Specications

Materials & Coatings:

Legs: Aluminium powder coated.

Head: Stainless steel powder coated.

Bolts & Pins: Stn. steel, Mild steel, Nickel plated

Straps: Polyester webbing.

Weight

Quadpod only: 12.8Kg

Leg Securing Straps: 1Kg

Storage Bag: 0.5Kg

Meanings Of Markings

• The name, trademark or any other means of identication provided

by the manufacturer or supplier.

• The batch or serial number

• The year of manufacture

• CE... EC logo followed by the number of the notied body

• EN... European standard attributed to this PPE

• Product description and/or reference

• Evaluation of capacity in Kg

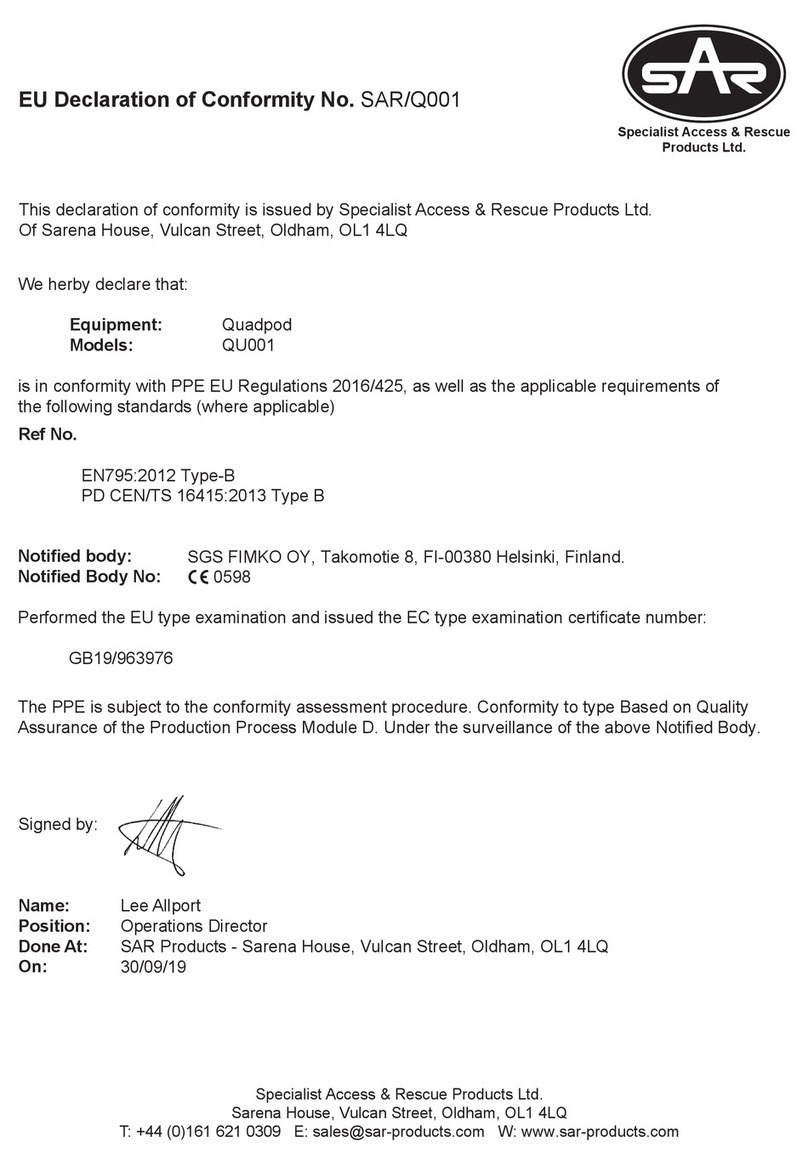

Notied body: SGS FIMKO OY, Takomotie 8, FI-00380 Helsinki, Finland.

Notied Body No: 0598

The Quadpod can be used in other positions as shown below.

The positions show below do not fall under the test requirements of

the above standards and careful consideration and calculations of

loads must be taken into account by the users before carrying out any

tasks.

1. Oset pyramid

2. Half pyramid

3. Overhanging

Settings 1, 2, & 3 do not fall under the test requirements for EN795 and

CEN/TS 16415. Option 3 & 4 positions must be anchored and the

anchors strong enough to conform to the standard 15kN.

1. The oset pyramid is best for tensioned cable lines using the central

connecting eye for your pulley. The reason for this is the force down

should be central to the Quadpod when you dissect the angle.

Another pulley can be tted under the cable pulley or pulleys for the

hauling.

