SFS Sotel HLL User manual

Soter HLL

User Manual

Soter HLL

User Manual

1.0 Introduction

2.0 SFS Soter HLL System Design

2.1 Work Restraint

2.2 Fall Arrest

3.0 Installation

4.0 Re-certification

4.1 General Maintenance

4.2 Warranty

5.0 Pre-use checks

5.1 Slyder Inspection

5.2 System Tag/Label

5.3 Documentation & Certificate

5.4 System Inspection

6.0 Personal Protective Equipment (PPE)

6.1 Harness & Lanyard Inspection

6.2 Cleaning, Storage and Lifespan

6.3 Correct Harness Wear

6.4 Lanyard Connection

6.5 Rope and Grab Use

6.6 Inertia Reels/blocks

7.0 Using the System

7.1 Accessing the System

7.2 Slyder Device

7.3 Tips and Tricks/ Ease of Use

7.4 Crossing Points

8.0 After a fall

8.1 Rescue and Emergency procedure

8.2 System Re-commissioning

9.0 Contract Specific User Information

3

4

4

4

5

5

5

5

5

5

6

6

6

7

7

7

8

10

11

11

12

12

12

14

14

14

14

14

15

32

Soter HLL

User Manual

1.0 Introduction

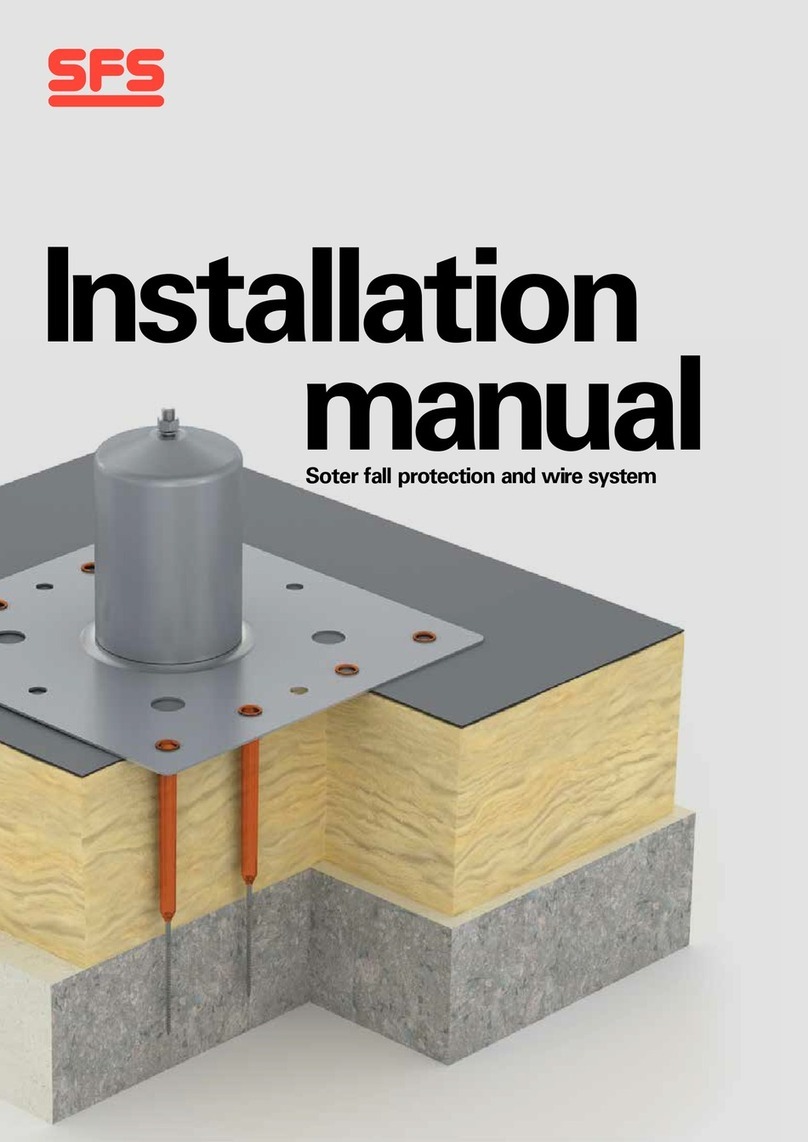

Soter HLL Systems are designed to act as a fall prevention

method, or a means of minimising the consequences of a

fall should it occur- reducing the risk of injury or death to

operatives working at height.

It is therefore vital that it is installed, maintained, and used

correctly as laid out in this manual.

The Soter system is a series of top fixed shock absorbing

posts anchored to the outer roof skin, joined through a

series of components to create a system using a 7x7

8mm wire cable. In some cases, systems can be installed

directly to structures utilising in-line shock absorbers in

place of shock absorbing posts.

