Tridonic EM converterLED PRO NF MH/LiFePO4 250 V User manual

www.tridonic.com 1

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

Product description

• Self-contained emergency lighting LED Driver with

DALI interface and automatic test function

• For LED modules with a forward voltage of 48 – 250 V

• For luminaire installation

• Nominal life-time up to 100,000 h

• 5-year guarantee

Functions

• Non maintained operation

• Integrated DALI bus power supply

• 1, 2 or 3 h rated duration selectable with duration link

• Compatible with most constant current LED Drivers (refer to

chapter „LED Driver compatibility“)

• 3-pole technology: 2-pole LED module changeover

and delayed power switching for the LED Driver

• Constant power output

• Two-colour status display LED

• Black Box data recording

Interfaces

• DALI interface for controlled testing and monitoring

• Near field communication (NFC)

Battery management

NiMH/LiFePO4:

• Intelligent charge system

• Deep discharge protection

• Polarity reversal protection for battery via polarized connector

plug

• Automatic detection of the connected battery technology

(NiMH or LiFePO4batteries)

LiFePO4:

• Tridonic LiFeGuard ensures safety in use (refer to chapter

„Safety LiFePO4“)

• Temperature protection

Batteries

• NiMH or LiFePO4batteries

• NiMH: 4-year design life / 1-year guarantee

• LiFePO4: 4 – 8 years design life / 3-year guarantee

• For battery compatibility refer to chapter „Battery selection“

È

Standards, page 5

Wiring diagrams and installation examples, page 6

EM converterLED PRO NF MH/LiFePO4 250 V

Powered DALI PRO NFC series

www.tridonic.com 2

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

Technical data

Rated supply voltage 220 – 240 V

AC voltage range 198 – 264 V

Mains frequency 50 / 60 Hz

LED module forward voltage range 48 – 250 V

Output current see chapter 5.3

Starting time < 0.5 s from detection of emergency

event

Overvoltage protection 320 V (for 48 h)

U-OUT (including open- / short-circuit and

double load)

300 V

Max. open circuit voltage 300 V

Ambient temperature range ta -25 ... +55 °C

Max. casing temperature tc 80 °C

Mains voltage changeover threshold according to EN 60598-2-22

Mains surge capability (between L – N) 1 kV

Mains surge capability (between L/N – PE) 2 kV

Type of protection IP20

Integrated DALI bus power supply IPS 50 mA

Functional test Weekly 5s test

Duration test Yearly 1 h / 2 h / 3 h test

Life-time up to 100,000 h

Dimensions LxWxH 179 x 30 x 21 mm

EM converterLED PRO NF MH/LiFePO4 250 V

Powered DALI PRO NFC series

30

21

30

179

169.2 Position A

3 h

No duration

link 2 h

Position B

1 h

Note: LED Driver supplied with duration link in 3 hours position. Duration link must be set

before battery and mains connection.

Ordering data

Type1Article

number

Rated

duration

Packaging,

carton

Packaging,

pallet

Weight

per pc.

EM converterLED PRO 303 MH/LiFePO4 250V 1/2/3 h 10 pc(s). 1,600 pc(s). 0.075 kg

EM converterLED PRO 304 MH/LiFePO4 250V 1/2/3 h 10 pc(s). 1,600 pc(s). 0.075 kg

EM converterLED PRO 305 MH/LiFePO4 250V 1/2/3 h 10 pc(s). 1,600 pc(s). 0.075 kg

Test switch EM3

ACCES-

SORIES

Ordering data

Type Article number Packaging,

bag

Packaging,

carton

Weight

per pc.

