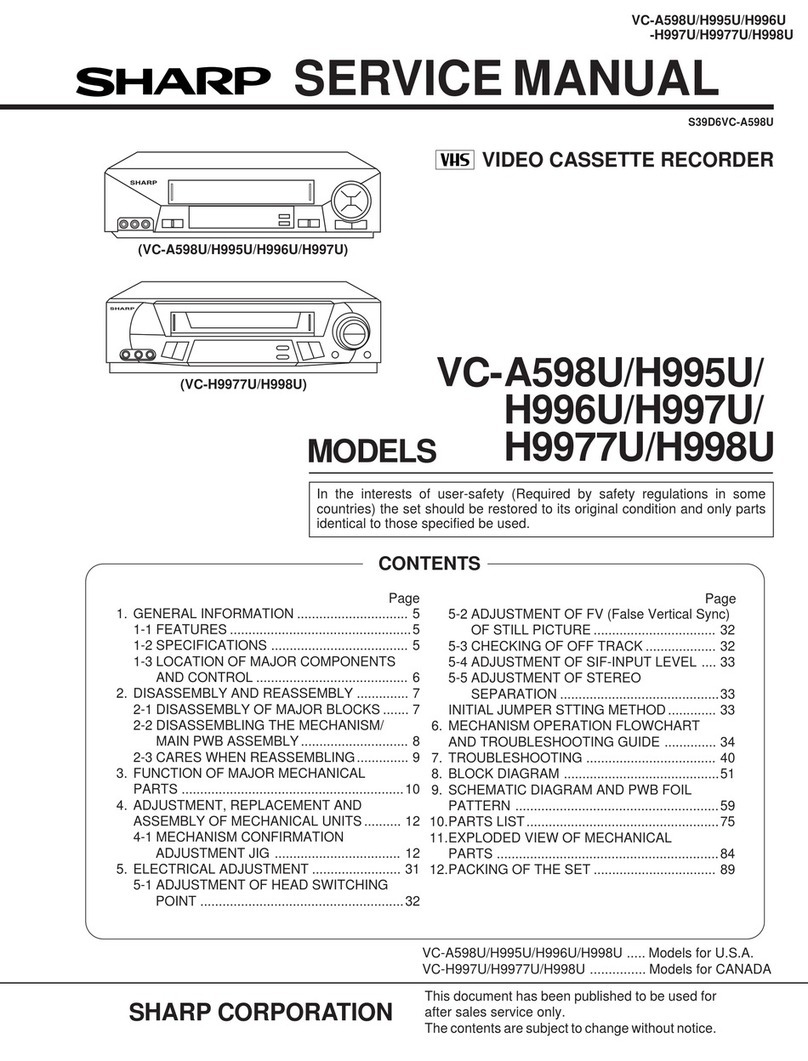

6

VC-MH705HM/LM

VC-MH815HM/LM,MH85HM

VC-MH715HM,MH835HM

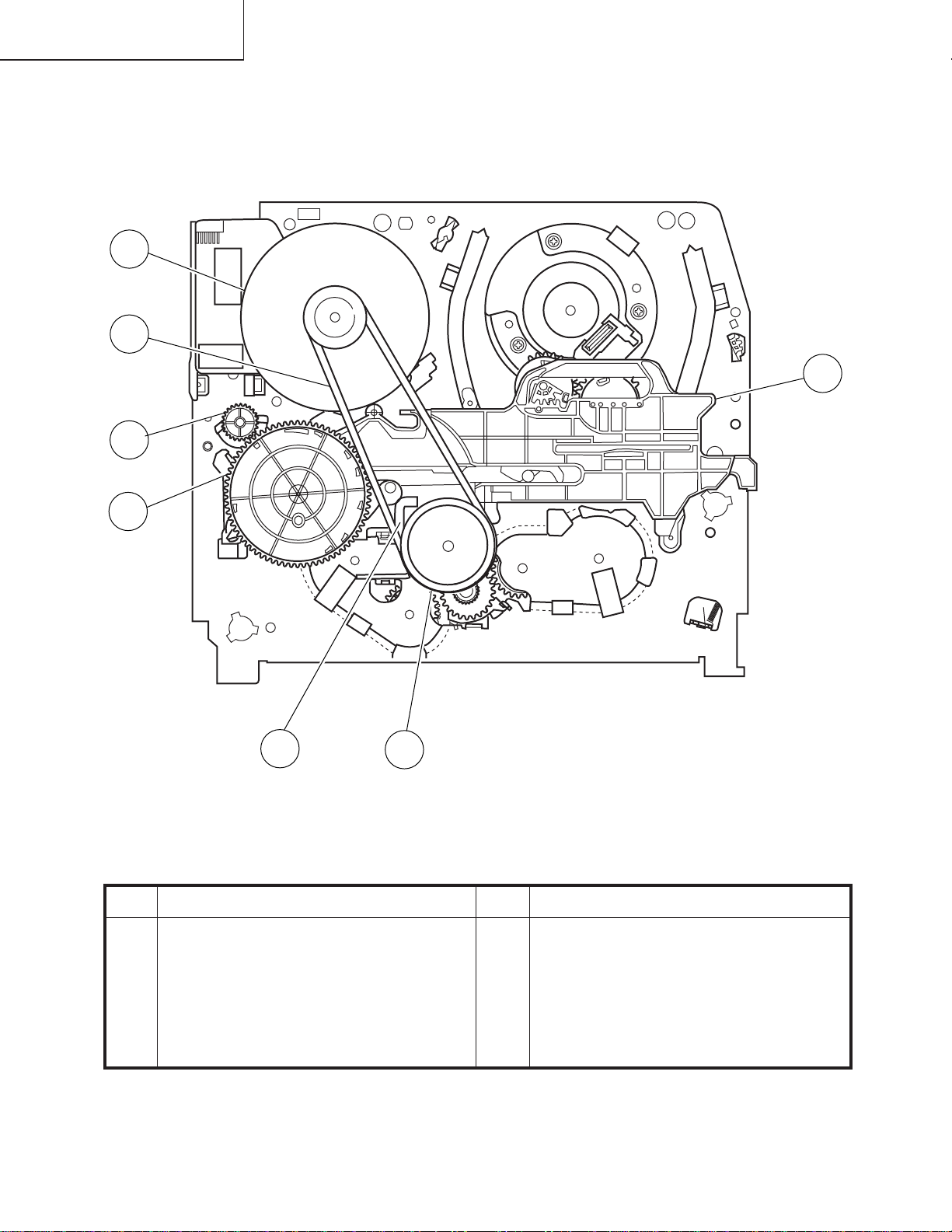

Pinch Drive Cam

Synchro Gear Master cam

Main Chassis

Drive Lever

2-2 CARES WHEN REASSEMBLING

INSTALLING THE CASSETTE HOUSING

When the cassette housing is installed on the mechanism,

the initial setting is essential condition.

Therearetwoinitialsettingmethods,namelyelectricaland

mechanical.

1. Electrical initial setting

So as to perform initial setting of mechanism execute the

Step1ofInstallationofcassettehousing.Afterascertaining

the return to the initial setting position install the cassette

housing. (Conditions: When mechanism and PWB have

been installed)

2. Mechanical initial setting

•Rotatethewormgearbypushingtheflangemanuallyuntil

return to initial position.

•When apply power supply to rotate the loading motor,

please remove/unsolder at least one terminal wire.

•If voltage applied to loading motor without diconnecting

the terminal wire, there is a possibility the capstan motor

IC will damage.

•The maximum applied voltage is 9V. If more than 9V,

there is apossibility the mechanism will damage.

•After ascertaining the return to the initial set position

installthecassettehousinginthespecifiedposition.(This

method is applied only for the mechanism.)

