2

WARNING

• The calipers and rotor will become hot when

the brakes are operated, so do not touch them

while riding or immediately after dismounting

from the bicycle, otherwise you may get

burned. Check that the brake components have

cooled down sufficiently before attempting to

adjust the brakes.

• The required braking distance will be longer

during wet weather.

Reduce your speed and apply the brakes early

and gently.

• If the road surface is wet, the tires will skid

more easily. If the tires skid, you may fall off

the bicycle. To avoid this, reduce your speed

and apply the brakes early and gently.

• Always make sure that the front and rear

brakes are working correctly before you ride

the bicycle.

• Be careful not to allow any oil or grease to get

onto the rotor and brake pads, otherwise the

brakes may not work correctly.

• If any oil or grease do get on the pads, you

should replace the pads. If any oil or grease

gets on the rotor, you should clean the rotor. If

this is not done, the brakes may not work

correctly.

• Use only genuine Shimano mineral oil. If other

types of oil are used, it may cause problems

with brake operation, and cause the system to

be unuseable.

• Be sure to use only oil from a freshly-opened

container, and do not re-use oil which has been

drained from the bleed nipple. Old oil or

already-used oil may contain water which could

cause vapor lock in the brake system.

• Be careful not to let water or air bubbles to get

into the brake system, otherwise vapor lock

may occur. Be particularly careful when

removing the cover of the reservoir tank.

• Vapor lock may occur if the brakes are applied

continuously. To relieve this condition,

momentarily release the lever.

• If fluid leaks occur, immediately stop using the

brakes and carry out the appropriate repairs. If

you continue riding the bicycle while fluid is

leaking, there is the danger that the brakes

may suddenly stop working.

• Check that the quick release lever is on the

right side (the opposite side to the rotor). If the

quick release lever is on the same side as the

rotor, there is the danger that it may interfere

with the rotor, so check that it does not

interfere.

• It is important to completely understand the

operation of your bicycle's brake system.

Improper use of your bicycle's brake system may

result in a loss of control or an accident, which

could lead to severe injury. Because each bicycle

may handle differently, be sure to learn the

proper braking technique (including brake lever

pressure and bicycle control characteristics) and

operation of your bicycle. This can be done by

consulting your professional bicycle dealer and

the bicycle's owners manual, and by practicing

your riding and braking technique.

• Obtain, read and carefully service instructions

when installing parts. A loose, worn, or

damaged parts may cause injury to the rider.

We strongly recommend that only genuine

Shimano replacement parts be used.

• Read these Technical Service Instructions

carefully, and keep them in a safe place for

later reference.

■Handling the mineral oil

• Use safety glasses when handling, and avoid

contact with eyes. Contact with eyes may result

in irritation.

• Use gloves when handling. Contact with skin

may cause a rash and discomfort.

• Inhalation of oil mist or vapors may cause

nausea. Cover nose and mouth with a respirator

type mask and use in a well ventilated area.

• Do not drink. May cause vomiting or diarrhea.

• Keep out of reach of children.

• Do not cut, heat, weld or pressurize the oil

container, as this may cause explosion or fire.

■Emergency Care

• In the event of eye contact, flush with fresh

water and seek medical assistance immediately.

• In the event of skin contact, wash well with

soap and water.

• If mist or vapor is inhaled, go immediately to

an area with fresh air. Cover up with a blanket.

Stay warm and stable and seek professional

medical advice.

■Disposal of Used Oil

• Follow local county and/or state codes for

disposal. Use care when preparing oil for

disposal.

■Directions

• Keep the container sealed to prevent foreign

objects and moisture from getting inside, and

store it in a cool, dark area away from direct

sunlight or heat.

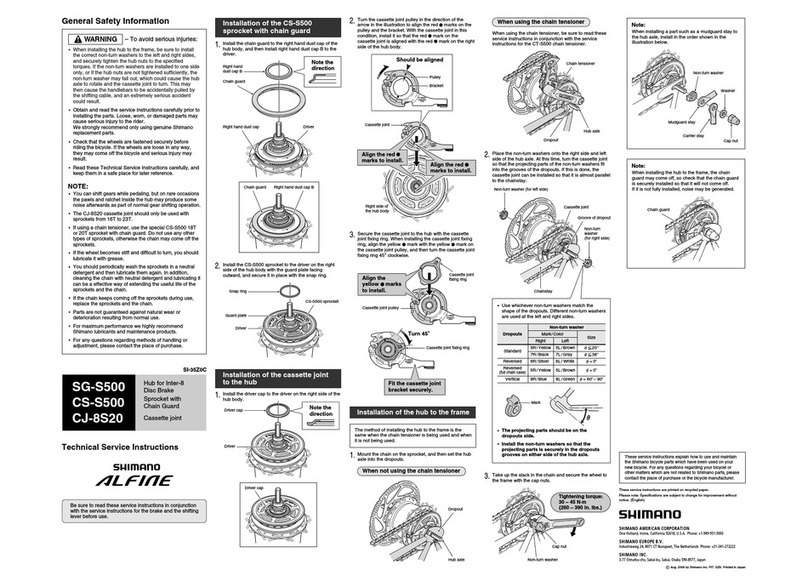

General Safety Information

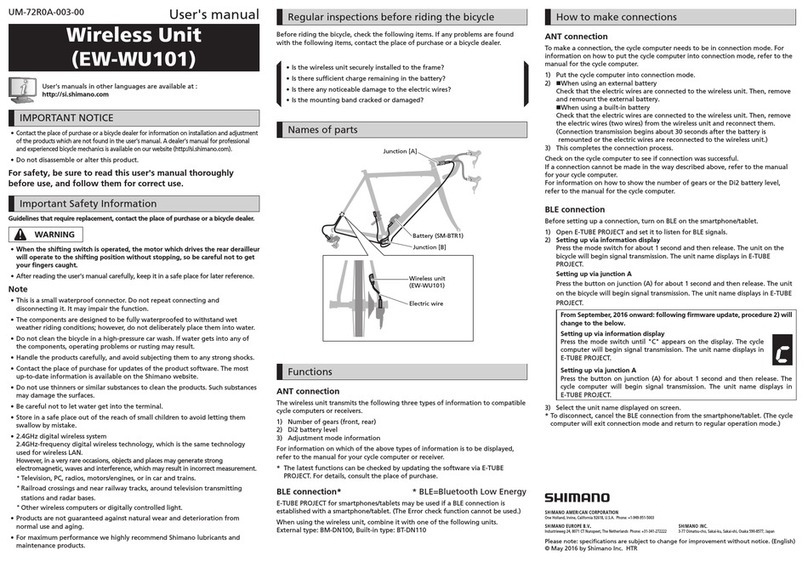

Vapor lock is a phenomenon in which the oil

inside the brake system becomes heated,

which causes any water or air bubbles inside

the brake system to expand. This can then

result in a sudden increase in the brake lever

stroke.

CAUTION

Hydraulic

Disc Brake