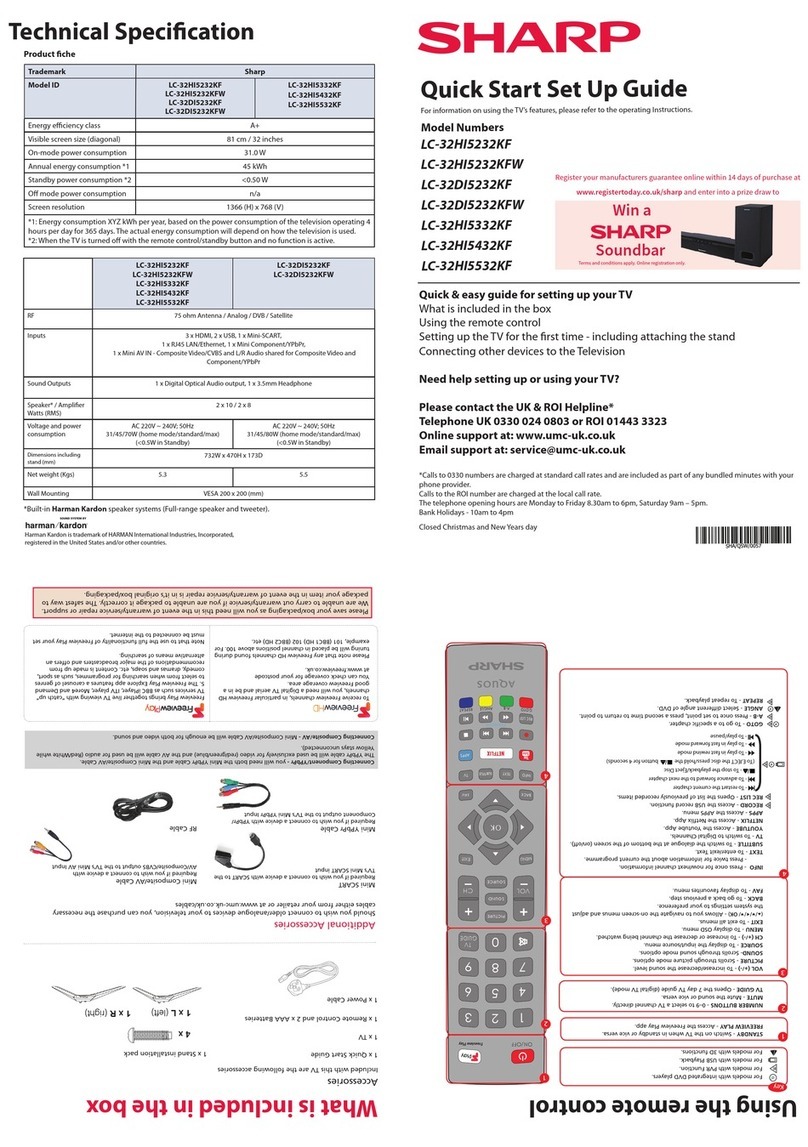