The system conforms to all local industry recognised

guidelines;

nEN795: 2012 Single User Class A & C

nCEN: TS16514 Multi-User Class A & C

nACR Magenta guidelines

nBS8610

All users of the system should be familiar with general

work at height safety, system pre-use checks, limitations,

precautions, and system operation. They should be

competent in the use of the system, having read and

fully understood this manual, and trained by a skilled/

competent person.

We recommend that systems should not be used by lone

operatives for safety and rescue reasons.

32

4 5

Soter HLL

User Manual

2.0 Soter

System Design

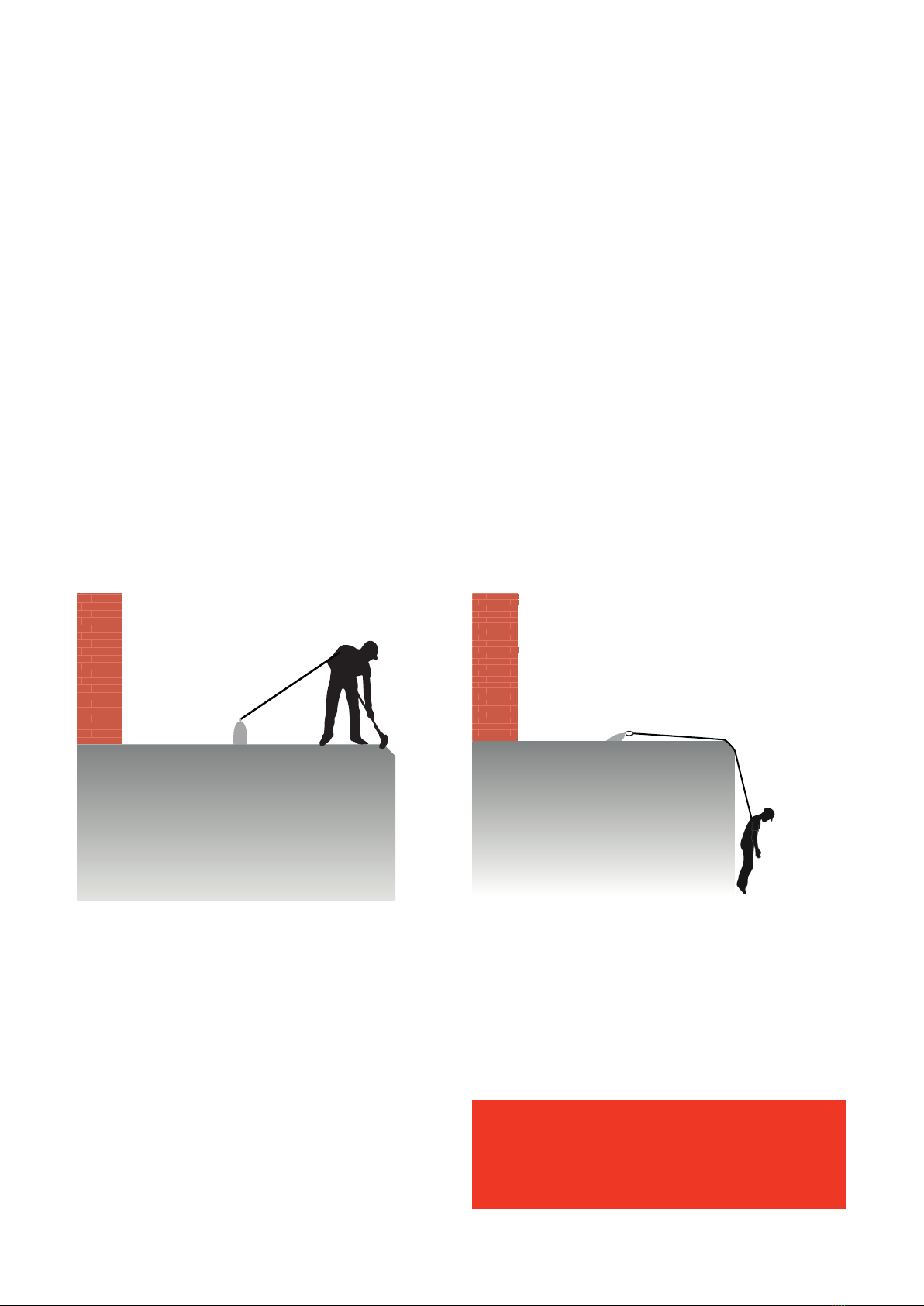

The Soter HLL system can be used as both a Work

Restraint or Fall Arrest system. The recognised Soter

installer will have looked at many factors before choosing

the safest system design relevant to the access needs

and factoring in risks on site. Work Restraint systems

should always be promoted before Fall Arrest systems are

considered.