2. When using the half pyramid or overhang setting for cli or edge

rescue, you should use the front outer ring connecting point. By

tting a Dee Mallion to the ring, then a karabiner for the pulley or a

Delta Mallion for twin pulleys. The angle of the load will be central to

the Quadpod and there should be no need to fasten down to secure

the legs. In these positions you MUST use a back securing rope from

a rm anchor to the top back outer ring prior to load being put onto

the system.

When using a guide rope all connectors must conform to EN362.

A guide rope should only be connected to the outer ring and no other

part of the Quadpod.

SAR Products do recommend training on using the Quadpod.

The SAR Quadpod conforms to:

CE 0598, EN795:2012 Type B for a one person load centre eye and

outside ring.

CEN/TS 16415:2013 Type B for a 2 person load outer ring only.

CEN/TS 16415:2013 Type B for a 4 person load centre eye only.

When the Quadpod is used above a one person load then this is not

classed as PPE and therefore does not fall under the PPE Regulation

2016/425.

Design

The Quadpod was designed specically for technical rescue. It is far

more adaptable than a normal tripod in the industrial environment. It

enables the user to access many areas a tripod or other devices

cannot. We strongly advise the user to be trained in its many uses and

learn about its physical strengths and weaknesses.

Use

The Quadpod has been designed as a removable elevated anchor

point as shown in the positions below. The positions and the working

load limits must be followed at all times to be compliant to the

standards list above.

The Quadpod should be assembled by a competent person or

organisation.

The Quadpod should only be used for personal fall protection

equipment and not for lifting equipment.

When the Quadpod is used as part of a fall arrest system then the user

must use a device that will limit the impact force to 6kN.

Weights must be taken into consideration or calculated before the

Quadpod is used.

During normal operating conditions and under the guidelines set out

in this user guide, there will be no deection or deformation.

Consideration to the surface the Quadpod will be used on must be

taken into account, for example: Can the ground take the loading that

will be applied and is the ground uneven? The feet must be as at as

possible on the ground, failure to check may result in dramatically

lower working load limits.

The Quadpod can also be used in many other positions which are

described further on.

The Quadpod can be used as an anchor in the following

recommended modes conforming to the standards above:

1. Standard pyramid, Short front legs, long back legs, short back legs,

long front legs as in diagrams A, B & C.

Working load limits of the Quadpod

The working load limit refers to the total load limit the Quadpod can

be used with in diagrams A, B & C.

The working load limit for a static load used with the Quadpod is

400Kg.

Where dynamic loads are to be used, please refer to the standard and

the part of the Quadpod that has been tested for these loads.

1. CE 0120, EN795:2012 Type B for a one person (100Kg) load centre

eye and outside ring.

2. CEN/TS 16415:2013 Type B for a 2 person (200Kg) load outer ring

only.

3. CEN/TS 16415:2013 Type B for a 4 person (400Kg) load centre eye

only.

Breaking load limits

For a single person load EN797:2012 the minimum breaking strength

is 12kN. The centre eye meets these requirements when used in the

positions in diagrams A, B & C.

For a 2 person load CEN/TS 16415/2013 the minimum breaking

strength is 13kN. The outer ring meets these requirements when used

in the positions in diagrams A, B & C.

For a 4 person load CEN/TS 16415/2013 the minimum breaking

strength is 15kN. The centre eye only meets these requirements when

used in the positions in diagrams A, B & C.

Assembling the Quadpod

The quodpod must be assembled in a safe area before use. It is the

responsibility of the user to ensure their own safety when doing so.

Inspection and Maintenance

• Before and after every use.

• Check all the locking nuts are secure.

• All retaining pins are in place.

• Ensure the eye bolt at the head of the Quodpod is free of dirt and

free in movement.

• Check the rubber feet are free from defects.

After use wipe down any excess moisture and coat pins and bolts in

light machine oil wiping away any excess oil.

Maintenance and inspections should only be carried out by a

competent person at least every 6 months.

Warning

Always remain within the foot print of the Quadpod when set up as a

removable anchor point and always remain below the anchor point,

this will minimise a pendulum fall onto the anchor point which could

potentially make the Quadpod unstable.

The Quadpod adjustable webbing leg straps must be used at all times.

Setting up the Quadpod

1. Set the Quadpod up as required.

2. Adjust the legs to the correct height and width and lock the legs

into position using the eye bolt pins. Ensure as to not catch the

ngers when doing so and always place the R clip in to the end of

the pins.

3. Connect the Quadpod adjuster buckles between the legs, These

need to be clipped into the small U bolts at the bottom of the legs

and must be used at all times.

4. Pull the strap through buckle as in gure 1.

5. Press inner buckle clamp to release in gure 2.

6. When using the Quodpod as a standard pyramid as in diagrams A, B

& C always use the centre eye when possible.

1.25 Metres

1.25 Metres

Level

Diagram A

Diagram B

Diagram C

Fig 1 Fig 2

Level