4 | Page

TABLE OF CONTENTS

INTRODUCTION .........................................................................................................................................................7

Read this Manual.................................................................................................................................................................... 7

Safety Considerations and Requirements ...................................................................................................................... 7

Contacting Assistance ..........................................................................................................................................................8

Manufacturing Warranty ......................................................................................................................................................8

Engineering Improvements..................................................................................................................................................8

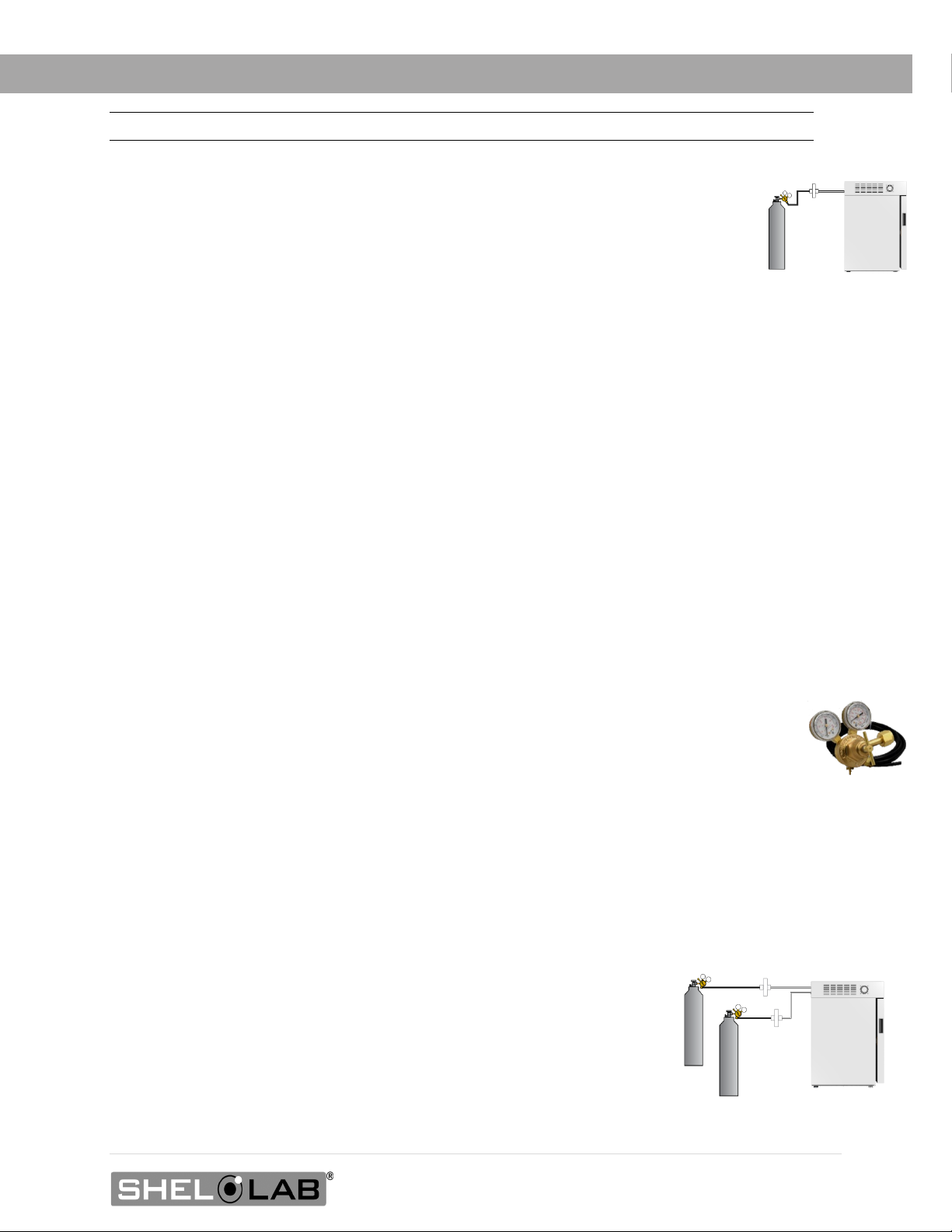

CO2Gas Supply ......................................................................................................................................................................9

