SFS Soter User manual

Soter fall protection and wire system

Installation

manual

2SFS / Installation manual Soter

Typical Fall Arrest System layout

Fall Arrest

When a work restraint system cannot be feasibly offered, then a

fall arrest system can then be considered.

Fall arrest systems are designed to ‘limit the consequences of a

fall should it occur’.

The Soter HLL system will arrest a users’ fall, only if the required

fall clearance has been allowed.

Fall clearances must be factored in when a fall arrest system is

designed, considering the following factors;

nBuilding height

nFree fall distance from roof edges

– To the ground

– Lower level roofs/adjacent buildings

nFree fall distance through fragile roof areas/roof lights/canopies

etc.

Although fall arrest systems are often employed to give a user full

roof access, they come with major disadvantages, such as;

nThey do not stop a fall from height occurring as the user has

flexibility of PPE lengths.

nThey can only be used on buildings with the required free fall

clearance from all fall hazards including through roof lights.

nA full rescue plan must be in place to return the user

to safety, often this is overlooked.

nThe users must be trained so they can use extra PPE equipment

safely including extended rope and grab devices and anti-

pendulum/swing posts.

*Soter systems should not be designed to arrest on standing seam

roof sheets due to the weakness of the connection between clip

and sheet which will not give required arrest figures.

Key:

A – Soter HL Start/End post with female M10/Universal

B – Soter R Intermediate post with intermediate bracket

C – Soter HL Corner with corner kit/solid corner

D – Soter anti-pendullum/swing post

Work Restraint

Work restraint systems are the safest method of HLL system

design. Keeping a user in restraint removes the possibility of fall

occurring. The users path, and what they have access to can be

dictated/controlled.

Keeping a user in restraint is dictated by the relationship of two

key distances;

nLanyard length (A)

nPosition of the system and distance away from fall hazard (B),

*see figure adjacent and on page 6

If the achievable distance between position of line and fall hazard

varies on the system route, the lesser distance and therefore

lanyard length should be preferred before any variable lanyard

lengths/multiple lanyards are proposed.

The general spacing from system to roof edge/fall hazard is 2.30m

based on a typical lanyard length of 1.85m.

Fall Hazards can be roof edges, roof lights or other fragile roof

areas such as windows/glass.

Main advantages of Work Restraint systems;

nNo possibility of a fall

nNo need for any rescue plan

nAdjacent buildings/lower level roofs and fall clearances do not

need to be factored

nMinimal system user training required

Typical Work Restraint System layout

Key:

A – Soter HL Start/End post with female M10/Universal

B – Soter R Intermediate post with intermediate bracket

C – Soter HL with intermediate bracket

D – Soter HL T-Off with 2 hole plate and intermediate bracket

E – Soter HL Corner with corner kit/solid corner

D

AB

A

C

DD

D

ABE

B

B

B

B B B

B

E

D C

A

A

Installation manual

SFS / Installation manual Soter 3

Free-Fall Clearances

Free fall clearances are often overlooked when a fall

arrest system is designed.

It’s imperative they are calculated using a calculation

programme by the manufacturer, to prove that if a fall

was to occur, the distances required for the system to

effectively arrest the users fall can be assured.

System deflection and wire elongation is calculated

using the Soter calculation package, taking into account

system length, post spacing and maximum span length,

and the number of users.

This calculation package is available to all approved

Soter installers. SFS can also make design calculations

in house on request.

Once system deflection and wire elongation is known,

this distance can be added to the following

measurements to calculate a free fall clearance

distance:

nUsers Height (A)

nLanyard Length (B)

nDeployed shock absorber length (C)

nSafety Factor (D)

= Minimum free fall clearance required (Z)

Maximum System Lengths

Soter systems can support straight system lengths

up to a maximum of 250m, however this figure

reduces once you add a corner, and further for every

subsequent corner added. This is mainly down to the

static loading that a corner post is subjected to under

system tensioning. The more corners, the more load

each corner post must support in two directions which

can cause post lean.

Please refer to guidelines adjacent, however this

should be assessed at the installers discretion on site.