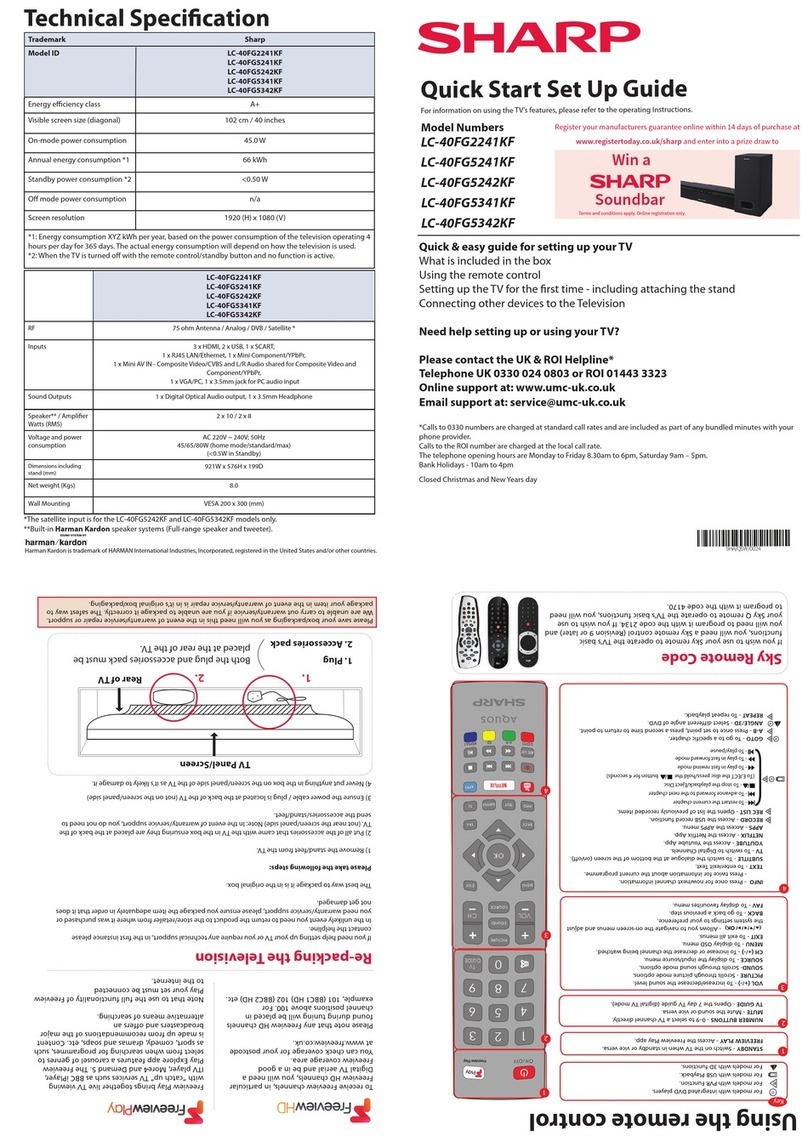

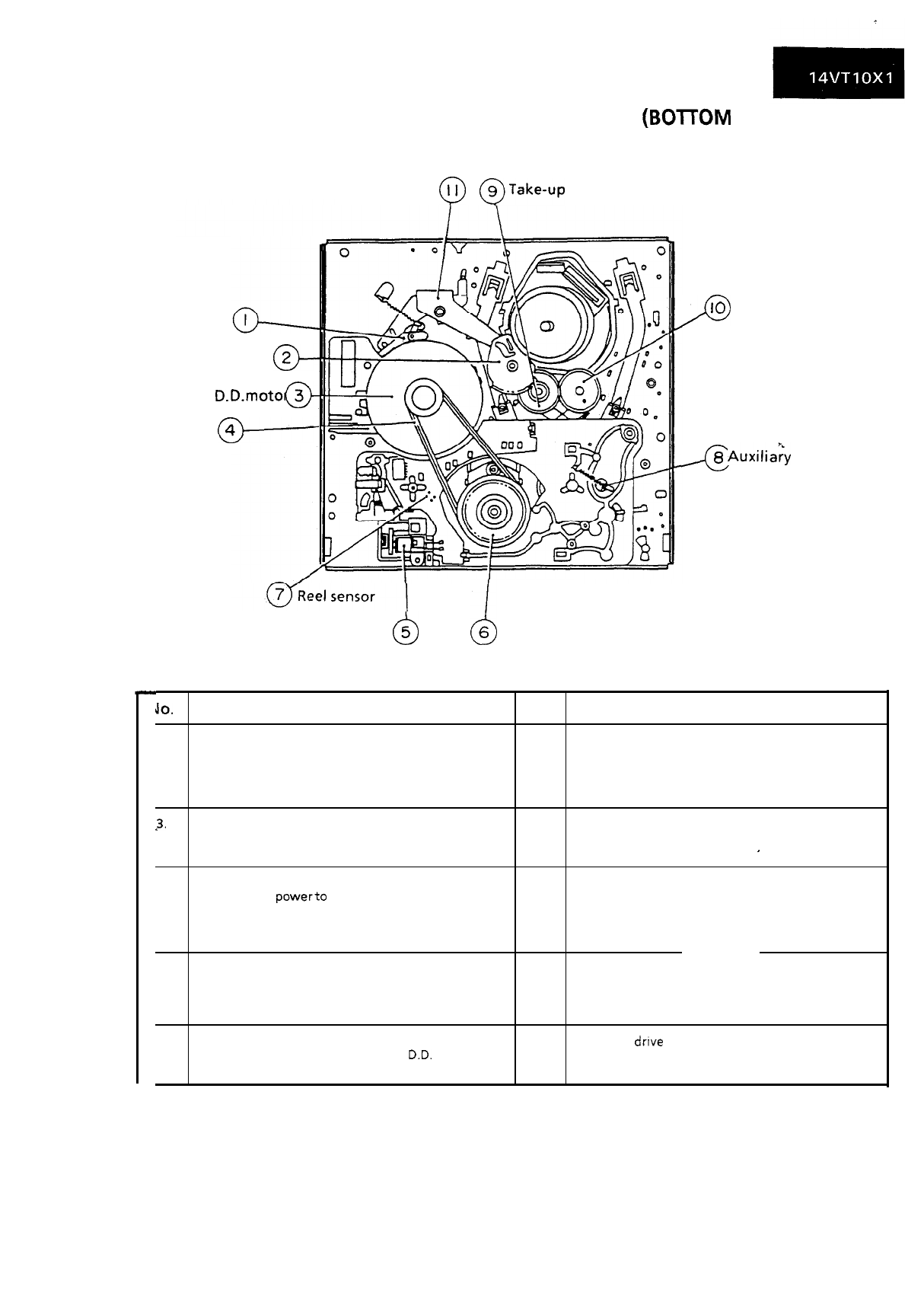

