I

Contents

Chapter 1 System Overview....................................................................................................................... 1

1.1 System introduction.........................................................................................................................1

1.2 System features............................................................................................................................... 1

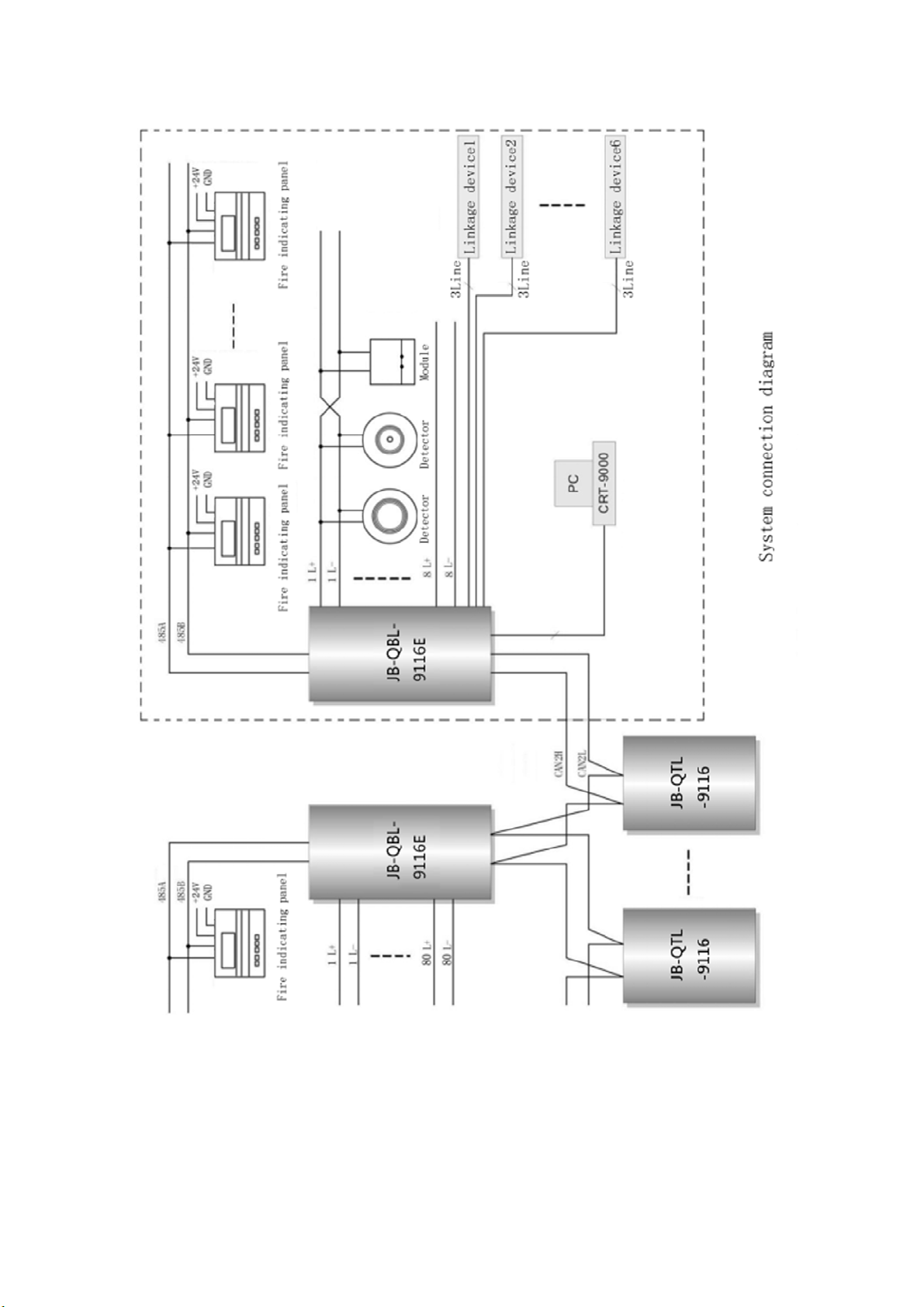

1.3 System connection diagram.......................................................................................................... 2

1.4 Introduction to system equipments...............................................................................................2

1.5 Technical parameters of system products................................................................................... 3

1.5.1 Power supply.........................................................................................................................3

1.5.2 System operating environment.......................................................................................... 3

1.5.3 Peripheral equipment.......................................................................................................... 3

Chapter 2 Engineering Installation and Dimension of the System....................................................... 4

2.1 Outline and dimension diagram of products............................................................................... 4

2.2 System installation...........................................................................................................................4

2.2.1 Items check........................................................................................................................... 4

2.2.2 Check of engineering configuration.................................................................................. 4

2.2.3 Check and connection of external equipment.................................................................4

2.2.4 Power-on test........................................................................................................................4

Chapter 3 System Debugging and Use.....................................................................................................5

3.1 System debugging.......................................................................................................................... 5

3.2 System operating instructions.......................................................................................................5