Rotate the flange of worm gear by using thin stick.

CW • • • Loading direction

CCW • • • Ejection direction

Note:

Be careful not to damage the gear of worm gear and

worm wheel gear. It miight cause a strange sound.

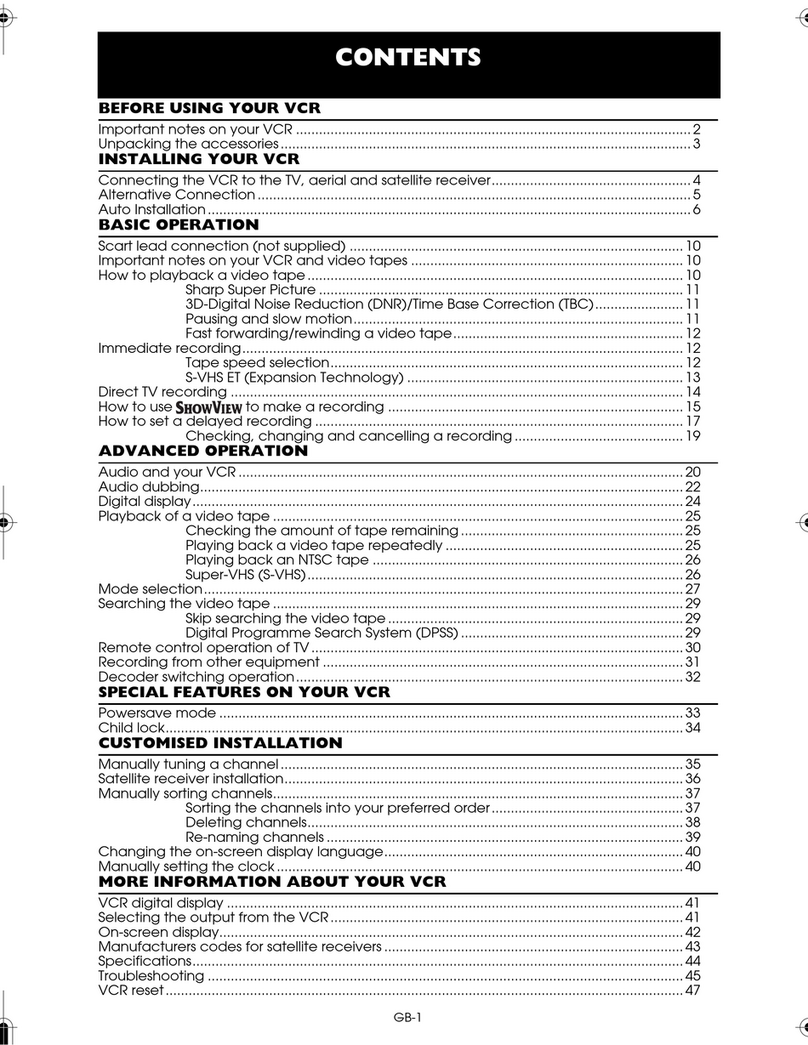

AH CONNECTOR

AE CONNECTOR

END SENSOR

END TIP SW

AA CONNECTOR

AD CONNECTOR

MODE SW

START SENSOR

VC-A50 only

AC CORD

90°

180°

270°

0°

MASTER CAM POSITION

This positioning hole

should be at front side.

INSTALLING THE MECHANISM ON PWB

Lower vertically the mechanism, paying attention to the

mechanism edge mode SW position, (Set the mode SW

position to 270° and make sure the master cam position

hole also in 270° position) and install the mechanism with

due care so that the parts are not damaged.

* Please make sure to insert correctly.

If not, strange moving will occur and will couse mecha-

nism damage.

PARTS WHICH NEED PARTICULAR CARE

When installing the mechanism chassis on the PWB unit,

take care so as to prevent deformation due to contact of

mechanism chassis with REC TIP SW.

www.freeservicemanuals.info

Digitized in Heiloo the Netherlands