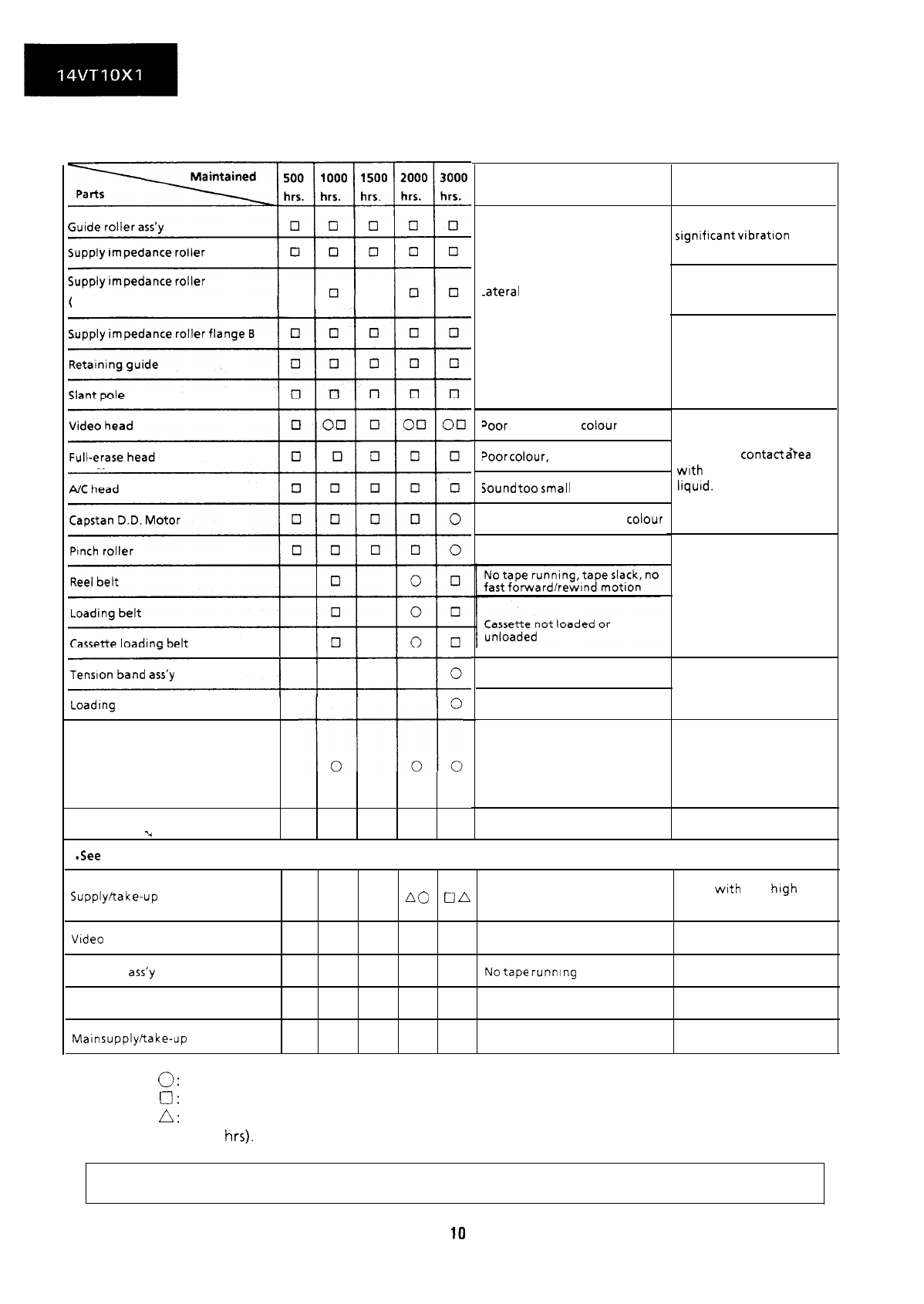

