3

CAUTIONS FOR USE

Never share the wall outlet with other appliances.

Insert the plug into the wall outlet firmly and when disconnecting, hold the plug and pull it out without touching

the power cord.

In case the power cord is broken, it must be replaced by manufacturer or appointed service providers or

equivalent professionals to avoid any damages.

Do not immerse the set in water or sprinkling water on the heater plate.

Never push the cook switch when the inner pot with rice is not placed in, never insert any object into the

switch. It may cause a trouble.

If the switch is turned off prematurely, resulting in cook failure, do not attempt to keep the switch pressed

forcibly. Malfunction may occur. The possible cause of premature turning-off of the switch is rice sticking to the

bottom of inner pot or the heater plate.

Keep the switch away from tableware.

Do not use the cooker on a wet floor, under direct sunlight or near the gas stove.

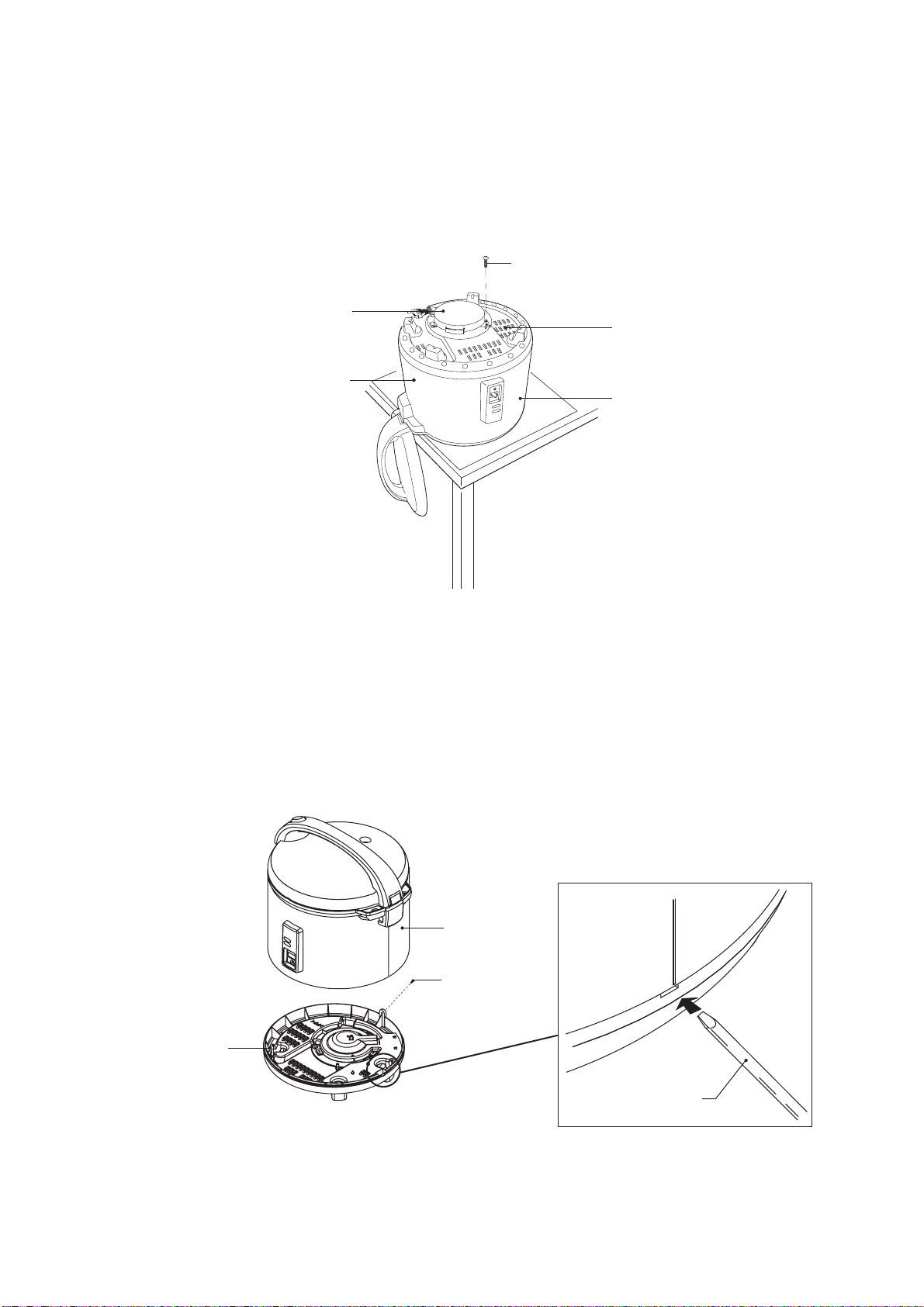

While cooking, do not put the rice cooker on or near combustible materials such as curtains or vinyl carpets.

