Shihlin electric SME Series User manual

i

Safety Precautions

Thank you for purchasing Shihlin Electric product. This user manual introduces how to install,

wiring, inspect and operate Shihlin Servo Drive and Motor. Please read related items in this

user manual prior to installation and operation for safety.

■There are 2 safety notification levels in this user manual: Danger and Caution.

It indicates that it may cause severe or fatal injuries if the

instructions are not followed.

It indicates that it may cause moderate injury or malfunction of the

product if the instructions are not followed.

Besides, for those items remark as CAUTION, it may cause bad consequences in some cases,

please follow the instructions to operate due to its importance.

■Below symbols indicate the items should be followed.

It indicates the FORBIDDEN items.

It Indicates the MANDATORY Items.

In this user manual, NOTE indicates the cautions which may not cause malfunction of the

product, but need pay attention.

Please read this manual carefully and keep it properly to make sure the user can reach it freely.

ii

Safety Instruction

1. Electric Shock Prevention

Do NOT operate the switch with wet hands, otherwise it may cause electric shock.

Any wring or inspection must perform AFTER turning off the power for over 20 minutes,

charging indicator is off and voltage test is confirmed, otherwise it may cause electric shock.

Well ground the servo drive and motor.

Install the servo drive and motor before wiring, otherwise it may cause electric shock.

Do NOT damage the cable, apply excessive pressure, place heavy objects or extrude the

cable, otherwise it may cause electric shock.

Do not disassemble the servo drive front cover when the power is on or under operation,

otherwise it may cause electric shock.

Do NOT run the equipment when the servo drive front cover is disassembled, otherwise

exposed the high voltage terminal and charging pins may cause electric shock.

Except for wiring and regular inspection, do NOT open the servo front cover, even if the

power has been turned off, due to a charge may still remain in the components, which may

cause electric shock.

Make sure that ground the servo drive protection grounding (PE) terminal (with

remark) on the protection grounding terminal (PE) of protection chamber.

Insulate the electrical terminal connection area to avoid electric shock.

2. Fire Disaster Prevention

Do NOT place the servo drive, motor or external regenerative resistor on or nearby

inflammable objects, otherwise, fire disaster may be caused.

iii

Turn off the servo drive power when problem occurs, otherwise, the high current flow may

cause fire disaster.

Turn off the power by regenerative abnormal signal when regenerative resistor is used. If

there is a regenerative brake transistor fault, which may make the regenerative resistor

overheat and may cause fire disaster.

Never let below items go inside of the servo drive or motor. Including: flammable matter,

such as oil, fat, etc. And conductive matter: such as screw, metal parts, etc.

Ensure the servo drive power supply is connected with a non-fuse breaker.

3. Injury Prevention

Do NOT apply voltages other than those specified in the specifications to each terminal,

otherwise, a burst or damage may occur.

Do NOT make mistake when wiring to the terminal. Otherwise, a burst or damage may

occur.

Do NOT make mistake on the(+ -)polarity. otherwise, a burst or damage may occur.

Do NOT touch the heat sink, regenerative resistor of the servo drive, servo motor and other

components during operation or soon after the power just turned off, because it may get hot

and cause injury.

4. Other cautions

Please pay attention to below notifications, improper operation may cause breakdown, injury ,

electric shock, etc.

(1) Delivery & Installation

Choose correct way to deliver the product base on its weight.

iv

Never stack products which is beyond limitation.

Do NOT hand carry the cable, motor shaft, and encoder when deliver the servo motor.

Servo drive and motor must be installed on the location with enough bearing capacity.

Do NOT stand or put heavy staff on the product.

Ensure the product is installed correctly as specified in this manual.

Inside the protective chamber, a specified space must be reserved between the servo drive

and other equipment.

Do NOT install, run the damaged or component missing servo drive and servo motor.

Do NOT congest the vent of servo drive. Otherwise, it may cause a malfunction.

Do NOT drop or strike the servo drive and servo motor as they are precision machinery.

Consult with Shihlin Electric system service representative if you need keep the product for

a long period without using.

(2) Wiring

Do wiring carefully, otherwise, it may cause error on servo motor.

Do NOT install phase-in capacitors, surge absorber, and EMI noise filters between the

servo drive and servo motor.

Connect the servo drive and motor correctly(terminal U,V,W), otherwise, it may cause

malfunction of servo motor.

Connect the servo drive output(terminal U,V,W)and servo motor input(terminal U, V, W)

directly, Do NOT connect them by electromagnetic contactor, otherwise, it may cause

abnormality or fault.

