SGS electronic TVC-B100 User manual

TVC-B100

1

© SGS electronic 2006-2023

TVC-B100

100A dual speed controller for RC tracked vehicles

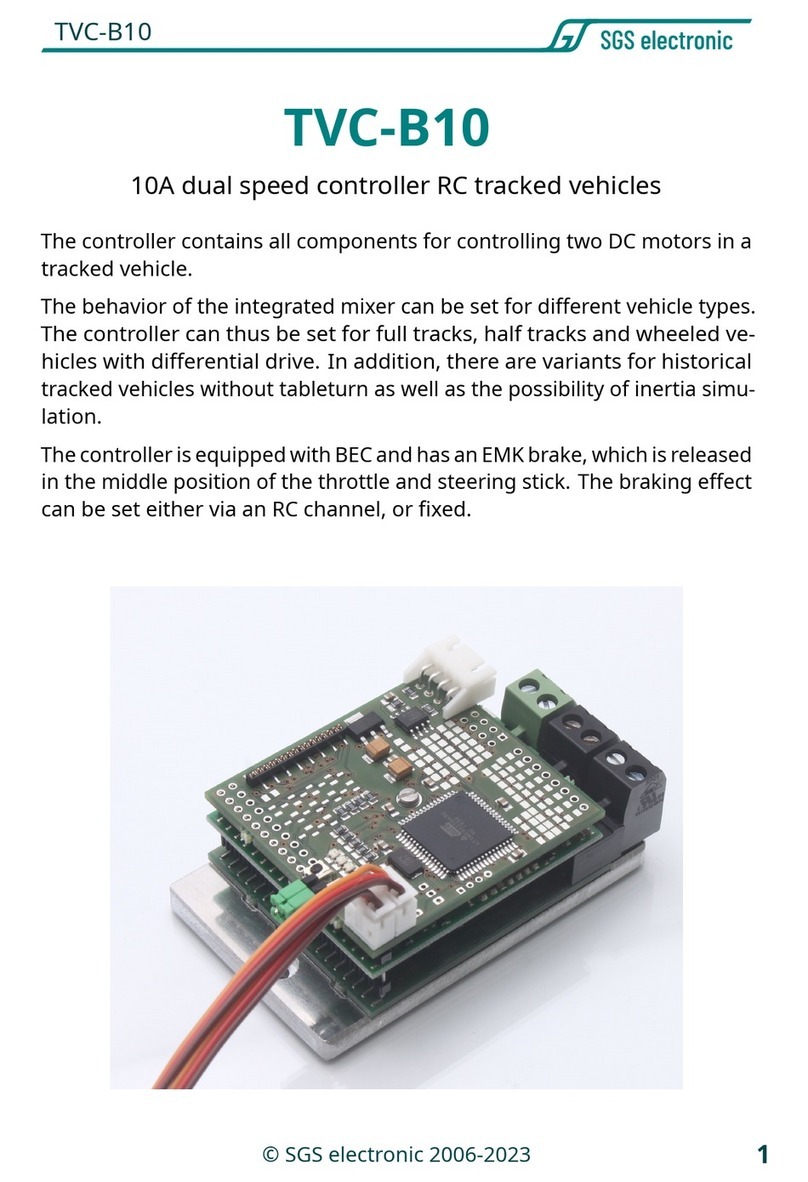

The controller contains all components for controlling two DC motors in a

tracked vehicle.

The behavior of the integrated mixer can be set for different vehicle types.

The controller can thus be set for full tracks, half tracks and wheeled

vehicles with differential drive. In addition, there are variants for historical

tracked vehicles without tableturn as well as the possibility of an inertia

simulation.

The controller has an adjustable EMF standstill brake, which is triggered in

the center position of the throttle and steering stick.

TVC-B100

2© SGS electronic 2006-2023

1 Note

Installation of the module requires intermediate to advanced modeling

skills. Soldering skills are required to connect the wiring. Inexperienced

modelers and persons aged under 16 years old should seek the assistance

of an experienced modeler. Always switch off power when working on

the wiring. Especial take care when connecting more than one receiver

energy source. Prevent the device from getting wet. Check loads before

connecting them to the modul at a current limited, or fuse protected

source.