For further information on the system please see the complete Soter installation manual on

www.sfsintec.biz/se

Number of Corners Max. System Length

Straight run 250m

1 175m

2- 4 150m

5+ 125m

*It is advised that systems of long lengths, or those that have multiple

turns, have a tensioning termination at both ends of the system, so

that the tension can be pulled into the line from both ends.

Introduction

The Soter guide

This guide has been compiled to ensure the correct

installation of Soter HLL systems is adhered to at all times.

The installer should have previous HLL system installation

knowledge, design understanding, or, have taken part in Soter

HLL training.

It is important that the installer fully understands this guide

before commencement of Soter installation on site.

Soter HLL Systems are designed to act as a fall prevention

method, or that of a means of minimising the consequences

of a fall should it occur.

Only trained personnel should be involved in the design,

correct installation, and recertification of HLL systems. Failure

to follow this guide could put people’s lives at risk.

It is imperative that the correct components are used for the

specific application, and any doubts should be resolved by

seeking guidance from SFS Fall Protection.

4SFS / Installation manual Soter

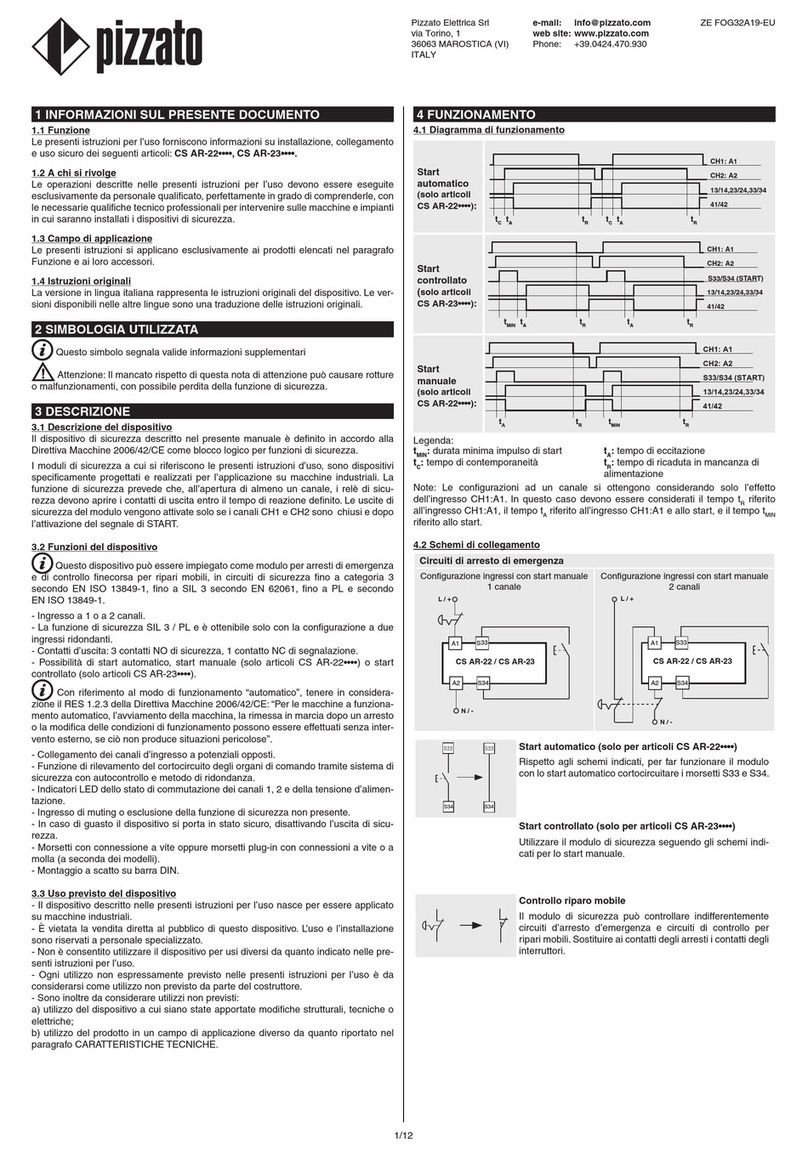

Use 8 no. PA Sleeve’s and TI Screws for concrete / Using 8 no. PA sleeves and BS screws

for 18mm Ply /OSB Board or 0.7mm Metal deck or tongue and groove deck

➊Ascertain location of base plate

picking up the crown or trough

of the deck based on the fixing

length supplied.

