Shimaden CP3705 User manual

User’s Manual

Thin/Plug-In Alarm Setter

CP3705

MCP3705-1AE

Aug., 2014

Thank you very much for employing Shimaden products.

Upon receipt of the product(s) please check the affixed label to

make sure the specifications shown conform to your requirements.

If you find any discrepancies and/or any damage on the product(s),

please contact Shimaden or its local representatives.

1. Introduction

For proper operation of the instrument(s), we recommend that you

carefully read this manual prior to operation. The manual should be

retained for future reference.

2. For safety operation

Be sure to observe the following safety clauses in your operation of

the instrument(s). Shimaden cannot undertake any responsibility

and guarantee for any damage and/or loss caused by improper

operation contrary to or neglecting these clauses.

3. Note for operation/installation

Be sure to observe the following clauses for making the best use

of the instrument(s). When the following clauses is disregarded,

the performance of the instrument(s), cannot be guaranteed.

For handling:

■Dropping or throwing-out may cause serious damage to the

instruments.

■Do not splash over or dip in water. For installation, select a

place where no condensation occurs.

■Avoid operation or storage in sunny, high-temperature, dusty,

humid or vibrant environment.

On Power Supply:

Check the power rating described in the specification label placed

on the unit(s).

■Rating 100-240VAC 50-60Hz 6.5VA max.

(Input range:85V-264VAC 47-63Hz)

■Rating 24VDC 2.0W max. (Input range: 24VDC±10%)

For installation:

■The instrument(s) should be installed indoors.