Do NOT put the diode which control the output signal in wrong direction. Otherwise, it may

cause malfunction: no signal output and protect circuit is disabled.

Fasten the cable which is connect to the terminal block with correct torque force. Otherwise,

it may cause overheat on the cable and terminal block.

v

(3) Trial run and adjustment.

Check the program and parameters before operation. Otherwise, it may lead to malfunction

of the machine.

Do NOT adjust the parameter settings drastically, otherwise, it may cause some abnormal

on the product.

(4) Operation

Set an emergency stop circuit outside the drive, which can be activated immediately in

urgent cases to turn off the power supply.

Do NOT disassemble, repair or modify the equipment.

Please confirm that the operation signal is off before clear the alarm. otherwise the motor

might restart immediately and you may get injured.

Use noise filter to minimize the influence of electromagnetic interference, otherwise, the

electric device nearby might be impacted.

Do NOT burn or disassemble the servo drive, or it may cause hazardous gas.

Ensure a specified combination of servo drive and motor is used.

The built-in electromagnetic brake is used to hold the motor shaft, do NOT use for ordinary

braking.

vi

(5) Maintenance and Inspection

Ensure the power LED indicator is off before maintenance or inspection.

Only qualified electricians can install, wire, repair and maintain the servo drive and servo

motor.

Do NOT disassemble the servo motor, otherwise you may get electric shock or injured.

When the power is ON, do NOT connect or disconnect the servo drive with motor.

The built-in electromagnetic brake is designed to hold the motor shaft, do NOT use for

ordinary braking.

Note: the content of this manual may be revised without prior notice. Please consult our

distributors or download the latest version at http://www. seec. com. tw/en/

vii

1. Product overview and model description.............................................................................1

1.1 Outline .........................................................................................................................1

1.2 Product checklist..........................................................................................................1

1.3 Product model overview ..............................................................................................2

1.3.1 Servo motor model naming rule.........................................................................2

1.3.2 Servo drive model naming rule ..........................................................................5

1.3.3 SDP servo drive and motor................................................................................6

1.4 Servo drive appearance and panel description............................................................7

1.4.1 200V drive appearance and panel.....................................................................7

1.4.2 400V servo drive appearance and panel ...........................................................8

1.5 Servo drive control modes introduction........................................................................9

1.6 Recommended breaker and fuse specification table .................................................10

2. Installation.........................................................................................................................11

2.1. Precautions and storage...........................................................................................11

2.2. Installation environment............................................................................................11

2.3. Installation Direction and Clearances .......................................................................12

3. Wiring and signal...............................................................................................................15

3.1. Connection of power supply and peripheral equipment ............................................15

3.1.1. Peripheral equipment wiring diagram - 200V system .....................................15

3.1.2. Peripheral equipment wiring diagram - 400V system .....................................16

3.1.3 Description of drive connectors and terminals .................................................17

3.1.4 Wiring for power supply ...................................................................................19

3.1.5 Specifications for the U,V,W connectors..........................................................21

3.1.6 Wire selection ..................................................................................................25

3.2. The function diagram of servo system ......................................................................27

3.3. Wiring for CN1(I/O signal).........................................................................................28

3.3.1. CN1 terminal diagram.....................................................................................28

viii

3.3.2 CN1 signal wire shielding and grounding.........................................................31

3.3.3 CN1 Terminal signal description ......................................................................33

3.3.4 Interface wiring diagram ..................................................................................56

3.3.5 The specified DI and DO signal .......................................................................64

3.4 CN2 encoder signal wiring and description................................................................65

3.4.1 Encoder connector specification......................................................................66

3.5 CN2L full-closed loop/linear scale signal and wiring description................................70

3.6 CN3 communication port signal and wiring description .............................................71

3.7 CN4 USB communication port...................................................................................72

3.8 CN5 battery connector of absolute encoder ..............................................................73

3.9 Standard wiring instruction ........................................................................................74

3.9.1 Position control mode(Pr Mode) wiring diagram ..............................................74

3.9.2 Position control mode(Pt Mode) wiring diagram ..............................................76

3.9.3 Speed control mode (S Mode)wiring diagram..................................................77

3.9.4 Torque control mode (T Mode)wiring diagram .................................................78

3.9.5 1PG wiring diagram .........................................................................................79

3.9.6 10PG wiring diagram .......................................................................................80