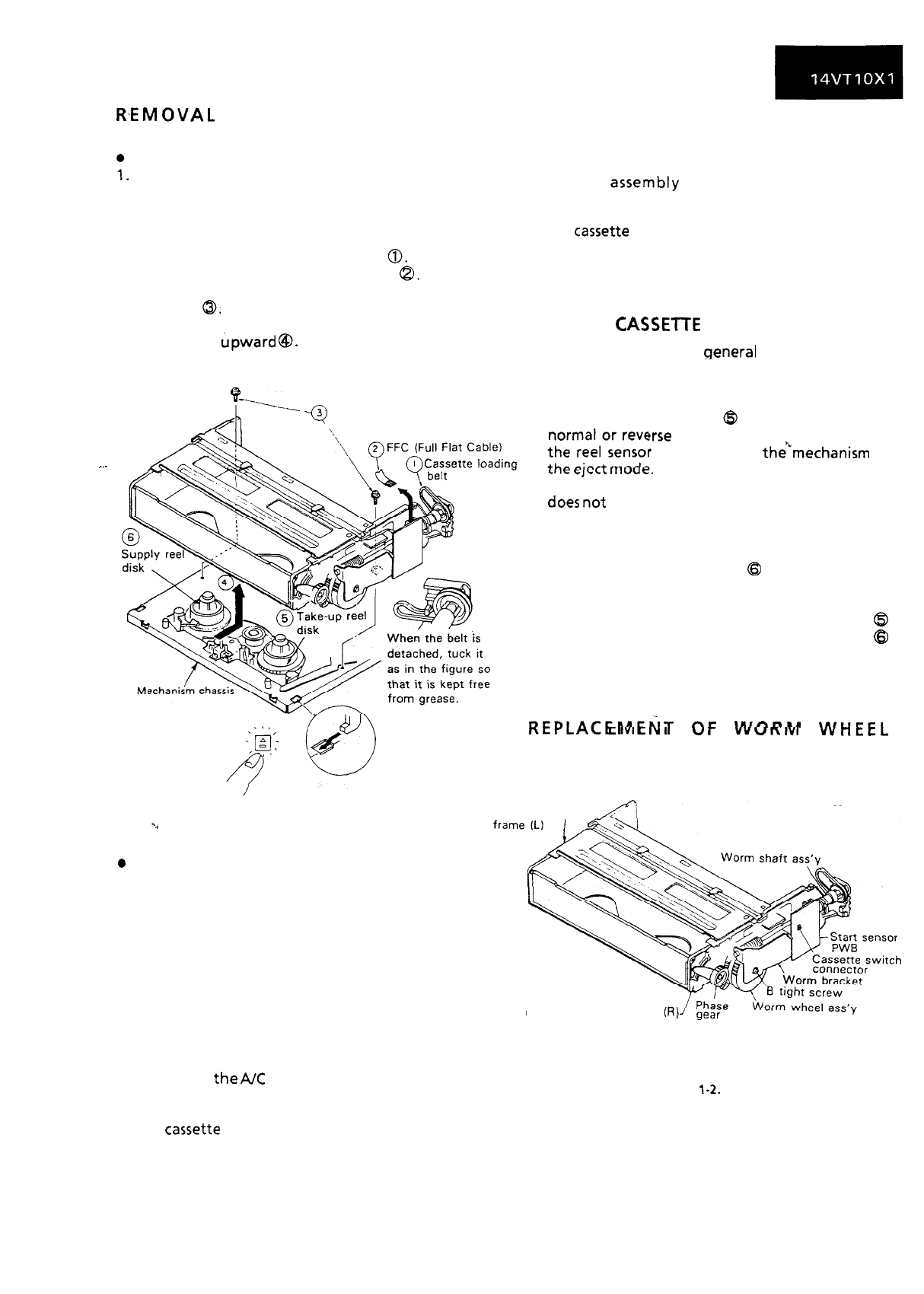

R,EMOVAL AND REASSEMBLY OF

5.