2.1 Work Restraint

Work restraint systems are the safest method of HLL

system design. Keeping the user in restraint removes the

possibility of a fall. The users path, and what they have

access to can be dictated and controlled.

The main advantages of Work restraint systems;

nNo possibility of a fall with correct PPE use

nNo need for a rescue plan

nAdjacent buildings/lower level roofs and fall clearances

do not need to be factored in.

2.2 Fall Arrest

Fall Arrest systems are designed to ‘limit the

consequences of a fall should it occur’. The Soter HLL

system will arrest a user’s fall only if the required fall

clearances are sufficient.

Although Fall Arrest systems are often employed to give a

user full roof access, they come with major disadvantages

such as;

nThey do not stop a fall occurring as the user is

responsible for correct use of PPE

nThey can only be used on buildings with the required

free fall clearance from all hazards including objects

below rooflights

nA full rescue plan must be in place to return the user

to safety

It is imperative that the user(s) are familiar with the

system type installed, the correct use of the system

including specified PPE, and areas of access to enable

safe working at heights and minimising risks.

This is detailed in Section 9.0 ‘Contract Specific User

information’ which will be supplied by the recognised

installer.

If a Fall Arrest system is installed, a rescue

plan must be in place in the event of a fall

occurring, not solely relying on emergency

services alone.

4 5

3.0 Installation

Only recognised installers trained by SFS are certified to

carry out design, installation, and recertification of Soter

HLL systems. If this is not followed, use of the system

could put lives at risk.

Section 9.0 ‘Contract Specific User information’ details

the minimum information which should be provided to

support and maintain safe use of the system.

4.0 Re-certification

All Horizontal Life Line systems are required to be re-

certified at periods no greater than 12 months to keep

them in use under EN 795:2012. This period can be

reduced in high corrosion locations, or if the systems are

deemed to be in high use. This will be determined by SFS

and laid out in documentation supplied by the installer.

Re-certifications should only be carried out by competent

persons, familiar with the fundamentals of the Soter

system, and preferably those who are recognised

installers.

Unless you are a recognised Soter installer or competent

person, never attempt to repair, modify, dismantle a

system, or adjust the pre-set tension as this will invalidate

the installation and may put lives at risk.

4.1 General Maintenance

The Soter system is made entirely from stainless steel

and is designed to have a product life that outlasts the

roof itself. Although considered maintenance free, factors

such as corrosive environments and aggressive conditions

can have a detrimental effect on its appearance. In these

areas we would recommend the system is cleaned

regularly with a mild detergent and warm water and

rinsed thoroughly.

Although resistant to most environmental conditions,

we advise that care is taken to avoid contamination with

mild steel materials, paint, cement, bitumen, acids etc.

If contamination occurs, please contact SFS or your

approved installer for advice.

4.2 Warranty

SFS offer a warranty of up to 25 years for Soter products,

from date of original purchase subject to normal use,

correct installation, and regular approved re-certification.

This warranty covers the products only, not the

installation.

Each warranty must be applied for and is subject to our

standard terms and conditions*.

*available on request

5.0 Pre-Use Checks

It is recommended that a detailed log of use is kept and

referred to prior to the system being used. This should

contain information such as;

nSystem use dates

nUser(s) name and competence

nReasons for use and areas accessed

nVisual inspection comments

nPPE condition/ inspection records

This information should be kept in a safe place, with

system PPE and user equipment which can be signed out

prior to each use.

5.1 Slyder Inspection

The Slyder device is manufactured from stainless steel

and should be stored in its case away from the roof,

together with the required PPE/user equipment. This will

help ensure the Slyder remains in good condition and

away from possible contaminants.

nCheck the Slyder device for any obvious damage

nThe device should open and close freely

nThe device is ‘locked’ when a karabiner is attached

nOnly SFS should carry out maintenance on the device.

The Slyder device is the only tested traveller for use with

the Soter HLL system. This ensures the system is fully

traversable without the need to clip on or off as the user

negotiates intermediate and corner posts. Please see

section 7.0 on Slyder attachment and correct use.

Soter HLL

User Manual

6 7

Soter HLL

User Manual

5.2 System Tag/Label

A system label or tag should be clearly visible at the

access point to the system, or at the system start point.