TVC-B100

3

© SGS electronic 2006-2023

Contents

1 Note 2

2 Introduction 5

2.1 Technology................................. 5

3 Installation 6

3.1 mounting.................................. 6

3.2 Driving battery and motors . . . . . . . . . . . . . . . . . . . . . . 6

3.3 connecting the receiver . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 EMFbrake ................................. 8

4 Commissioning 10

4.1 startup ................................... 10

4.2 error acknowledgement . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Correct driving direction . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Scalebusoperation ........................... 12

4.5 Changing the mixing function . . . . . . . . . . . . . . . . . . . . 13

4.5.1 How to change mixer function . . . . . . . . . . . . . . . . 13

5 Glossary of terms 15

6 Technical data 17

7 Important 18

7.1 Warning .................................. 18

7.2 Environmental protection . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 Address................................... 19

7.4 Contact ................................... 19

7.5 Documentdate.............................. 19

7.6 Documentation.............................. 19

List of Figures

1 Connectionsoverview.......................... 6

TVC-B100

5

© SGS electronic 2006-2023

2 Introduction

The controller is designed for an input voltage range from 12V to 36V. Two

standard automotive fuses (strip fuse) protect the model and the battery

from excessive currents.

In addition, the controller has electronic overload protection (

2t

monitor-

ing) and electronic temperature monitoring of the power output stage.

2.1 Technology

The controller is microprocessor controlled. The processor works with

16MHz clock frequency. The software is coded in C and assembler.

As a failsafe function, an extensive plausibility check of the transmitter

signals is integrated in the software.

The power amplifier is built with N-channel MOSFETs, which have an inrush

resistance of only 0.001 Ohm and a current capability of 180A. To make

effective use of the low internal resistance, the output stage transistors are

driven by sophisticated push-pull MOSFET output stages with integrated

charge pump.

Under normal ambient conditions, a maximum continuous current of 100A

is achieved. The controller operates with a PWM frequency of 16kHz.

. To prevent ground loops and resulting interference, the servo inputs

are galvanically isolated. Accordingly, the receiver not is supplied by the

controller.

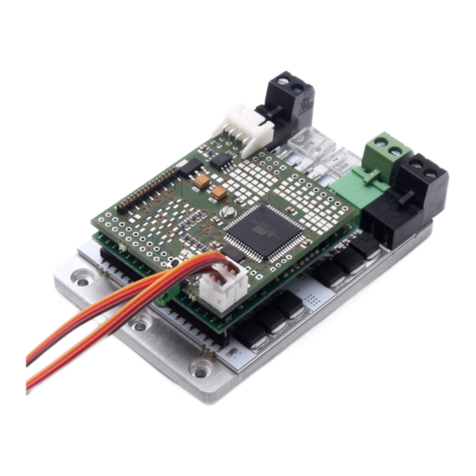

The housing of the controller is CNC milled from aluminum.

TVC-B100

6© SGS electronic 2006-2023

3 Installation

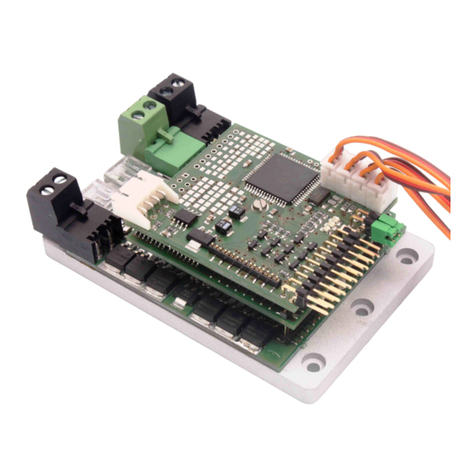

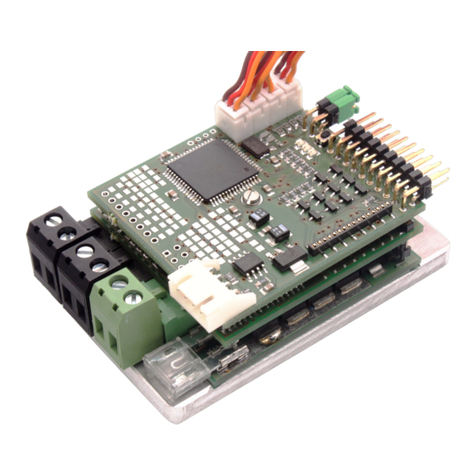

3.1 mounting

The module can be screwed onto a flat surface with max. six M5 screws.