3.9.7 10GM wiring diagram ......................................................................................81

3.9.8 20GM wiring diagram ......................................................................................82

3.9.9 FX3U wiring diagram .......................................................................................83

3.9.10 QD75 wiring diagram.....................................................................................84

4. Panel display and operation..............................................................................................85

4.1. Panel description ......................................................................................................85

4.2. Display procedure.....................................................................................................86

4.3. Status display ...........................................................................................................88

4.4. One-touch Tuning Function ......................................................................................93

4.5. Alarm mode...............................................................................................................93

ix

4.6. Diagnosis mode ........................................................................................................95

4.6.1. External I/O signal indicator............................................................................96

4.6.2 DO Forced output ............................................................................................98

4.6.3 JOG operation ...............................................................................................100

4.6.4 Positioning test operation ..............................................................................101

4.6.5 Auto-offset of analog input .............................................................................103

4.6.6 Inertia estimation and tuning by communication software .............................104

4.7. Parameter mode .....................................................................................................107

4.7.1 16 bit parameter setting instruction................................................................107

4.7.2 32 bit parameter setting instruction................................................................108

4.7.3 Other precautions ..........................................................................................112

5. Running operation...........................................................................................................113

5.1. Check items Before Running ..................................................................................113

5.2. Test without load .....................................................................................................114

5.2.1. JOG test without load ...................................................................................114

5.2.2. Positioning Test without load ........................................................................116

5.3. Tuning procedure....................................................................................................118

5.3.1. Tuning method and type ...............................................................................118

5.3.2. One-touch Tuning Function ..........................................................................121

5.3.3 Auto tuning function .......................................................................................130

5.3.4 Tuning in manual mode .................................................................................135

5.3.5 Interpolation mode.........................................................................................137

5.4. Position mode parameter setting and operation .....................................................138

5.5. Speed mode parameter setting and operation........................................................140

5.6. Torque mode parameter setting and operation .......................................................142

6. Control Function..............................................................................................................144

6.1. Selecting the control mode .....................................................................................144

x

6.2. Torque control mode ...............................................................................................145

6.2.1. Analog torque command...............................................................................146

6.2.2. Offset adjustment of the analog torque command ........................................147

6.2.3. Torque command smoothing ........................................................................148

6.2.4. Torque limit of torque control mode...............................................................149

6.2.5. The speed limit of torque mode ....................................................................149

6.3. Speed control mode................................................................................................152

6.3.1. Selecting the Speed command.....................................................................154

6.3.2. Scaling of the analog speed command.........................................................155

6.3.3. Smooth Speed command .............................................................................156

6.3.4. Torque limit of speed control mode...............................................................159

6.3.5. Gain adjustment of the speed loop ...............................................................161

6.3.6. Resonance suppression unit ........................................................................163

6.3.7. Gain switch function .....................................................................................169

6.4 Position control mode ..............................................................................................176

6.4.1 External pulse command(Pt command).........................................................178

6.4.2 Internal position command (Pr command) .....................................................179

6.4.3 Position command smoothing........................................................................180

6.4.4 Electronic gear ratio.......................................................................................183

6.4.5 Torque limit of position loop ...........................................................................184

6.4.6 Position loop gain. .........................................................................................185

6.5 Dual control mode....................................................................................................186

6.5.1 Position/speed dual mode .............................................................................187

6.5.2 Speed / Torque dual mode.............................................................................188

6.5.3 Torque/position dual mode.............................................................................189

6.6 Other functions ........................................................................................................191

6.6.1 Selection of regenerative resistor ..................................................................191

xi

6.6.2 Analog monitor function .................................................................................196

6.6.3 Operation of electromagnetic brake...............................................................199

7. PR (procedure) program control introductions ................................................................202

7.1 PR introduction......................................................................................................202

7.2 The difference between the PR mode of SDP and SDA. ......................................202

7.3 DI/DO and sequences in PR mode .......................................................................204

7.4 Parameter setting of PR mode..............................................................................206

7.5 PR sequence status ..............................................................................................215

8. Parameters .....................................................................................................................221

8.1. Parameter definitions..............................................................................................221

8.2. List of Parameters...................................................................................................223

8.3. Parameter group introduction .................................................................................259

Table 8.1 Digital input (DI) descriptions ..................................................................397

Table 8.2 Digital output (DO) descriptions ..............................................................399

9. Communication function..................................................................................................401