This should be inspected prior to use and correlate with

system specific documentation supplied by the installer,

ensuring that;

nThe system is in date and certification is valid

nThe system type is detailed, and the risks

are understood

nIf the system is specified arrest, aspects such as

free fall distances have not changed

nCorrect PPE/User Equipment is being used

nThe maximum number of users is not exceeded

nSupplier contact details are available in case of queries

about the system

If tag/label is missing, or the recertification period has

been exceeded, the system should not be used until the

system has been re-certified and re-tagged as safe

for use.

CERTIFICATION TAG

Contract No.

SYSTEM TYPE

Restraint

Arrest

PPE REQUIREMENTS

No. of persons

Max lanyard length

Date installed

Inspection due

M

5.3 Documentation & Certificate

Contract/ system specific information should be

referred to prior to system use to ensure the user(s) fully

understand the following;

nAccess point(s)

nSystem layout

nSystem purpose- what areas it will allow users

to access

nSystem type and risks associated

nValid system certification

nMaximum users permitted to use the system

These documents will be supplied by the recognised

installer and are described in more detail in section 9.0.

5.4 System Inspection

If possible, before attaching to the system/accessing

the roof area carry out a visual inspection of the system.

Check that there are no obvious signs of damage such as;

nDeployed posts

nSag in the wire (where it is touching the roof)

nKinks or breaks in the wire

nServices or goods impeding the users route or resting

on the line or posts themselves.

If you have any concerns about the

products appearance, general condition of

the system, or installation, please contact

your installer and remove the system from

service until remedied.

6 7

6.0 Personal Protective Equipment

(PPE)

It is imperative that the correct PPE as detailed on both

the tag and system specific information supporting the

system are worn, and their correct use understood. It is

also recommended that PPE should be issued to one user

for their own use, wherever possible.

6.1 Harness & Lanyard Inspection

All PPE should be examined prior to use and an

examination record filled out. It is the responsibility of the

user to carry out a visual inspection of their equipment.

If there is any doubt, withdraw the equipment from

service. The withdrawn equipment should be inspected

by a competent person (other than the user) before being

returned to service. A full comprehensive inspection of

the harness and lanyards should not be greater than

6 months - with this period reduced if the equipment is

heavily used, and recorded.

6.2 Cleaning, Storage and Lifespan

Cleaning:

Harness and lanyards should be cleaned in warm water

using a mild detergent, rinsed thoroughly, and allowed

to dry naturally away from open fire or other sources of

direct heat.

Storage:

The equipment should be properly stored and transported

in the bag supplied to prevent any contact with sharp

objects and harmful substances and stored in an area

which is dry and free from direct sunlight.

Lifespan:

The lifespan of PPE is generally 10 years from date of

manufacture in unopened bags, 5-7 years from first use

(individual manufacturers may differ slightly). The working

life will be reduced through age, general wear and tear,

and frequency of use.

Inspection Checklist

3Information label should be present

3Check all webbing and stitching. There should be no evidence of cuts,

fraying or burns, the webbing should not be discoloured, and each stitch

pattern should be examined. There must be no broken stitches or cuts,

the stitch pattern should be intact.

3All metal fittings should be free from excess wear, rust, and

deformation. Ensure all moving parts are clean and if necessary,

lubricated.

3Avoid all contact with chemicals. Generally speaking, if it harms the

skin, it will harm the equipment. Evidence of chemical contamination

is shown by discolouration or powdering of the webbing.

3All markings on the product should be clear and legible

Soter HLL

User Manual

8 9

Soter HLL

User Manual

6.3 Correct Harness Wear

Harness Use:

It is recommended that the user should carry out a

suspension test in a safe place before using the harness

for the first time, in order to ensure that it is the correct

size, has sufficient adjustment and an acceptable level of

comfort.

The Harness has been designed and manufactured in

accordance with BS EN361:2002: Personal protective

equipment against falls from height- Full Body Harnesses.

The full body harness can be used as follows;

nAs part of an assembly to protect the user in a fall

from height

nUsed with a restraint lanyard to prevent the user

from falling

nUsed as part of a work positioning assembly

nUsed as part of a rescue system

In the event of the user falling from height, the intended

purpose of the harness is to hold the user in a safe and

upright position and to dissipate the resulting pressure on

the body evenly.

When used to protect the user in the event of a fall,

the harness must be used in conjunction with an

energy absorber (manufactured to BS EN355) a lanyard

(manufactured to BS EN354) and an anchorage point (to

BS EN795). The user should be aware that, usually, when

a 2 metre lanyard fitted with an energy absorber is

deployed, the length of the lanyard will increase to

3.75 metres. The user should always read the

manufacturers instructions, which accompany the lanyard

and energy absorber, to verify the exact measurements.

