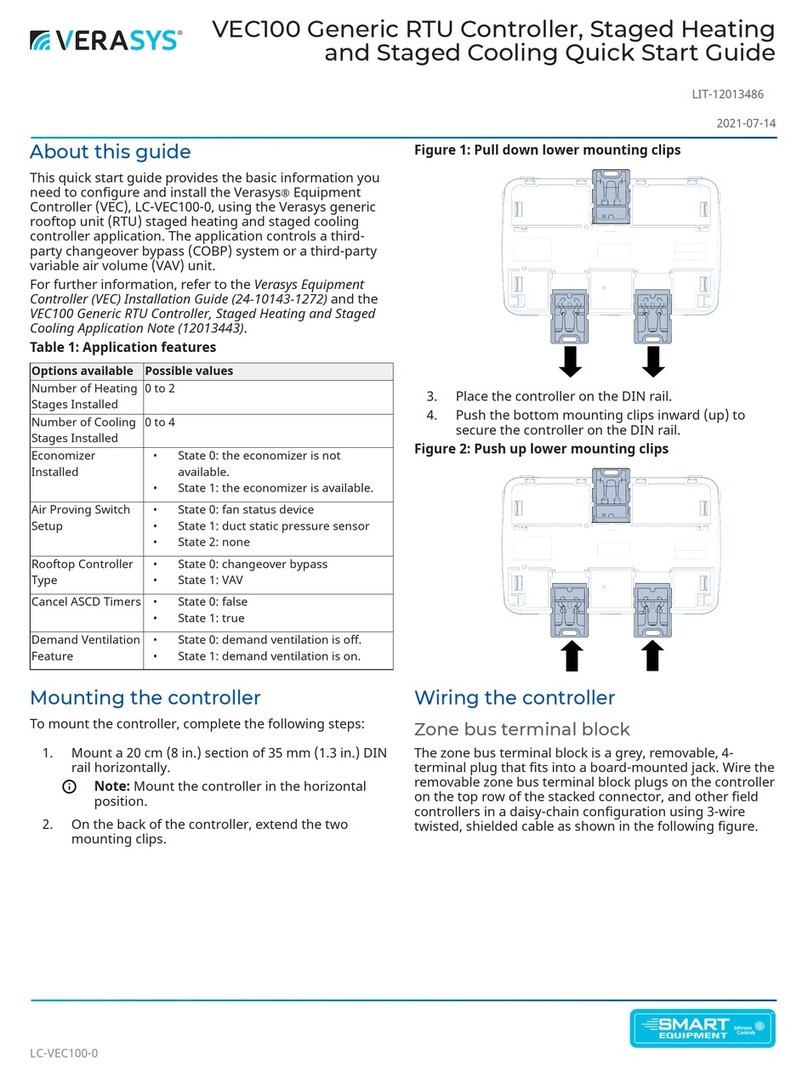

Mounting

Observe the following guidelines when mounting a PCV:

Note: When the air supply to the VAV box is below

10°C (50°F), make sure that any condensation on the

VAV box, particularly on the damper shaft, does not

enter the FX-PCV

• Ensure that the mounting surface can support the

controller and any user-supplied enclosure. Mount

the controller vertically above the damper shaft to

allow any shaft condensation to fall away from the

controller. Additional measures may be required in

some installations.

• Mount the controller on a hard, even surface whenever

possible.

• Use shims or washers to mount the controller securely

and evenly on the mounting surface.

• Mount the controller in an area free of corrosive vapors

that matches the ambient conditions specified in the

Technical specifications section.

• Provide sufficient space around the controller for cable

and wire connections and adequate ventilation through

the controller (at least 50 mm [2 in.] on the top, bottom,

sides, and front of the controllers).

• Mount the VMA vertically above the damper shaft to

allow any shaft condensation to fall away from the

VMA.

Do not mount the controller in areas where

electromagnetic emissions from other devices or wiring

can interfere with controller communication.

• Avoid mounting the controller on surfaces with

excessive vibration.

