-.--...-

---.---..--.-

CIHCU17

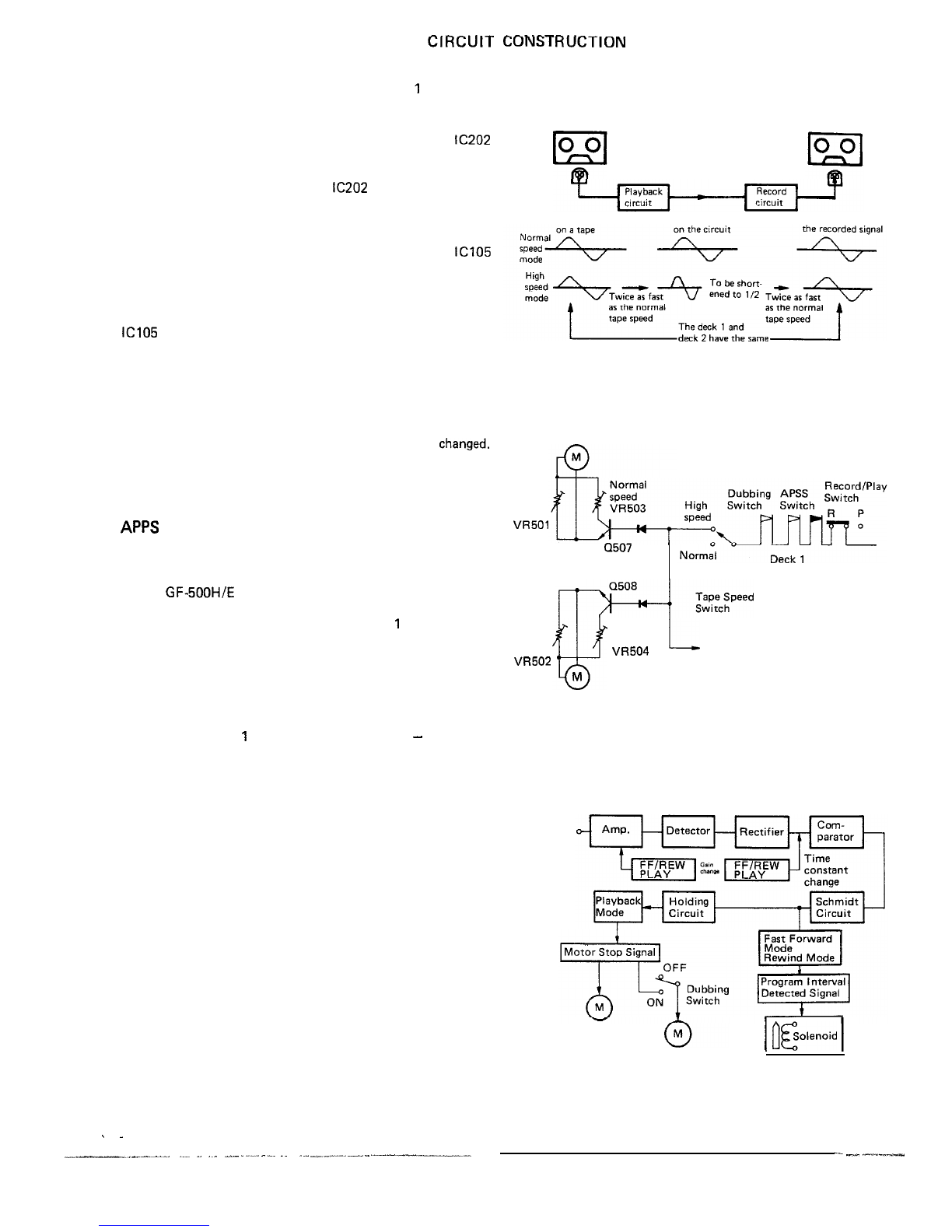

It is possible to select either normal tape speed or high tape

speed when you perform dubbing from the deck

1

to the deck

2 and the high speed is twice as fast as the normal speed.