Before using any absorber, which is part of a fall arrest

system, check there is sufficient free fall space, clear of

hazards below the users’ feet to prevent collision with any

structures or the ground. This information should also be

detailed in contract specific documentation provided by

the installer- proving the free fall clearance is adequate.

The equipment should not be used for any other purpose,

other than which it has been designed.

The harness is manufactured from 100% polyester

webbing and thread, steel fittings, and elastic webbing

‘tidies’.

Meaning of Marks

Book Symbol:

Read the instructions for use

before using equipment

CE Symbol:

This equipment conforms

with EU

0120

ALet ter ‘A’:

‘A’ is laser marked on each

fall arrest attachment point

The equipment should not be altered or added to without

the prior written consent of the manufacturer. Should it

be re-sold outside the original country of manufacture,

then the re-seller shall provide instructions for use,

maintenance, and periodic examination in the language of

the country in which the equipment is re-sold.

If you are in any doubt about the integrity of this

equipment, remove it from use and return it to your

supervisor. The equipment should not be used again until

inspected by a competent person.

8 9

Soter HLL

User Manual

Fitting the Harness

Ref 1:

Hold the harness by the dorsal

attachment point stitched on the

back of the harness.

Ref 2:

Fit the shoulder straps ensuring that

the rear D link is on the outside of the

harness and there aren’t any twists in

the webbing.

Ref 3:

Fit the chest strap and adjust to fit.

Ref 4:

Fit the thigh straps making sure that

the straps are fitted to the correct

buckle again ensuring webbing

isn’t twisted.

Ref 5:

Adjust straps so that the rear lower

straps fit under the buttocks.

Ref 6:

Adjust the harness to achieve a

comfortable tension.

Slide the nearest elastic tidy up to

the metal fittings in place and use the

second elastic tidy to retain any

surplus webbing.

10 11

Soter HLL

User Manual

Buckle Fittings

6.4 Lanyard Connection

Whether a shock absorbing lanyard or fixed restraint

lanyard is specified, both should be connected to the user

at the dorsal attachment of the harness. It is imperative

that the correct lanyard used correlates to both the

detailed specific system information supplied by the

installer and the tag/ label on the system itself.

When using a shock absorbing lanyard, the shock

absorbing end should be connected to the dorsal

attachment. Orientation is not detrimental when using

a fixed restraint lanyard.

Always ensure that the locking mechanism on each

karabiner is fully locked.

1 2

3 4

10 11

Soter HLL

User Manual

6.5 Rope and Grab Use

The use of rope and grab equipment should only be

carried out by persons competent and trained in their safe

use, due to the greater potential of a fall occurring with

an arrest system. We recommend that user(s) should go

through site specific equipment training in relation to the

system and layout installed.

In general;

nConnection to the Slyder device on the system should

be made using the karabiner at the end of the rope

itself.

nThe grab device should be attached to the rope with the

up arrow facing towards the line system

nThe free karabiner of the shock absorbing lanyard

connected to the user should then be secured through

the ring of the grab

nThe user can then, while holding the grab in one hand,

lower themselves to the area they wish to work taking

into consideration the lanyard length

nThe user needs to ensure the grab is set so that they

are using the full extent of the lanyard and neither the

lanyard or rope is slack.

nIt is recommended the user should keep the rope at the

shortest length possible at all times returning back to

the system before moving to another area of the roof,

shortening the rope as they go, to prevent a trip hazard.

If an arrest system has been installed with anti-pendulum

posts, the user must clip their rope through the karabiner

attached to the post prior to nearing any roof edge.

This will limit the possible swing of a user’s fall from an

exposed gable end.

6.6 Inertia Reels/ Blocks

Only inertia blocks tested and approved by SFS can be

used in conjunction with the Soter HLL system.

12 13

Soter HLL

User Manual

7.0 Using the System

The system is ready to be used once all documentation is

understood by the competent user(s), all pre-use checks

have been completed and the system certificate is valid.

Lone use of HLL systems is not recommended.

Two users allows for operatives to check each other’s

equipment before use and in the event of an accident,

effect a rescue.

Roof Access

Fall protection required

beyond this point.

Warnings

nIt is not advisable to the use the equipment if

pregnant or on any medication that may cause

drowsiness or make the user unsteady.

nThe device should only be used by trained or

competent persons.

nThe device is for one person only, to be used on a

fall arrest or work restraint Soter HLL system and

should not be used for any other purpose. The

rating of the system may be for multiple users,

but only one user per device.

nIt is not permitted to alter or repair the device in

anyway, without the written permission of the

manufacturer.

nThe device must only be used on certified Soter

HLL systems and be connected to the system as

shown opposite.

nThe device must be withdrawn from use should a

fall occur. If any doubt arises about the state and

condition of the device, it should be returned to

SFS or be confirmed in writing by a competent

person that the device is still fit for purpose.

nOnce the device is locked onto the HLL system it

should be checked that the device cannot come

away from the wire rope without the removal

of the karabiner and unlocking the device. This

check ensures that the device has not been

subjected to a fall and that the gap is still within

tolerance.

nThe device is manufactured from 316 stainless

steel, and requires no maintenance, but should be

checked for any damage prior to use.

nIt should be transported and stored in suitable

packaging to prevent damage and kept away from

corrosive materials.