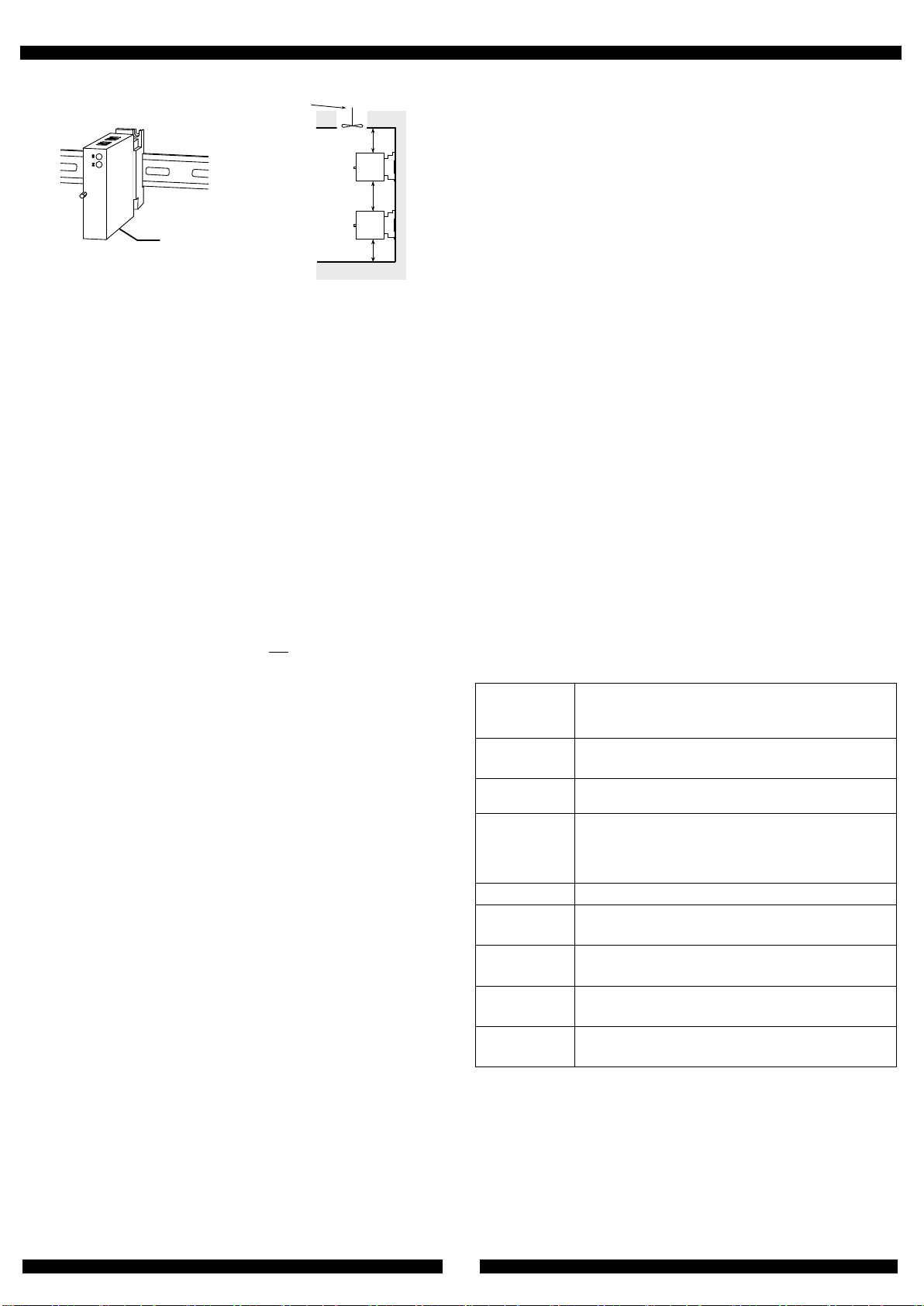

■As shown in the section 9 “Mounting and Demounting”, install the

unit by Din-Rail mounting or Wall mounting.

■Operating environmental conditions

・Ambient temperature: -5 to +55℃

・Humidity: 5 to 90%RH

・Altitude up to 2000 meters

■Be sure that the ventilation in the chassis can be secured.

■Be careful not to ground the minus(-) terminal of the power

supply.

■The instrument should be installed as shown in the sketch below

namely, in such a position as the front panel label can be

readable in the right direction.

■For effective heat radiation, ample space (at least 100mm)

should be allowed at the top and the bottom of the units.

Also when the units are installed in multiple stacks, the space

between each stack should be at least 130mm.

Disregard of this clause may cause fatal

harm of serious bodily injury due to or

electric shock.

Disregard of this clause may cause bodily

harm or damages to nearby objects due to

electric shock or other accidental

happenings.

■

For wiring to the terminal block, make sure that the power is

turned OFF. Otherwise, electric shock may be caused.

■Do not break up, do not give any modification to modules, and do

not replace Power fuse at user’ side. Otherwise, fire or electric

shock may be caused.

■In case any foreign matters(metal chip, water, liquid, etc.)

penetrate inside modules, immediately remove the power wiring

and contact Shimaden or its distributor.

■When Main Unit is intended for use in the equipment for

transportation, communication, power-generation control and

medical care which require higher reliability and safety

characteristics. A special consideration should be taken in safety

designing for preventing malfunction of such an equipment as a

whole system.

■

Do not operate the instrument such an environment as

Flammable gases or dusts are present. Otherwise, explosion may

be caused.

■Avoid the installation of the instruments in the vicinity of any

combustibles.

■Because no power switch is provided on the instrument, the power

supply of the instrument cannot be turned OFF on the instrument

side. So, be sure to install a power shut-down breaker in the power

source of the instrument, and place the breaker close to the

instrument for the convenience of operation. And the breaker should

be marked as “disconnecting device” for the instruments.

■

Check out that the power supply voltage, input signal value and

terminal location conform to the published specifications of the

instrument(s). An operation under conditions outside the

specifications, heating up or burn out of the instrument(s) may

result.

■Avoid using the instrument(s) in such a place as the ambient

temperature fluctuates rapidly to cause condensation.

