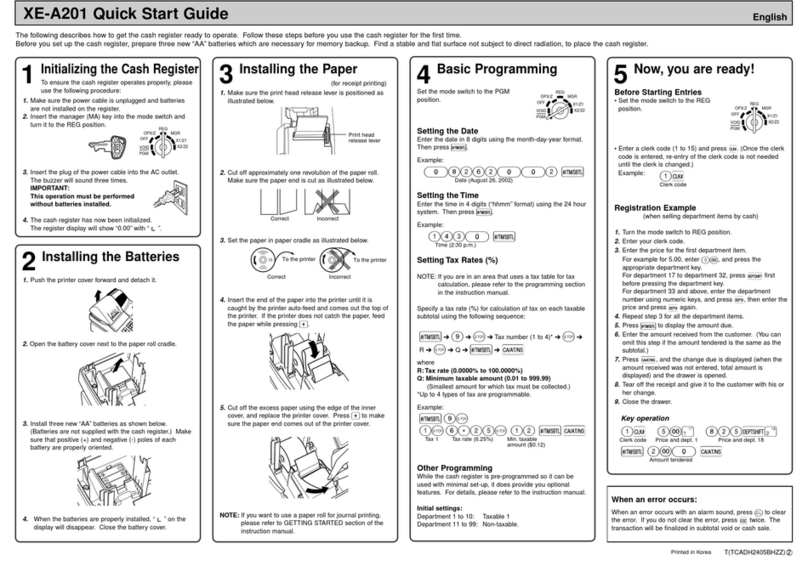

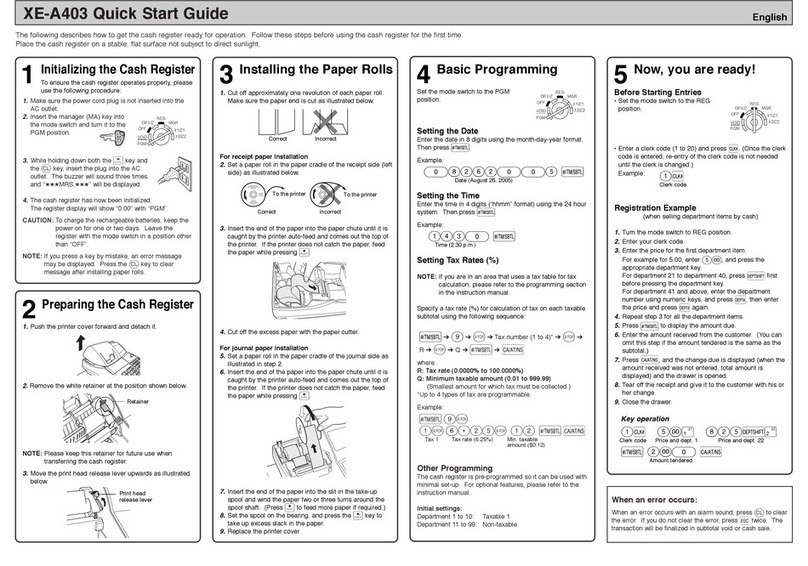

3) TEST PROGRAMMING KEY SHEET LAYOUT

: The shaded area contains the character keys which are

used for programming characters.

KEY TOP DESCRIPTION

SHIFT Used for programming characters.

Entering upper-case letters

You can enter an upper-case letter by using this

key. Press this key just before you enter the

upper-case letter. You should press this key each

time you enter an upper-case letter.

DC Used for programming characters.

Entering double-size characters

This key toggles the double-size character mode

and the normal-size character mode. The default

is the normal-size character mode. When the

double-size character mode is selected, the letter

"W" appears at the bottom of the display.

INS Used for programming characters.

To select a text editing mode

Toggles between the insert mode ("_") and the

overwrite mode ("■").

DEL Used for programming characters.

To delete a character or figure

Deletes a character or figure in the cursor position.

BACK SPACE Used for programming characters.

To delete a character or figure

Backs up the cursor for deleting the character or

figure at the left of the cursor. When your POS

terminal is in the insert mode, this key deletes the

character or the value at the cursor position.

Used to move the cursor.

ENTER Used to program each setting.

TL Used to finalize programming.

CANCEL Used to cancel programming and to get back to

the previous screen.

PREV

RECORD Used to go back to the previous record, e.g. from

the department 2 programming window back to

the department 1 programming window.

NEXT

RECORD Used to go to the next record, for example, in

order to program unit prices for sequential

departments.

PAGE DOWN Used to scroll the window to go to the next page.

PAGE UP Used to scroll the window to go back to the

previous page.

CL Used to clear the last setting you have

programmed or clear the error state.

Used to toggle between two or more options.

SBTL Used to list those options which you can toggle by

the [ ] key.

RECALL Used to call up a desired code.

Numeric keys Used for entering figures.