Test switch EM 3 25 pc(s). 200 pc(s). 0.013 kg

Status indication bi-colour LED

ACCES-

SORIES

Specific technical data

Type Battery

technology

Rated

duration

Typ. λ

(at 230 V,

50 Hz)

Typ. output

power

P emergency

Mains current in charging operation Rated power in charging operation

Initial charge3Fast recharge3Trickle charge23 Initial charge3Fast recharge3

Trickle charge23

EM converterLED PRO 303

MH/LiFePO4 250V

NiMH

1 h 0.6C 2.5 W 17 mA 20 mA 17 / 12 mA 2.3 W 2.8 W 2.3 / 1.6 W

2 h 0.6C 2.5 W 24 mA 25 mA 20 / 12 mA 3.2 W 3.4 W 2.7 / 1.6 W

3 h 0.6C 2.5 W 24 mA 25 mA 20 / 12 mA 3.2 W 3.4 W 2.7 / 1.6 W

LiFePO4

1 h 0.6C 2.5 W 22 mA 22 mA 22 / 12 mA 3.0 W 3.0 W 3.0 / 1.6 W

2 h 0.6C 2.5 W 27 mA 27 mA 27 / 12 mA 4.0 W 4.0 W 4.0 / 1.6 W

3 h 0.6C 2.5 W 27 mA 27 mA 27 / 12 mA 4.0 W 4.0 W 4.0 / 1.6 W

EM converterLED PRO 304

MH/LiFePO4 250V

NiMH

1 h 0.6C 3.5 W 18 mA 22 mA 18 / 12 mA 2.5 W 3.1 W 2.5 / 1.6 W

2 h 0.6C 3.5 W 26 mA 27 mA 22 / 12 mA 3.8 W 4.1 W 3.0 / 1.6 W

3 h 0.6C 3.5 W 26 mA 27 mA 22 / 12 mA 3.8 W 4.1 W 3.0 / 1.6 W

LiFePO4

1 h 0.6C 3.5 W 22 mA 22 mA 22 / 12 mA 3.0 W 3.0 W 3.0 / 1.6 W

2 h 0.6C 3.5 W 27 mA 27 mA 27 / 12 mA 4.0 W 4.0 W 4.0 / 1.6 W

3 h 0.6C 3.5 W 27 mA 27 mA 27 / 12 mA 4.0 W 4.0 W 4.0 / 1.6 W

EM converterLED PRO 305

MH/LiFePO4 250V

NiMH

1 h 0.6C 4.5 W 20 mA 24 mA 20 / 12 mA 2.8 W 3.5 W 2.8 / 1.6 W

2 h 0.6C 4.5 W 28 mA 30 mA 24 / 12 mA 4.4 W 4.7 W 3.3 / 1.6 W

3 h 0.6C 4.5 W 28 mA 30 mA 24 / 12 mA 4.4 W 4.7 W 3.3 / 1.6 W

LiFePO4

1 h 0.6C 4.5 W 22 mA 22 mA 22 / 12 mA 3.0 W 3.0 W 3.0 / 1.6 W

2 h 0.6C 4.5 W 27 mA 27 mA 27 / 12 mA 4.0 W 4.0 W 4.0 / 1.6 W

3 h 0.6C 4.5 W 27 mA 27 mA 27 / 12 mA 4.0 W 4.0 W 4.0 / 1.6 W

1 EM = Emergency

2In case of NiMH batteries: Intermittent charge is used. Value 1 is for 4 min. charge on / Value 2 is for 16 min. charge o. In case of LiFePO4 batteries voltage dependent constant current charging is used. Value 1 is

for charge on / Value 2 is for charge o

3Integrated DALI bus power supply is switched OFF. With the Integrated DALI bus power supply switched ON and fully loaded the input power and current is increased by 1 W and 6 mA in any charging mode.

www.tridonic.com 3

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

Product description

• For connection to the emergency lighting unit

• For checking the device function

• Plug connection

Test switch EM3

ACCES-

SORIES

Ordering data

Type Article number Packaging,

bag

Packaging,

carton

Weight

per pc.

Test switch EM 3 25 pc(s). 200 pc(s). 0.013 kg

Product description

• Two-colour status display LED

• Green: system OK, red: fault

• Plug connection

Status indication bi-colour LED

ACCES-

SORIES

Ordering data

Type Article number Packaging,

bag

Packaging,

carton

Weight

per pc.

LED EM bi-colour, 1.0 m CON 25 pc(s). 200 pc(s). 0.015 kg

LED EM bi-colour, high brightness HO 1.0 m CON 25 pc(s). 200 pc(s). 0.015 kg

LED EM bi-colour, 0.6 m CON 25 pc(s). 200 pc(s). 0.005 kg

LED EM bi-colour, high brightness HO 0.6 m CON 25 pc(s). 200 pc(s). 0.005 kg

LED EM bi-colour, 0.3 m CON 25 pc(s). 200 pc(s). 0.005 kg

LED EM bi-colour, high brightness HO 0.3 m CON 25 pc(s). 200 pc(s). 0.005 kg

www.tridonic.com 4

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

Product description

• Connection cable for NiMH batteries

• Cable length 500 mm

• 2-pole plug connection for batteries and 3-pole plug connection

for LED Driver

Connection Cable NiMH

ACCES-

SORIES

Ordering data

Type Article number Packaging,

bag

Packaging,

carton

Weight

per pc.

CONNECTION CABLE NiMH 500mm 10 pc(s). 200 pc(s). 0.015 kg

Product description

• Extension cable for LiFePO4batteries

• Cable length 500 mm

• 3-pole plug connection

Extension Cable LiFePO4

ACCES-

SORIES

Ordering data

Type Article number Packaging,

bag

Packaging,

carton

Weight

per pc.

EXTENSION CABLE LiFePO4 500mm 10 pc(s). 200 pc(s). 0.01 kg

www.tridonic.com 5

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

1. Standards

• EN 61347-1

• EN 61347-2-13

• EN 61347-2-7

• EN 55015

• EN 61000-3-2

• EN 61000-3-3

• EN 61547

• EN 60068-2-64

• EN 60068-2-29

• EN 60068-2-30

• EN 62384

• EN 62386-101 (DALI-2), only IPS relevant requirements

• EN 62386-102 (DALI-2), only IPS relevant requirements

• EN 62386-202

• according to EN 50172

• according to EN 60598-2-22

• according to EN 62034

1.1 Glow-wire test

according to EN 61347-1 with increased temperature of 850 °C passed.

1.2 Insulation and electric strength testing of luminaires

Electronic LED-Drivers can be damaged by high voltage. This has to be consid-

ered during the routine testing of the luminaires in production.

According to IEC 60598-1 Annex Q (informative only!) or ENEC 303-Annex A,

each luminaire should be submitted to an insulation test with 500VDC for 1 sec-

ond. This test voltage should be connected between the interconnected phase

and neutral terminals and the earth terminal. The insulation resistance must be

at least 2 MΩ.

As an alternative, IEC 60598-1 Annex Q describes a test of the electrical

strength with 1,500 VAC (or 1,414 x 1,500 VDC). To avoid damage to the electronic

devices this test must not be conducted.