l

Normal speed/high speed record selector circuit

Being provided at the deck 2, the integrated circuit

IC202

works to select the normal speed mode or the high speed

mode: the frequency at the high speed is two times higher

than that at the normal speed. The

IC202

also works to detect

whether a normal tape or a metal tape has been loaded in the

unit.

l

Normal speed/high speed playback selector circuit

Being provided at the deck 1, the integrated circuit

ICI05

works to select the normal speed mode or the high speed

mode: the frequency at the high speed is two times higher

than that at the normal speed. Here is also given proper

equalization for the signals of both speed modes. Further the

IC105

changes its constant according to whether a normal tape

or a metal tape has been loaded in the unit.

l

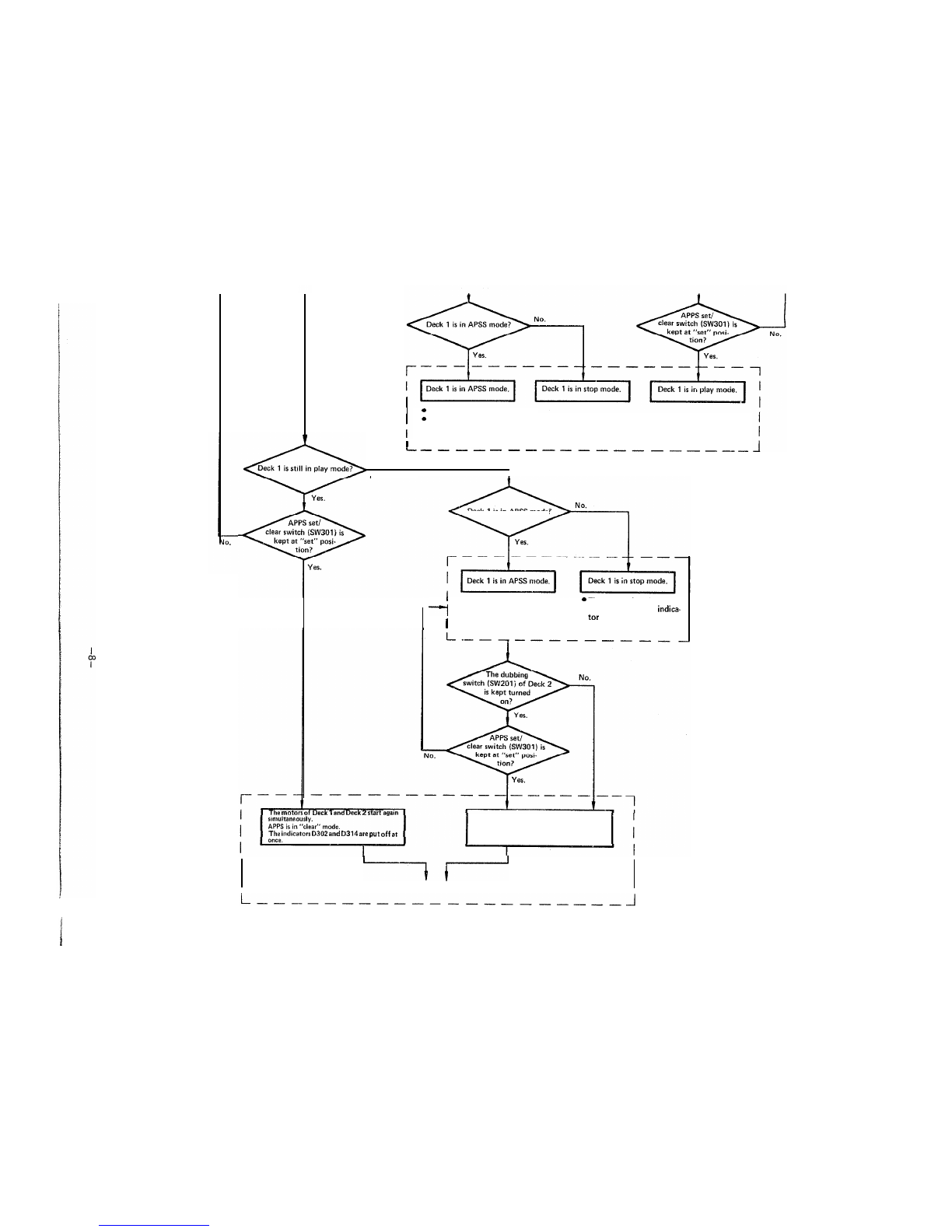

Normal speed/high speed selector circuit

Change of the motor’s rotational speed results in a changeover

between the tape normal speed and high speed modes. The

electronic switch is used to act on the motor control circuits

of the deck 1 and deck 2 at a time as their speeds are

changed.