During or immediately after cooking the areas near the steam vent hole are kept at high temperature.

Do not touch those areas to avoid burns.

Never connect the plug with your wet hand as it may be dangerous from electric leakage. Disconnect the plug

from the wall outlet when you do not use the rice cooker.

Keep the rice cooker out of the children’s reach, especially when cooking rice.

Do not opening the lid when during boiling because touched hot steam.

Do not use the inner pot with heater appliance such as a gas stove. The inner pot may be transformed and it

may cause poor cooking result.

Do not give strong vibration of impact during cooking. It may cause an irregular operation of thermostat to lead

to poor rice-cooker.

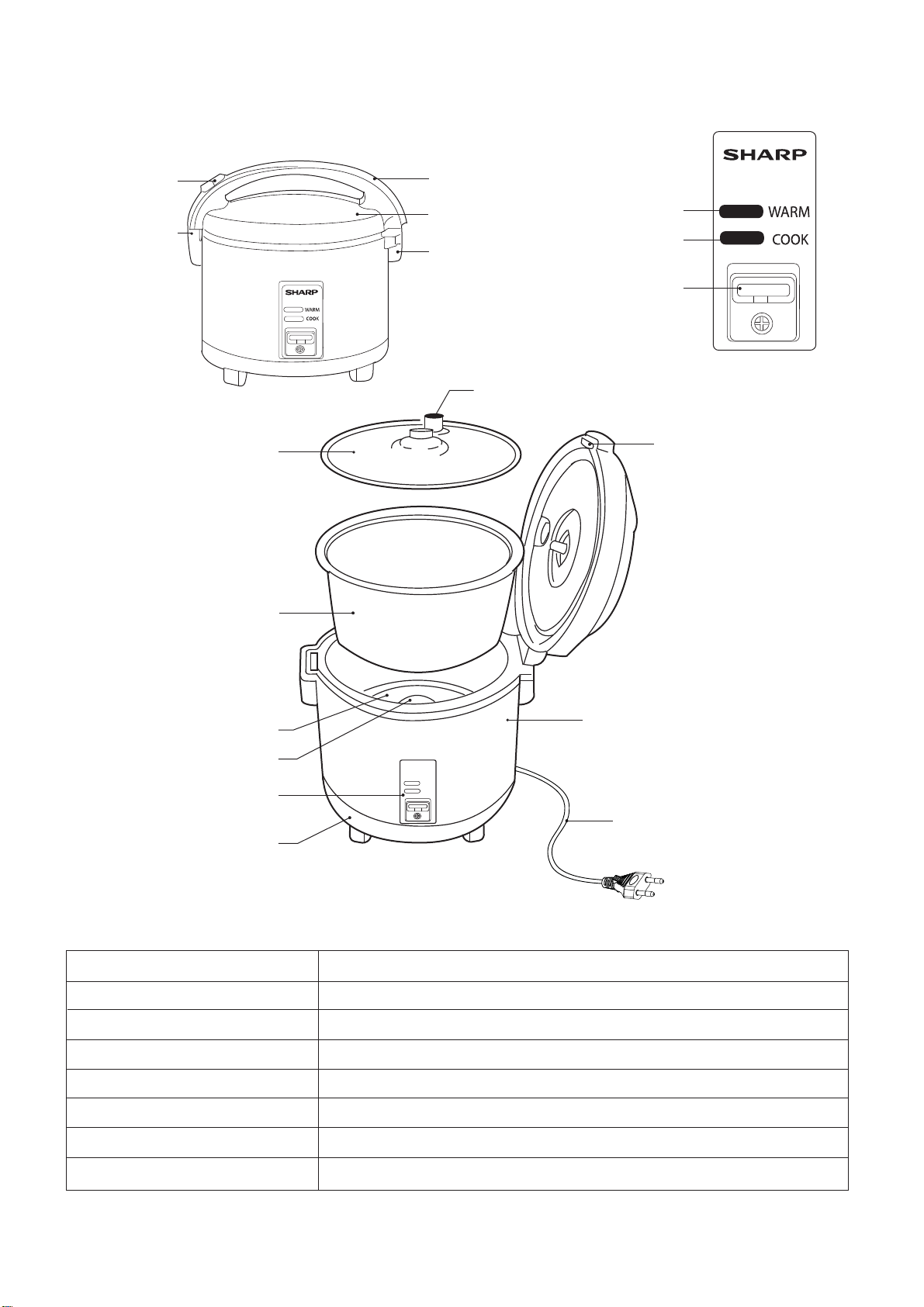

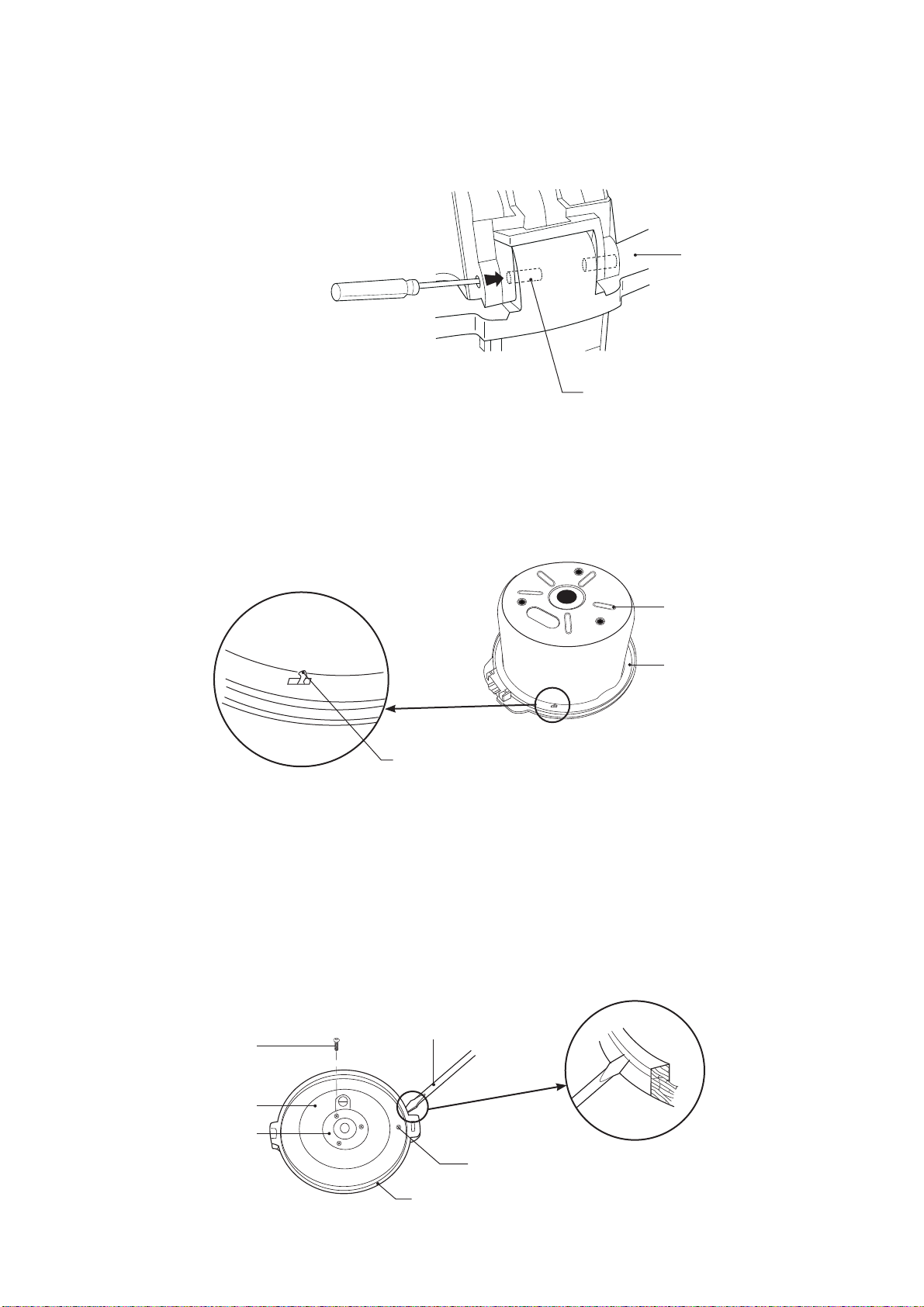

Always keep clean the flange part and the bottom of the inner pot, the heater plate and the inner lid, etc. so

that they do not accumulate rice grain or foreign matter.

Do not place a wiping cloth or the like on the lid or the handle during use.

This model is for rice cooking and heat retention. Do not use it as follows. Boiling-over or smell permeation will

occur.

“Heat retention of food (boiling rice, steamed rice with red beans) which spoils quickly”. “Cooking and heat

retention and addition of cool boiled rice”. “Heat retention with plastic spoon put in the rice cooker”.

Do not apply strong vibration and shock during cooking rice. Thermostat error may occur, resulting in cooking

failure.

Do not give strong vibration or impact during cooking. It may cause an irregular operation of thermostat to lead

to poor rice cooking. This is not indication of trouble.

Be sure to put the steam tube and inner lid when using. Otherwise cooking failure or poor heat retention may

occur.

Do not turn the rice cooker on without both rice and water in the inner pot.

Do not disassemble or repair the cooker by yourself. It may cause trouble such as a fire of electric shock.

Consult your nearest dealer.

Do not use metal spoon that can scratch the inner pot.

Do not use any other inner pot except the provided one.