➍With all 8 fixings installed turn

S2 can onto female boss in base

plate by hand firstly then to the

desired tightness by hand or with

the help of a tool.

➎Anchor installation is complete

and is ready for Soter

components to be secured.

➋Insert the sleeves ➌Take drill fitted with extended drive

bar and T25 Torx bit and fix all 8 no.

fasteners through tubes, insulation

build up and deck, securing firmly.

DO NOT OVERDRIVE.

Step 1

Anchor installation

SFS / Installation manual Soter 5

➋Mark on the termination where

the wire ends. This shows where

the hollow part of the termination

ends, and where the first crimp

will be located.

➎Mark on the termination where

the wire ends. This shows where

the hollow part of the termination

ends, and where the first crimp

will be located. This needs to

be done on all terminations-

tensioners and toggle fork ends.

➌Repeat step 2 on all terminations-

tensioners and toggle fork ends.

Re-insert the wire fully ensuring

the wire is fully engaged in the

termination up to the point marked.

➏Re-insert the wire fully ensuring

the wire is fully engaged in the

termination up to the point marked.

➍Take the crimping tool and set the

barrel to ‘close’. Position the central

section of the die so that the first

crimp is made next to the line

marked on the termination itself.

➊Pull the wire though the whole system and through all posts. Before any accurate measurement can be made, the

wire must first be loosely pulled from the start of the system, through every component fitted to posts to the end point.

Step 2

Wire measure & wire crimp

➐As you reach the start of the line,

you will have manually pulled the

wire enough so that it doesn’t

touch the roof surface, and has

reasonable tension in it.

6SFS / Installation manual Soter

Step 3

Cutting & tensioning

➎By holding the crimped barrel and

line in one hand the turnbuckle/

central barrel of the tensioner can

be turned tensioning the line with

the other hand.

➏Once the required amount of tension has been achieved the red tension

indicating disc will loosen and can be turned. Although this indicates the

required amount of tension (0.8kN) has been achieved, it is the installers

responsibility to check each straight-line span has enough tension in it and

the tension is evenly distributed throughout the system. The nuts on the

tensioner can now be tightened against the turnbuckle, locking it in place.

➍Once the end termination has

been fully crimped it can be

properly secured onto the end

component and the nut and bolt

fully tightened.

➊To gain the most accurate mea-surement it is advised to swage/crimp the end termination and fix to the end post

component.

➋Work your way back to the end

of the system making sure the

wire has the right tension and cut

the wire.

➌Repeat the wi recrimp procedeur

2-6 at the start of the system.

