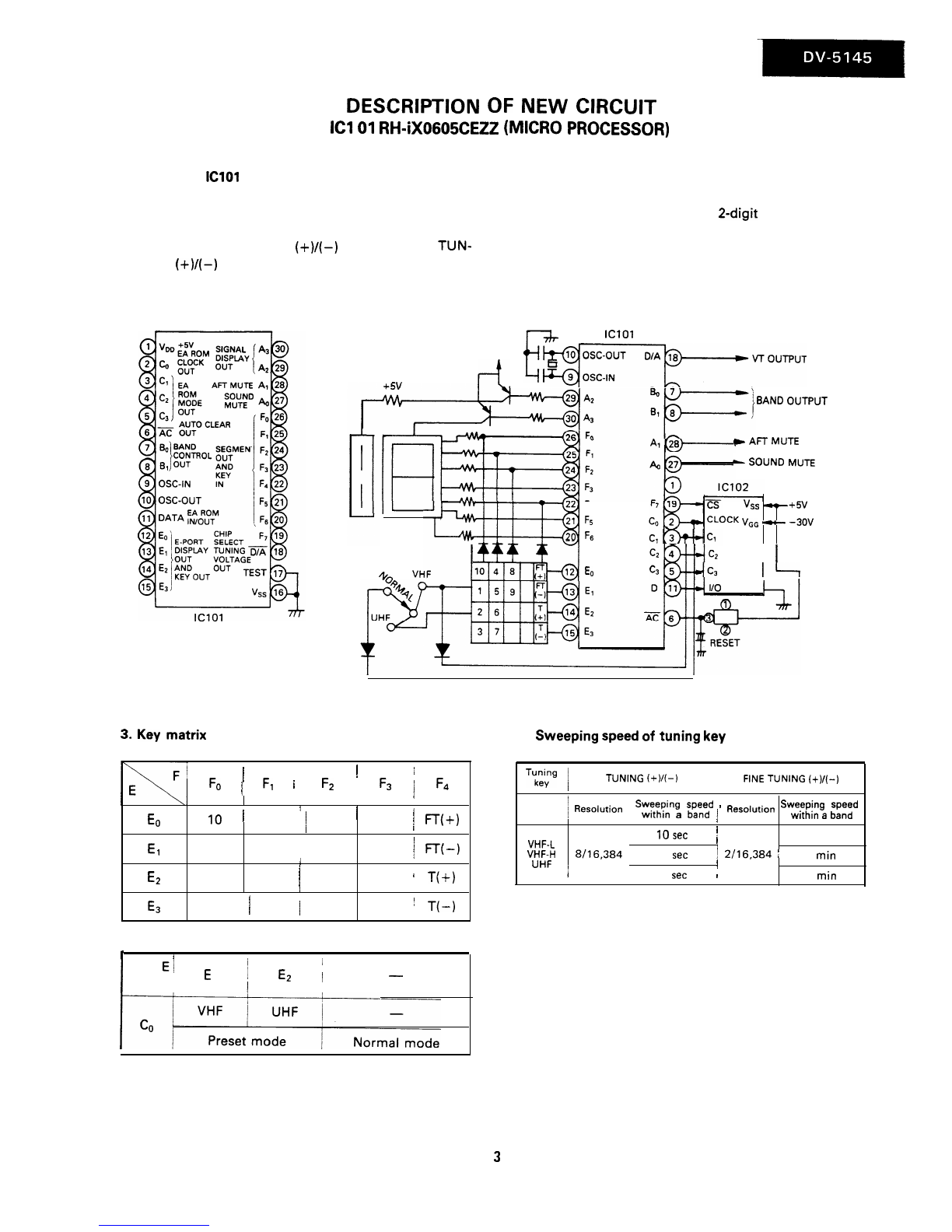

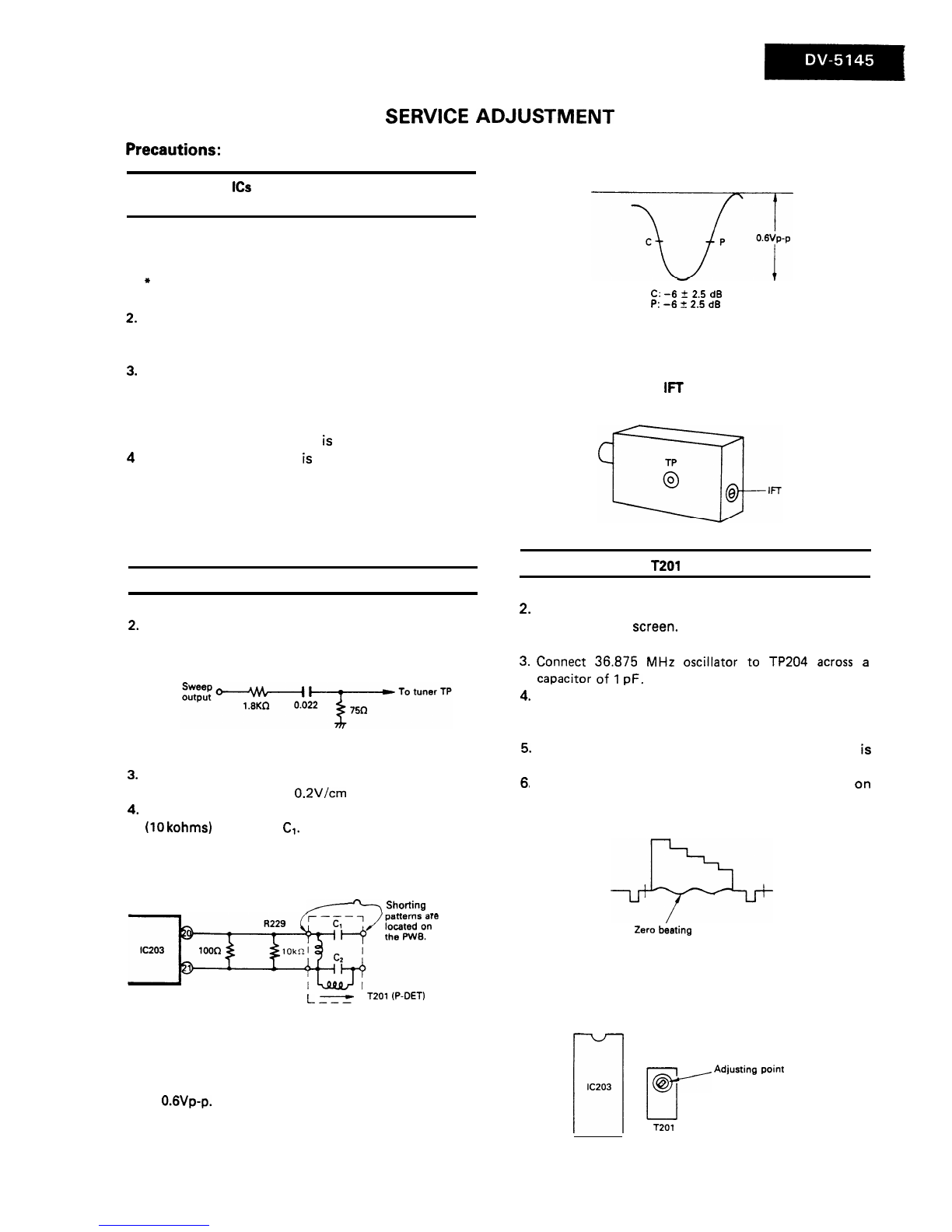

RF AGC cut-in adjustment:

RZ25

1. Receive 10 ch. signal.

2. Set the signal input level at 52 +1

dBu.

3. Connect CR oscillator to TP202 across a capacitor of

10

uF/lGV:

This capacitor is to cut off DC supply.

I

aIsl2.L

ToTP202

c

r

-,

r.

I

-

To TP201

l Oscillation frequency: 1

kHz

sine wave

l Output voltage : 0.1 vp-p

(when connected to TP202)

4. Adjust R225 so that 1

kHz

signal disappears from TV

screen.

5. Set the signal input level at

52+3

dBp

and check that

1

kHz

signal appears on TV screen.

If 1

kHz

signal does not appear, set the input signal

level at 52

dBu

again and follow the procedure in

step 4 again.

Sound detector coil adjustment:

T301

1. Connect signal generator’s output to TP301.

l Generator’s central frequency: 5.5 MHz

l Modulation: No modulation

l Generator output: 80

dBu

(terminated with

50R)

2. Connect DC voltmeter to TP302.

3. Adjust sound volume to minimum and measure the

voltage then available at TP302; this voltage (about

2.5V)

should be regarded as a reference voltage.

4. Adjust sound volume to maximum and turn the core

of T301 (sound detector coil) until DC voltmeter reads

the reference voltage obtained in step 3 above.

Horizontal

frequency

adjustment: R605

1. Receive monoscope pattern signal.

2. Short TP601 and TP602 (at both ends of

R606).

3. Adjust R605 to obtain good horizontal sync on

TV

screen.

4. Remove the short-circuit between TP601 and TP602.

Sub-brightness adjustment: R415

1. Short TP401 and TP402.

2. Set each control as follows:

l Screen control: at MIN position

l G-bias control

(R853-A):

at MIN position