■Avoid operation or storage in such locations as corrosive gases are

present or splash of any chemical is feared.

■The units are hot-swappable, but this operation should be avoided

as for as possible.

■For the sake of safety, the installation and wiring should be taken

care of by fully-knowledgeable and well experienced persons.

!

WARNING

CAUTION

!

!

WARNING

CAUTION

!

User’s Manual Thin/Plug-In Alarm Setter CP3705

.

2

Bot t om

130mm mi ni mum

Cool i ng Fan

or Vent

100mm mi ni mum

100mm mi ni mum

On wiring:

■Connections to the instruments should be made to the terminal

block. For assignment of the terminal block, refer to section 6.

Screwing Torque: 0.8-1[N・m] (recommendable)

■Lead wire shall be twisted conductor with enough flexibility.

Nominal cross-sectional area of leadwire conductor: 0.5 to

2.0mm2 (recommendable).

■The connection of the lead wire to the terminal block shall be

made with insulated crimp terminals attached on an end of the

wire. Without the insulation, short-circuit or electric shock may

occur. The crimp terminal of 0.7-1.0mm thickness is

recommended.

Only up to 2 crimp terminals can be connected to 1 (one)

terminal screw.

※In this case, the thickness of the crimp terminal should be

smaller than 0.8mm.

To satisfy the performance of instrument(s)

■In order to lessen the influence of noise etc, the input/output

wire and power supply wire should not be used in a same

bundle or same conduit. They should be installed separately

with the minimum distance of 200mm.

■Avoid wiring of signal lines in the vicinity of such equipment as

electric motors, large scale transmitters, etc. , generating

magnetic field or electromagnetic wave. If inevitable, anti-noise

measure such as employment of shielded wire shall be

indispensable.

■At least 30 minutes of warm-up is required before operation.

■Any sensor or equipment to be connected to the instruments

should be selected in consideration of the input/output

impedance of the same (For the detailed specifications of the

unit, refer to section 4 or the description in URL:

http://www.shimaden.co.jp/).

Special note for CE marking

■The instrument is designed to conform EMC Directive and Low

Voltage Directive listed below;

EMC Directive (2004/108/EC)

Standard conformity EN61326-1 Class A

Low Voltage Directive (2006/95/EC)

Standard conformity EN61010-1/IEC61010-1

Installation category Ⅱ

Pollution degree 2

■The instruments should be install in a control panel.

■The instrument maintains basic insulation between input and

output, output and GND. Prior to installation, check that the

insulation class of the instrument satisfies system

requirements.

■When the instrument is installed in a control panel, the

measures to be taken for CE marking conformity may vary with

the type of devices connected, wiring to the instrument(s) or

structure of the control panel, etc. Therefore, check the control

panel as a whole to conform to CE marking regulations.

4. About the product

CP3705 compares DC input signal with two set points setting with

rotary switch of front panel of unit, and outputs the relay contact

signal.

Features

■Each trip point is set separately with rotary switches on front

panel. Setting Range: 0-99% (in steps of 1%)

■The contact part of unit and socket is gold-plated

(0.2μm) to ensure reliability and long-term stability.

■High Dielectric Strength of 2000VAC across Input-Output-

Power input-Ground

■The power unit can deliver AC power ranging from 85 to 264V

steplessly without switching to effectively meet varied power

requirements.

■Plug-in type for better maintainability

■Drop-proof terminal screws for ease and safety of installation

■Fuse installed in power line as standard attachment

■Anti-humidity coating on PCB for improved environmental

protection.

Specifications

Input

Resistance

Voltage input: 1MΩ min.

(1MΩ minimum without power)

Current input: 250Ω

Allowable

Input Voltage

Voltage input: 30VDC max. continuous

Current input: 40mADC max. continuous

Output Signal

Two independent type C relay contact closure

signals

Trip point

Setting: Setting with Rotary switch of front panel

Range: 0-99% set by 1% step

Stability: ±0.5% of span

Hysteresis: 1.0%±0.3% of span

Monitor Lamp

Red LED lights when relay is activated.

