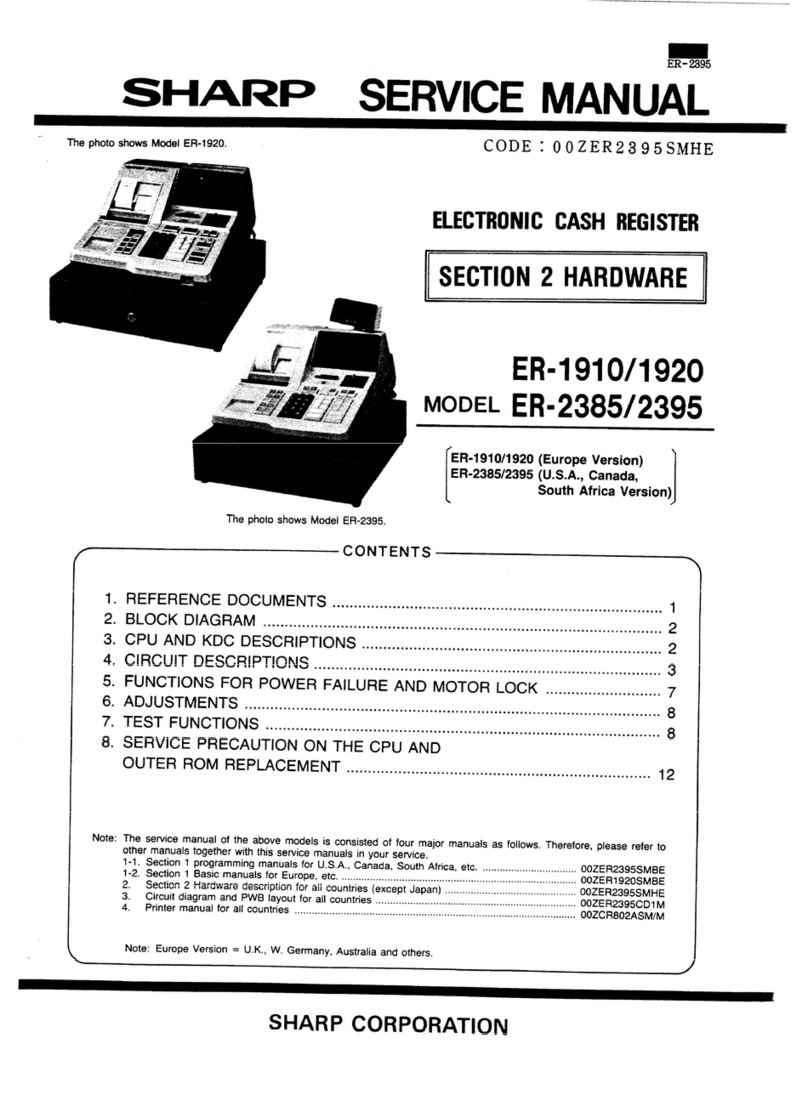

ER-A410/ER-A420 SPECIFICATIONS

– 4 –

■

■■

