MX-2310U Transit, Installation (using) environment, Note – i

MX-2310U Service Manual

Transit, Installation (using) environment, Note

1. Installing (use) conditions

Before installing the machine, check that the following installing

(use) conditions are satisfied.

If the installing (use) conditions are not satisfied, the machine may

not display full performances, resulting in troubles. It may also

cause safety problems. Therefore, be sure to arrange the installing

(use) conditions before setting up the machine.

A. Bringing space

For installation of a large size machine, be sure to check that the

door size is wide enough before bringing in.

B. Installing space

The following space must be provided around the machine in order

to assure machine performances and proper operations.

If any option is installed, provide the additional space for installing

it.

Adequate space must be provide behind the machine for proper

ventilation heat and dust. If not, the machine cannot exhibit func-

tions against heat and dust, causing some troubles.

C. Power source (Capacity, voltage, frequency,

safety, plug)

If the power specifications are not satisfied, the machine cannot

exhibit full performances and may cause safety trouble.

Strictly observe the following specifications.

(1) Power capacity

Check that the following power capacity is satisfied. If not, addition-

ally provide a power source.

Current capacity

Japan: 20A or more

100V: 15A or more

200V: 10A or more

Check the shape of the power plug of the machine, and insert it into

a power outlet of the acceptable shape.

(2) Power voltage

Measure the voltage during copying to check that the voltage is in

the range of the specified voltage ±10%.

If the voltage is outside the specified range, use thicker lead wires

to reduce impedance.

(An electrical work is required.)

Use of a step-up transformer is also available. In this case, the

capacity must be great enough for the max. power consumption of

the machine.

(3) Power frequency, waveform

The frequency must be within the range of the specified frequency

±2%. If power waveform is deformed, a trouble may occur.

(4) Safety

Be sure to properly ground the machine.

Grounding (earth connection) must be performed before inserting

the power plug into the power outlet.

When disconnecting the earth connection, be sure to disconnect

the power plug from the power outlet in advance.

(5) Power plug

Check the shape of the power plug of the machine, and insert it into

a power outlet of the acceptable shape.

Power plug stated in power capacity.

D. Floor strength and level

This machine is considerably heavy and becomes heavier with an

option installed.

The floor must be strong enough to safely support the weight of the

machine as well as any installed options.

If the unit is not horizontally installed, the toner density control is

not performed normally, degrading the copy quality.

If not, color shift or image distortion may occur.

To assure proper Image quality, make sure the machine is setting

level.

E. Direct rays of the sun, dust, temperature,

humidity, gasses, chemicals, vibration

(1) Temperature and humidity (Environmental

conditions)

This machine is designed to perform properly under the specified

temperature and humidity. If the temperature and humidity exceeds

the specified range, the machine may not operate properly and or

cause equipment failure.

Especially when the humidity is too high, paper absorbs humidity to

cause a paper jam or dirty copy.

Do not install the machine near a heater, a cooler, or a humidifier.

Condensation may form inside the machine causing multiple trou-

bles. Use enough care for ventilation.

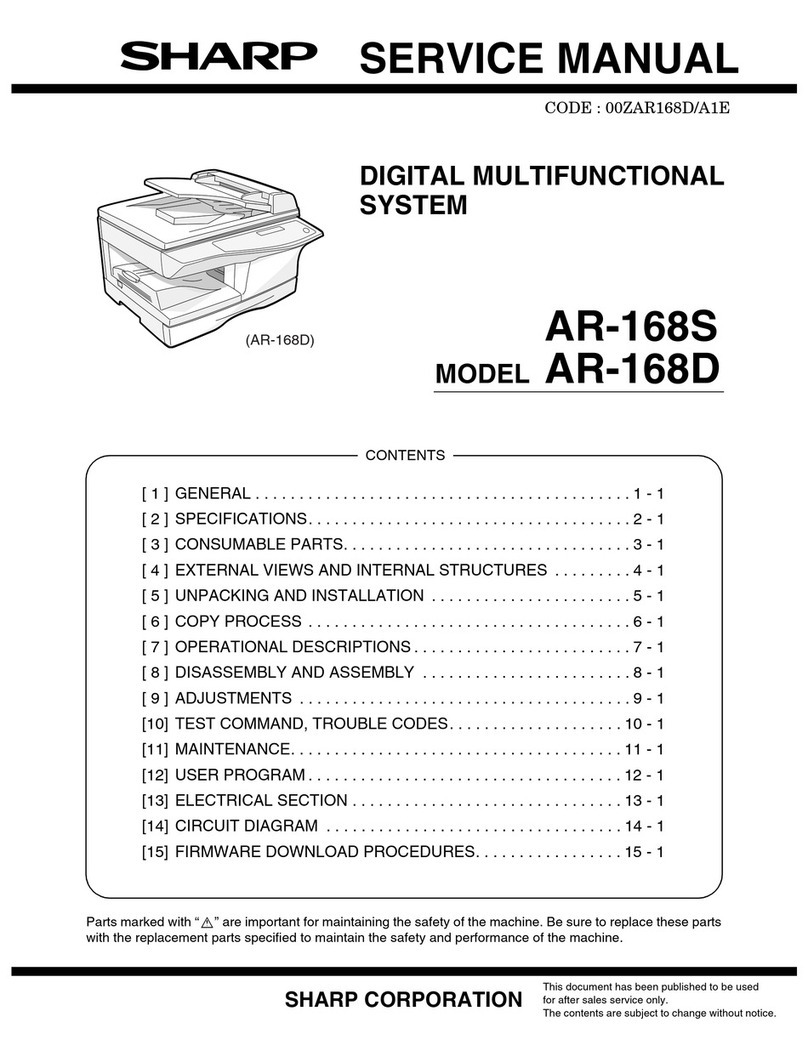

No. Content

1 Bringing space

2 Installing space

3 Power source (Capacity, fluctuation, safety)

4 Floor strength

5 Direct rays of the sun, dust, temperature, humidity, gases,

chemicals

11-13/16"

(30cm)

11-13/16"

(30cm)

17-23/32"

(45cm)