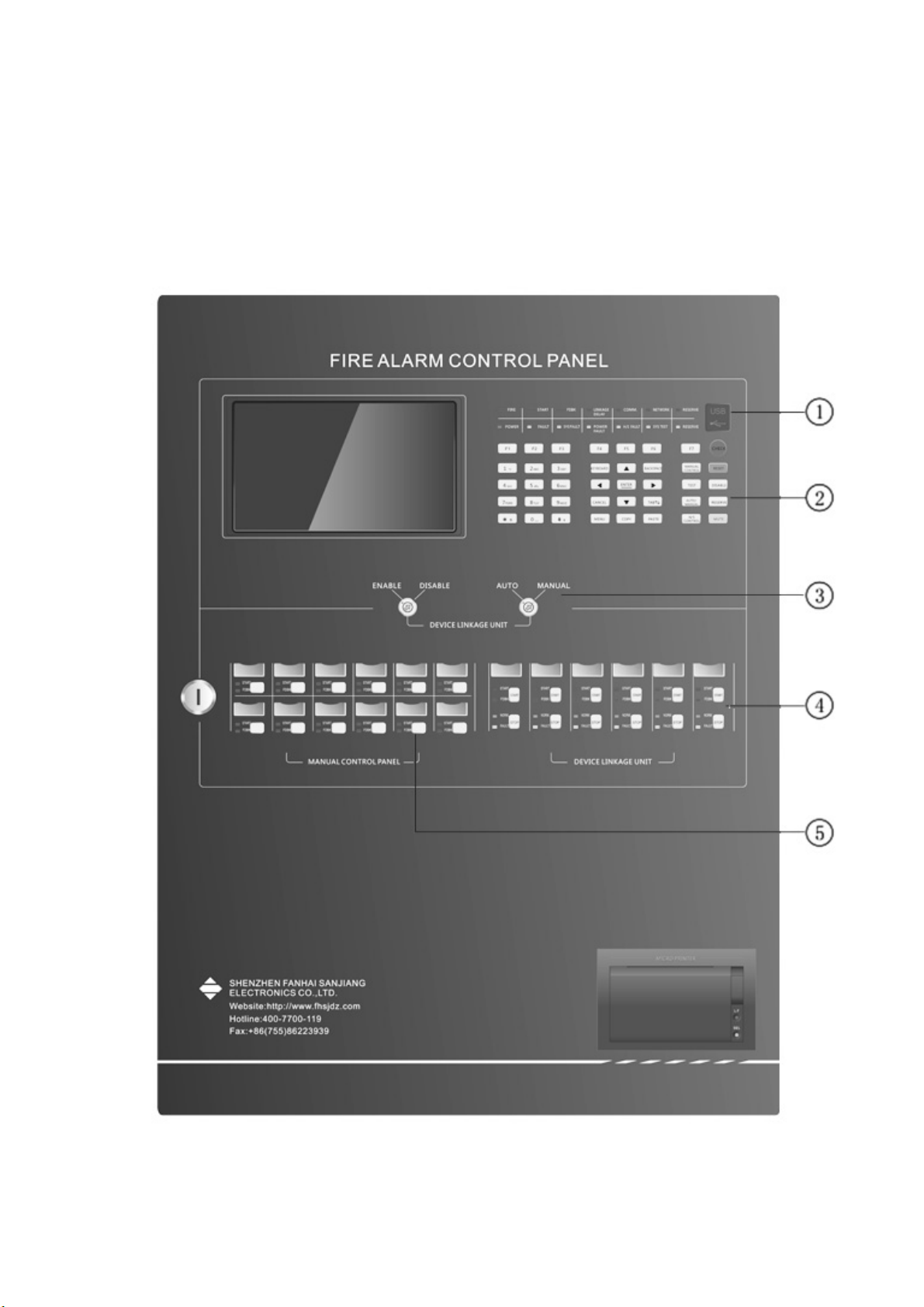

3.2.1 Functions of the panel......................................................................................................... 5

3.2.2 Start-up and power-on.......................................................................................................11

3.2.3 Login operation of the users.............................................................................................12

3.2.4 Special function keys of the system................................................................................14

3.2.5 Input of characters............................................................................................................. 15

Chapter 4 System Configuration Details.................................................................................................17

4.1 System setup..................................................................................................................................17

4.1.1 Time setup........................................................................................................................... 17

4.1.2 Zone setup, Building setup, floor setup..........................................................................18

4.1.3 Network setup..................................................................................................................... 20

4.1.4 Password setup.................................................................................................................. 24

4.1.5 FIP/Extender setup............................................................................................................ 24

4.1.6 EXT.-connected FIP setup................................................................................................ 25

4.1.7 Power setup........................................................................................................................ 25

4.1.8 Printer setup........................................................................................................................26

4.1.9 Rename system..................................................................................................................26

4.1.10 LCD Auto-off......................................................................................................................26

4.2 CAN-bus..........................................................................................................................................27

4.2.1 IO-Board setup................................................................................................................... 27

4.2.2 Detector/module setup...................................................................................................... 27

4.2.3 Working mode setup..........................................................................................................32

4.3 Linkage............................................................................................................................................ 32

4.3.1 System linkage setup................................................................................................................ 33

4.3.2 Zone linkage setup.....................................................................................................................37

4.3.3 Building linkage setup................................................................................................................37

4.3.4 Floor linkage setup.....................................................................................................................38

4.3.5 Room linkage setup................................................................................................................... 39

4.3.6 Complex linkage setup.............................................................................................................. 40

4.3.7 Manual control panel................................................................................................................. 40

4.3.8 Fire Hydrant Setup..................................................................................................................... 41

4.4 Operation.........................................................................................................................................42

4.4.1 Mute,Reset,System test,Horn/strobe control,Linkage Auto/Manual,Sounder

Auto/manual,Manual permit/PRHB...........................................................................................42

4.4.2 Recoding check.................................................................................................................. 42

4.4.3 Single Point Test.................................................................................................................43