Power

Failure Effect

COM-NC of each output turn ON.

Relay Action

Limitation

To be ready for action about 2sec after power-up.

Temperature

Characteristics ±0.15% of span @ 10℃variation

Response

Time

150msec. max. 90% set @100% step input

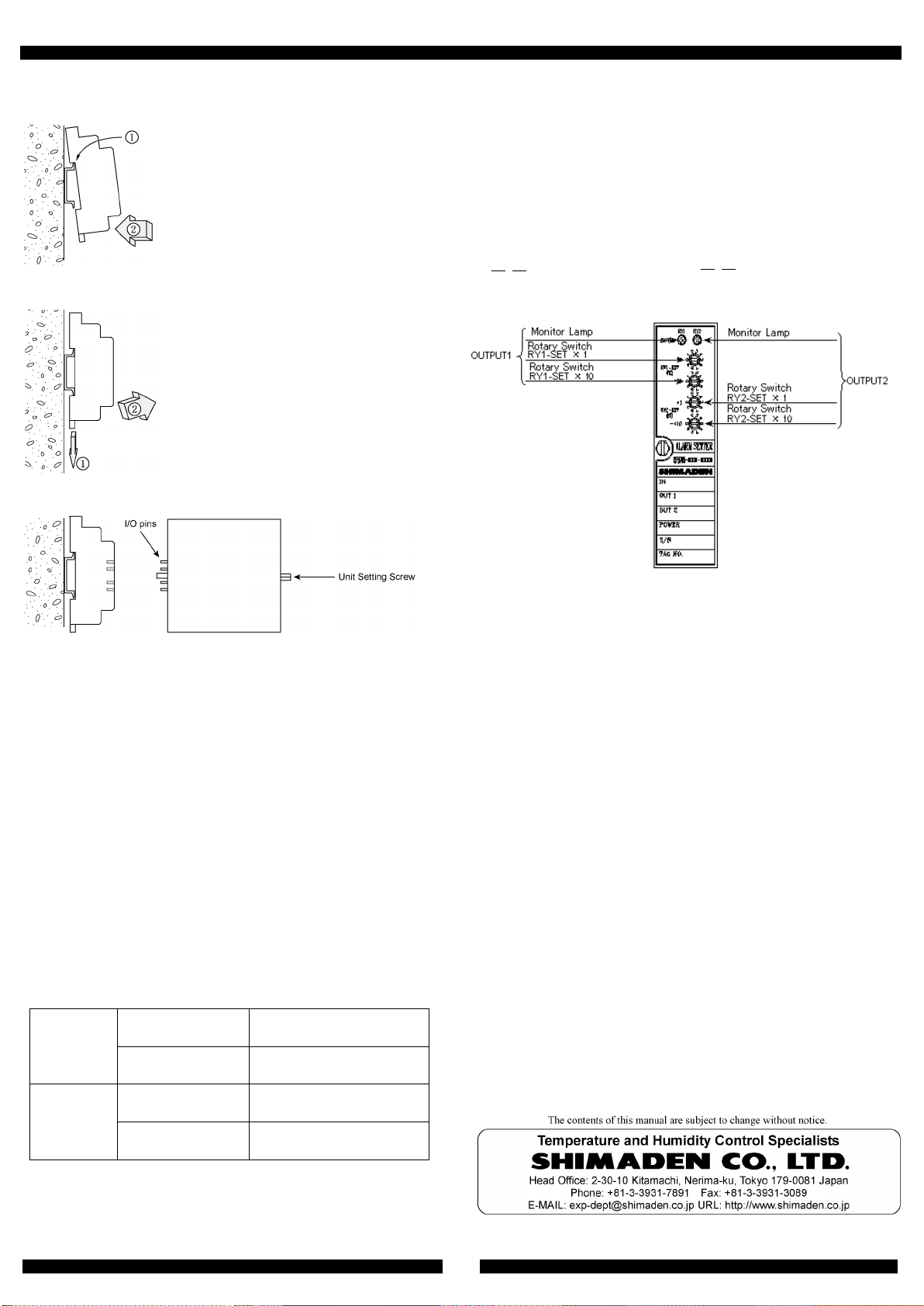

Installing Position Installation Example

User’s Manual Thin/Plug-In Alarm Setter CP3705

.