• When using the PCV1930 to replace an FX-PCV1610 or

FX-PCV1620 controller, plug the unused open hole in

the duct work from the original FX-PCV mounting if

possible. Plug the hole using the sheet metal screw

from the original installation (preferred option).

On panel or enclosure mount applications, observe these

additional guidelines:

• Do not install the controller in an airtight enclosure.

• Mount the controller so that the enclosure walls do

not obstruct cover removal or ventilation through the

controller.

• Mount the controller so that the power transformer

and other devices do not radiate excessive heat to the

controller.

To mount the controllers, complete the following steps:

1. Set all the switches on the controller to their known

settings.

2. Place the controller in the proper mounting position

on the damper shaft so that the wiring connections

are easily accessible. Make sure the controller base is

parallel to the VAV box (perpendicular to the damper

shaft). If needed, use a spacer to offset tipping of the

controller caused by the shaft bushings.

Note: Use the alignment marks to center the

captive spacer to ensure sufficient movement in

either direction.

3. Secure the self-drilling No. 10 screw through the

captive spacer (Figure ) with a power screwdriver

and 100 mm (4 in.) extension socket. Otherwise, use

a punch to mark the position of the shoulder washer,

and then drill a hole into the VAV box using a 3.5

mm (9/64 in.) drill bit. Insert the mounting screw

and tighten against the spacer. For the FX-PCV1628

models, use the additional 1.25 inch screw to mount

to one of the two holes provided near the actuator

opening (Figure ) to mount the controller.

Important: Do not overtighten the screw, or

the threads may strip. If mounting to the VAV

box, make sure the screws do not interfere with

damper blade movement.

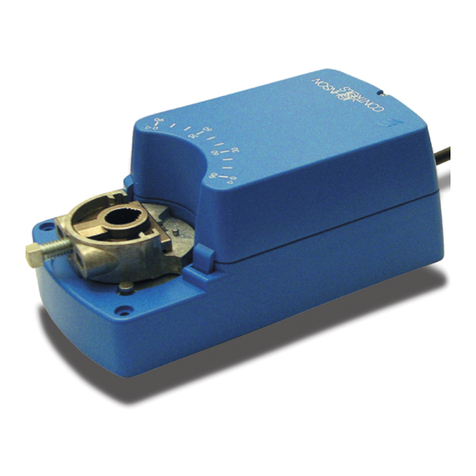

4. Locate the damper position using the typical

marking on the end of the damper shaft as shown in

the following figure.

Figure 2: Typical Damper End Shaft Icons

5. Note the direction, clockwise (CW) or

counterclockwise (CCW), required to close the

damper. Grasp the damper shaft firmly with pliers,

and either manually close the damper for 90° boxes

or manually open the damper for 45° or 60° boxes.

6. Push down and hold the Manual Override button

(see FX-PCV1930 physical features) and turn the

controller coupler until it contacts the mechanical

end-stop at either the full-closed (90° boxes) or full-

open (45° and 60° boxes) position.

7. If the damper for a 90° box closes CCW, rotate the

coupler to the CCW mechanical limit. If the damper

for a 90° box closes CW, rotate the coupler to the CW

mechanical limit. The open end-stop is automatically

set for 90° boxes. For 45° and 60° boxes, hard stops

must be provided at both full-closed and full-open

damper positions. By installing the controller at the

full-open position, the controller provides the open

stop for 45° and 60° boxes. The closed damper seal

provides the full-closed stop.

Note: The integrated actuator has a stroke

time of 60 seconds for 90° of travel. The stroke

time is the amount of time (in seconds) that

it takes the actuator to move from the fully

closed to fully opened position or from fully

open to fully closed position. For proper

operation, the actuator stroke time must be

configured in the CCT application based on

the actual time it takes the actuator to drive

the damper. The default setting is 60 seconds

(for 90° VAV boxes). For 45° and 60° VAV boxes,

the actuator stroke time must be adjusted.

Refer to Controller Tool Help (LIT-12011147) for

instructions on setting the actuator stroke time

in the application.

FX-PCV1930 VAV Controller Installation Guide4