Ideally, the module should be mounted on a large metal surface to improve

heat dissipation.

The housing of the controller is on the ground potential.

Figure 1: Connections overview

3.2 Driving battery and motors

High, high-frequency currents flow between the drive battery in both

directions. Provide a low-resistance connection between the drive

battery and the controller and use a suitable switch or a high-current

relay. Use only fuses for protection. We strongly advise against the

TVC-B100

7

© SGS electronic 2006-2023

use of electromagnetically tripped circuit breakers, anti-flash devices

for limiting the starting current, rechargeable batteries with electronic

current limiting, etc. We strongly advise against this.

The drive battery and drive motors are connected to the M5 screw terminals

via ring cable lugs.

Insulate the ring cable lugs with the enclosed heat shrink tubing to avoid

short circuits. Clamp the enclosed ring cable lugs in the following order

(from bottom to top):

1. washer

2. ring cable lug

3. washer

4. Toothed lock washer

5. nut

Use a suitable ring or socket wrench to tighten the nut. Tighten the nut

so that the toothed lock washer is compressed by approx. 0.5 mm. When

tightening the nut, align the line in the desired direction when tightening.

Please do not twist the already tightened ring cable lug by force.

Too much torque on the nut can damage the PCB!

A mix-up of the connection terminals for the power supply must be

avoided at all costs!

It makes sense to provide a switch at the supply line from the battery

to switch the model on/off. Commercially available battery switches or

high-load relays are suitable for this purpose. The motors must be radio

interference suppressed, as is usual in model building.

3.3 connecting the receiver

The controller feeds itself from the drive battery with a built-in switching

regulator. The three servo lines are galvanically isolated from the controller.

The receiver is therefore not supplied with power from the controller, but

must be supplied from another power source.

This is usually from a receiver battery. The input circuit also requires the

receiver supply voltage (approx. 15mA) and obtains this from the receiver

TVC-B100

8© SGS electronic 2006-2023

battery through the servo leads.

The servo cables are labeled.

3.4 EMF brake

The controller has an adjustable EMF brake. It is activated by moving the

throttle and steering stick to the center position.

The braking effect with which the brake is applied is indicated by the yellow

LED. The longer the yellow LED is on, the stronger the braking effect.

• LED Off corresponds to 0% braking effect.

• LED On corresponds to 100% braking action.

note

When the brake is active (stick in center position and braking effect

set greater than 0%) you can hear a hiss from the motors. This is the

modulated braking current. As soon as you drive off or deactivate the

brake, the noise disappears.

The adjustment of the brake can be done in two ways: Via an RC channel of

the controller (so it can be changed via the transmitter at any time) or via

a button on the controller. Adjustment via an RC channel of the controller

Here the braking effect is adjusted directly via the transmitter. As soon as

you press the corresponding slider/knob, you will see that the pulse/pause

ratio changes.

You can use it at any time, for example, light braking and further increase

the braking effect.

If you have a channel free on your RC system, we recommend this method.

Make sure that they do not stop from full speed with full braking effect,

this puts a lot of stress on the entire drive train.

Without RC channel with button on the controller If you want to change

the braking effect, you have to press the button. There is a small hole

under the three LEDs for this purpose. Use a thin stick made of plastic or

wood to push the button. The button has a clearly noticeable pressure

point. If you move the throttle in one direction the on phase of the yellow

LED gets longer and longer, in the other direction shorter and shorter

until it is completely off. The stronger the lever deflection, the faster the

TVC-B100

9

© SGS electronic 2006-2023

adjustment.

The green LED lights up continuously as soon as you take the lever out of

the neutral position to indicate that the controller is making a change.

If you press the button again, the brake setting is saved and is retained

even after switching off and on again.

LED function

red Error (overtemperature, overcurrent,short circuit)

yellow

EMF Brake Brake effect (flashes with variable duty cycle) ;In

Scalebus mode it is permanently on

green operating status

Table 1: LED-Codes

TVC-B100

10 © SGS electronic 2006-2023

4 Commissioning

4.1 startup

1. Put the throttle and steering levers into the receiver.

2.

