AR-5316 ADJUSTMENT 6-1

[6]ADJUSTMENTS

1.Adjustment item list

2.Copier adjustment

A.Process section

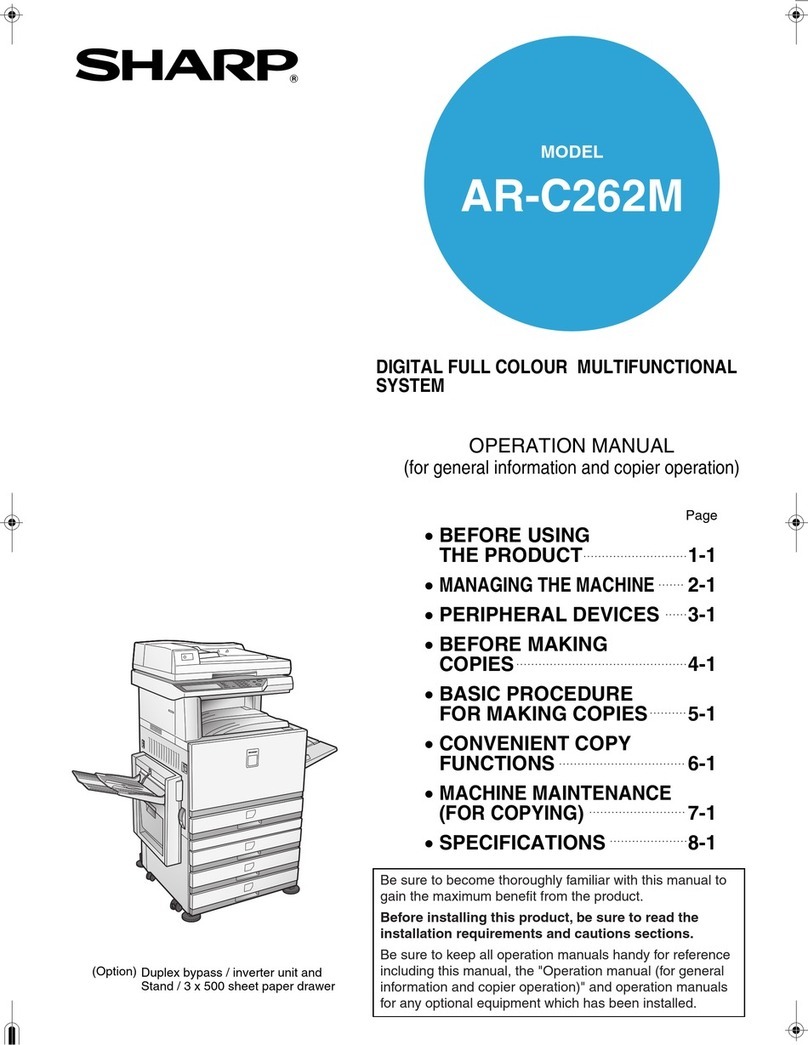

(1) Developing doctor gap adjustment

1) Loosen the developing doctor fixing screw A.

2) Insert a thickness gauge of 1.5mm to the three positions at 20mm

and 130mm from the both ends of the developing doctor as shown.

3) Push the developing doctor in the arrow direction, and tighten the

developing doctor fixing screw. (Perform the same procedure for the

front and the rear frames.)

4) Check the clearance of the developing doctor. If it is within the

specified range, then fix the doctor fixing screw with screw lock.

* When inserting a thickness gauge, be careful not to scratch the

developing doctor and the MG roller.

<Adjustment specification>

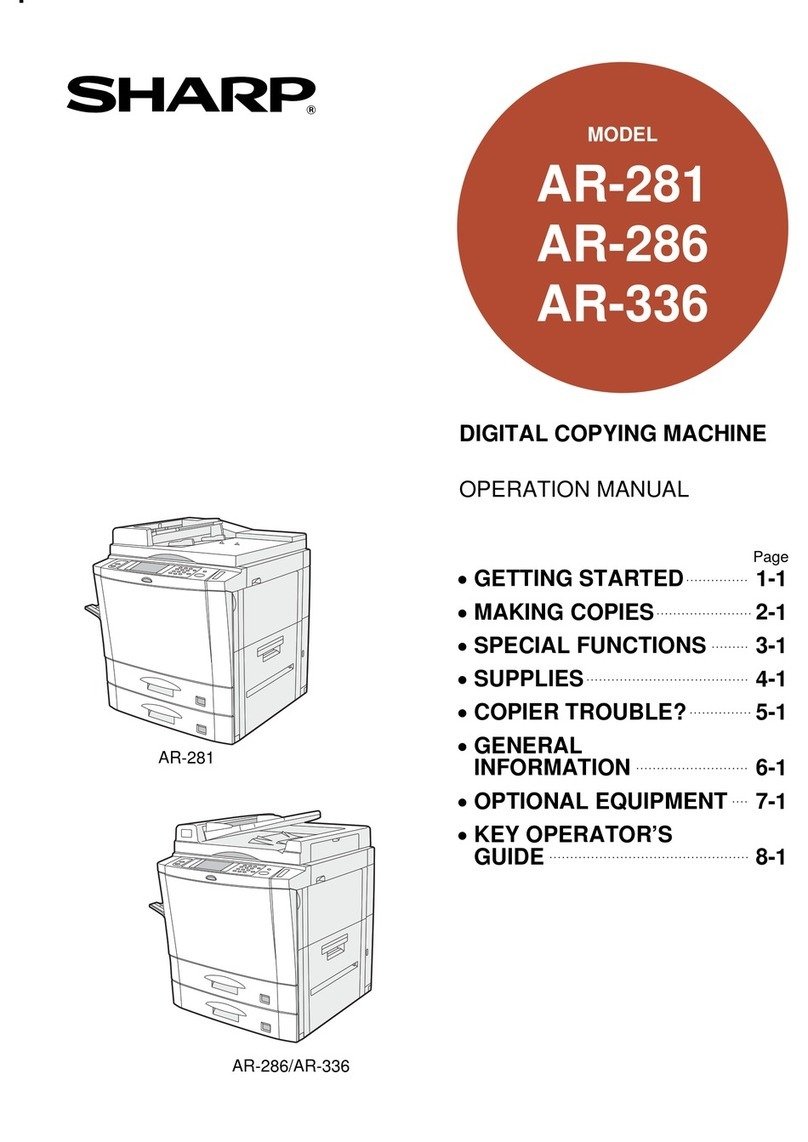

(2) MG roller main pole position adjustment

1) Remove and separate the waste toner box and put the developing

unit on a flat surface.