3

5. Outer Dimensions and Terminal Signal Assignment

6. Connection Diagram

7. Connection to terminals

The following measures should be taken prior to the connection.

8. Output Connection

When any Inductive load, such as electric motor, etc. is to be

connected, be sure to connect a protection circuit for the relay

contact.

9. Power Line Connection

The terminal for power supply connection, pin number ①and

②, are covered with plastic plate for safety. (Refer to the sketch

(1).)

Lift the plastic cover plate and connect the power line to the

terminals. (Refer to the sketch (2).)

Return the cover plate to the original position. (Refer to the

sketch (3).)

(1) (2) (3)

45

12

P/+ N/-

45

45

Ter mi nal Cover

For the sake of safety, the wiring work should be performed with no

power supplied to the instrument. After wiring, check that all

terminal screws are securely fastened.

Insulation

Resistance

100MΩ min.

(

@500V DC

)

Across Input, Output-1, Output-

2, Power Supply

and Ground, mutually

Dielectric

Strength

Input/ Out-1/Out-2/ [Power Supply, Ground]:

2000VAC for 1 minute (cutoff current: 0.5mA)

Power Supply/ Ground:

2000VAC for 1minute (cutoff current: 5mA)

Relay

Contact

Rated Load: 5A 125VAC, 5A 30VDC

Maximum Voltage: 250VAC, 30VDC

Maximum Current: 5A(N.O.) / 3A(N.C.)

Electrical Life Span: 5A 250VAC(N.O.) 50k times

Frequency 1800 times/h

5A 30VDC(N.O.) 100k times

Frequency 1800 times/h

Physical Life Span: 5,000,000 times

Frequency 18000 times/h

Relay Response time: 3msec.

Surge

Withstand

Capability

Tested for ANSI/IEEE C37.90.1-1989

Storage

Temperature

-10 to +60°C

①Loosen the terminal screw.

②Insert tip of a screw driver bit

under the washer and push it

up to make ample room to

receive cable

Example of

AC power connection

Example of

DC power connection

Protection Circuit

(Barrister, CR circuit, etc.)

Protection Circuit

(Diode, Barrister CR circuit,

etc.)

POWER

SUPPLY

P(+)

N(-)

OUTPUT1

OUTPUT2

GND

+

-

INPUT

Terminal

No

8

10

11

7

9

6

5

4

2

1

COM

NO

NC

COM

NO

NC

Inductive

Load

COM

NO

NC

Inductive

Load

COM

NO

NC

User’s Manual Thin/Plug-In Alarm Setter CP3705

.

4

10. Mounting and Demounting

Mounting Terminal Block Socket

Demounting Terminal Block Socket

Installation to socket / Removal from socket

Installation to socket

①First, identify the top and the bottom of the unit and insert I/O pins

straight into corresponding pin slots(receptacles) on the socket.

②Tighten the set screw to fix the unit firmly on position.

Removal from socket

②Loosen the set screw.

②Pull out the unit carefully not to bend I/O pins.

11. Trip point Setting

Trip point is set by rotary switch at front panel of unit.

Refer to the following table, rotate the rotary switch by driver, etc.

and set trip point.

※Note for trip point setting

Set trip point without power supply.

When operating the rotary switch for limit value setting special

care should be taken to confirm ”clicking” the dial indicator stay in

between (on the halfway to) the desired right setting positions.

