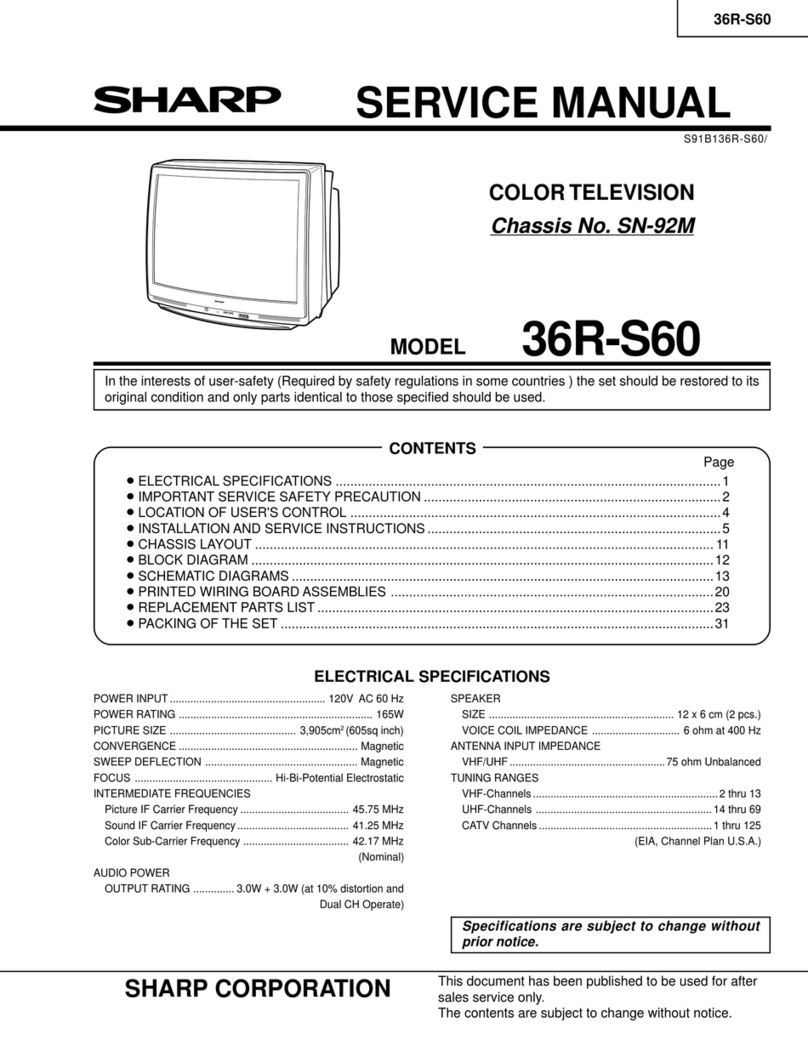

VIDEO CIRCUIT ADJUSTMENT

CRT CUT-OFF ADJUSTMENT

l

R853:

Red Bias control

l

R859:

Green Bias control

l

R865: Blue Bias control

l

Screen control (a part of

T602)

l

R857:

Green Drive control

l

R863: Blue Drive control

*

Note:

Prior to this adjustment, warm up the unit

with the beam current of more than 700uA for

more than

30

minutes.

1.

Receive “MONOSCOPE PATTERN” signal with

pattern generator.

6.

Turn

5401

(service switch) at the horizontal

line position.

2.

Set Red Bias control at

MIN

position.

Set Green Bias control at

MIN

position.

Set Blue Bias control at MIN position.

Set Green Drive control at CENTER position.

Set Blue Drive control at CENTER position.

3.

Turn the

“N”

key on the remote controller.

4.

Set the Screen control at MIN position.

5.