9.1 Communication hardware interface and wiring........................................................401

9.2 Communication specifications. ................................................................................404

9.3 Modbus communication protocol .............................................................................405

9.3.1 ASCII mode ...................................................................................................405

9.3.1 RTU mode .....................................................................................................411

9.4 Write and read communication parameters. ............................................................417

10.Troubleshooting .............................................................................................................430

10.1 Alarm list and corrective actions............................................................................430

11. Specifications ................................................................................................................454

11.1 Servo drive standard specifications. ......................................................................454

11.2 Interface and out dimensions of the servo drive.....................................................462

11.3 Dimensions of servo drive......................................................................................463

xii

11.4 SME series servo motor general specification .......................................................467

11.4.1 Standard specification of low capacity servo motor .....................................467

11.4.2 Standard specification of medium capacity servo motor ..............................469

11.4.3 High inertia motor specification....................................................................471

11.4.4 (400V)High inertia motor specification .........................................................473

11.5 Motor dimensions...................................................................................................475

11.5.1 Dimensions of 300rpm motor. ......................................................................475

11.5.2 Dimensions of 2000rpm motor.....................................................................476

11.5.3 Dimensions of 1500rpm motor.....................................................................477

11.5.4 (400V) dimensions of 1500rpm motor..........................................................478

11.5.5 Dimension of servo motor keyway ...............................................................480

11.6 Electromagnetic Interference Filter (EMI Filter)......................................................482

11.7 EMI interference countermeasure..........................................................................483

12. Features........................................................................................................................485

12.1 Motor T-N curve/S-T curve.....................................................................................485

12.2 Overload protection feature ...................................................................................493

13.Absolute servo system ...................................................................................................497

13.1 Mitsubishi Absolute Position Detection System .....................................................501

13.1.1 Signal description ........................................................................................501

13.1.2 Start procedure............................................................................................502

13.1.3 Absolute position data transmission protocol...............................................503

13.2 Delta absolute position detection system...............................................................512

13.2.1 Signal description ........................................................................................512

13.2.2 Start procedure............................................................................................513

13.2.3 Use DI/DO to initialize absolute coordinates................................................514

13.2.4 Use parameter settings to initialize absolute coordinates ............................515

13.2.5 Absolute position data transmission protocol...............................................516

xiii

13.3 Absolute battery specifications...............................................................................518

14. Appendix .......................................................................................................................520

14.1 Accessories............................................................................................................520

14.2 Regenerative resistor.............................................................................................531

14.3 Table of communication address ...........................................................................532

14.4 Compliance with global standards .........................................................................537

14.4.1. Safety instructions ......................................................................................537

14.4.2. Professional technicians. ............................................................................537

14.4.3. Compliance with standards.........................................................................537

14.4.4. Correct use .................................................................................................539

14.4.5. Basic inspection and maintenance .............................................................540

14.5 Manual version and revision history.......................................................................542

1

1. Product overview and model description

1.1 Outline

Shihlin general type AC servo includes single mode and multi-mode. Single mode has the

following four types of control mode: position mode(terminal input), position mode(internal

register), speed mode and torque mode. And multi-mode has the following 8 types of control

mode: position mode(terminal input)/speed mode, position mode(terminal input)/torque mode,

position mode(internal register)/speed mode, position mode(internal register)/torque mode,

speed mode/torque mode, position mode(terminal input)/position mode(internal register),

position mode(terminal input)/position mode(internal register)/speed mode and position

mode( terminal input)/position mode(internal register)/torque mode.

The servo can be used for high-precision positioning system, speed control smoothing system

in general machinery industry, host machine and tension control system.

Shihlin servo provides RS-485 serial communication function, and it also provides the most

convenient USB communication function, this enable you can rapidly perform parameter setting,

test operation, status monitoring and gain adjustment control by a computer which is installed

with Shihlin communication software.

Shihlin servo provides auto tuning function, servo gain can automatically perform adjustment

with the mechanical. The Shihlin servo is equipped with 23&24-bit pulse/rev absolute encoder,

it can perform high-precision control.

1.2 Product checklist

Please check below items before you start to use our product

Any loose or fall off screw on motor or drive.

Check if the product model name on nameplates of the motor and drive are align with your

purchase order. You can refer to the product model list in next section.

Check if any damage or scratch on the surface of the motor and drive.

Check if any abnormality on the motor shaft, you can manually rotate the motor shaft to

check if it can move smoothly. But if the motor is equipped with electromagnetic brake,

you cannot manually rotate the motor shaft.

If any of the above problems occurs, please contact the distributor.