CASSETTE HOUSING CONTROL ASSEMBLY

0

1.

2.

3.

Removal

Set the cassette ejected condition in the cassette

eject mode.

6.

Unplug the recorder from the main source.

Follow the procedures below in the specified

order.

a) Remove the cassette loading belt

0.

b) Disconnect the FFC (full Flat Cable)

8.

c) Remove the cassette housing installation

Place the unit in the eject mode in removal or

reassembly of the cassette housing control

assembly.

Load the cassette once onto the cassette housing

control

assembly

after reassembly. (If the

cassette housing control assembly normally

operates after this, the phases of mechanism and

the

cassette

controller are accurately adjusted

after ejection.)

screws

0.

d) Slide and pull out the cassette housing control

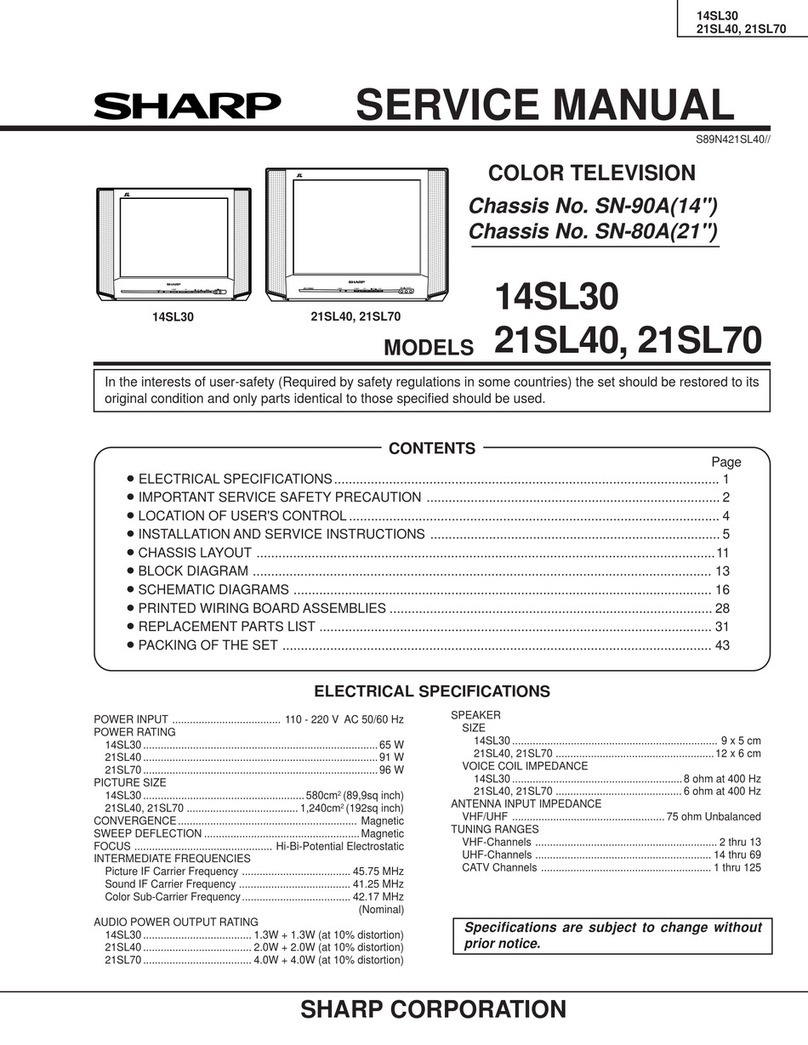

MECHANICAL OPERATION CHECK

WITHOUT

CASSElTE

assembly

upward

@I.

When power is on, the general operations of the

~-I-

/==h

-

_

Q

3

Cassette housing

setscrew

mechanism can be checked without a cassette.

Note the following points.