3. Installation / Wiring

3.1 Wiring diagram

One or more LED modules with a total forward voltage of 48 to 250 V can be

connected to the EM converterLED module. These LED module(s), marked with

“Emergency” are operated in emergency mode from the associated battery. In

normal mains mode all LED modules are operated by the mains LED Driver.

Meaning of marking

Double or reinforced insulation for built-in electronic LED Drivers. The control

gear relies upon the luminaire enclosure for protection against accidental contact

with live parts.

2. Thermal details and life-time

2.1 Life-time

Average life-time 50,000 hours under rated conditions with a failure rate of

less than 10 %. Average failure rate of 0.2 % per 1000 operating hours.

Expected life-time with LiFePO4batteries, DALI power supply off

Type ta 40 °C 45 °C 50 °C 55 °C

EM converterLED PRO 303

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 82,000 h 58,000 h

EM converterLED PRO 304

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 82,000 h 58,000 h

EM converterLED PRO 305

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 82,000 h 58,000 h

Expected life-time with LiFePO4batteries, DALI power supply on, load 50 mA

Type ta 40 °C 45 °C 50 °C 55 °C

EM converterLED PRO 303

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 80,000 h 56,000 h

EM converterLED PRO 304

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 80,000 h 56,000 h

EM converterLED PRO 305

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 79,000 h 56,000 h

The emergency lighting LED Driver is designed for a life-time stated above

under reference conditions and with a failure probability of less than 10 %.

The relation of tc to ta temperature depends also on the luminaire design.

If the measured tc temperature is approx. 5 K below tc max., ta tempera-

ture should be checked and eventually critical components (e.g. ELCAP)

measured. Detailed information on request.

Expected life-time with NiMH batteries, DALI power supply off

Type ta 40 °C 45 °C 50 °C 55 °C

EM converterLED PRO 303

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 80,000 h 56,000 h

EM converterLED PRO 304

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 79,000 h 56,000 h

EM converterLED PRO 305

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 78,000 h 55,000 h

Expected life-time with NiMH batteries, DALI power supply on, load 50 mA

Type ta 40 °C 45 °C 50 °C 55 °C

EM converterLED PRO 303

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 78,000 h 55,000 h

EM converterLED PRO 304

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 76,000 h 53,000 h

EM converterLED PRO 305

MH/LiFePO4 250V

tc 65 °C 70 °C 75 °C 80 °C

life-time > 100,000 h > 100,000 h 72,000 h 51,000 h

www.tridonic.com 6

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

EM converterLED PRO with one LED module for non-maintained emergency operation

EM converterLED PRO with a standard LED LED Driver and one LED module for mains and emergency operation

EM converterLED PRO with a standard LED LED Driver and series operation of LED modules

One LED module is operated in emergency mode.

All LED modules are operated in mains mode.

Neutral

+

+

–

–

Bat

–

+

P

O

Lout

Lin

N

DA+

DA-

L

L

N

EM ConverterLED

PRO

Neutral

DALI

DALI

Un-Switched Line Test

switch

Indicator

LED

Switched Line out

Switched Line in

Control gear

LED

LED

Control gear LED Module

Emergency

–

+

–

+

LED Module

–

+

LED Module

LED control gear

max. 150 W in operation

DALI bus

Integrated power supply

Battery

Neutral

+

+

–

–

Bat

–

+

P

O

Lout

Lin

N

DA+

DA-

L

L

N

EM ConverterLED

PRO

Neutral

DALI

DALI

Un-Switched Line Test

switch

Indicator

LED

Switched Line out

Switched Line in

Control gear

LED

LED

Control gear LED Module

Emergency

–

+

LED control gear

max. 150 W in operation

DALI bus

Integrated power supply

Battery

+

+

–

–

Bat

–

+

P

O

Lout

Lin

N

DA+

DA-

L

EM ConverterLED

PRO

Neutral

DALI

DALI

Un-Switched Line Test

switch

Indicator

LED

DALI bus

Integrated power supply

Not connected

Not connected

Control gear

LED

LED

Control gear

Battery

LED Module

Emergency

www.tridonic.com 7

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

EM converterLED PRO with a standard LED LED Driver and parallel operation of LED modules

One LED module is operated in emergency mode.

All LED modules are operated in mains mode.

8 – 9 mm

wire preparation:

0.5 – 1.5 mm²

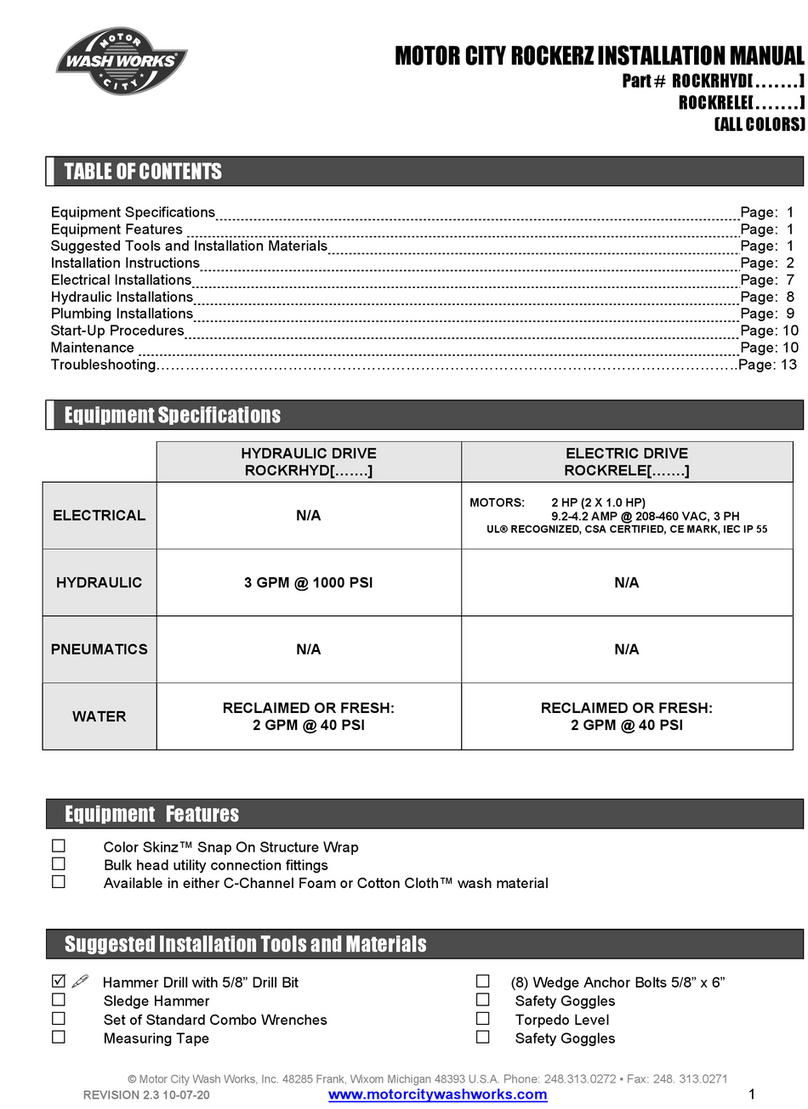

3.2 Wiring type and cross section

Solid wire with a cross section of 0.5 – 1.5 mm². Strip 8 – 9 mm of insulation

from the cables to ensure perfect operation of terminals.

Wiring: LED module/LED Driver/supply

3.3 Battery connection

LiFePO4: Direct connection

NiMH: Connection with extension cable

When using an EM converterLED in combination with a NiMH battery, order the

CONNECTION CABLE NiMH 500mm seperately.

LiFePO4: Connection with extension cable

Battery

300

EM converterLED

Battery

500

300

EM converterLED

Battery

500

300

EM converterLED

Neutral

+

+

–

–

Bat

–

+

P

O

L

N

EM ConverterLED

PRO

Test

switch

Indicator

LED

Control gear

LED

LED

Control gear LED Module

Emergency

–

+

–

+

LED Module

–

+

LED Module

LED control gear

max. 150 W in operation

Lout

Lin

N

DA+

DA-

L

Neutral

DALI

DALI

Un-Switched Line

Switched Line out

Switched Line in

DALI bus

Integrated power supply

Battery

www.tridonic.com 8

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

3.4 Loose wiring

Loosen wire through twisting

and pulling or using a Ø1 mm

release tool

3.5 Wiring guidelines

• The output to the LED is DC but has high frequency content, which should be

considered for good EMC compliance.

• LED leads should be separated from the mains and DALI connections and

wiring for good EMC performance.

• Maximum lead length on the LED terminals is 3 m. For a good EMC

performance keep the LED wiring as short as possible.

• The secondary wires (LED module) should be routed in parallel to ensure

good EMC performance.

• Maximum lead length for the Test switch and Indicator LED connection is 1 m.

The test switch and Indicator LED wiring should be separated from the LED

leads to prevent noise coupling.

• Battery leads are specified with 0.5 mm cross section and a length of 0.8 m

• DALI terminals are mains voltage proof

• To avoid the damage of the control gear, the wiring must be protected against

short circuits to earth (sharp edged metal parts, metal cable clips, louver, etc.)

To ensure that a luminaire containing LED emergency units complies with

EN 55015 for radio frequency conducted interference in both normal and

emergency mode it is essential to follow good practice in the wiring layout.

Within the luminaire the switched and unswitched 50 Hz supply wiring must be

routed as short as possible and be kept as far away as possible from the LED

leads.Through wiring may affect the EMC performance of the luminaire.

3.6 Maximum lead length

LED 3 m (6 m loop)1

Status indication LED 1 m

Batteries 0.8 m

1Note: The length of LED leads to the LED module must not be exceeded. Note that the length

of the EM converterLED leads to the LED module is added to the length of the leads from the

LED Driver to the EM converterLED module when considering the max. permitted lead length of

the LED Driver. Keep the leads always as short as possible.

3.7 Use of different phases

The use of different phases for switched line and unswitched line is allowed.

When using different phases, the unswitched line must fail if the switched

line fails. This is required to assure correct switching into emergency mode. It

can be realised with a relay.

4. Mechanical values

4.1 Housing properties

• Casing manufactured from polycarbonate.