A complete servo system includes:

2

(1) A servo drive and a servo motor.

(2) A UVW motor power cable: its one end with the U, V, W cables connect to the

corresponding terminal block, and the other end connects to the UVW connector on the

motor. The green wire connects to the ground terminal of the servo drive (optional

purchase).

(3) An encoder control signal cable: its one end connects to the CN2 of the servo drive and

the other end to encoder.

(4) A USB communication cable, its one end connects to CN4 of the drive, the other end to

USB port of the computer. (Optional purchase).

(5) A 50 Pin connector for CN1.

(6) A 12 pin (P,D,C,N,L1,L2,R,S,T,U,V,W) terminal block for servo below 1KW.

(7) A 6 pin(P,D,C,N,L1,L2) terminal block for1.5KW~3KW servo.

(8) A 6 pin (R,S,T,U,V,W) terminal block for 1.5KW~3KW servo.

(9) An installation guide.

(10) Shihlin servo user manual, the electric copy can be download from the website.

1.3 Product model overview

1.3.1 Servo motor model naming rule

1. Naming rule

S M E -

(8)Keyway and outlet type

(7)Brake and oil seal

(6)Encoder type

(5)Rated speed

(4)Motor capacity

(3)Inertia type

(2)Model name

(1)Servo motorcode

(9)Safety certification

2.Description of each code item

(1) Servo motor code: SM indicates servo motor.

(2) Model code: E(200V), P(400V).

3

(3) Inertia classification: coding according to motor inertia:

Code

Classification

L

Low inertia

M

Middle inertia

H

High inertia

(4) Motor capacity: motor output power

(5) Rated speed: the rated motor speed.

Code

15

20

30

Rated speed(rpm)

1500

2000

3000

(6) Encoder type: Shihlin servo motor encoder type.

Code

S

M

Single turn resolution type

200V:

24bit (50W~750W)

23bit (850W~7KW)

200V:

24bit (50W~750W)

23bit (850W~7KW)

400V:

23bit (1.8KW~7.5KW)

Multi-turn resolution type

-

16bit

Code

005

010

020

040

075

085

100

200V motor power(W)

50

100

200

400

750

850

1000

Code

130

150

180

200

300

500

700

200V motor power(W)

1300

1500

1800

2000

3000

5000

7000

Code

180

290

440

550

750

400V motor power(W)

1800

2900

4400

5500

7500

4

(7) Brake and oil seal: the following codes is to indicate whether the motor is equipped with

brake and oil seal.

Code

Item

A

B

C

D

Brake

-

●

-

●

Oil seal

-

-

●

●

(8) Keyway and outlet type: the following code indicates the configuration of motor keyway and

outlet type.

Code

Item

A

B

C

D

Keyway

-

●

-

●

Back side cable

-

-

●

●

(9) Safety certification: the certified safety certification of the motor is indicated by the

following code:

Code

Item

CE certification

Compliant with UL/CE certification

Code

-

U

Coding example:

Example(1): for a 200W motor, low inertia, rated speed 3000rpm, without brake&oil seal&

keyway, single turn encoder, CE certified model, its model name is as follows: SME-L02030SAA.

Example(2): for a 750W motor, low inertia, rated speed 3000rpm, with brake, without oil seal,

with keyway, multi-turn encoder, back side cable, UL certified, its model name is SME-

L07530MBDU.

Example(3): for a 3000W motor, low inertia, rated speed 2000rpm, without brake, with oil seal

and keyway, multi-turn encoder, CE certified, the model name is SME-L30020MCB.

5

1.3.2 Servo drive model naming rule

1. Naming rule

S D P - ○○○ △△ □

(1)Model code

(2)Power type

(3)Drive capacity

(4)Product series

(5)Drive code

2.Description of each coding item

(1) Drive code: SD means Servo Drive

(2) Product series: P

(3) Drive capacity: motor output power. Multiply the motor output power by 1/10 and then

indicate it as a three-code number. For models above 1000W, the third code uses the

English letter K to represent 1000W. The example is as follows:

020 means 200W

150 means 1500W

300 means 3000W…like that.

(4) Power type: input power specification

A2: single-phase or three-phase 200 ~ 240 VAC

A4: three-phase 380 ~ 480 VAC

(5) Mode code

A: without full-closed loop. (CN2L)

C: with full-closed loop. (CN2L)

Example:

Example (1): A 200W drive, single-phase or three-phase 200 ~ 240 VAC, with full-closed loop

control function, the code is as follows: SDP-020A2C.