SFS / Installation manual Soter 7

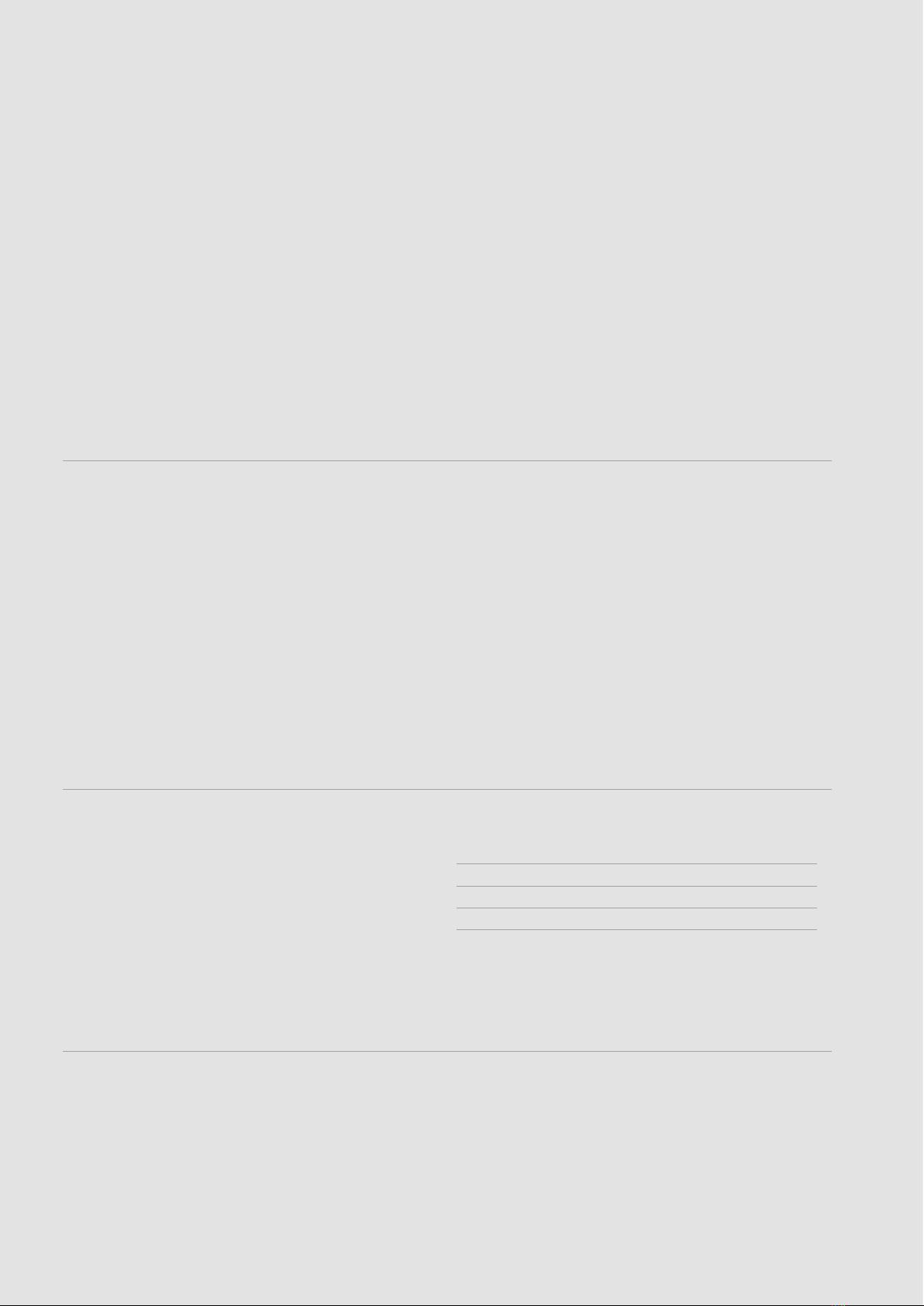

Final tightening &

system tagging

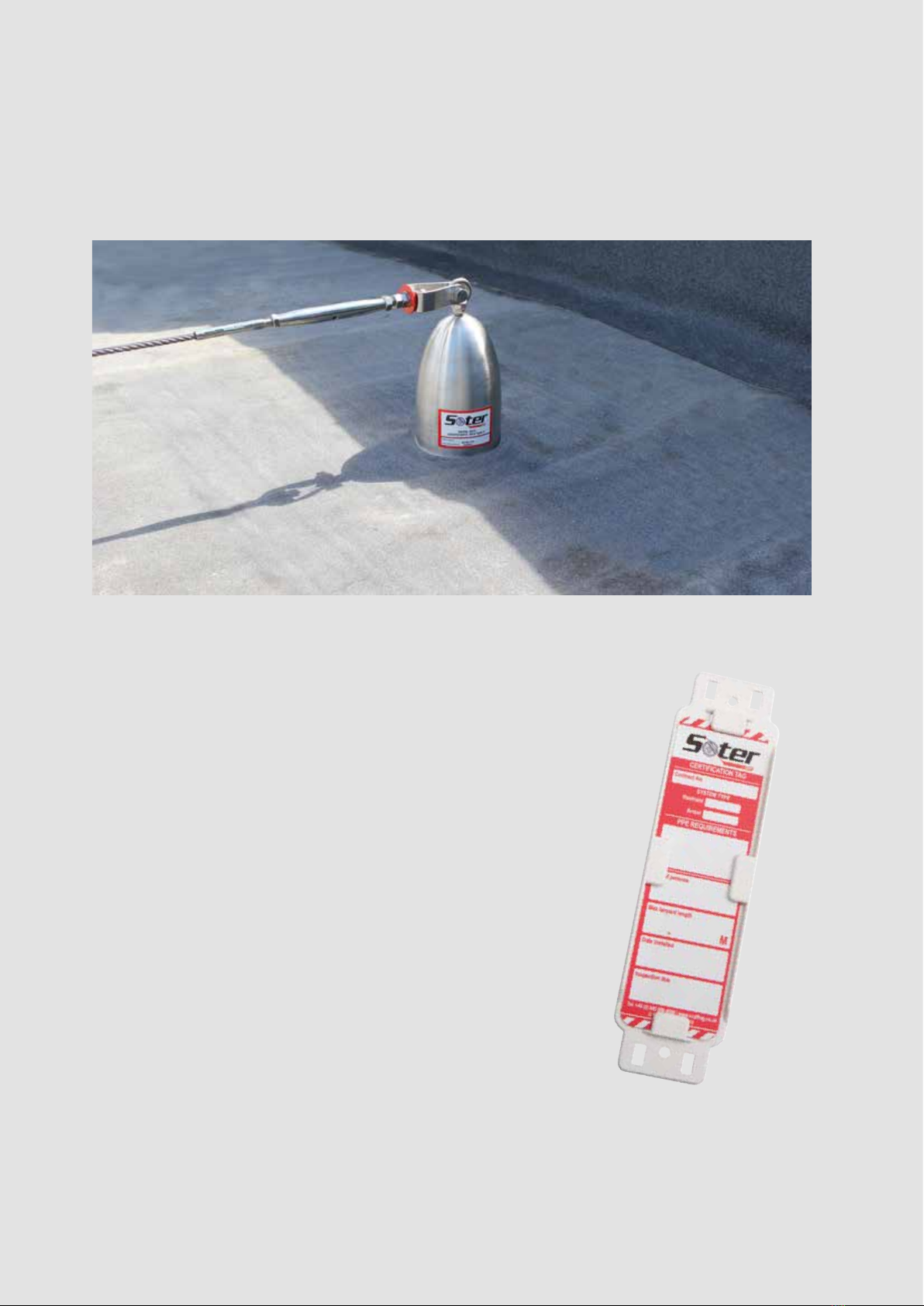

It is important that all installed systems are fitted with a certification tag at

the point of access, similar to the tag shown opposite. Conforming to BS EN

365:2004

The certification tag should include the following information to support the

more detailed O&M Manual:

nContract number/name so that the system can be identified

nSystem type- Restraint/Arrest

nPPE Requirements for the user to use the system safely & correctly

nNo. of persons the system is designed for

nMaximum lanyard length- imperative in work restraint systems

nInstallation date

nRecertification/inspection due by date

If the recertification date has lapsed, the system should not be used until a

recognised/approved Soter installer has recertified the system as fit for use.

Systems are required under EN795 to be recertified annually.

➊Finally, all system components should be fully tightened down to each post, and a final walk of the system

should be performed ensuring everything is secure and nothing has been missed.