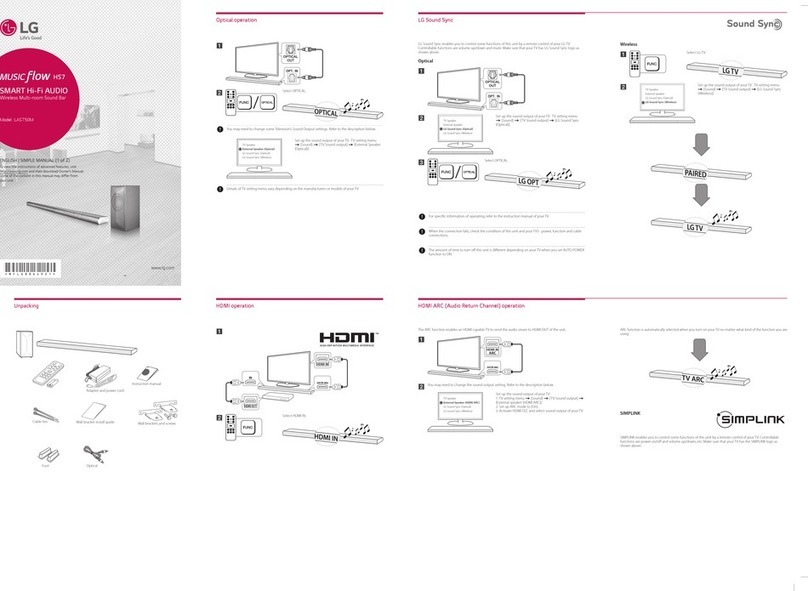

Fig. 6-2 shows how the circuit works to get the unit in the

high speed mode, whose expression is made with use of the

mechanical switch instead of the electronic switch.

APPS

(Automatic Program Pause System)

The existing APSS, as you know, is to automatically detect an

end of the program when the unit is in fast forward or rewind

mode and then to return it to play mode. The APPS employed

for the GF-SOOH/E is something new which is based on the

same ideas as with such APSS, and it is activated not only

when the unit is in play mode (at the deck

1

only) but also

when it is in dubbing mode (from the deck 1 to the deck 2).

In the dubbing mode (either at normal speed or at high speed),

as soon as an end of the program is detected by the APSS in

the deck 1, the APPS works to stop the motor circuits of both

decks 1 and 2 simultaneously -that is, motions of the deck 1

and deck 2 are stopped just at a time.

Therefore, the deck

1

has two automatic controls

-

APSS and

APPS, that is, it is controlled by the APSS when it is in play

mode (with the deck 2 in stop mode) and by the APPS when it

is in dubbing mode.

The two controls APSS and APPS are differentiated by the

following:

l

Difference in gain and frequency characteristic between

APSS and APPS.

l

Difference in program detect time between APSS and

APPS.

These differences are due to that the tape speed is different

according to whether the unit is in play mode or dubbing

mode, and according to these, the electronic switch selects the

APSS or APPS to get it in action.

CUNS~I

KUCTION

Deck 1

Dubbing

Deck2

Wave length

Wavelength Wave length of

signalwavelength.