7.1 Accessing the System

The unique design of the Slyder device allows for

attachment/ detachment from the line at any point.

The system should be accessed from the designated

point, allowing the user to check the information tag and

date of last inspection before use.

Where access is being gained by use of a MEWP or

external ladder, care should be taken to ensure the user

is attached to an anchor point during access and egress

of the system at all times. This can be achieved by using

a second/ split leg lanyard and a loose leg strop from the

main system. The user may then traverse connected, on

to the main system and connect their Slyder device.

7.2 Slyder Device

nThe Slyder Device is a mobile anchor, designed for

use with the Soter HLL System as a one person work

restraint or fall arrest device

nThe device must be used with the following PPE

equipment; Full Body Safety Harness along with a fixed

lanyard for work restraint systems or a shock absorbing

lanyard for fall arrest systems.

nThe lanyard must be connected to the device as shown

in the illustrations on the following page.

12 13

Soter HLL

User Manual

Figure 1 shows the device open

(top view) to allow connection to the

wire rope.

Figure 2 shows the increase between

the jaws of the device (bottom view).

Figure 3 shows the offset of the jaws

and the interlocking section of the

two parts.

Figure 4 shows the device closed (top

view) without a karabiner.

Figure 5 shows the decrease between

the jaws when closed.

Figure 6 shows everything in line with

reduced gap when closed.

Figure 7 shows part closed on the

wire but not locked.

Figure 8 shows fully closed ready for

locking onto the wire rope.

Figure 9 shows fully closed and

locked with the karabiner.

Soter Device Operation

Soter Device closed

Soter Device open

Soter Device open, closed, locked with karabiner on line

14 15

If a Fall Arrest system is installed, a rescue plan

must be in place in the event of a fall occurring,

without relying on emergency services alone.

Soter HLL

User Manual

8.0 After a Fall

It is imperative that the building owner has the means

to recover a user in the event of a fall, otherwise an

arrest system is not a safe means of fall protection and a

restraint system should be offered instead.

8.1 Rescue and Emergency Procedure

It is strongly recommended that a written emergency

and rescue plan is devised by the building owner.

Those responsible for rescue should be trained to the

required level. This should include the understanding and

treatment of presyncope symptoms (Light headedness;

nausea; flushing sensations; tingling or numbness of the

arms or legs; anxiety; visual disturbance; or a feeling they

are about to faint) or syncope (unconsciousness) in the

fallen person.

More information of dealing with the above can be found

on the HSE’s website www.hse.gov.uk

As noted previously, the best practice for roof access is

not to do it alone. Having 2 workers at all times allows one

to aid the rescue of the other, or raise the alarm quickly

and summon help.

8.2 System Re-commissioning

Should a fall occur on the system it should be immediately

taken out of use, removing the system label/ tag, to show

the ‘do not use’ symbol.

The system then needs to be serviced and re-certified by

a recognised Soter installer before it’s used again.

7.3 Tips and Tricks / Ease of Use

The Soter HLL system has been specifically designed so

that it is simple and easy to use.

Due to the way the Slyder device has been designed it

allows the user to traverse the whole system without

the need to disconnect. The Slyder will pass over all

intermediate brackets (even up to 45 degrees) and corner

posts.

To traverse posts and brackets with ease, the user should

walk alongside the system and using one hand hold their

lanyard so that the Slyder device remains level with a

degree of sag in the lanyard itself. This will ensure the

Slyder glides over each bracket.

7.4 Crossing Points

The unique passing loop on the intermediate bracket

allows users connected to the same line the ability to

pass each other without the need to fully detach from the

line.

One user should use the spare leg on their twin legged

lanyard and connect their karabiner to the passing loop

on the intermediate bracket. Once connected they are

safe then to remove their Slyder device from the line

itself. This will allow the other user to pass. The first user

can then re-attach their Slyder device to the line before

removing their spare lanyard from the passing loop.

This ensures neither user is disconnected from the

system at any time.

This should only be done in a safe area, away from any

potential fall hazards (i.e roof lights).