55

04/2015

11

WFR-T-T20-4 x L

Material: Carbon steel

Coating: zinc electroplating

Diameter: 4 mm

Drive: TORX

® T20

WFR-T-T20-4,5 x L

Material: Carbon steel

Coating: zinc electroplating

Diameter: 4,5 mm

Drive: TORX

® T20

WFR-T-T25-5 x L

Material: Carbon steel

Coating: zinc electroplating

Diameter: 5 mm

Drive: TORX

® T25

WFR-T-T30-6 x L

Material: Carbon steel

Coating: zinc electroplating

Diameter: 6 mm

Drive: TORX

® T30

d

l

WF A comprehensive range for timber to timber

Fastening System and steel to timber connections

Fastener Range

Type Material

T =

carbon

steel

Drive Diameter

d in mm

Length

l in mm

WFR - T - T25 - 5 x 20

WFR - T - T25 - 5 x 25

WFR - T - T25 - 5 x 30

WFR - T - T25 - 5 x 35

WFR - T - T25 - 5 x 40

WFR - T - T25 - 5 x 50

WFR - T - T25 - 5 x 60

WFR - T - T25 - 5 x 70

WFR - T - T25 - 5 x 80

WFR - T - T25 - 5 x 90

WFR - T - T25 - 5 x 100

WFR - T - T25 - 5 x 110

WFR - T - T25 - 5 x 120

WFR - T - T20 - 4 x 20

WFR - T - T20 - 4 x 25

WFR - T - T20 - 4 x 30

WFR - T - T20 - 4 x 35

WFR - T - T20 - 4 x 40

WFR - T - T20 - 4 x 45

WFR - T - T20 - 4 x 50

WFR - T - T20 - 4 x 60

WFR - T - T20 - 4 x 70

WFR - T - T20 - 4,5 x 20

WFR - T - T20 - 4,5 x 25

WFR - T - T20 - 4,5 x 30

WFR - T - T20 - 4,5 x 35

WFR - T - T20 - 4,5 x 40

WFR - T - T20 - 4,5 x 45

WFR - T - T20 - 4,5 x 50

WFR - T - T20 - 4,5 x 60

WFR - T - T20 - 4,5 x 70

WFR - T - T20 - 4,5 x 80

Fastener Range

Type Material

T =

carbon

steel

Drive Diameter

d in mm

Length

l in mm

Fastener Range

Type Material

T =

carbon

steel

Drive Diameter

d in mm

Length

l in mm

WFR - T - T30 - 6 x 50

WFR - T - T30 - 6 x 60

WFR - T - T30 - 6 x 70

WFR - T - T30 - 6 x 80

WFR - T - T30 - 6 x 90

WFR - T - T30 - 6 x 100

WFR - T - T30 - 6 x 110

WFR - T - T30 - 6 x 120

WFR - T - T30 - 6 x 130

WFR - T - T30 - 6 x 140

WFR - T - T30 - 6 x 150

WFR - T - T30 - 6 x 160

WFR - T - T30 - 6 x 180

WFR - T - T30 - 6 x 200

WFR - T - T30 - 6 x 220

WFR - T - T30 - 6 x 240

WFR - T - T30 - 6 x 260

WFR - T - T30 - 6 x 280

WFR - T - T30 - 6 x 300

Fastener Range

Type Material

T =

carbon

steel

Drive Diameter

d in mm

Length

l in mm

Turn ideas into reality.

SFS intec AG / Division Construction / CH-9435 Heerbrugg / construction@sfsintec.biz / www.sfsintec.biz

© SFS intec, i-TW 905984, 05-2014

WF_01_EC5_en_CH_Hgg_1.02_general

Technical changes reserved. Created in Switzerland

All calculations have to be checked and approved by the responsible

planner ahead of execution. The user is responsible to assure compliance

with all applicable laws and regulations.

11.

WF

Timber toTimber and Steel toTimber Connections

Technical documentation and data sheets Technical documentation and data sheets

© SFS February 2018.

Subject to technical modifications

and price changes. Printed in Sweden.