Figure 6-l

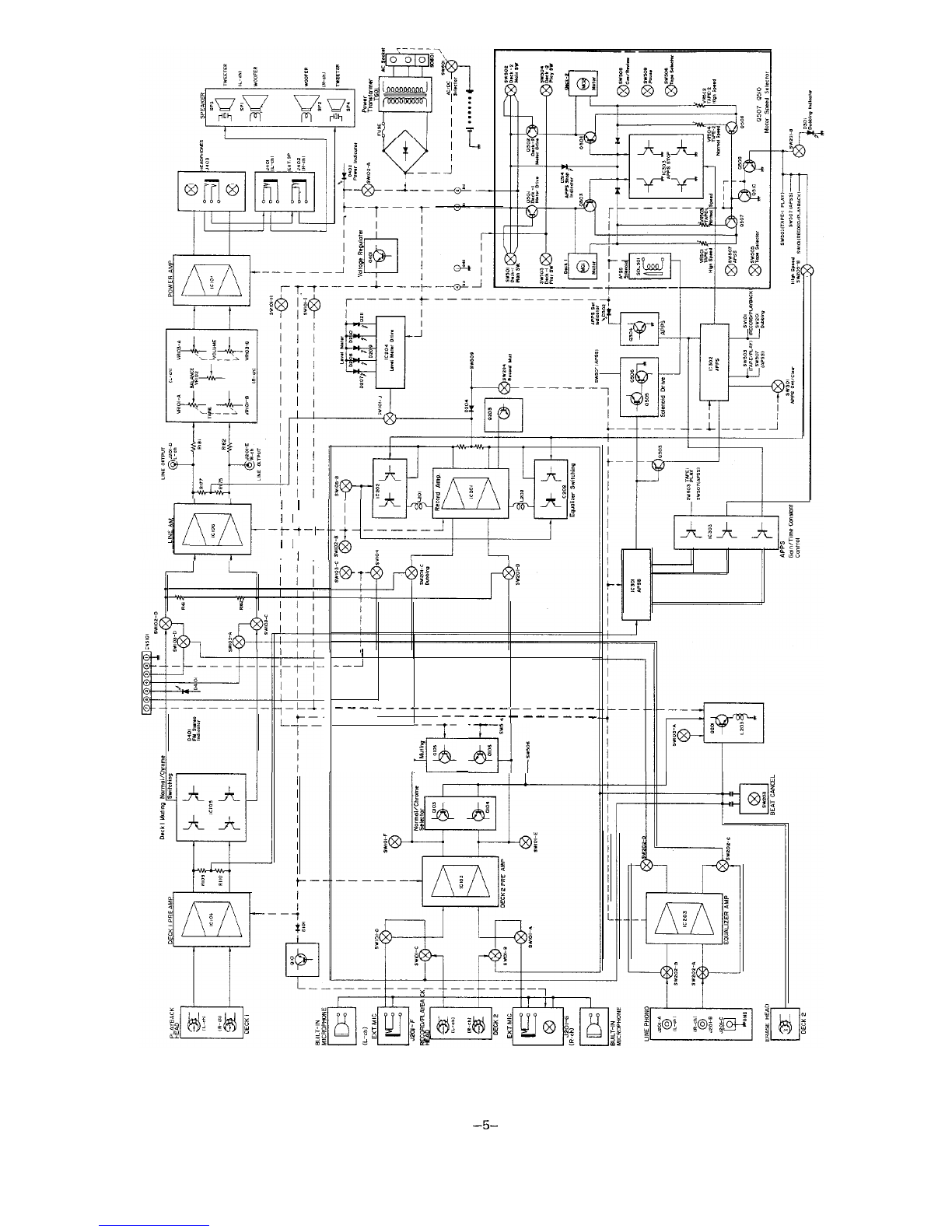

Deck 1 Motor

High

Speed

VR501

Q507

Motor Selector

Transistor

Deck 2

Speed

Play Switch

‘k”

Normal

High

Speed Speed

L

Deck 1 Playback Equalizer Selector

VR504

VR502 Deck 2 Record Equalizer Selector

M

Deck 2 Motor

Figure 6-2

Input

signal

Deck 1 Motor

Deck 2 Motor

Figure 6-3

-6-

/

fleolenoid

1

/

.

__-L-__Illl.

___

---.-.

.._

_

.~_

,_.-

.

.._-

.

-.

.~

.

.I

__.,

--~

.---

--

.--1----_--

-

._.._