Passing loop

14 15

Soter HLL

User Manual

9.0 Contract Specific

User Information

It is important that the system installer provides specific

user information to support this user manual, also known

as an O&M Manual which should lay out the following in

detail to allow safe use of the system;

nClient, location, project name, address

nSystem layouts - types, reason and area system gives

access to, access point(s)

nValid Test Certificate including installation

completion date

nPPE & System Use Record

nRisk Assessment

Technical advice and sales service

SFS Ltd.

Division Construction

153 Kirkstall Road

UK-Leeds, LS4 2AT

Tel +44 1924 472 251

Fax +44 1924 440 237

www.sotersafetysystems.com

www.sfsintec.biz/uk

SFS:

Your strong partner

SFS is an international company with over

50 years experience of manufacturing innovative fastening

systems. Our customers profit from:

nA solution oriented culture to create customer value

nIn-house development and production in Europe,

North America and Asia

nExemplary process and technology competence

nLocal presence linked to an international network

SFS: Assuring innovation and quality!

Version 1.0

This manual suits for next models

1

Table of contents

Other SFS Safety Equipment manuals

Popular Safety Equipment manuals by other brands

DBI SALA

DBI SALA 3M 3400130 User instructions

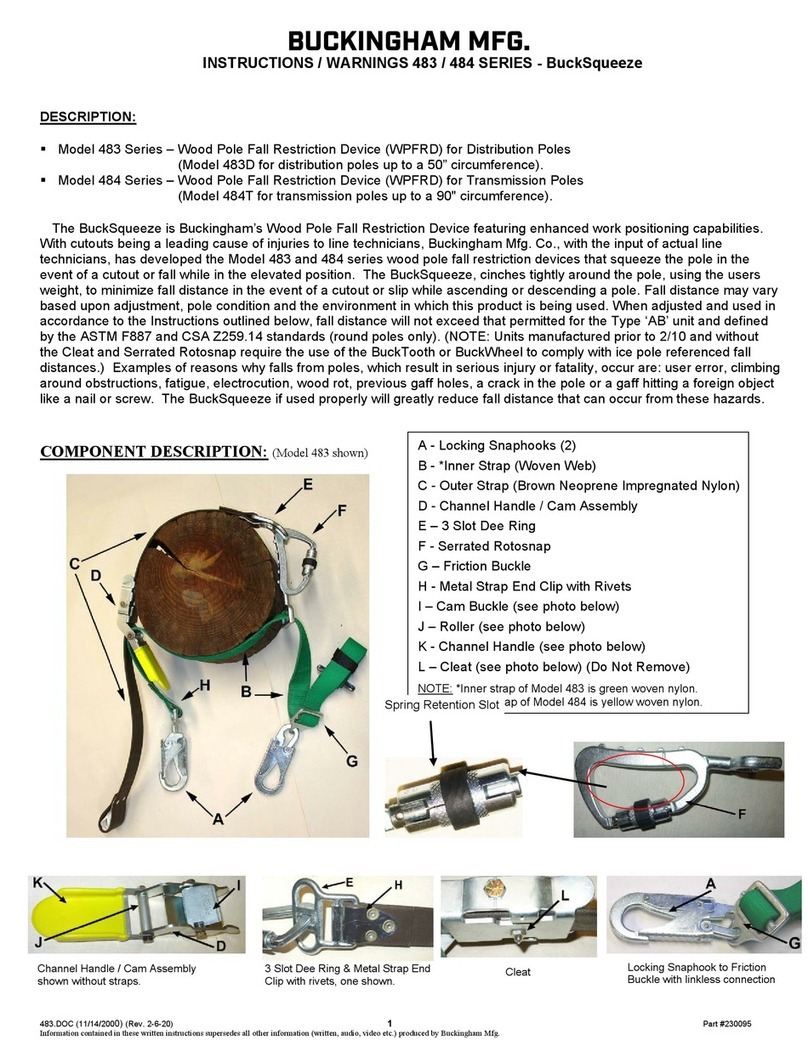

BUCKINGHAM MFG

BUCKINGHAM MFG BuckSqueeze 483 Series Instructions & warnings

Reliance

Reliance Roto-Loc 44 Series Instructions for use

IKAR

IKAR ASS-1 Log book and instructions for use

KRATOS SAFETY

KRATOS SAFETY OLYMPE-S manual

3M

3M SEALED-BLOK 3400944 instruction manual

EUCHNER

EUCHNER MGB-L B-PN Series operating instructions

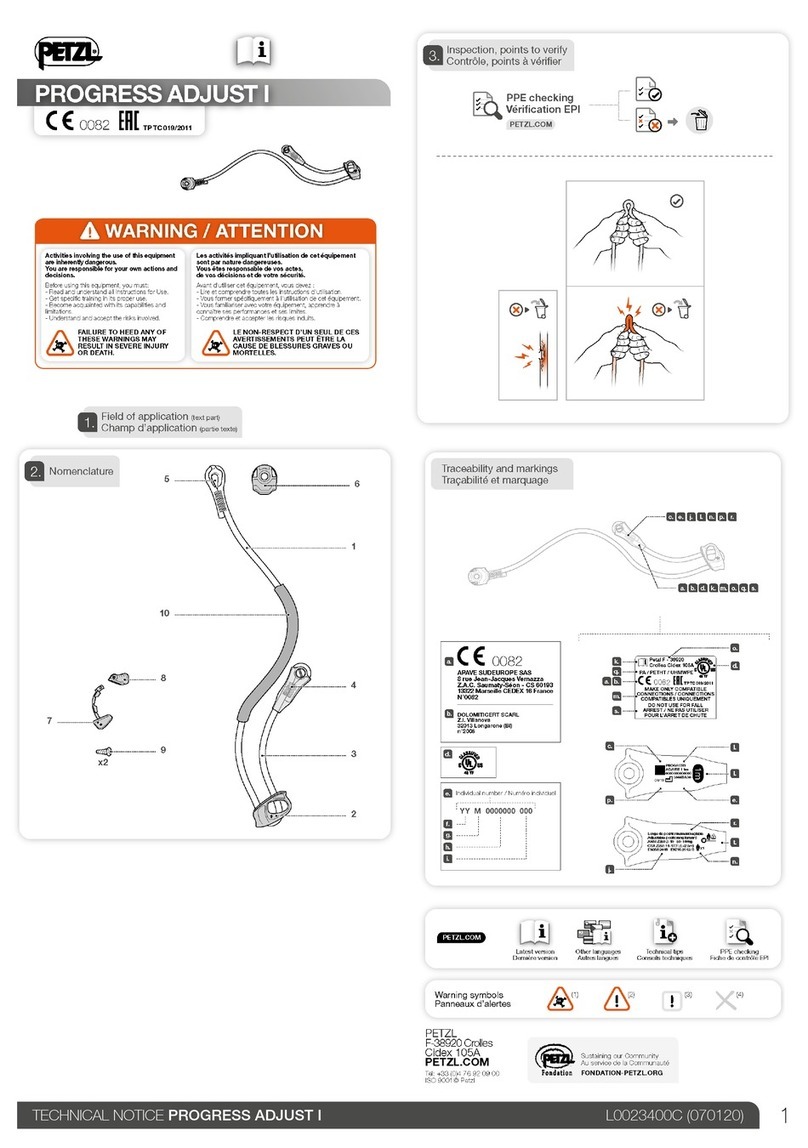

Petzl

Petzl PROGRESS ADJUST I TECHNICAL NOTICE

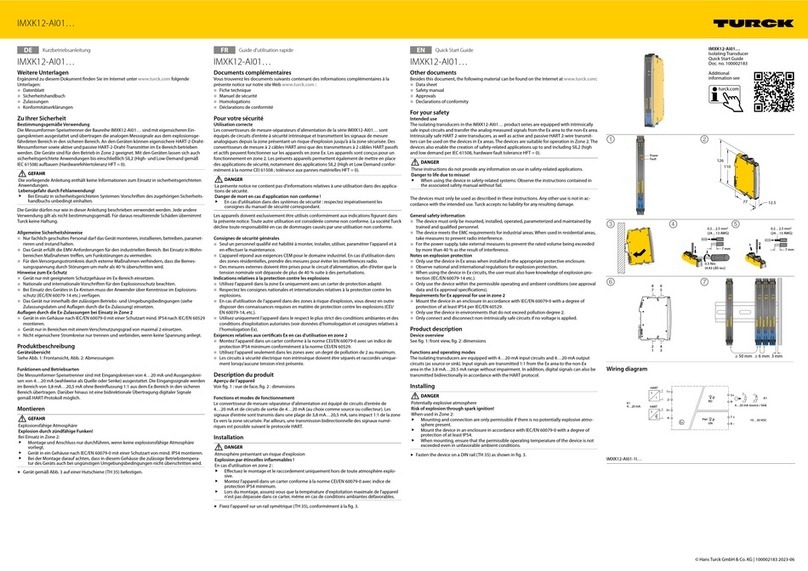

turck

turck IMXK12-AI01 Series quick start guide

optrel

optrel weldcap bump RCB 3/9-12 quick start guide

Petzl

Petzl ASAP'SORBER 40 Instructions for use

Tractel

Tractel CSK3 Installation, operating and maintenance manual