OUTPUT-1

RY1-SET×10 Place of ten of set point

(%) for input span

RY1-SET×1

Place of one of set point

(%) for input span

OUTPUT-2

RY2-SET×10

Place of ten of set point

(%) for input span

RY2-SET×1

Place of one of set point

(%) for input span

Ex.) When input signal is 0-5V and trip point of output-1 is set 4V

and trip point of output-2 is set 2.25V:

Since 4V is 80% of input span 5V, set RY1-SET×10 to 8 and

RY1-SET×1 to 0.

Since 2.25V is 45% of input span 5V, set RY2-SET×10 to 4 and

RY2-SET×1 to 5.

12. Maintenance

Checking of the adjustment and calibration in every 2 years is

recommended to secure accurate operation.

13. Warranty

WARRANTY

Shimaden's hardware products are warranted against defects in

materials and workmanship for a period of seven (7) year after the

date of shipment. Shimaden shall, at its option, either repair or

replace hardware products that prove to be defective, if Shimaden

receives notice of such defects during the warranty period.

Shimaden does not warrant that the operation of the hardware shall

be uninterrupted or error free. No other warranty is expressed or

implied. Shimaden specifically disclaims the implied warranties of

merchantability and fitness for a particular purpose.

LIMITATION OF LIABILITY

The warranty and remedies set forth above are in lieu of all other

warranties expressed or implied, oral or written, either in fact or by

operation of law, statutory or otherwise. Shimaden neither

assumes nor authorizes any other liability in connection with the

sales, installation, or use of its products. In no event shall

Shimaden be liable for direct, indirect, special, incidental, or

consequential damages (including loss of profits) of any kind arising

out the sale, installation or use of its products.

Hook the upper edge of the cavity on

the rear of the socket at the upper

blade of the rail ①, then push the

lower part of the socket against the

lower blade of the rail so as to make

the slide clamp engaged firmly with

the rail.

Push the slide clamp downward with a

screw driver bit or the like ①, and pull

the lower part of the socket toward

you ②.

80%

│└Set RY1-SET×1 to 0.

│

└

Set RY1-SET

×

10 to 8.

45%

│└Set RY2-SET×1 to 5.

│

└

Set RY2-SET

×

10 to 4.