2) Tie a string to a needle or a pin.

3) Hold the string and bring the needle close to the MG roller

horizontally. (Do not use paper clip, which is too heavy to make a

correct adjustment.) (Put the developing unit horizontally for this

adjustment.)

4) Do not bring the needle into contact with the MG roller, but bring it to

a position 2 or 3mm apart from the MG roller. Mark the point on the

MG roller which is on the extension line from the needle tip.

5) Measure the distance from the marking position to the top of the

doctor plate of the developing unit to insure that it is 18mm.

If the distance is not within the specified range, loosen the fixing

screw A of the main pole adjustment plate, and move the adjustment

plate in the arrow direction to adjust.

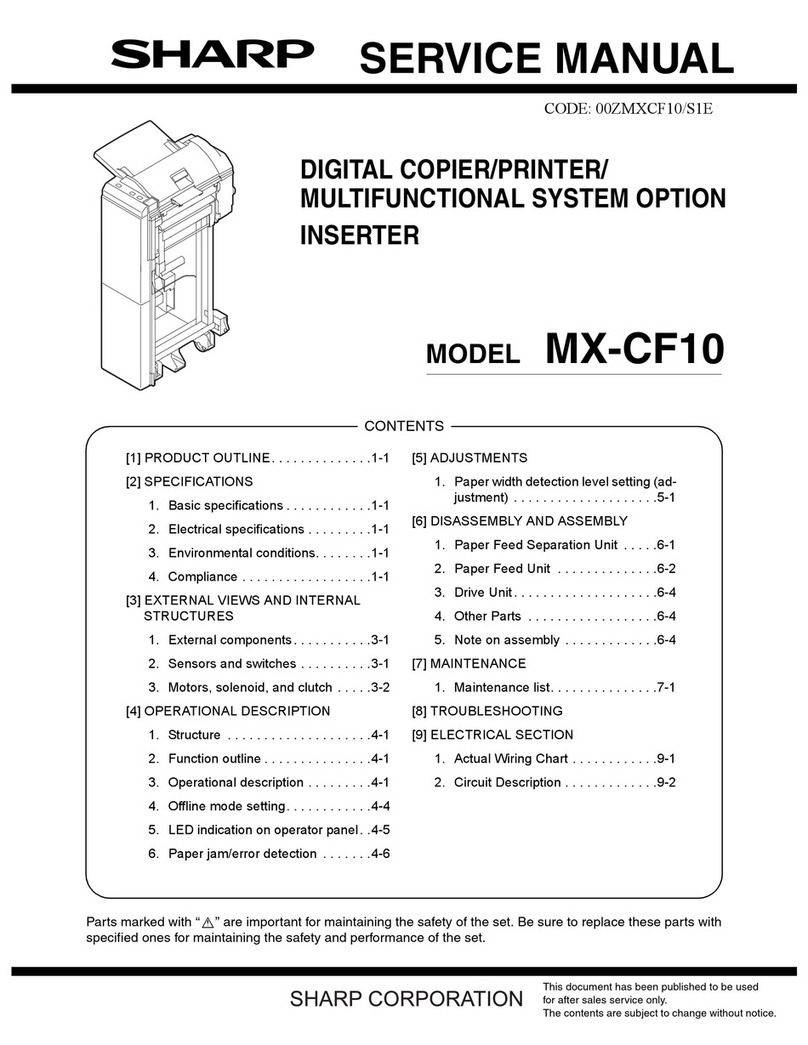

Section Adjustment item Adjustment procedure/SIM No.

A Process

section (1) Developing doctor gap adjustment Developing doctor gap adjustment

(2) MG roller main pole position adjustment MG roller main pole position adjustment

(3) Developing bias voltage check

(4) Main charger voltage check

B Mechanism

section (1) Image position adjustment SIM-50

(2) Main scanning direction (FR direction) distortion balance

adjustment No. 2/3 mirror base unit installing position adjustment

Copy lamp unit installing position adjustment

(3) Main scanning direction (FR direction) distortion adjustment Rail height adjustment

(4) Sub scanning direction (scanning direction) distortion

adjustment Winding pulley position adjustment

(5) Main scanning direction (FR direction) magnification ratio

adjustment SIM 48-1

(6) Sub scanning direction (scanning direction) magnification ratio

adjustment OC mode in copying (SIM 48-1)

SPF mode in copying (SIM 48-5)

(7) Off center adjustment OC mode (SIM 50-12)

SPF mode (SIM 50-12)

(8) SPF white correction pixel position adjustment

(

required in an SPF model when replacing the lens unit)

SIM63-7

C Image density

adjustment (1) Copy mode SIM 46-1

Developing doctor gap

Both ends (20mm from the both ends) :

C (Center) (150mm from the both ends) :

1.5 mm

+0.1

- 0.15

1.55 mm

+0.15

- 0.2

[06]ADJUSTMENT.fm1ページ2005年7月1日 金曜日 午後5時27分