• Type of protection: IP20

• Max. torque at the mounting screws: 0.8 Nm

4.2 Mechanical data accessories

LED status indicator

• Bi-colour

• Mounting hole 6.5 mm diameter, 1 – 1.6 mm thickness

• Lead length 0.3 m / 0.6 m / 1.0 m

• Insulation rating: 90 °C

• Plug connection

Test switch

• Mounting hole 7.0 mm diameter

• Lead length 0.55 m

• Plug connection

Battery connection

• Plug connection 0.3 m

• Extension cable 0.5 m

www.tridonic.com 9

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

Automatic circuit breaker type B10 B13 B16 B20 C10 C13 C16 C20 Inrush current

Installation Ø1.5 mm21.5 mm21.5 mm22.5 mm21.5 mm21.5 mm21.5 mm22.5 mm2Imax time

EM converterLED PRO MH/LiFePO4 250V 90 130 130 130 180 260 260 260 3.6 A 120 μs

5. Electrical values

5.1 Maximum loading of automatic circuit breakers

5.2 Insulation matrix

Mains Switched Live Battery, LED, Test

switch, Indicator LED DALI

Mains – • • • •

Switched Live • – • • •

Battery, LED, Test

switch, Indicator LED • • • • – •

DALI • • • –

• Represents basic insulation

• • Represents double or reinforced insulation

When using a non-SELV LED Driver insulate the battery, LED, test switch and indicator LED in the luminaire according to the

U-OUT rating of the LED Driver.

www.tridonic.com 10

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

5.3 Typ. LED current/voltage characteristics

The LED current in emergency mode is automatically adjusted by the EM converterLED module based on the total forward voltage of the LED modules con-

nected and the associated battery. The start of the LED in emergency mode does not result in a current peak.

EM converterLED PRO 303 MH/LiFePO4 250V

Article number: 89800643

NiMH battery, 3.6 V battery voltage

800 – 860 mA battery discharge current (tolerance)

LiFePO4battery, 3.2 V battery voltage

920 – 980 mA battery discharge current (tolerance)

EM converterLED PRO 304 MH/LiFePO4 250V

Article number: 89800644

NiMH battery, 4.8 V battery voltage

810 – 870 mA battery discharge current (tolerance)

LiFePO4battery, 3.2 V battery voltage

1,285 – 1,375 mA battery discharge current (tolerance)

LED current [mA]

VLED [V] VLED [V]

LED current [mA]

EM converterLED PRO 305 MH/LiFePO4 250V

Article number: 89800645

NiMH battery, 6.0 V battery voltage

820 – 880 mA battery discharge current (tolerance)

LiFePO4battery, 3.2 V battery voltage

1,700 – 1,820 mA battery discharge current (tolerance)

LED current [mA]

VLED [V]

LED current at nominal battery voltage and

min. battery discharge current

LED current at nominal battery voltage and

max. battery discharge current

0 15010050 200 250 300

10

20

30

60

50

40

0

0

20

40

60

80

0

100

15010050 200 250 300

0

20

40

60

80

0

100

120

15010050 200 250 300

www.tridonic.com 11

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

7.4 Testing

DALI Control

A DALI command from a suitable control unit can be used to initiate func-

tion and duration tests at individually selected times. Status flags are set for

report back and data logging of results.

When a DALI bus has not been connected or when a DALI bus is connected

but the DALI default DELAY and INTERVAL times have not been re-set

by sending appropriate DALI commands, then the EM converterLED PRO

will conduct self-tests in accordance with the default times set within the

EEPROM.

These default times are factory pre-set, in accordance with the DALI stan-

dard EN 62386-202, to conduct an automatic function test every 7 days and

a duration test every 52 weeks. Since the DELAY time is factory pre-set to

Zero, all units are tested at the same time. Test times can be changed with a

command over the DALI bus.

5.4 LED Driver compatibility

The EM converterLED emergency unit use 3 pole technology and is compa-

tible with most LED Drivers on the market, however it is important to check

that the rating of the LED Driver does not exceed the values specified below:

• The max. allowed output current rating of the associated LED Driver is

2.4 A peak (current rating of switching relays of EM converterLED)

• The max. allowed inrush current rating of the associated LED Driver is

60 A peak for 1 ms or 84 A for 255 μs (inrush current rating of switching

relay of EM converterLED)

• The max. allowed output voltage (U-OUT) of the associated LED Driver

applied to the EM converterLED output is 450V (voltage withstand

between adjacent contact of the single switching relay of the

EM converterLED)

• The max. allowed LED load of the associated LED Driver is 150 W in

operation. The load must be an LED module.

Check compatibility with the carried out function test (duration at least 5

seconds) individually for each device.

7.3 Status indication

System status is indicated by a bi-colour LED and by a DALI status flag.

LED indication Status Comment

Permanent green System OK AC mode

Fast flashing green

(0,1 sec on – 0,1 sec o)

Function test

underway

Slow flashing green

(1 sec on – 1 sec o)

Duration test

underway

Red LED on Load failure Open circuit / Short circuit / LED failure

Slow flashing red

(1 sec on – 1 sec o)

Battery failure Battery failed the duration test or function

test / Battery is defect or deep discharged/

Incorrect battery voltage

Fast flashing red

(0,1 sec on – 0,1 sec o)

Charging failure Incorrect charging current

Double pulsing green Inhibit mode Switching into inhibit mode via controller

Binary transmission of address

via green/red LED

Address

identification During address identification mode

Green and red o DC mode Battery operation (emergency mode)

7. Functions

7.2 Duration link selection

Emergency lighting LED Driver supplied with duration link in 3 hours positi-

on (position A).

The position of the link will only be read on first power up. If it is changed

afterwards both the battery and mains supply must be disconnected for 10

seconds to enable the EM converterLED to read the new link position on

reconnection of the battery and mains. It will lead to a false battery failure

indication if the link is changed after installation without this reset.

2 hr

3 hr

No duration link

Position A

Duration Link position

1 hr

Position B

6.2 Nearfield communication (NFC)

The NFC Interface allows wireless communication with the LED Driver in

unpowered state. This interface offers the option to write configuration and

to read configuration, errors and events via a suitable NFC antenna and the

companionSUITE software.