Example (2): A 3000W drive, three-phase 400 ~ 480 VAC, with full-closed loop control function,

the code is as follows: SDP-300A4C.

6

1.3.3 SDP servo drive and motor

200VAC system

Servo drive

Corresponding

servo motor

100W

SDP-010A2C

SME-L00530○□□□

SME-L01030○□□□

200W

SDP-020A2C

SME-L02030○□□□

SME-H02030○□□□

400W

SDP-040A2C

SME-L04030○□□□

SME-H04030○□□□

750W

SDP-075A2C

SME-L07530○□□□

SME-H07530○□□□

1000W

SDP-100A2C

SME-H08515○□□□

SME-M10020○□□□

SME-L10020○□□□

1500W

SDP-150A2C

SME-M15020○□□□

SME-L15020○□□□

2000W

SDP-200A2C

SME-M20020○□□□

SME-L20020○□□□

3000W

SDP-300A2C

SME-H13015○□□□

SME-H18015○□□□

SME-M30020○□□□

SME-L30020○□□□

Note 1: refer to section 1.3.1 for the description of ○□□□ in servo motor model name.

400VAC system

Servo drive

corresponding servo motor

1800W

SDP-200A4C

SMP-H18015○□□□

2900W

SDP-300A4C

SMP-H29015○□□□

4400W

SDP-500A4C

SMP-H44015○□□□

5500W

SMP-H55015○□□□

7500W

SDP-700A4C

SMP-H75015○□□□

Note 1: refer to section 1.3.1 for the description of ○□□□ in servo motor model name.

7

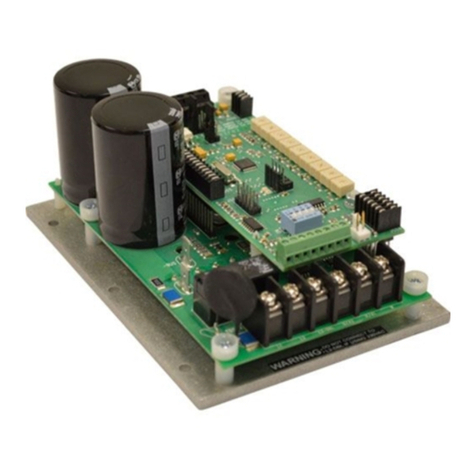

1.4 Servo drive appearance and panel description

1.4.1 200V drive appearance and panel

Power indicator

If the indicator is on, it means the

servo drive still has high voltage at

that time.

Control board power supply.

Use single-phase( 200-240VAC, 50-60HZ

power supply) to L1, L2 terminal.

Main circuit power supply

Connects R,S,T to commercial

power ( AC200-240V,50-60HZ

power)

Servo motor output

Connects to the motor power connector

U, V, W, Do not connect to the main

circuit power. Incorrect wiring will cause

damage to the servo drive.

Heat sink

For fixing the servo and heat

dissipation.

Display

The 5-digit 7 segment LED

displayer displays the alarm, servo

status, parameter, etc.

Operation panel

To perform function and

parameters setting.

MODE:Mode selection

5:add one on the

displayed value

6:deduct one from the

displayed value

SET:Press SET button to

confirm the setting

USB connector

Connects the PC and controller.

RS-485 connector

Connects the PC and

controller.

Encoder connector

Connects to the motor encoder

Control interface.

1.controls the external I/O

2. connects to PLC

Grounding terminal

L1

L2

CHARGE

SDP-010A2C

Position feedback

connector

1. Linear scale feedback.

2. Hall sensor connector

STO terminal

Internal /external regenerative

resistor/brake control module.

1. When external regenerative resistor is

used, P and C connect to the resister; P

and D are left open.

2. When internal regenerative resistor is

used, P and C are left open; P and D are

short-circuited (connected)

3. When external regenerative brake unit

is used, P andN connect to the brake

unit; P & C and P & D are left open.

This manual suits for next models

12

Table of contents

Other Shihlin electric DC Drive manuals

Popular DC Drive manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC VLB Series installation manual

Danfoss

Danfoss Native BACnet VLT HVAC Drive operating instructions

Eaton

Eaton GVX9000 quick start guide

Emerson

Emerson Unidrive M200-01100017 quick start guide

Danfoss

Danfoss VLT AQUA Drive FC 202 Design guide

American Control Electronics

American Control Electronics Minarik Drives MDBL05 manual