21HF2-SS

3 – 5

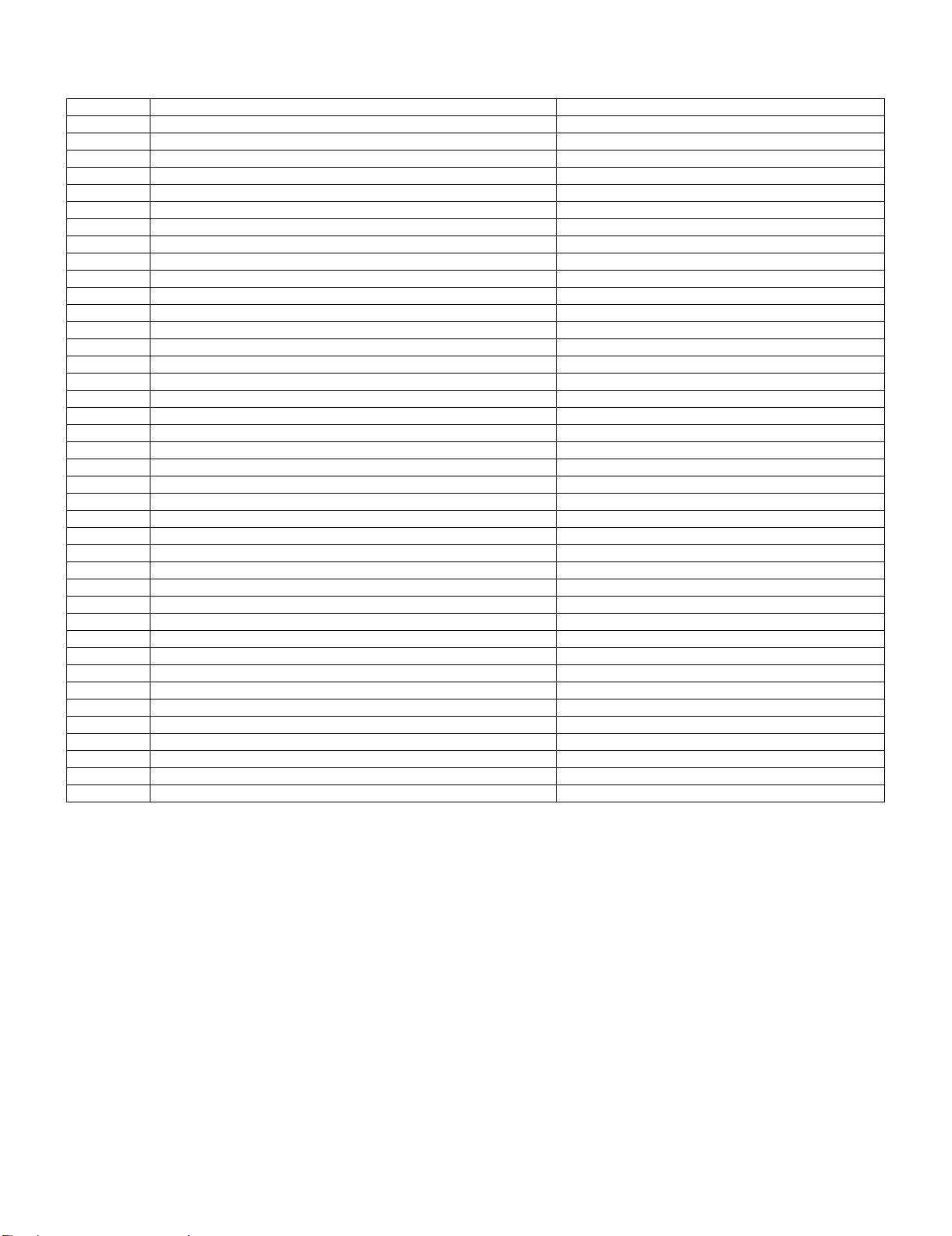

SETTING MODE (SECOND STAGE)

EEPROM ITEMS FUNCTION OSD DATA LENGTH INITIAL DATA FIX/ADJ/AUTO REMARK

STRAPQ-BG RAISE Q SOUND TRAP B/G F01 0(NORMAL)/1(Q-UP) 0 FIX

STRAPQ-I RAISE Q SOUND TRAP I F02 0(NORMAL)/1(Q-UP) 0 FIX

STRAPQ-DK RAISE Q SOUND TRAP D/K F03 0(NORMAL)/1(Q-UP) 0 FIX

STRAPQ-M RAISE Q SOUND TRAP M F04 0(NORMAL)/1(Q-UP) 0 FIX

STRAPQ-574 RAISE Q SOUND TRAP BILINGUAL F05 0(NORMAL)/1(Q-UP) 0 FIX

C.CLIP-LVL CLIP LEVEL CONTRAST CONTROL F06 0(20H)/1(40H) 0 FIX

OF RGB INPUT 0(20H)/1(40H)