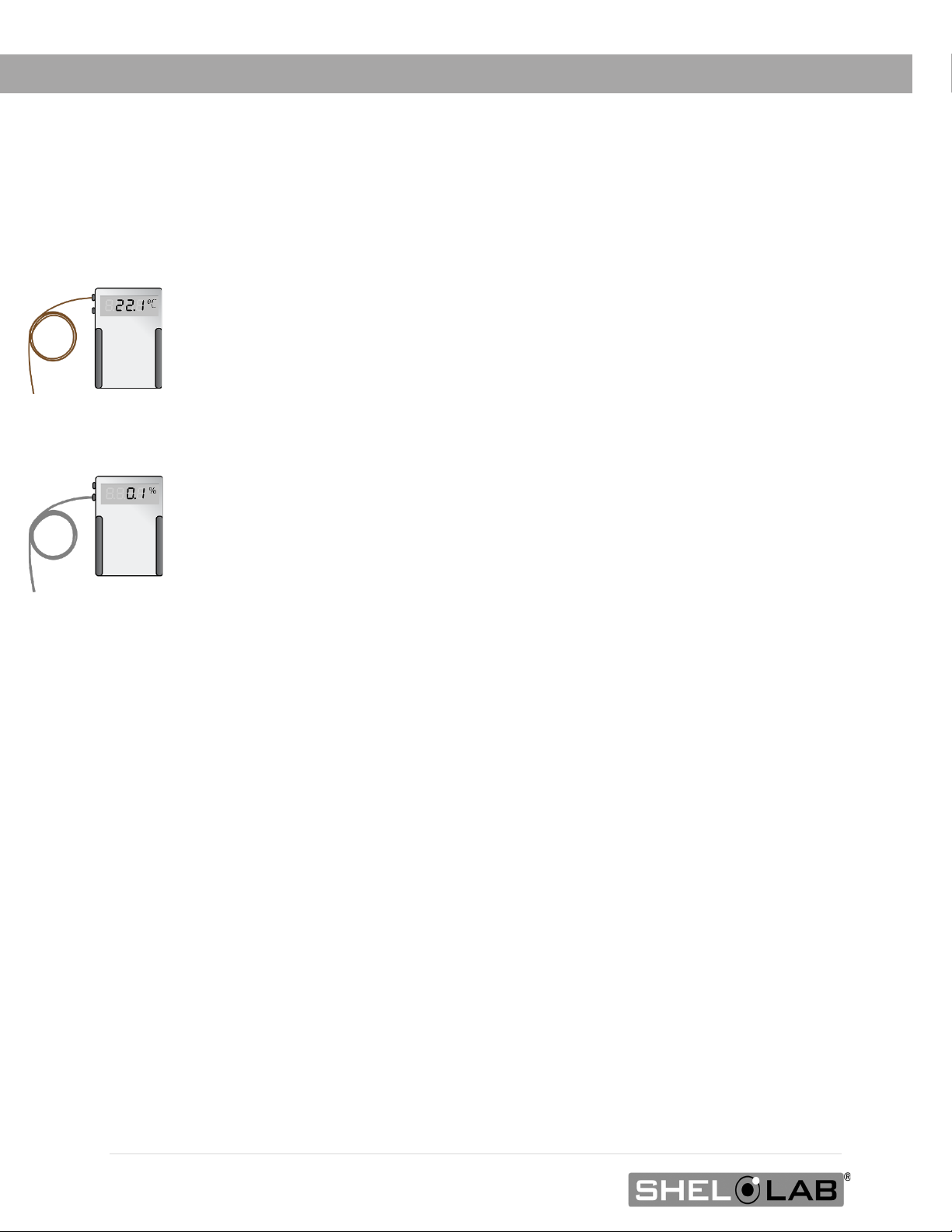

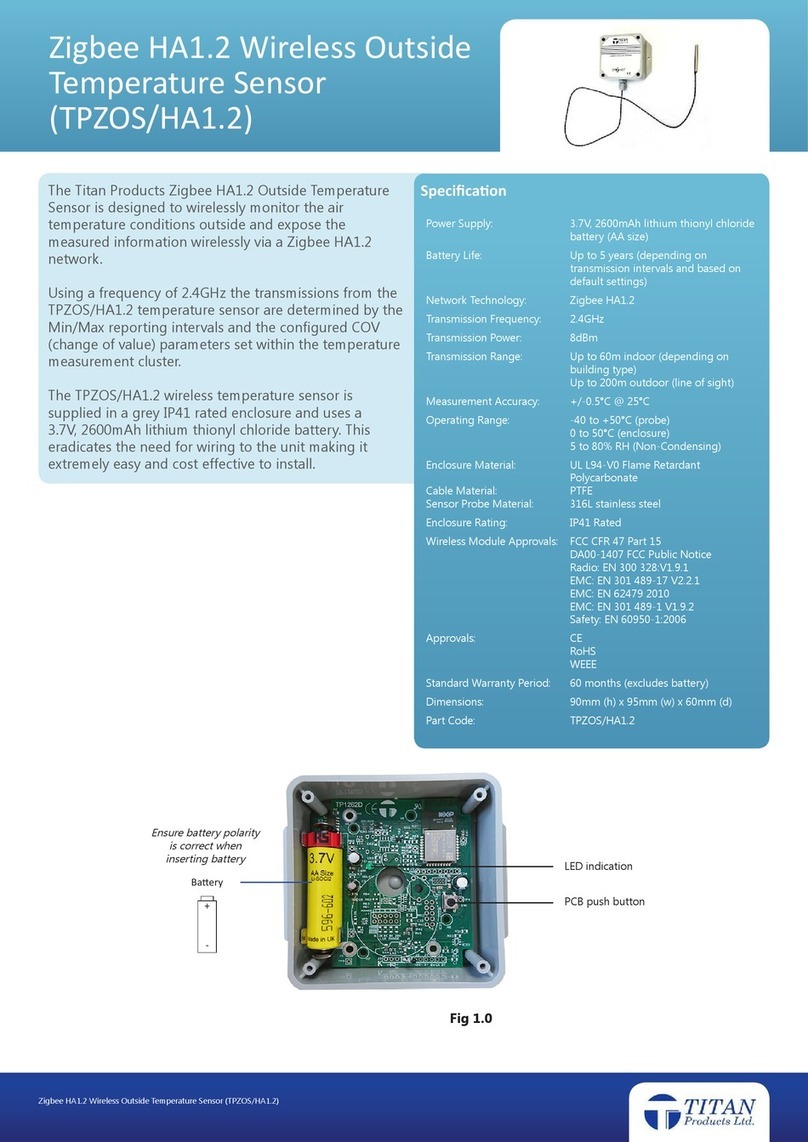

Reference Sensor Devices ................................................................................................................................................ 10

RECEIVING YOUR UNIT ...........................................................................................................................................11

Inspect the Shipment............................................................................................................................................................ 11

Orientation Image ................................................................................................................................................................ 12

Recording Data Plate Information................................................................................................................................... 13

INSTALLATION .........................................................................................................................................................15

Installation Checklist ........................................................................................................................................................... 15

Required Ambient Conditions........................................................................................................................................... 16

Required Clearances........................................................................................................................................................... 16

Environmental Disruption Sources .................................................................................................................................. 16

Power Source Requirements .............................................................................................................................................17

Lifting and Handling ............................................................................................................................................................ 18

Leveling................................................................................................................................................................................... 18

Install Incubator in Location .............................................................................................................................................. 18

Deionized and Distilled Water.......................................................................................................................................... 18

Installation - Clean and Disinfect..................................................................................................................................... 19

Shelving Installation............................................................................................................................................................. 19

Access Port Stopper ............................................................................................................................................................ 21

GRAPHIC SYMBOLS ............................................................................................................................................... 23

CONTROL PANEL OVERVIEW .............................................................................................................................. 25

OPERATION.............................................................................................................................................................. 27

Theory of Operation ............................................................................................................................................................27

Put the Incubator into Operation .................................................................................................................................... 29

