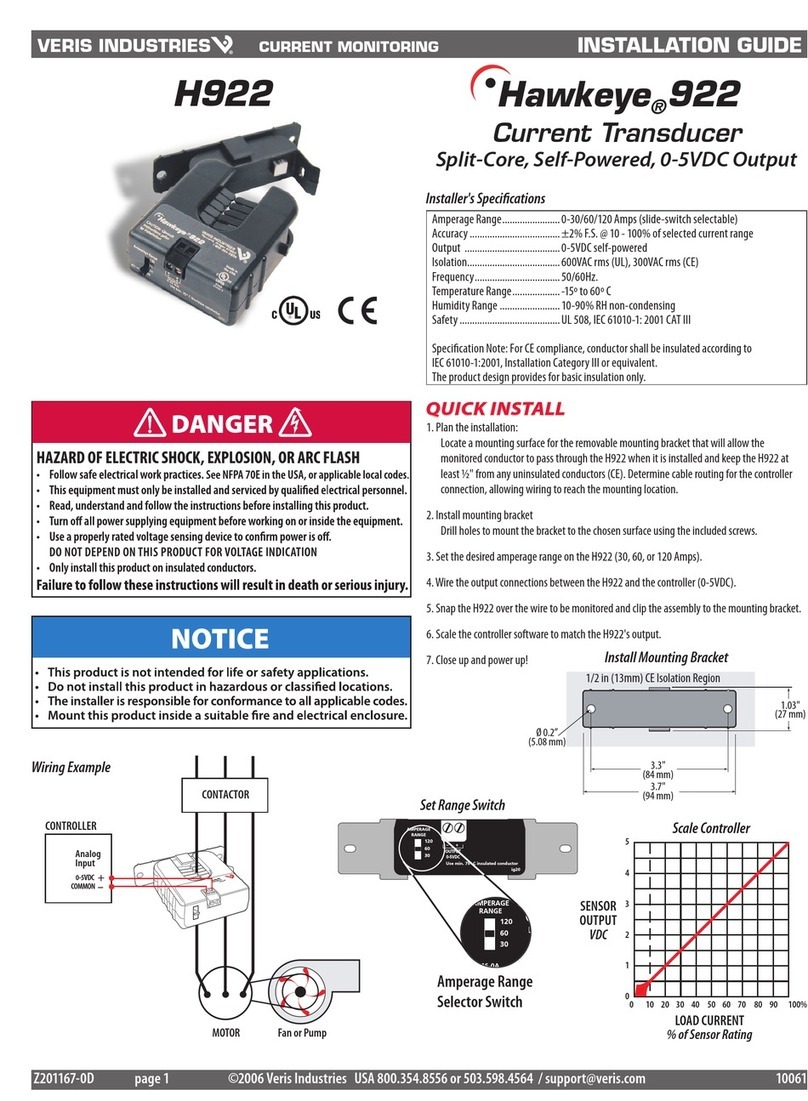

Veris Industries

Veris Industries Hawkeye 922 installation guide

Baker Hughes

Baker Hughes Masoneilan 8000 instruction manual

Balluff

Balluff BTL5-S M A Series user guide

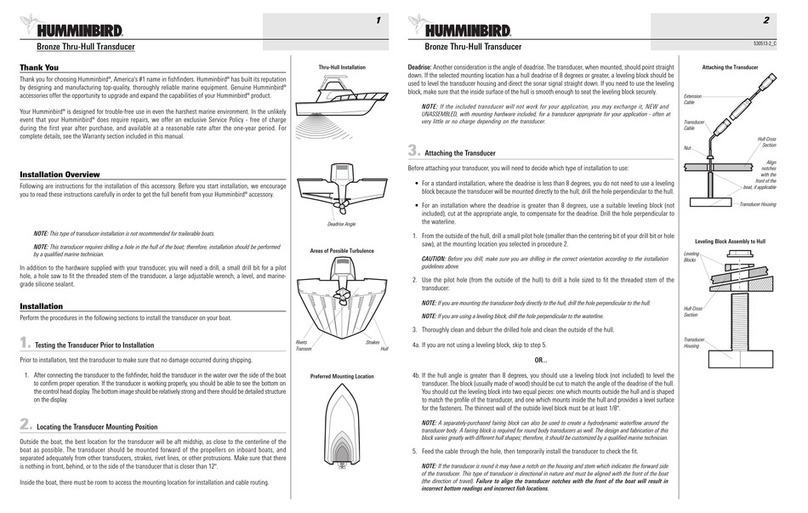

Humminbird

Humminbird XTH 9 20 P manual

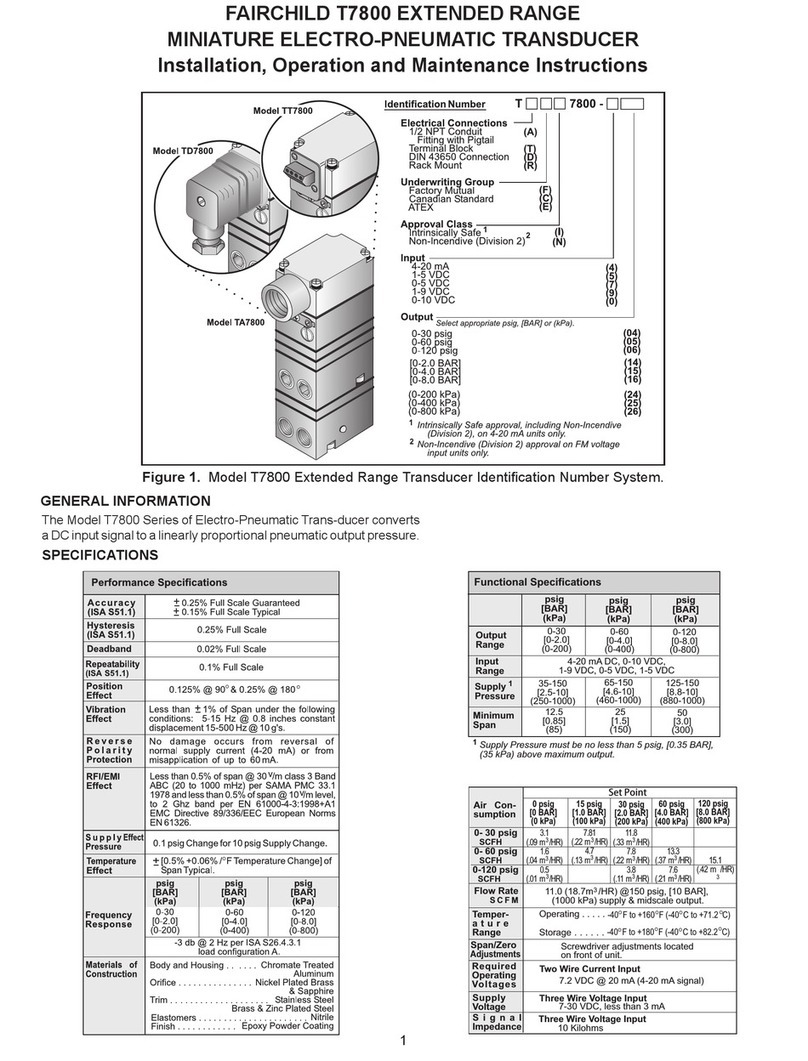

Fairchild

Fairchild T7800 Series Installation, operation and maintenance instructions

HBM

HBM C4 Mounting instructions

Milltronics