If the brake is to be adjusted via the transmitter, it must also be

plugged into a free channel of the receiver.

3. Switch on transmitter

4.

Set brake, throttle and steering levers to center position (The corre-

sponding trim as well).

5.

Turn on receiver power supply. Note that the controller does not

provide receiver power (BEC voltage) due to galvanic isolation.

6. Switch on the drive voltage (= supply voltage of the controller).

7.

The LED on the board flashes until the controller has detected the

center position of the channels. If zero point detection is not possible,

the green LED flashes and the yellow one is permanently on. A new

determination of the zero point is only done after switching on/off

the driving voltage. If the driving voltage is interrupted, please wait

until the LEDs on the controller have gone out. This takes some

seconds, because of the integrated switching regulator and the large

capacities. the green LED is on continuously, the vehicle is ready to

run.

This automatic calibration is done in this way at every switch-on. I.e. the

position detected at switch-on is stored as the neutral position. This applies

to all channels except for the brake channel.

4.2 error acknowledgement

The controller shuts down in the event of overtemperature,undervoltage,

overvoltage, excessive motor currents, excessive current source impedance,

and loss of receive signal. It indicates these error conditions by flashing

the green LED (blink code) and lighting the red LED.

Special attention should be paid to the overvoltage error during regenera-

tive power supply. A regenerative overvoltage fault is triggered when the

TVC-B100

11

© SGS electronic 2006-2023

blink

code

meaning reset

double

no valid signal at control inputs

connect servo channels and

switch on/off

triple overtemperature let cool down

quad overcurrent (2t) shutdown

throttle and steering in neutral

fivefold undervoltage supply voltage

apply minimum voltage , throt-

tle and steering in neutral posi-

tion

sixfold overvoltage at regen switch supply off/on

seven-

fold

overvoltage supply voltage switch supply off/on

eightfold

hardware overcurrent or fuse

failure

throttle and steering in neutral

position

Table 2: Error codes

power from the motor is prevented from being fed back to the battery via

the controller. Generally this is called too high impedance of the power

source. In particular, this can be caused by, among other things:

1.

too small wire cross-section between battery and controller. circuit

breakers between battery and controller (do not use circuit breakers

for alternating current)

2. batteries with built-in electronic current limiter

3. operation on an alternator without buffer battery

4. operation on an electronic power supply unit

5. high contact resistance in the connections

If this error has occurred once, components and connections should be

checked carefully. Since this error is very critical, it can only be acknowl-

edged by switching the supply voltage off/on.

4.3 Correct driving direction

The direction of travel depends on the mechanical arrangement of the

engines in the vehicle. Usually, the motors are mounted so that the motor

shafts are in opposite directions. As a result, the motors must be connected

TVC-B100

12 © SGS electronic 2006-2023

with different polarity in order to travel in one direction.

Of course, correcting the direction of travel can be done directly on trans-

mitters with the servo reverse setting. If the transmitter does not have this

facility, the following procedure can be followed:

1.

model moves forward when steered backward and vice versa: Change

connections on both motors (reverse polarity).

2.

Model moves left when steered to the right and vice versa: Change con-

nections from both motors, reversing polarity. (connecting line from

motor 1 to motor 2 and vice versa).

3.

The directional control is set to neutral, but the model does not drive

straight ahead: Correct with steering trim

4.4 Scalebus operation

As an alternative to control via the servo connectors, the controller can

also be controlled via the Scalebus. To do this, connect the controller to

the other modules using the scale bus cable (white, four-pin connector).

For example, the FO module TVC-MF-10 can control the controller. The

controller switches to Scalebus mode if there is no servo signal on the

servo cables when it is switched on.

TVC-B100

13

© SGS electronic 2006-2023

4.5 Changing the mixing function

Different vehicles and transmission types need different mixers. In the

past, we offered different versions of the controller (”OG”, ”CM”, ”HT”, etc.).

With this controller, you can now define the mixer function yourself. An

overview of the available mixers is shown in table 3 on page 14.

Notes

Note that the maximum current consumption of mixers with table-

turn is not significantly higher because the drives work against each other

in tableturn.

Be careful when operating with inertia simulation. The vehicle then natu-

rally reacts with a delay to the commands of the radio remote control.

4.5.1 How to change mixer function

1.

Connect everything as described under commissioning and switch

on the transmitter.

2.

press the button when switching on the controller. The setting mode

is indicated by the red and yellow LEDs lighting up.

3.

With the throttle and steering channel you can now select nine posi-

tions by setting the sticks in left/right stop or leave neutral position.

The position number is indicated by the red LED flashing while the

green LED is lit. If the green LED goes out, the cycle starts again.

4.

For example, if the red LED flashes three times, mixer number three

of the table is selected. save this, hold the sticks in position and press

the button again.

5. Then release the stick. Now the mixer is selected and saved.

TVC-B100

14 © SGS electronic 2006-2023

Code

drive type name

table-

turn

vehicle type description

1 full track

simulation

superposition

gearbox 100%

yes

tracked con-

struction

machines,

modern

tanks, snow

groomers

Simulation of the driving behavior

of a mechanical superimposed trans-

mission without limitation of the

drive power

2 full track

simulation

superposition

gearbox 80% /

60%

yes

tracked con-

struction

machines,

modern

tanks, snow

groomers

Simulation of the driving behavior

of a mechanical superimposed trans-

mission with straight-line driving lim-

ited to 80% and steering limited to

60%. Only when cornering is 100%

given to the drives to account for the

increased friction.

3

half track/

wheeled

classic mixer no

wheeled on-

struction

machines,

halftracks

The chain inside the curve is reduced

from 100% to 50% of the driving

speed at steering angle

4 full track

mechanical

superimposed

gearbox

yes

modern

tanks, snow

groomers

This setting is for mechanical super-

imposed gear units

5 full track

no mixer, sin-

gle chain con-

trol

yes

Operation via

manual mixer

or mixer in ra-

dio

This variant has no mixer, only a

brake that acts when both drives

come to a standstill.

6 full track

classic mixer

with tableturn

yes

tracked con-

struction

machines,

modern

tanks, snow

groomers

Mixing function as used e.g. by

Tamiya

7 full track

classic mixer

without table-

turn

no

historical

construction

machinery and

tanks

Mixing function as used for exam-

ple in Tamiya but when cornering the

chain does not run backwards.

8 full track

simulation

superposition

gearbox 100%

and inertia

simulation

yes

tracked con-

struction

machines,

modern

tanks, snow

groomers

Table 3: list of optional mixing functions available

TVC-B100

15

© SGS electronic 2006-2023

5 Glossary of terms

BEC Battery Eliminator Circuit

This circuit replaces a extra Battery needed for the receiver and con-

nected servos, by generating a fixed voltage from the drive battery.

ESC Electronic Speed Controller

This is a unit to control the speed and direction of a DC motor.

LED Light Emmitting Diode

A light-emitting diode (LED) is a semiconductor device that emits

visible light when an electric current passes through it. Benefits of

LEDs are low power requirement and long life. Disadvantages is the

more complicated wiring, compared to a classic bulb, it has a polarity

and a resistor is needed to limit the current.

Scalebus

The Scalebus is a development of

SGS electronic

to connect con-

trollers and modules to compose solutions for complex RC models.

SBus

The Sbus has been introduced by

Futaba

to simplify the wiring be-

tween RC Receivers and servos / esc.

SBus

The SBus was introduced by the company

Futaba

to simplify the

wiring between receiver and servos/controllers. This is especially

useful for models with many controllers.

IBus

The IBus was introduced by the company

Flysky

to simplify the wiring

between receiver and servos/controllers. This is especially useful for

models with many controllers.

SUMD

The SUMD sum signal has been introduced by the company

Graup-

ner

to simplify the wiring between receiver and servos/controllers.

This is especially useful for models with many controllers.

TVC-B100

16 © SGS electronic 2006-2023

Abbre-

vation

meaning explanation

Stick Stick Stick not self centering

StickS S

tick

Selfcentering

self centering Stick

TSMS T

hree

S

tage

M

omentary

Switch

self centering momentary switch with three

stages

TSS T

hree

S

tage

Switch

switch with three stages

Pot Potentiometer linear- or rotary knob

PotC Pot

entiometer

with Center key

linear- or rotary knob with a center key

Table 4: Abbrevation for the manipulators in the transmitter housing

TVC-B100

17

© SGS electronic 2006-2023

6 Technical data

Rated motor current (per motor) 100 amps

up to 30s: 150 amps

Supply voltage drive 12V to 36V

Supply voltage servo input 3.3V to 8.0V

PWM frequency 16kHz

Typical maximum power dissipation 22W

Typical voltage drop in power stage 0.15V

Dimensions (height without connectors) 165 ×105 ×17mm

distance screws row 154mm

Screw spacing 35mm

Bore diameter 5.2mm

Software version 02.01.20

TVC-B100

18 © SGS electronic 2006-2023

7 Important

This equipment described above has been tested and inspected for quality

and function. And it is intended for installation and use only as described

above. This equipment does not contain any user serviceable parts. The

supplier accepts no responsibility, financially or otherwise, for damages

caused by use or misuse of the equipment described above. The equip-

ment must be protected from exposure to water to prevent short circuit.

Do not open the equipment or attempt to change function, wiring, or doc-

umentation in any way. Do not connect to incorrect voltage or reverse the

battery polarity. Do not use in a careless or abusive fashion around persons

or property. Do not attempt to repair. Any legitimate use, e.g. Installa-

tion in a model makes the user responsible to ensure that the operating

instructions and non-liability agreement are provided to the purchaser of

the module described above.

Do operate the device only in the permissible operating conditions. Do

not make any changes to the controller through. The device shall not be

exposed to splashing water or rain (causing a short circuit).

7.1 Warning

Due to choking hazard caused by small parts that may be swallowed, this

product is not suitable for children under 6 years of age.

7.2 Environmental protection

For defective devices, repair is possible in many cases. Please contact us. If

you do decide to dispose of the device, you will be making a contribution to

environmental protection if you return the device to a municipal collection

point for recycling. Electronic devices do not belong in household waste.

TVC-B100

19

© SGS electronic 2006-2023

7.3 Address

SGS electronic

Zeppelinstraße 36

47638 Straelen

Germany / Europe

7.4 Contact

Web www.sgs-electronic.de

Email [email protected]

Ust-IdNr.: DE 249033623

WEEE-Reg.-Nr.: DE 90290947

7.5 Document date

This document was created on 2023-03-31 01:05:02+02:00

7.6 Documentation

We reserve the right to make updates, changes or additions to the infor-

mation and data provided.

The documentation that accompanies your product applies.

Please note that documents obtained later via download may not corre-

spond to the status of your module.