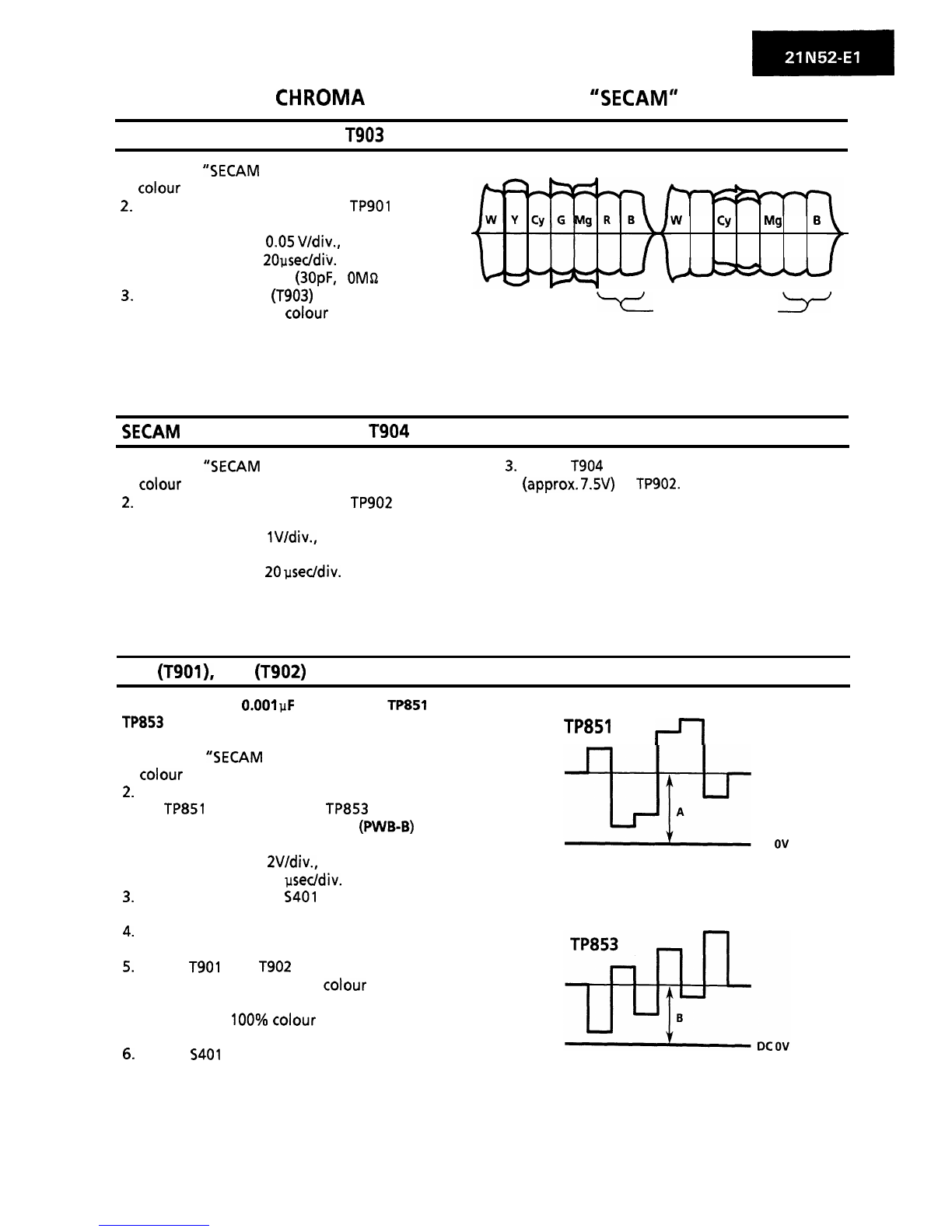

Connect the oscilloscope to

TP852

(red

cathode).

7.

Adjust Sub-Brightness control

R425

to obtain a

blanking pulse level of

10

+

lVp-p

at

TP852.

n

nqvpmp

I-1H-I

8.

Disconnect the oscilloscope

fromTP852.

9.

Slowly turn the Screen control clockwise until

the horizontal raster appears slightly, and

stop it.

11

.Turn

the Screen control counterclockwise until

the horizontal raster disappears, and stop it.

IO-Here,

one of the three

colours

(red, blue,

green) appears first as the Screen control is

turned. So, touching off the Bias control

belonging to the first

colour,

use and move

the other two controls so that the horizontal

raster becomes white.

WHITE BALANCE AND BACK GROUND

l

R857:

Green Drive control

l

R863: Blue Drive control

l

R436: Sub Contrast control

*Note:

Prior to this adjustment, warm up the unit

with the beam current of more than 700pA for

more than

30

minutes.

I. Receive “MONOSCOPE PATTERN” signal with

pattern generator..

2.

Set the Contrast control and Brightness

control at MAX position.

3.

Connect ammeter to TP601 and

TP602.

(Full scale: 3

mA)

4.

Adjust Sub-Contrast control so that the beam

current becomes

1.1

mA

(rough adjustment).

5.

Adjust Green Drive control and Blue Drive

control so that the

colour

temperature is at

9300°K.

(High beam:

1.1

mA).

6.

Adjust the Contrast control and Brightness

control so that the beam current is

approx.

200pA, and check that the colour temperature

is at 9300°K. If the temperature is not at

9300”K,

go back to “CRT CUT-OFF

ADJUSTMENT” and repeat the adjustment.

(X

=

0.285, Y = 0.292)

SUB-CONTRAST CONTROL: R436

* Note:

Prior to this adjustment, warm up the unit

with the beam current of more than 700uA for

more than

30

minutes.

1.

Receive “MONOSCOPE PATTERN” signal with

.

pattern generator..

3.

Connect beam ammeter to TP601

(-)

and

TP602 ( +).

(Full scale: 3

mA)

4.

Adjust Sub-Contrast control so that the beam

current becomes

1.1

mA.

2.

Set the Contrast and Brightness controls at

MAX position.

7