Milltronics ST-50 Series instruction manual

Camille Bauer

Camille Bauer SINEAX DME 440 operating instructions

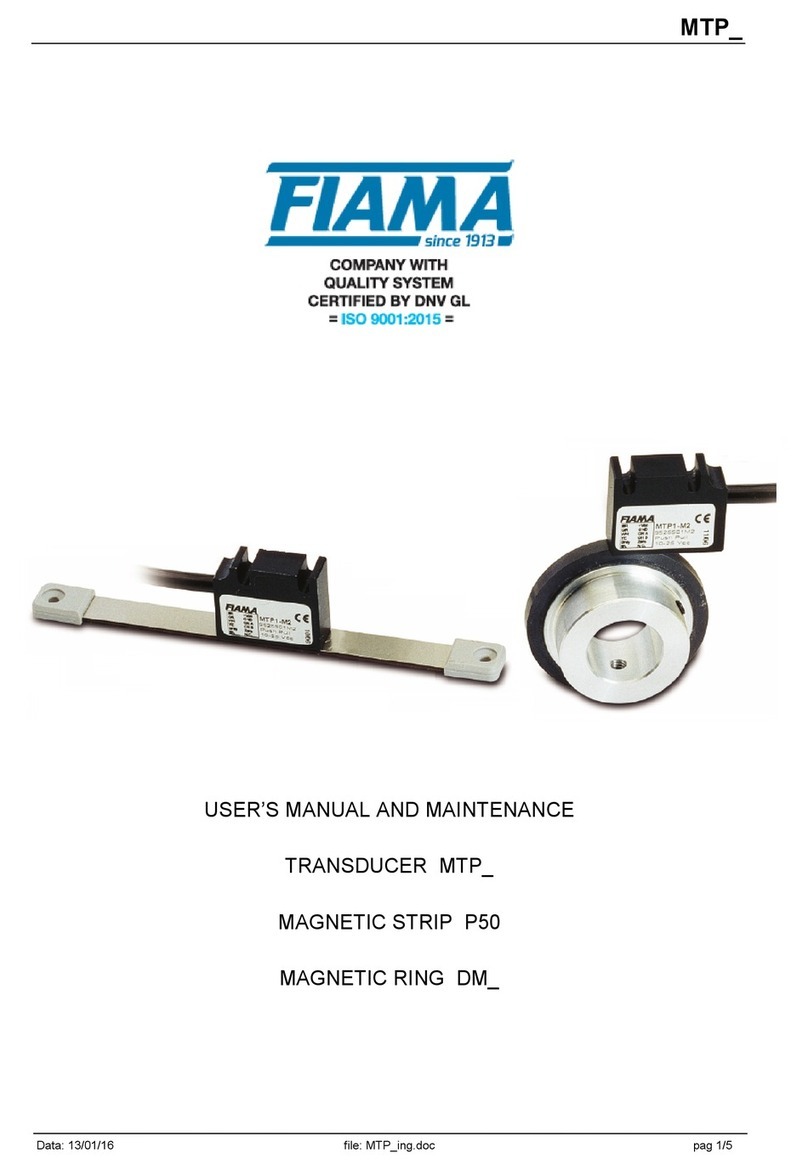

FIAMA

FIAMA P50 User manual and maintenance

S+S Regeltechnik

S+S Regeltechnik THERMASGARD ATM2-VA Operating Instructions, Mounting & Installation

Daiichi Electronics

Daiichi Electronics AETT2-91A instruction manual

Simrad

Simrad ES 18 - DATASHEET REV C datasheet

Simrad

Simrad ES120-7 - REV C datasheet

Milltronics

Milltronics ST-100 SERIES instruction manual