6

S19-320B, S19-320E Installation

11/17/08 Bradley Corporation • 215-693B Rev. F; ECN 07-512A

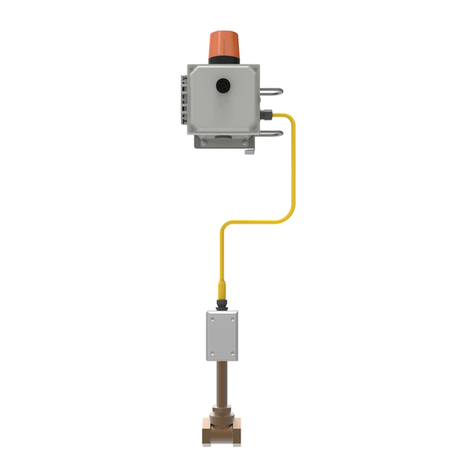

Test The Alarm System

NOTE: Testing the alarm for the first time using the drench shower may expose the flow switch to an unnecessary water

hammer since the downstream piping may be empty of water. The flow switch is designed to withstand such a water

hammer, but using the smaller eyewash flow is recommended.

1. Apply power to the alarm branch circuit. The alarm should remain in the “OFF” position.

2. Make sure the alarm horn cut-out switch is in the “ON” position. This switch is located on the PVC tee beneath the alarm.

3. Open the eyewash valve. The alarm should sound and the strobe light flash shortly after water flows from the system.

4. Use the alarm horn cut-off switch to silence the horn. Flipping the switch down one or two clicks (either the horizontal or

DOWN position will work) should shut off the horn but allow the strobe light to keep flashing.

5. Shut off the eyewash flow valve. The strobe light should stop flashing.

6. Reset the alarm horn cut-off switch to its uppermost “ON” position.

7. Repeat the tests in procedures 1-6 above, this time using the drench shower only.

Troubleshooting

1. If the alarm (horn and strobe light) does not operate when water flows:

• Check that the circuit breaker or fuse is supplying power to the alarm.

• Check that the direction of water flow corresponds to the arrow on the flow switch body.

• Check that water flow is sufficient (4 gallons per minute is required).

• Check all electrical connections, including the power supply and the quick-connect cable from the alarm to the flow

switch.

Strobe flashtube replacement

1. Loosen the locking band and remove the clear plastic dust cover from the top of the strobe light.

2. Loosen (but do not remove) the three screws holding the amber dome in place. Rotate the dome slightly clockwise and

remove the dome.

3. Remove the flashtube assembly by simply unplugging it from the top of the strobe light.

4. Replace the flashtube assembly with a new one BUT avoid touching the flashtube glass with your fingers. Be sure the

flashtube assembly is firmly plugged into the socket.

5. Reattach and tighten the amber dome.

6. Reattach and tighten the clear dust cover.

7. Test the alarm as described in “Test the Alarm System.”

Alarm system maintenance

The Bradley Alarm System is designed to be virtually maintenance free. An occasional damp cloth wiping of the clear dust cover is

all that is needed to ensure maximum visual attention-getting ability.

The alarm horn is factory-set at the loudest possible sound level, 103 decibels at 10 feet. This sound level will attract

attention in shop areas with loud background noise levels or at large distances outdoors. If the alarm is used in a more quiet

environment or over shorter distances, the sound level is easily adjustable to lower levels (down to 78 decibels at 10 feet)

with a simple external adjustment.

• Use 1/16" Allen wrench to adjust the sound to the appropriate alerting level. The adjusting hex screw is located on the

front centerline of the horn grille about an inch from the bottom. Turning the hex screw clockwise quiets the horn.

Remote Sensing Option

If remote sensing is wanted, remove the pipe plug from the back of the junction box. Connect the extra black wire (common to both

switch arrangements) and the blue wire (normally open switch arrangement) or red wire (normally closed switch arrangement) to

your application per local electrical codes. The switch is rated at 5 amps at 120 volts and is isolated from the contacts used by the

alarm system. Your connection should be water tight.