3

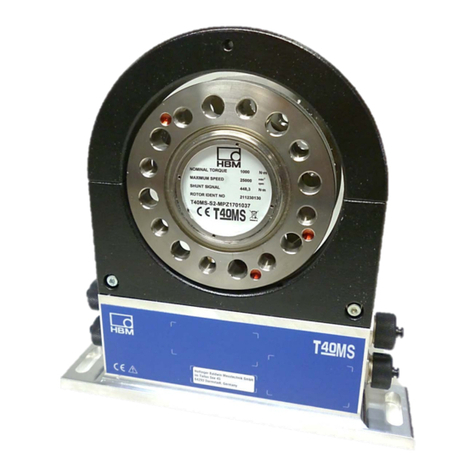

T40

HBMA24633.0en/de

Contents Page

Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Application 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Structure and mode of operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Mechanical installation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Conditions on site 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Mounting position 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Installation options 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Installation without dismantling the antenna ring 11. . . . . .

3.3.2 Installation with subsequent stator mounting 12. . . . . . . . .

3.4 Installing the rotor 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Installing the stator 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Electrical connection 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General hints 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Shielding design 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Connector pin assignment 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Supply voltage 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Shunt signal 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Triggering the shunt signal 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Settings 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Output frequency settings 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Functional testing 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Rotor status LED 1 (upper LED) 23. . . . . . . . . . . . . . . . . . .

6.2.2 Stator status LED 2 (lower LED) 23. . . . . . . . . . . . . . . . . . .

7 Loading capacity 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Measuring dynamic torque 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Specifications 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Dimensions 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 T40/500N@m and 1kN@m29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 T40/2kN@m and 3kN@m31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Supplementary technical information 33. . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Runout and concentric tolerances 33. . . . . . . . . . . . . . . . . . . . . . . . .

11 Order numbers 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Accessories 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .