PAGE 7

PAGE 6

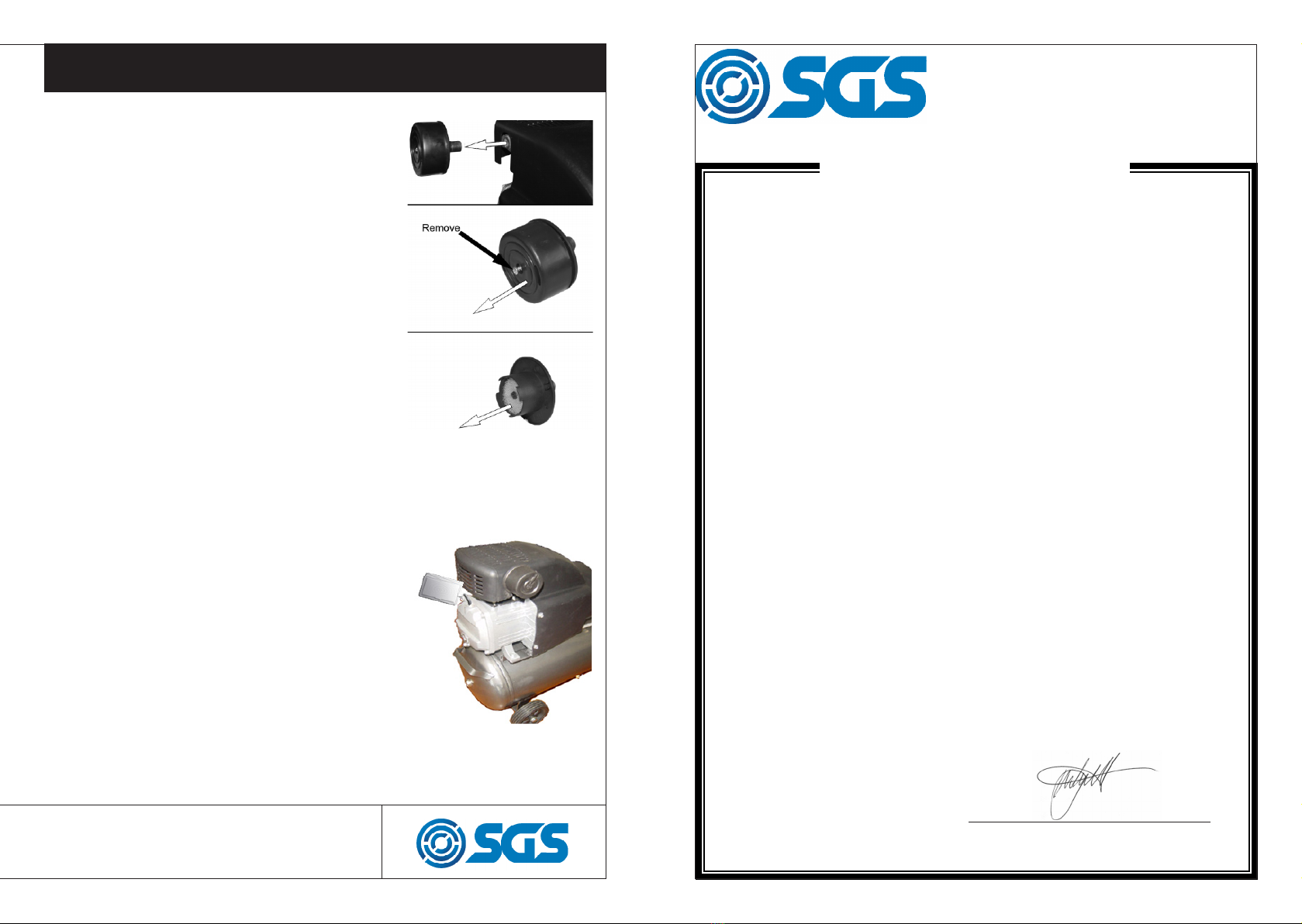

DISCONNECT THE AIR COMPRESSOR: Always disconnect the air compressor

from the mains power supply and decompress before performing maintenance,

changing any parts and when not in use.

MAINS POWER CABLE PRECAUTIONS: Never pull on the cable when removing

the plug from the mains socket, or lift the compressor by the mains cable.

AVOID UNINTENTIONAL STARTING: When connecting the air compressor to the

mains supply make sure the red button on top of the air compressor is in the OFF

(down) position.

STORE THE AIR COMPRESSOR PROPERLY: When not in use the air compressor

should be stored in a secure, dry place out of the reach of children. Always lock up

the storage area.

MAINTAIN THE AIR COMPRESSOR WITH CARE: If the air compressor is dam-

aged in any way, have it repaired by a qualified engineer.

DO NOT USE EXTENSION LEADS: Using extension leads can cause your com-

pressor motor to burn out. Only use extension hoses.

DO NOT WELD TO THE PRESSURE VESSEL

Do not weld or modify the pressure vessel in any manner.

SAFETY PRECAUTIONS

KEEP VISITORS/CHILDREN AWAY: Do not allow visitors/children to handle the

air compressor or attachments and ensure that any people in the work area are

suitably dressed.

KEEP THE WORK AREA CLEAN: Cluttered areas mean accidents, so clear the

work area of all unnecessary tools, debris and furniture.

DO NOT TOUCH HOT SURFACES: During operation, the motor, connections,

compressor body, cylinder head and tubes may get hot, do not touch.

DO NOT DIRECT AN AIR STREAM AT THE BODY: Do not direct the air stream at

people or animals, as injury may result. Compressed air can cause soft tissue dam-

age and propel dirt and other particles at high speed.

BREATHING AIR: This compressor should not be used to supply breathing quality

air. Never use it as breathing apparatus.

STAY ALERT: Watch what you are doing, use common sense, and do not operate

the air compressor when you are tired. The air compressor should not be used if

you are under the influence of alcohol, drugs or any medication that makes you

drowsy.

DISPOSAL INFORMATION

The air compressor should be disposed of in a safe an environmentally friendly

manner. Contact your local Council for disposal assistance.

SAFETY PRECAUTIONS

WWW.SGS-ENGINEERING.COM