Place the NFC antenna directly on the LED Driver to guarantee a correct

communication between the LED Driver and the NFC antenna. Any material

placed between the LED Driver and the NFC antenna can cause a deteriora-

tion of the communication quality. We recommend the use of following NFC

antennas:

www.tridonic.com/nfc-readers.

NFC is complied with ISO/IEC 15963 standard.

After programming the device via NFC power up the device one time for one

second till the deviceANALYSER can read out the parameters.

7.1 Integrated DALI bus power supply voltage (IPS)

This feature can optionally be activated (by default it is disabled).

IPS = 50 mA and IPS_max = 250 mA.

The minimum guaranteed output current is 50 mA.

Imax = 250 mA

Note: The voltage drop in the DALI wires must not exceed 2 V.

No other DALI power supply is allowed to be connected in parallel.

If the IPS function is activated, do not integrate the Driver into an

existing DALI network with active DALI bus power supply.

6. Interfaces / communication

6.1 Control input (DA+, DA–)

The DALI Interface allows communication with the Driver via a suitable DALI

control unit. The DALI interface is not SELV. Install the control cable (DALI

bus) in accordance to the requirements of low voltage installations.

DALI terminals are mains voltage proof.

www.tridonic.com 12

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

The DELAY and INTERVAL time values must be re-set when the emergency

system test times are to be scheduled by a DALI control and monitoring

system.

Note that once the default values have been set to Zero, tests will only be

conducted following a command from the control system. If the DALI bus is

disconnected the EM converterLED PRO does not revert to self-testing

mode.

Note: If the battery is connected the DALI communication is only possible

after power reset.

Addressing

The EM converterLED PRO includes the EZ easy addressing system which

allows addressing and identification by using the bi-colour LED. Binary

address codes given by the LED can be simply converted to the DALI

addresses 0 to 63. For single handed addressing using this method it is

necessary to send a broadcast ident command every 3 to 9 seconds. During

this command the LEDs will be switched off and the indication LED will flash

the 6 bit binary address preceded by a 3 second start indication period.

Commissioning

After installation of the luminaire and initial connection of the mains supply

and battery supply to the EM converterLED PRO the unit will commence

charging the batteries for 20 hours (initial charge). Afterwards the module

will conduct a commissioning test for the full duration. The 20 hours rechar-

ge occurs also if a new battery is connected or the module exits the rest

mode condition. The following automatic commissioning duration test is only

performed when a battery is replaced and fully charged (after 20 hrs) and

the interval time is not set to zero, otherwise the system is expected to per-

form the testing.

Functional test

The time of day and frequency of the 5 seconds function test can be set by

the DALI controller. The default setting is a 5 seconds test on a weekly basis.

Duration test

The time of day and frequency of the duration test can be set by the DALI

controller. The default setting is a duration test conducted every 52 weeks.

For 2 h operation:

The first commissioning duration test has a time of 120 minutes, subse-

quent through life tests are conducted for 90 minutes. When the battery is

changed or disconnected and re-connected the unit will next conduct a 120

minute test.

Prolong time

Prolong time can be set by the DALI controller. This is the delay time bet-

ween return of the mains supply and the end of the emergency operation.

The default prolong time is set as 0 minutes as specified within the DALI

standard.

Indicator LED will stay off for the duration of the prolong time.

Rest Mode / Inhibit Mode

Emergency operation is automatically started when the mains supply is

switched off. If the Rest Mode is activated, the discharging of the battery will

be minimized by switching off the LED output. If the Inhibit Mode has been

activated before the mains supply is switched off, Rest Mode will be automa-

tically switched on if the mains supply is switched off within 15 minutes.

Rest Mode and Inhibit Mode can be initiated by the DALI controller. The

REST command has to be sent after the mains supply has been discon-

nected and whilst the EM converterLED PRO is in emergency operation.

The INHIBIT command has to be sent while the EM converterLED PRO is

supplied by mains.

After a mains reset the EM converterLED PRO exits the Rest Mode. Rest

Mode and Inhibit Mode can both be disabled by sending the RE-LIGHT/

RESET INHIBIT command.

Test switch

An optional test switch can be wired to each EM converterLED.

This can be used to to:

• Initiate a 5 seconds function test: press 200 ms < T < 1 s

• Execute function test as long as switch pressed: press > 1 s

• Reset selftest timer (adjust local timing): press > 10 s

Timer reset functionality

The timer for function and duration test can be set to a particular time of the

day by either pressing the test switch for longer than 10 seconds or cycling

the unswitched line supply 5 times within 1 minute. The timer adjustment

will enable the test start time to be defined manually at time in day when

the timer was reset. It will also disable the adaptive test algorithm thereby

forcing the unit to perform the test at the same time rather than it being

defined by the adaptive algorithm. This function will only work provided the

interval time is greater than zero (automatic test mode enabled). The delay

timer value set when the unit was commissioned will be reloaded in order to

randomise the tests between adjacent units.

BlackBox data recording

Parameters providing information about the application and use are stored

in the EM converterLED PRO. The parameters stored provide information on

the mains, battery, LED output and emergency operation.

The BlackBox can be read out with the masterCONFIGURATOR and

deviceANALYSER.

