1.2.2 Insert the power cord into power socket (10), then connect

AC220V/110V power supply. Make sure the machine is grounded.

1.2.3 As for outputs of the high-frequency power, connect the red

alligator clip (positive pole) to the work piece, the other line

(negative pole) to the spindle by electrode chuck.

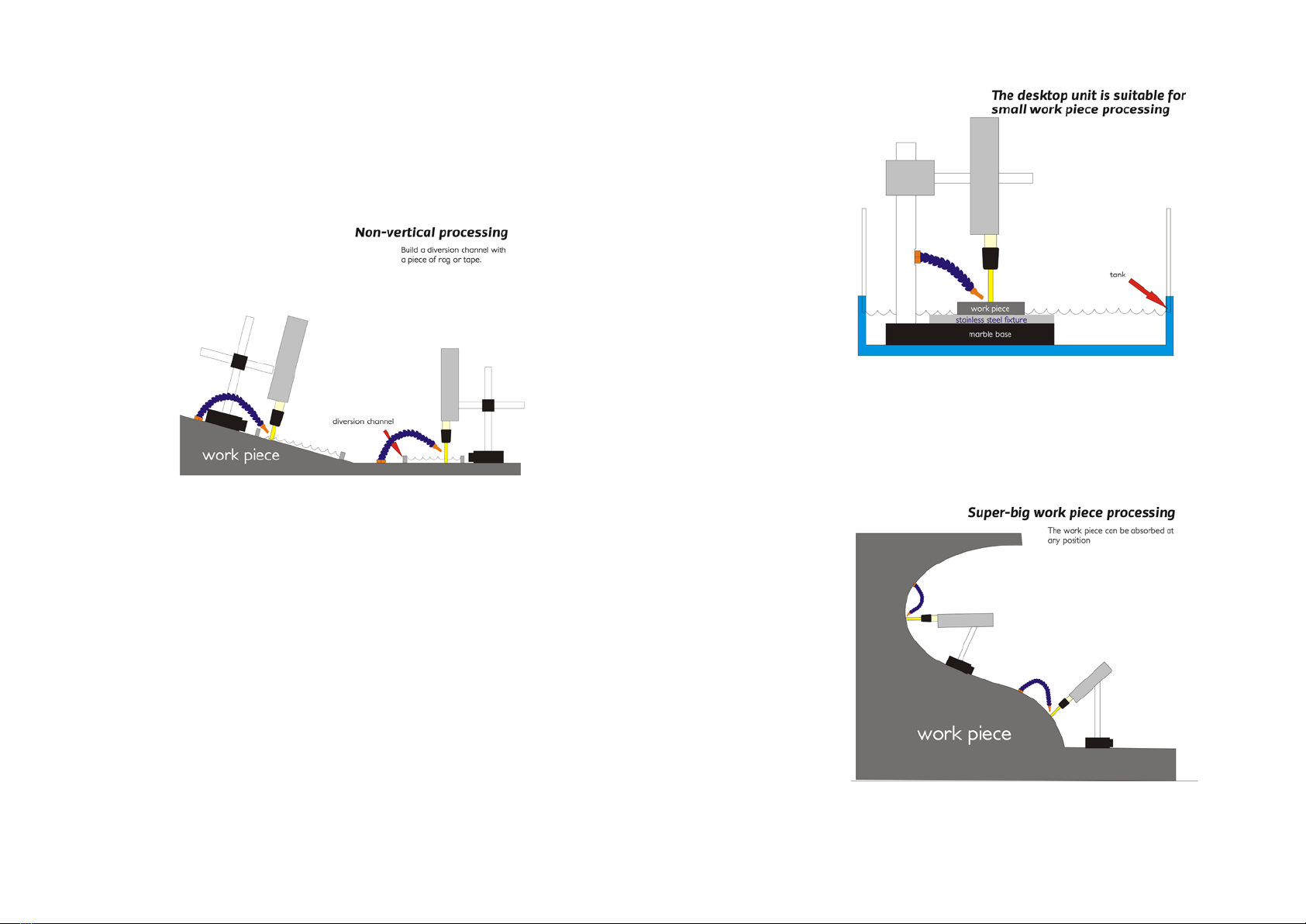

1.3 Connection of water pipe

Connect the water outlet of external water pump with universal joint

and set the universal joint at the machining parts, then align the

processing point. Put the water inlet with filter into the tank, ensure

that the water pump submerged in the liquid to avoid the pump

damaging.

2. Processing Steps:

2.1 Adjust position and height of the spindle, make sure the electrode

and broken items are coaxial to avoid damaging the work piece.

2.2 After adjusting the position, turn on the power switch (8), press the

water pump button (3) press high-frequency button (2) after water

flowing. Press servo switch (4) to the bottom position. Turn Servo

Control (5) clockwise to the right of central line until Down

Indicators light up, the spindle begins to decline. When electrode

approaches the work piece, up and down indicators flash alternately,

the processing begins. At this moment, you can adjust the discharge

gap by turning the servo adjusting knob (5) or adjust the current by

pressing the stepper current buttons(6).

3. Usage of Reset Key

When work head reaches the default depth, spindle would start the

trip switch and fallback automatically. At the same time, power box

would alarm. Then you can press the reset button(15) to stop the

alarm and get the work head back to work.

4. Usage of Vibration Button

During processing, turn the servo switch (4) to the upper position to

start vibration motor in the work head. The vibration motor would

oscillate the electrode which would double the processing efficiency.

When processing high precision holes, the vibration should be closed

as oscillation may reduce accuracy.

5. Shutdown Procedures

When the processing is unstable or processing speed is too fast or the

spark is visible from the bottom , it is proved that the drill or tap has

been smashed. Shutdown procedures.

5.1 Press the high-frequency button (2)

5.2 Turn Servo Control (5) counterclockwise until up indicator lights on

and spindle begins to rise , leaving the electrode away from the

work piece. Turning off the spindle servo and water pump.

5.3 Turn off main power switch(8)

V. Attentions

1. The external water pump is a precision part, please be careful when using.

1.1 The working liquid must be clean water or special cutting liquid. The

inlet pipe should install the filter.

1.2 At the first time, you should wait for about 3-5 seconds, after there is

no air in the pipe, the water will flow out.

1.3 When the temperature is below zero, if you do not use the machine,

please guarantee no water in pump to avoid damaging.

2. In case the working liquid is kerosene (the flashing point is above 70℃),

PLEASE DO NOT USE THE PUMP (the pump will be broken when it

meets kerosene). The level of working liquid should be more than 20mm

higher than the work piece. Otherwise, fires will occur when the oil level

is too low.

78