Popular Security System manuals by other brands

Pilz

Pilz PSEN ml b 1.1 operating manual

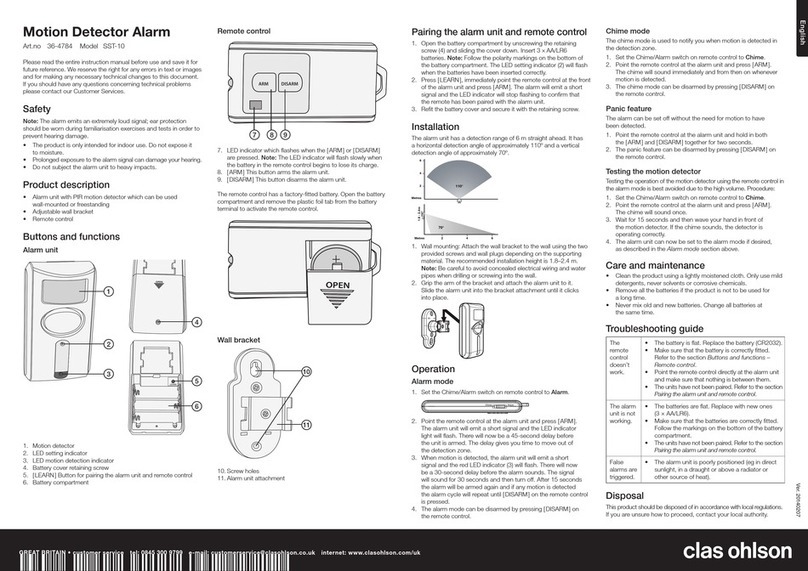

Clas Ohlson

Clas Ohlson SST-10 user manual

SVAT

SVAT ClearVu 1202 instruction manual

PPP Taking Care

PPP Taking Care Personal Alarm Setup & user guide

DSC

DSC PTD1610-SCW Installation instructions and operators manual

DirecTV

DirecTV LifeShield Home Security Upgrade manual

Swann

Swann DVRx-2500 Setup guide

Bosch

Bosch FLM-420-RLE-S installation guide

Abra

Abra Kit-ABRA-101 quick start guide

Perenio

Perenio PEKIT01 quick start guide

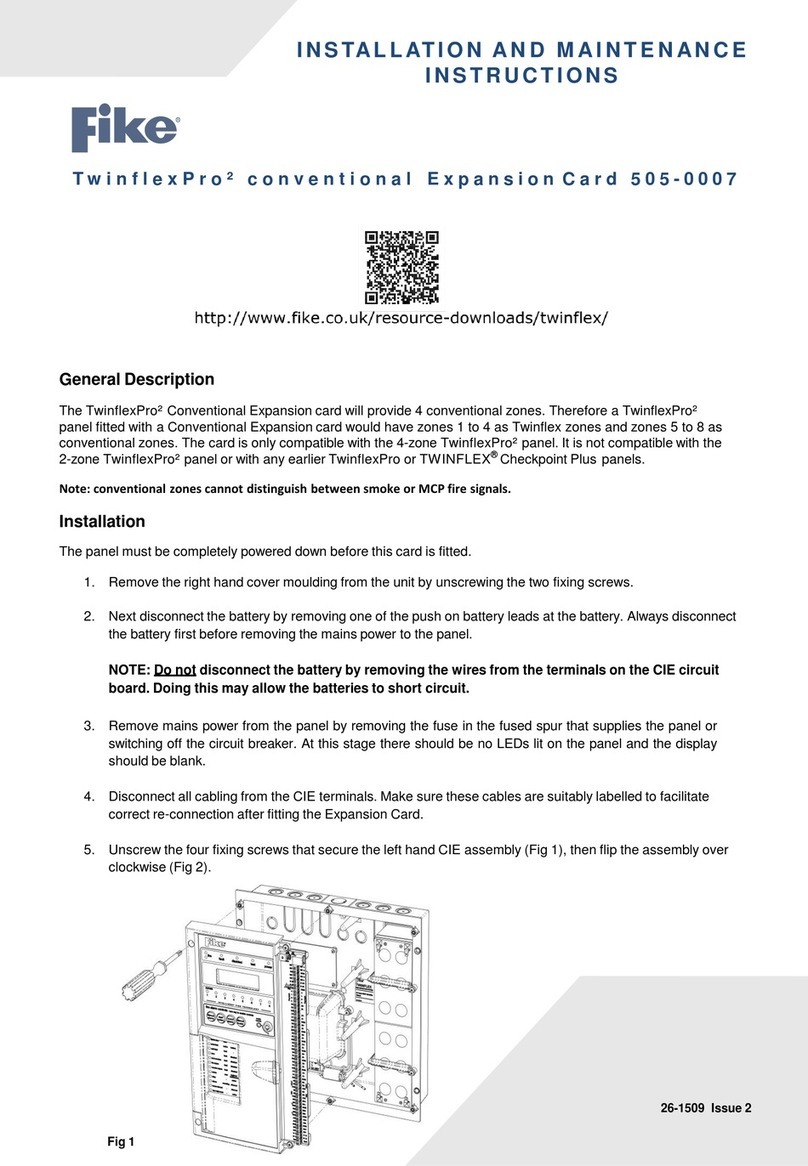

Fike

Fike TwinflexPro2 conventional Expansion Card Installation and maintenance instructions

Star Headlight & Lantern

Star Headlight & Lantern Star X FIRE 200A Series manual