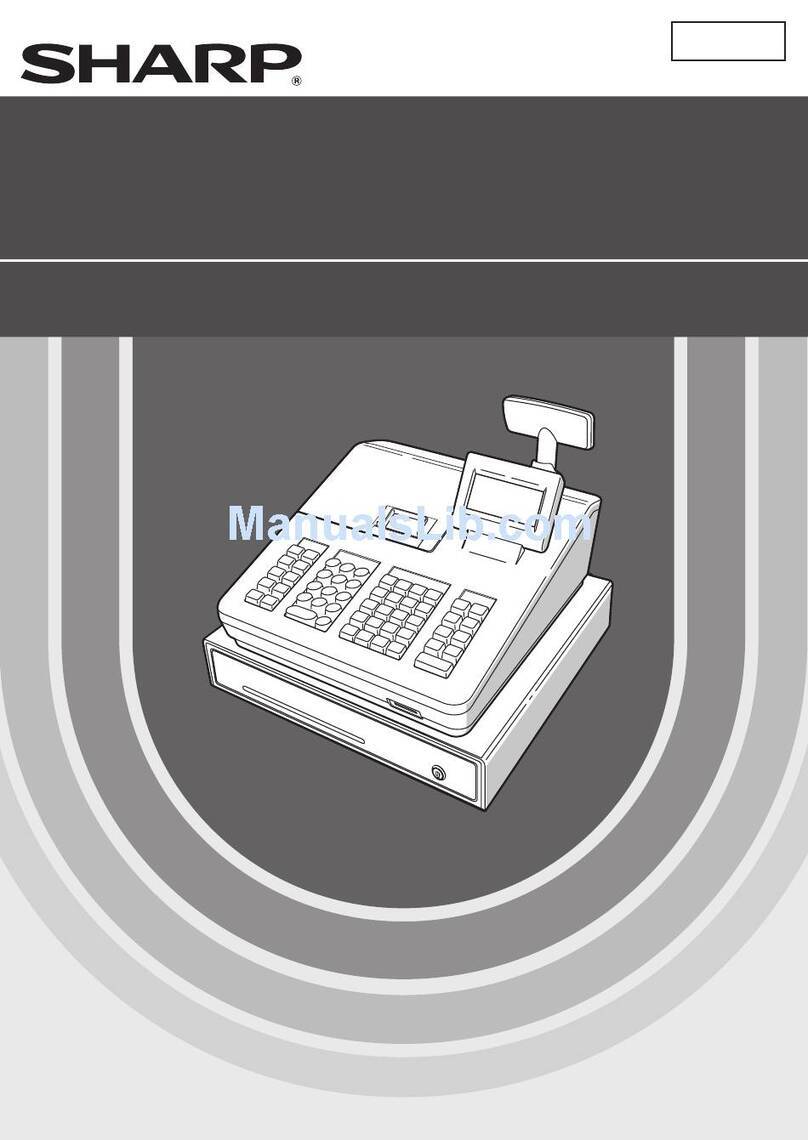

3. DISPLAY

1) OPERATOR DISPLAY

•Screen example 1 (REG mode)

Price level shift indicator

(P1-P6) : Shows the PLU/UPC price level

currently selected.

PLU level shift indicator

(L1-L5) : Shows the PLU level currently se-

lected.

Receipt shift indicator (r) : Shows the receipt shift status.

T-Log near full indicator

( ) : Appears ( ) when the used mem-

ory is 80%.

: Appears ( ) when the used mem-

ory is 90%.

: Appears ( ) when the used mem-

ory is 95%.

Stock alarm indicator ( ! ) : Appears when the stock of the PLU

which you entered is zero, negative

or reaches the minimum stock.

Electronic mail indicator

(M) : Appears when an electronic mail is

received. (Status 1 area)

Receipt ON/OFF status in-

dicator (R) : Appears when the receipt ON-OFF

function signs OFF.

Sentinel mark (X) : Appears in the lower right corner of

the screen when the cash in drawer

exceeds a programmed sentinel

amount.

The sentinel check is performed for

the total cash in drawer.

•Screen example 2 (PGM mode)

SBTL

7

4

1

000

CA/AT

2

56

89

3

@

FOR

CL

E

D

C

B

A

J

I

H

G

FKQ

PV

U

Z

Y

X

O

N

M

L

T

S

R

W

Scroll guidance:

Server code

Mode name

Status area 1:

Time

Status area 2:

Numeric entry

When a transaction information

occupies more than 5 lines, scroll

key(s) appears to indicate you can

scroll to the direction.

Sales information

area:

Sales information

you have just entered

such as items and

prices will appear

between 2nd line and

6th line.

Total is always appear

at 7th line.

Programming item

information area

Programming area:

Programmable items

are listed.

Double-size character mode

indicator (W):

Appears when the double-size

character mode is

selected during text programming.

Caps lock indicator

(A/a):

The upper-case letter “A”

appears when caps lock is on,

and the lower-case letter “a”

appears when caps lock is off

during text programming.