DALI Controller

DALI controllers and hardware/software solutions are available from Trido-

nic. Please refer to the Lighting controls section.

www.tridonic.com 13

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

8. Battery data

8.1 Battery selection

8.2 Battery charge / discharge data

EM converterLED PRO, 1 / 2 / 3 h, NiMH

Type EM converterLED PRO

303 MH/LiFePO4 250V

EM converterLED PRO

304 MH/LiFePO4 250V

EM converterLED PRO

305 MH/LiFePO4 250V

Article no. 89800643 89800644 89800645

Duration 1 h 2/3 h 1 h 2/3 h 1 h 2/3 h

Battery charge

time

Initial charge 20 h

Fast recharge 10 h 15 h 10 h 15 h 10 h 15 h

Trickle charge continuously

Charging current

Initial charge 110 – 150 mA 280 – 320 mA 110 – 150 mA 280 – 320 mA 110 – 150 mA 280 – 320 mA

Fast recharge 190 – 230 mA 310 – 350 mA 190 – 230 mA 310 – 350 mA 190 – 230 mA 310 – 350 mA

Trickle charge 110 – 150 mA / 4 min.

0 mA / 16 min.

180 – 220 mA / 4 min.

0 mA / 16 min.

110 – 150 mA / 4 min.

0 mA / 16 min.

180 – 220 mA / 4 min.

0 mA / 16 min.

110 – 150 mA / 4 min.

0 mA / 16 min.

180 – 220 mA / 4 min.

0 mA / 16 min.

Discharge current 800 – 860 mA 800 – 860 mA 810 – 870 mA 810 – 870 mA 820 – 880 mA 820 – 880 mA

Charge voltage range10.9 – 1.65 V per cell

Discharge voltage range 1.65 – 1.05 V per cell

1The battery will be charged below 0.9 V. The EM converterLED will indicate a battery fault.

The emergency lighting LED Driver will recharge the battery normally after running the test of 61347-2-7 CL 22.3 (abnormal operating conditions).

EM converterLED PRO, 1 / 2 / 3 h

Type EM converterLED PRO

303 MH/LiFePO4 250V

EM converterLED PRO

304 MH/LiFePO4 250V

EM converterLED PRO

305 MH/LiFePO4 250V

Article no. 89800643 89800644 89800645

Duration 1 h 2/3 h 1 h 2/3 h 1 h 2/3 h

Technology

and capacity

Design Number

of cells

Type Article no. Assignable batteries

NiMH 4,0 Ah

LA cells

stick 1 x 3 Accu-NiMH 3A CON •

stick 1 x 4 Accu-NiMH 4A CON •

stick + stick 2 + 2 Accu-NiMH 4C CON •

stick + stick 2 + 3 Accu-NiMH 5C CON •

remote box 1 x 3 Pack-NiMH 4Ah 3 CON •

remote box 1 x 4 Pack-NiMH 4Ah 4 CON •

LiFePO4 1,5 Ah

18650 cells

stick 1 x 2 Accu-LiFePO4 2A CON • • •

stick 1 x 4 Accu-LiFePO4 4A CON •

stick 1 x 5 Accu-LiFePO4 5A CON •

stick 1 x 6 Accu-LiFePO4 6A CON •

stick + stick 2 + 2 Accu-LiFePO4 4C CON •

stick + stick 2 + 3 Accu-LiFePO4 5C CON •

stick + stick 3 + 3 Accu-LiFePO4 6C CON •

side by side 2 x 1 Accu-LiFePO4 2B CON • • •

side by side 4 x 1 Accu-LiFePO4 4B CON •

side by side 5 x 1 Accu-LiFePO4 5B CON •

side by side 6 x 1 Accu-LiFePO4 6B CON •

www.tridonic.com 14

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

EM converterLED PRO, 1 / 2 / 3 h, LiFePO4

Type EM converterLED PRO

303 MH/LiFePO4 250V

EM converterLED PRO

304 MH/LiFePO4 250V

EM converterLED PRO

305 MH/LiFePO4 250V

Article no. 89800643 89800644 89800645

Duration 1 h 2/3 h 1 h 2/3 h 1 h 2/3 h

Battery charge

time

Initial charge 24 h

Fast recharge 24 h

Trickle charge continuously and battery voltage controlled

Charging current

Initial charge 250 – 290 mA 430 – 470 mA 250 – 290 mA 430 – 470 mA 250 – 290 mA 430 – 470 mA

Fast recharge 250 – 290 mA 430 – 470 mA 250 – 290 mA 430 – 470 mA 250 – 290 mA 430 – 470 mA

Trickle charge1250 – 290 mA / 0 mA 430 – 470 mA / 0 mA 250 – 290 mA / 0 mA 430 – 470 mA / 0 mA 250 – 290 mA / 0 mA 430 – 470 mA / 0 mA

Discharge current 920 – 980 mA 920 – 980 mA 1,285 – 1,375 mA 1,285 – 1,375 mA 1,700 – 1,820 mA 1,700 – 1,820 mA

Charge voltage range22.0 – 3.65 V

Discharge voltage range 3.65 – 2.60 V

1Automatic recharge when battery voltage falls below 3.4 V. Charger o (0 mA) when battery voltage exceeds 3.6 V.

Note: Battery protected against operation at excessive temperatures (charging stopped when battery cell temperature < -5 °C or > 60 °C).

The emergency lighting LED Driver will recharge the battery normally after running the test of 61347-2-7 CL 22.3 (abnormal operating conditions).

2The battery will not be charged below 2.0 V.