RGB-CLIP CLIPPING OF RGB CONTRAST F07 0(CLIP OFF)/ 0 FIX

CONTROL 1(CLIP ON)

BS BLACK STRETCH F08 0(ON)/1(OFF) 0 FIX

ABCL ABCL PROCESSING F09 0(OFF)/1(ON) 0 FIX

(ACL PROCESSING)

ABCL-GAIN ABCL PROCESSING GAIN F10 0(LOW)/1(HIGH) 0 FIX

S-OUT-LVL AUDIO OUTPUT GAIN CONTROL F11 0~127 95 FIX

VIF-G P-IF DETECTION GAIN OUTPUT F12 0~7 4 FIX

SHPG SHARPNESS GAIN F13 0(NORMAL)/1(HIGH) 0 FIX

SHPG-P SHARPNESS GAIN PAL F14 0(NORMAL)/1(HIGH) 0 FIX

SHPG-S SHARPNESS GAIN SECAM F15 0(NORMAL)/1(HIGH) 0 FIX

SHPG-N4 SHARPNESS GAIN N443 F16 0(NORMAL)/1(HIGH) 0 FIX

SHPG-N3 SHARPNESS GAIN N358 F17 0(NORMAL)/1(HIGH) 1 FIX

YDL Y SIGNAL DELAY F18 0~7 5 FIX

YDL-P Y SIGNAL DELAY PAL F19 0~7 5 FIX

YDL-S Y SIGNAL DELAY SECAM F20 0~7 7 FIX

YDL-N4 Y SIGNAL DELAY N443 F21 0~7 5 FIX

YDL-N3 Y SIGNAL DELAY N358 F22 0~7 5 FIX

YDL-AV Y SIGNAL DELAY AV F23 0~7 6 FIX

YDL-AV-P Y SIGNAL DELAY PAL (AV) F24 0~7 6 FIX

YDL-AV-S Y SIGNAL DELAY SECAM (AV) F25 0~7 7 FIX

YDL-AV-N4 Y SIGNAL DELAY N443 (AV) F26 0~7 6 FIX

YDL-AV-N3 Y SIGNAL DELAY N358 (AV) F27 0~7 6 FIX

YDL-YUV Y SIGNAL DELAY YUV F28 0~7 6 FIX

COL-AV (OFFSET) COLOUR OFFSET AV F29 -31~0~+31 +10 *FIX BUS SET UP

COL-P (OFFSET) COLOUR OFFSET PAL F30 -30~0~+31 0 FIX

COL-S (OFFSET) COLOUR OFFSET SECAM F31 -31~0~+31 +9 FIX

COL-N4 (OFFSET) COLOUR OFFSET N443 F32 -31~0~+31 -8 FIX

COL-N3 (OFFSET) COLOUR OFFSET N358 F33 -31~0~+31 -7 FIX

COL-ADJ (OFFSET) COLOUR OFFSET ADJUST F34 -31~0~+31 0 *FIX BUS SET UP

SHP-AV (OFFSET) SHARPNESS OFFSET AV F35 -31~0~+31 +5 FIX

SHP-YUV (OFFSET) SHARPNESS OFFSET YUV F36 -31~0~+31 0 FIX

SHP-P (OFFSET) SHARPNESS OFFSET PAL F37 -31~0~+31 0 FIX

SHP-S (OFFSET) SHARPNESS OFFSET SECAM F38 -31~0~+31 -5 FIX

SHP-N4 (OFFSET) SHARPNESS OFFSET N443 F39 -31~0~+31 0 FIX

SHP-N3 (OFFSET) SHARPNESS OFFSET N358 F40 -31~0~+31 0 FIX

TINT-AV (OFFSET) TINT OFFSET AV F41 -63~0~+63 0 *FIX BUS SET UP

TINT-ADJ (OFFSET) TINT OFFSET ADJUST F42 -63~0~+63 0 *FIX BUS SET UP

TINT-YUV-ADJ TINT YUV OFFSET ADJUST F43 -63~0~+63 0 FIX

(OFFSET)

R-R (OFFSET) R-DRIVE OFFSET WHEN WHITE F44 -63~0~+63 +8 *FIX BUS SET UP

TEMP IS RED

B-R (OFFSET) B-DRIVE OFFSET WHEN WHITE F45 -63~0~+63 -10 *FIX BUS SET UP

TEMP IS RED

R-B (OFFSET) R-DRIVE OFFSET WHEN WHITE F46 -63~0~+63 -3 *FIX BUS SET UP

TEMP IS BLUE

B-B (OFFSET) B-DRIVE OFFSET WHEN WHITE F47 -63~0~+63 +16 *FIX BUS SET UP

TEMP IS BLUE

DT WIDEBAND CHROMA TRAP F48 0(NARROW)/ 0 FIX

(FOR SECAM) 1(WIDE)