l B-bias control

(R853-B):

at MIN position

l R-bias control (R869): at MIN position

l G-drive control

(R854-A):

at CENTER position

l B-drive control

(R854-B):

at CENTER position

l

Contrast control (R 1110) : at M IN position

l Brightness control

(Rl

110): at CENTER position

l

Picture control

(R

1110) : at CENTER position

l Colour control

(Rl

110) : at MIN position.

3. Receive monoscope pattern signal.

4. Connect oscilloscope to TP850 (with L2 connected to

ground)

5. Adjust

R415

(sub-brightness control) so that the

output waveform on oscilloscope is at 15 Vp-p.

6. Remove the short-circuit between TP401 and

TP402.

Background adjustment:

R854-A;

G-drive control,

R853-A;

G-bias control

R854-B;

B-drive control,

R853-B;

B-bias control

Screen control, R869; R-bias control

1. Receive monoscope pattern signal.

2. Set each control as follows:

l Brightness control: at CENTER position

l Contrast control: at MIN position

l Screen control: at MIN position

l G-, B-drive controls: at CENTER position

l R-, G-, B-bias controls: at MIN position

3. Short

TP401

and TP402.

4. Turn screen control until horizontal raster slightly

appears on TV screen.

5. One of the colours (R, G and B) appears first as

screen control is turned. So touching off the bias

control belonging to the first colour, adjust the other

controls as follows to make white the horizontal

raster.

I

First

/

colour

1

Bias controls to be next turned.

I

Red

I

R853-A,

R853-B

I

Green

1

R869, R853-B

I

Blue

1

R869,

B853-A

6. Turn screen control until the raster disappears and

stop it.

7. Remove the short-circuit between TP401 and TP402.

8. Set contrast control at MAX position.

10