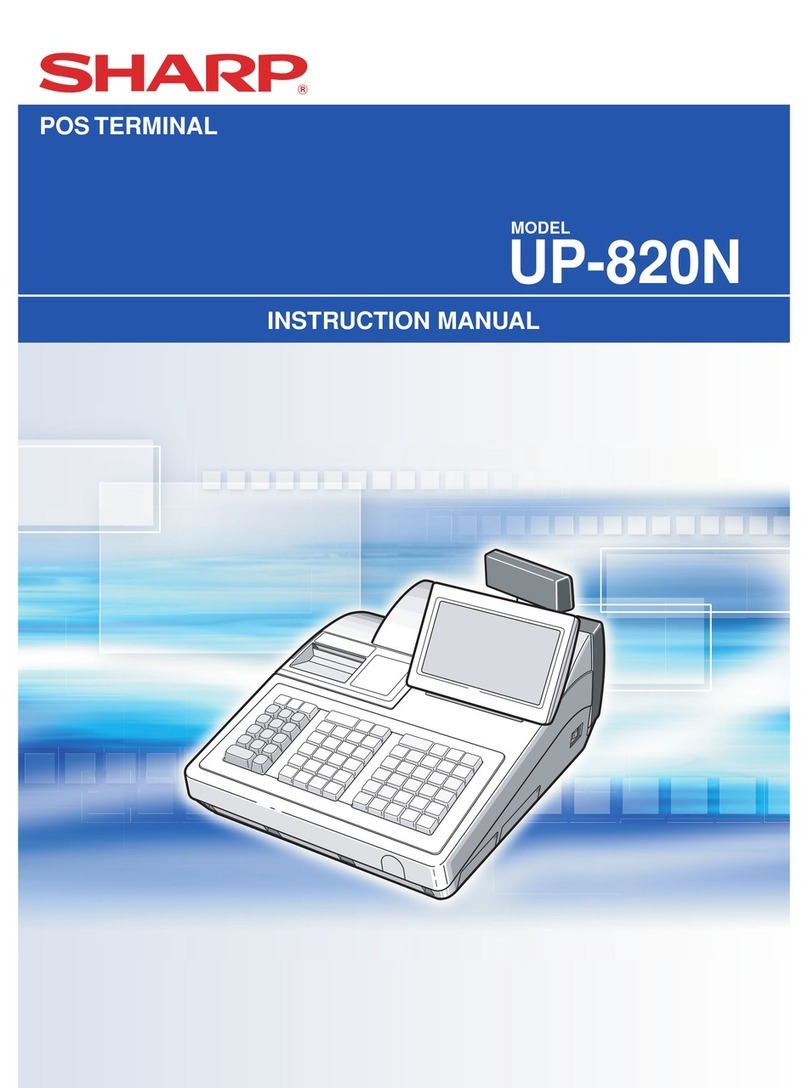

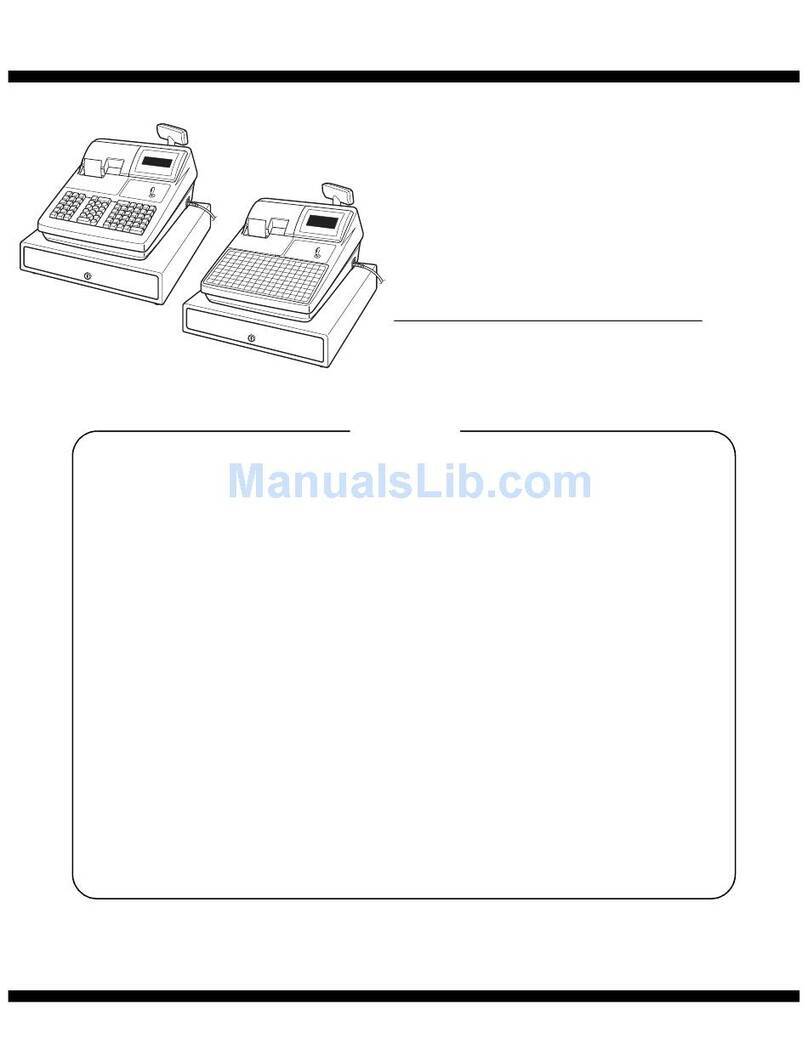

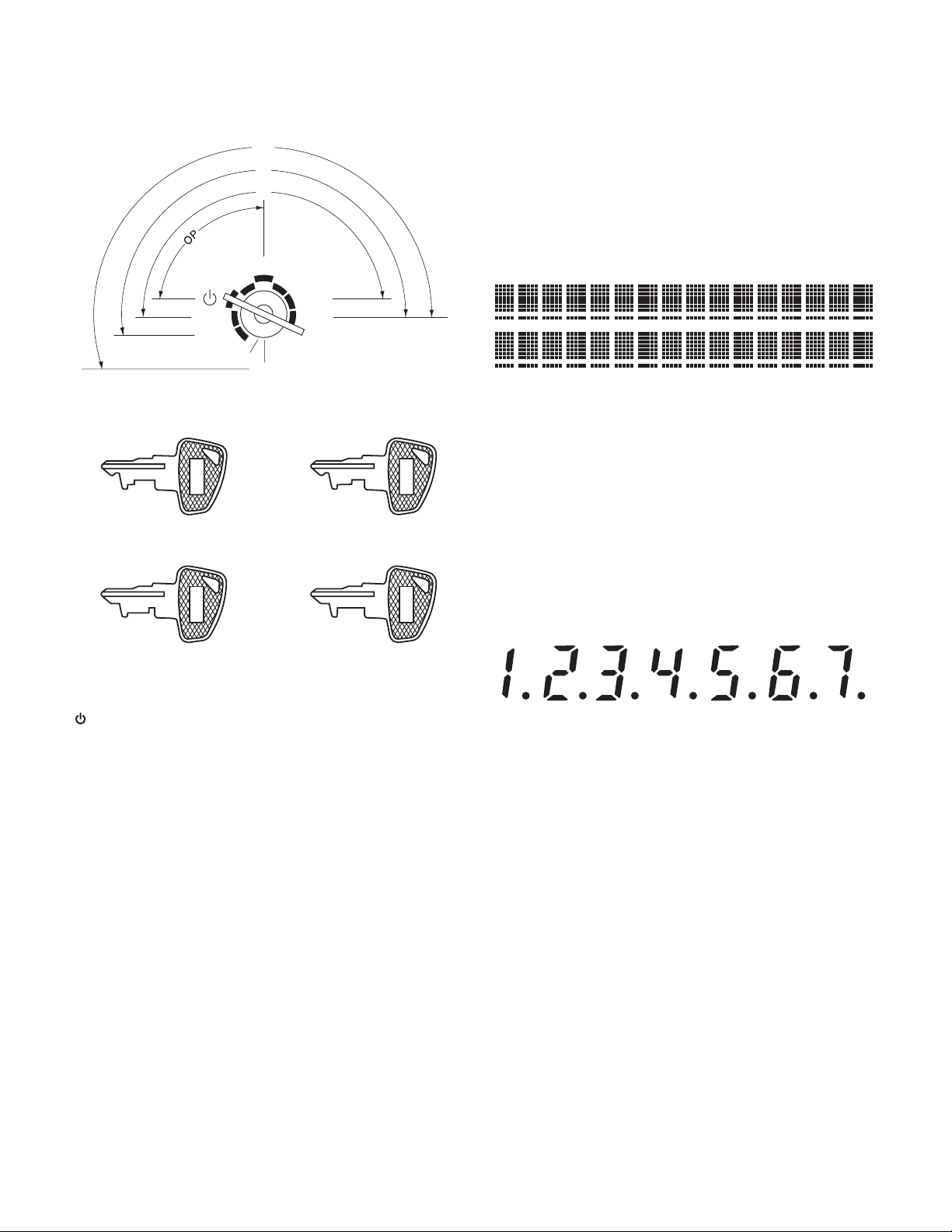

■Operator display

The operator display consists of a 2-line LCD dot-matrix display (16

characters/line).