SFS

Olivehällsvägen 10

SE-645 42 Strängnäs

T +46 (0)-152 71 50 00

www.sfsintec.biz/se

Table of contents

Other SFS Safety Equipment manuals

Popular Safety Equipment manuals by other brands

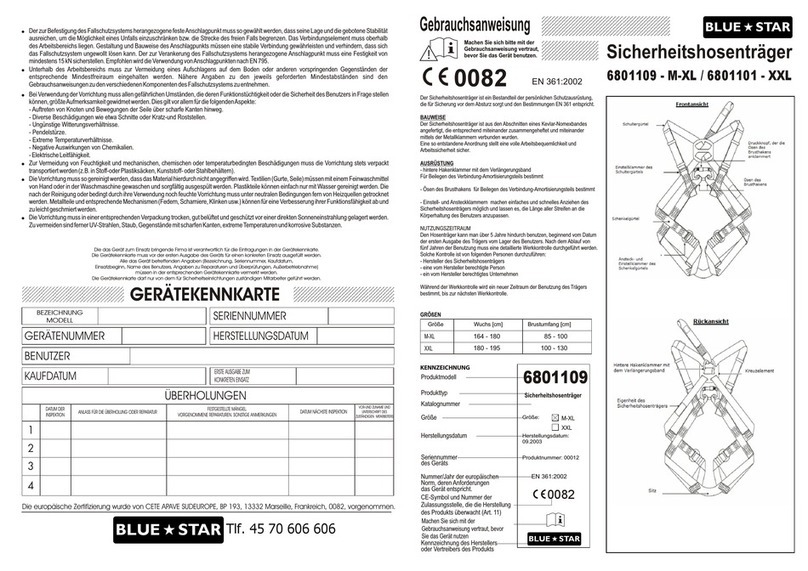

Blue Star

Blue Star 6801109 instruction manual

FormFit

FormFit HDW 5R 02 quick start guide

Wenglor

Wenglor OSEI Z0103 Series operating instructions

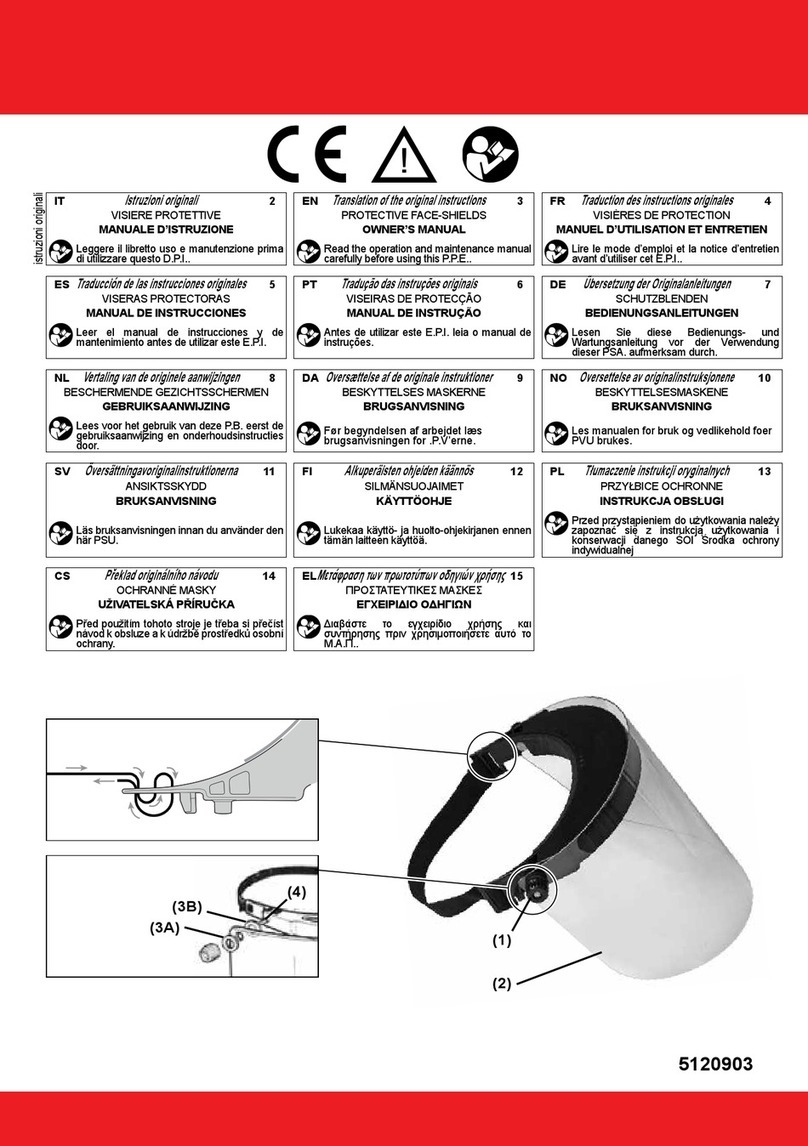

Tecomec

Tecomec 5120903 owner's manual

Chloride

Chloride F100 Installation and operating instructions

Falltech

Falltech DuraTech Max Web Single User instruction manual