1. Check video search rewind and rewind, rotating

the take-up reel disk

@

by hand (in either

!rse

direction). If it is not rotated,

*

works to shift

the’Lmechanism

to

C1I.c

G,\-LC

,,,““d.

2. When the stop button is pressed, the mechanism

does

not

stop at a normal stop position. It shifts

to the eject mode and stops.

3. When the stop button is pressed in the playback,

video search rewind, and video search forward

modes, the supply reel disk

0

keeps on rotating

for several seconds for elimination of tape slack

in the course of shifting to the eject mode. In

such a case, rotate the take-up reel disk

@

somewhat by hand, and the supply reel disk

0

stops, which can reduce the working time.

Insert the tab of

the cassette hosing

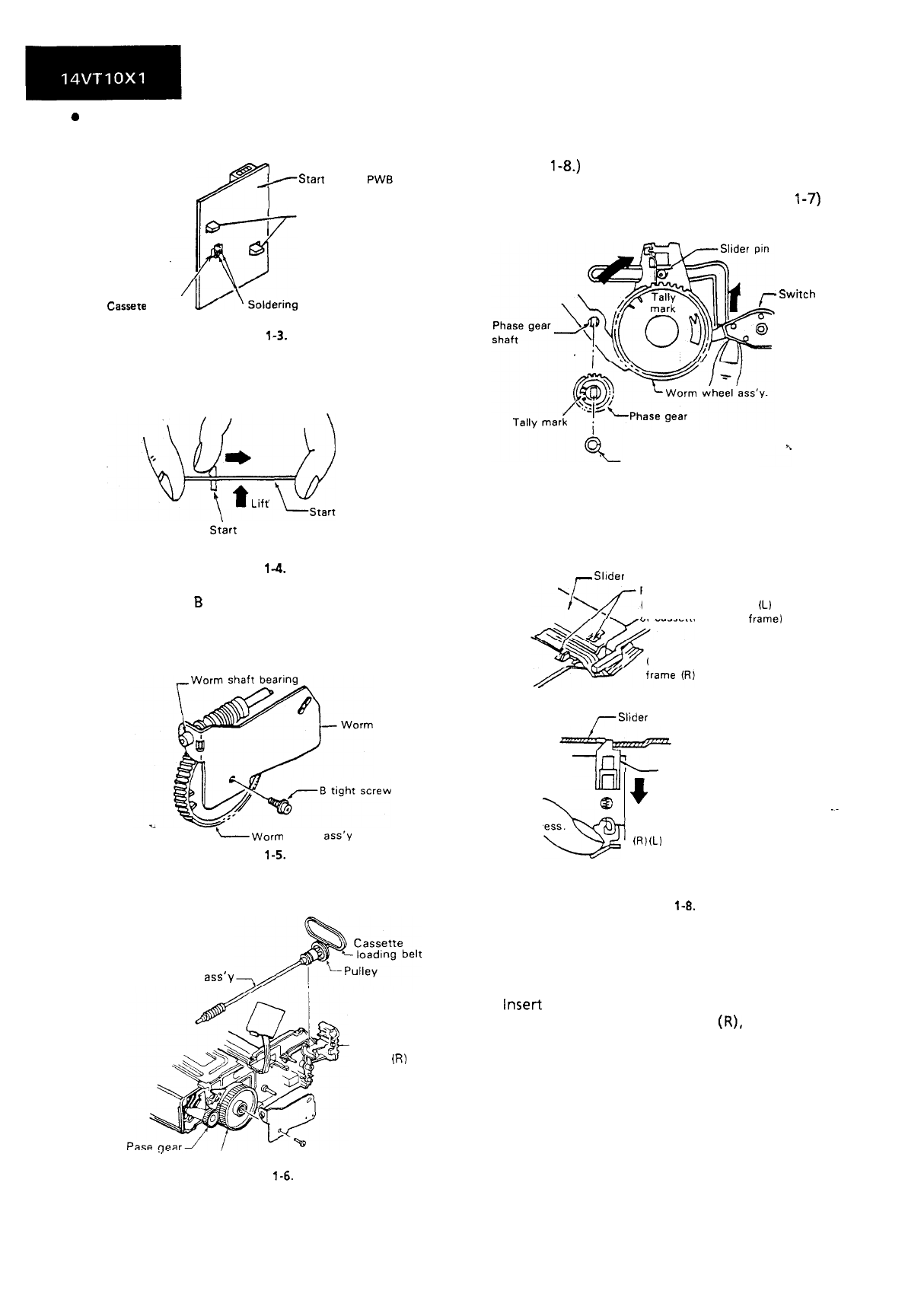

REpLAC~liACil’

fiC

\Il,h”l”

\“,,,rrl

,

E

IVI

c

IY

I

u

r

vv

u

n

WI

VvnrcL

control assembly to

ASSEMB

LY

the mechanism chassis.