• Cashier/clerk code or mode name

The mode you are in is displayed. When a cashier/clerk is

assigned, the corresponding cashier/clerkcode is displayed in

the REG or OP X/Z mode. For example, “0001” is displayed

when cashier 0001 is assigned.

• Repeat

The number of repeats is displayed, starting at “2” and incremen-

tal with each repeat. When you have registered ten times, the

display will show “0”. (2 33......9 30 31 32...)

• Sentinel mark

When the amount in the drawer reaches the amount you prepro-

grammed, the sentinel mark “X” is displayed to advice you to

remove the money to a safe place.

• Power save mark

When the cash register goes into the power save mode, the

power save mark (decimal point) is displayed.

• Stock alarm indicator

When the stock of the PLU which you entered is zero or nega-

tive, the alarm indicator (decimal point) is displayed.

• Function message display area

Item labels of departments and PLU/subdepartments and func-

tion texts you use, such as %1, (–) and CASH are displayed

here. For the details of function texts.

When an amount is to be entered or entered, “AMOUNT” is dis-

played: When an amount is to be entered, – – – – – – – is dis-

played in the numeric entry display area with “AMOUNT”. When

a preset price has been set, the price is displayed in the numeric

entry display area with “AMOUNT”.

• Numeric entry display area

Numbers entered using numeric keys are displayed here.

Date and time display

Date and time appear on the display in the OP X/Z, REG, or MGR

mode. In the REG or MGR mode, press the [#] key to display the date

and time.

Error message

When an error occurs, the corresponding error message is displayed

in the function message display area.

■

■■

■Customer display (Pop-up type)

6. PRINTER

6-1. PRINTER

6-2. PAPER

6-3. LOGO STAMP

• No

6-4. CUTTER

• Method: Manual

Function message

displayarea

Cashier

/

clerkcode or

mode name

Numeric entry

displayarea

Receipt OFF indicator("_")

/

Stockalarm indicator(" ")

Repeat

/

Sentinelmark

/

Powersave mark

Dept.name

/

PLU name

/

function text

Price level

/

PLU level

(e.g.P2L3)

Power save mark(This markappears only inthe power save mode)

• Part number: PR-45MII (PR-45M compatible)

• NO. of station: 2 (Receipt and journal)

• Validation: No

• Printing system: Line thermal

• No. of dot: Receipt 288 dots

• Journal 288 dots

• Dot pitch: Horizontal 0.125mm

Vertical 0.125mm

• Font: font A: 12 dots x 24 dots

font B: 9 dots x 24dots

• Printing capacity: Receipt max. 24 characters

Journal max. 24 characters

• Character size: 1.5mm (W) x 3.0mm (H) at 12 x 24 dots

1.125mm (W) x 3.0mm (H) at 9 x 24 dots

• Print pitch: Column distance 1.5mm at 12 dots

1.125mm at 9 dots

Row distance 3.75mm

• Print speed: Approximate 50mm/s

• Paper feed speed:

(Manual feed) Approximate 40mm/s

• Reliability: Mechanism MCBF 5 million lines

• Paper end sensor: Set up (Receipt and journal)

• Cutter: Manual

• Near end sensor: No

Note : PR-45MII is minor change model of the PR-45M.

This printer is not set gear cover (GCOVH7146BHZZ) from PR-

45M only.

• Paper roll dimension: 44.5 m0.5mm in width

Max. 83mm in diameter

• Paper quality: (Journal/Receipt)

High-quality paper

paper thickness: 0.06 to 0.08mm