TVC-B100

20 © SGS electronic 2006-2023

Table of contents

Other SGS electronic Controllers manuals

Popular Controllers manuals by other brands

Samson

Samson FOUNDATION 3730-5 Mounting and operating instructions

Servomech

Servomech ILA 15 A Installation, operation and maintenance manual

TREND

TREND IQ251 installation instructions

Gree

Gree XE70-33/H owner's manual

flamco

flamco MeiTronic W10B user manual

Mitsubishi Electric

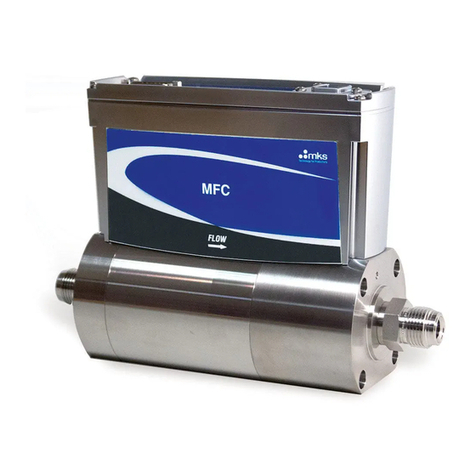

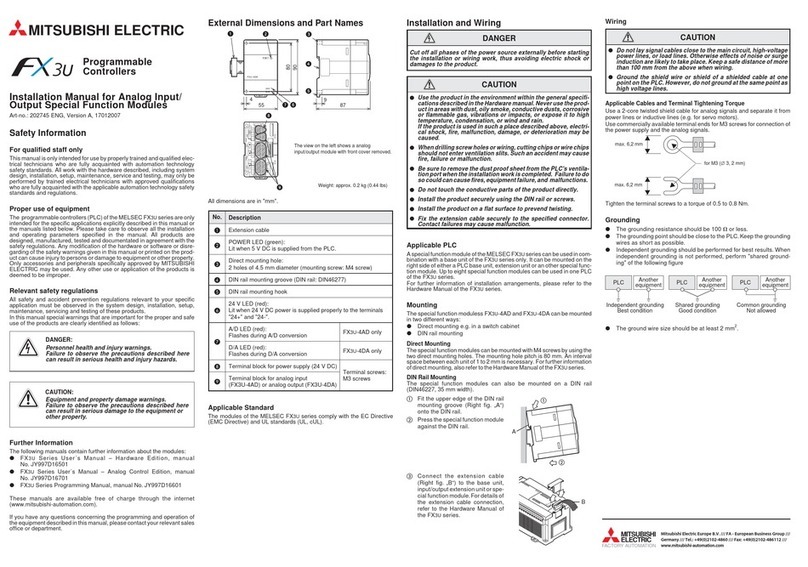

Mitsubishi Electric FX3U-4AD installation manual

Tamarack Technologies

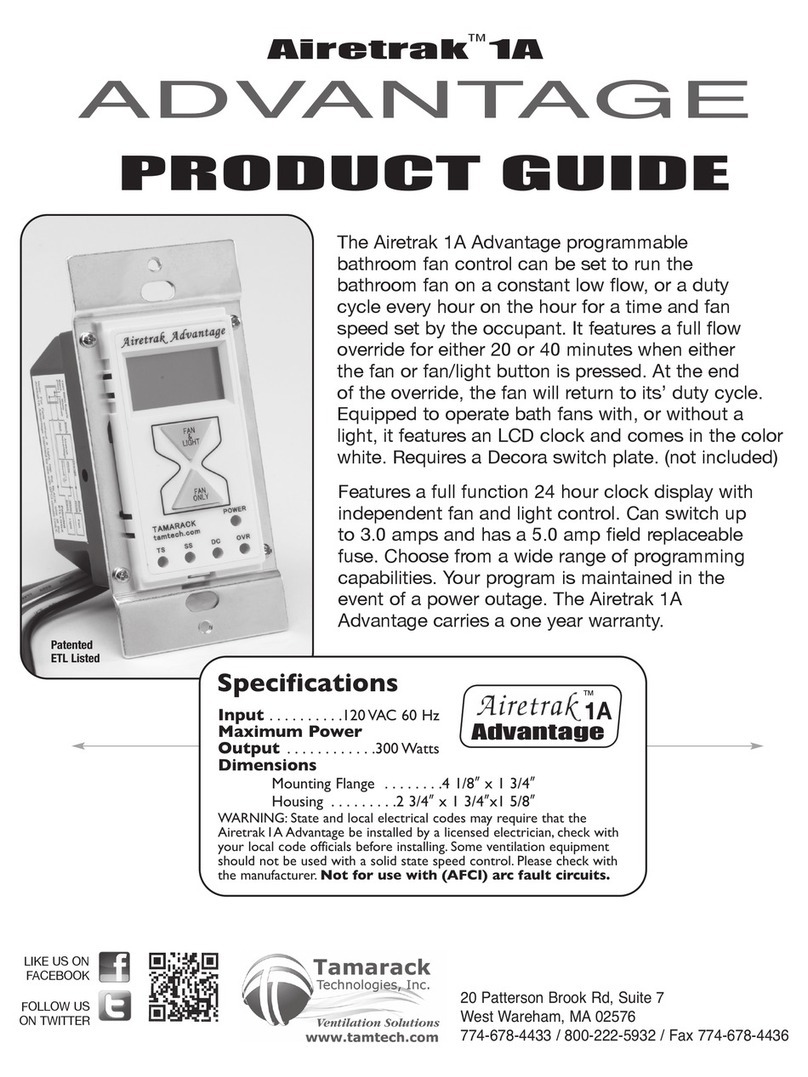

Tamarack Technologies Airetrak 1A ADVANTAGE Product guide

Woodward

Woodward 723PLUS Installation and operation manual

Pentair

Pentair FLECK SXT user manual

ITC

ITC VersiControl 22500-RGBW Series Install instructions

kincrome

kincrome K13350 instruction manual

Stober

Stober SR6 Commissioning instructions