-.

Figure 1-l.

0

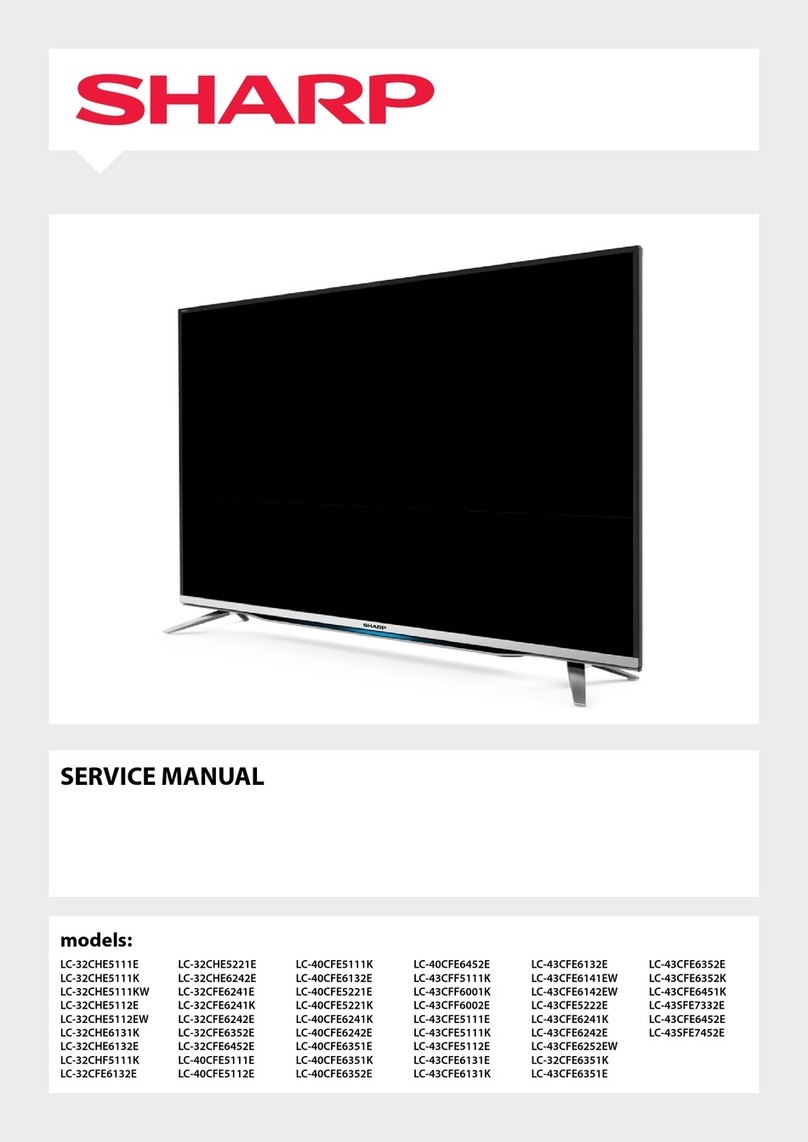

Reassembly

1. Before installation of the cassette housing

control assembly, place the unit in the stop mode

with the power on, then unplug the power cord.

(The main body is placed in the eject mode.)

2. Follow the procedures for removal in the reverse

order.

Notes:

1. Be sure to unplug the power cord in removal and

reassembly.

2. Keep the cassette loading belt free from grease.

In case of its adhesion, clean the belt.

3. In using a magnet screw driver, be sure to keep it

away from

the

A/C

head, FE (Full Erase) head, or

the drum.

4. In removal and reassembly, take care not to hit

the

cassette

housing control assembly or tools

against the guide pin, drum, or the like

thereabout.

Cassette housing

Cassette housing frame

(R)

Figure

l-2.

11