8.3 Accu-NiMh

Capacity 4.0 Ah

International designation HRMU 19/90

Battery voltage/cell 1.2 V

Cell type LA

Case temperature range

to ensure 4 years design life +5 °C to +50 °C

Max. short term temperature (reduced life-time) 70 °C

Max. number discharge cycles 4 cycles per year plus

30 cycles during

comissioning

Max. storage time 12 months

at +5 °C to +25 °C

8.4 Accu-LiFePO4

Capacity 1.5 Ah

International designation IFpR 19/66

Battery voltage/cell 3.2 V

Cell type 18650

Case temperature range to ensure

4 years design life +5 °C to +55 °C

6 years design life +5 °C to +45 °C

8 years design life +5 °C to +35 °C

Max. short term temperature (reduced life-time) 70 °C

Max. number discharge cycles 50 cycles total

Max. storage time 12 months

at +5 °C to +25 °C

Only use Tridonic batteries.

Comply with UN 38.3 and IEC 62133 (safety testing) protected against over

charge, over discharge, charging at excessive temperatures, short-circuit and

over current.

8.6 Safety LiFePO4

8.6.1 Deep discharge protection

When the battery remains connected without charging for a long period of time

after the battery cut off of the driver the battery voltage can still drop. To make

sure the cells are not damaged by this voltage drop, the battery protection

prevents the battery from further discharge below 2.0 V.

8.6.2 Overcharge protection

If in case of an error or the use of a wrong driver the battery gets overcharged

the battery protection will disconnect the battery from the driver at a voltage of

3.9 V. A discharge of the battery is still possible after the protection circuit was

triggered to guarantee emergency operation.

8.6.3 Short-circuit protection

In case of a short circuit the battery protection opens the connection to the

driver and the output is therefore free of voltage. The output will be reactivated

again when the short circuit is removed.

8.5 Accupack-NiMH

4.0 Ah

Battery voltage/cell 1.2 V

Cell type LAL

Ambient temperature range

to ensure 4 years design life +5 °C to +35 °C

tc point +40 °C

Max. short term temperature (reduced life-time) 70 °C

Max. number discharge cycles 4 cycles per year plus

4 cycles during

comissioning

Max. storage time 12 months

www.tridonic.com 15

Subject to change without notice. Information provided without guarantee.

Data sheet 11/20-EM111-1

Emergency lighting units

EM converterLED

8.7 Storage, installation and commissioning

Relevant information about storage conditions, installation and commissioning

are provided in the battery datasheets.

Activating NiMH batteries:

In order to activate new batteries, 2-3 full charge-discharge cycles could be

needed. This activating process is defined by charging (24 h) and discharging

(1/2/3 h) of the batteries. If the first duration test fails, please repeat the test

after a 24 hour charging period.

9. Miscellaneous

9.2 Maximum number of switching cycles

EM converterLEDs are tested with 50,000 mains switching cycles of the

associated LED driver.

9.3 Battery replacement

After a battery replacement and a subsequent full charge cycle (24 h) a

duration test is mandatory to prove that with the new battery the rated

duration is achieved.

9.4 Black Box data recording

Several parameters in respect to the application and use of the product are

stored in the EM converterLED. The parameters provide information about

the mains, battery, LED output and emergency operation.

The Black Box can be read out with the masterCONFIGURATOR and

deviceANALYSER via DALI and NFC.

In order to allow a safe detection of a battery replacement through the “Black

Box data recording” follow the below described process.

Battery replacement

1. Disconnect mains

2. Disconnect battery

3. Reconnect and disconnect mains while no battery is not connected1

4. Connect new battery

5. Connect mains2

1Battery fault is safely recorded by the EM converterLED

2Connection of new battery is recorded by the EM converterLED

9.1 Conditions of use and storage

Humidity: 5 % up to max. 85 %,

not condensed

(max. 56 days/year at 85 %)

Storage temperature: -40 °C up to max. +80 °C

The devices have to be acclimatised to the specified temperature range (ta)

before they can be operated.

8.6.4 Overtemperature protection

The battery is protected against temporary thermal overheating. If the tempera-

ture limit is exceeded the further charging of the battery is no longer possible.

The temperature protection is activated below approx. 0 °C and above approx.

+60 °C. The discharging of the battery is still possible to guarantee emergency

operation.

9.5 Additional information

Additional technical information at www.tridonic.com →Technical Data

Guarantee conditions at www.tridonic.com →Services

Life-time declarations are informative and represent no warranty claim.

No warranty if device was opened.

This manual suits for next models

6

Table of contents

Other Tridonic DC Drive manuals

Popular DC Drive manuals by other brands

ABB

ABB ACS850 series Quick start up guide

Magnetek Elevator

Magnetek Elevator Axial Flux HPV900 2 Series Start guide

Parker

Parker Compax3 Series operating instructions

Pentair

Pentair Pentek Intellidrive Series owner's manual

Wittenstein Alpha

Wittenstein Alpha LK Series operating manual

Magnetek

Magnetek Impulse G+ series 4 Technical manual

Vacon

Vacon 100 INDUSTRIAL Application guide

ABB

ABB ACS260-04 Series user manual

Festo

Festo CMMT-AS-C2-11A-P3 S1 Series instructions

INVT

INVT Goodrive3000 Series Operation manual

Motion

Motion DM805-A Software Operation manual

STG-BEIKIRCH

STG-BEIKIRCH M2 Series Technical information and operating instruction