Humidifying the Incubator.................................................................................................................................................. 31

Set the Temperature Setpoint ......................................................................................................................................... 32

Muting the Audible Temperature Alarm....................................................................................................................... 33

Automatic Door Cutoff ....................................................................................................................................................... 33

Start a Flow of CO2............................................................................................................................................................. 34

Set the CO2Setpoint .......................................................................................................................................................... 35

Muting the Audible CO2Alarm ........................................................................................................................................ 36

No Gas Supply Alarm (ngs)............................................................................................................................................... 36

Set the Over Temperature Limit.......................................................................................................................................37

Decontamination Cycle ..................................................................................................................................................... 38

Aborting the Decontamination Auto Cycle ................................................................................................................... 41

Load the Incubator.............................................................................................................................................................. 42

Accessory Compatibility.................................................................................................................................................... 42

Data Output Capabilities .................................................................................................................................................. 42

Condensation and the Dew Point .................................................................................................................................. 44

USER MAINTENANCE............................................................................................................................................. 45

Cleaning and Disinfecting................................................................................................................................................. 45

Minimizing Contamination Exposure ............................................................................................................................. 46

Gas Lines and HEPA Filters...............................................................................................................................................47

Storage of the Incubator ....................................................................................................................................................47

Maintaining Atmospheric Integrity ..................................................................................................................................47

Electrical Components........................................................................................................................................................47

Calibrate the Temperature display................................................................................................................................ 48