Shimpo DT-5TG User manual

Aros

COOOGOOOorStG

0.0

:

http://www

1718veb.

net

FEATURES:

©

Multiple

purpose

digital

tachometer

measures

rotational,

linear,

and

flow

rate

speeds.

If

desired,

this

unit

can

also

function

as

an

elapse

time

counter

or

ratiometer.

New

Digital

Tachometer

@An

insertion

of

new

cassette

type

adapter

increases

functions.

(CASSETTE

TYPE

OPTIONAL

UNIT)

(including

DC

POWER

MODEL)

Instruction

Manual

@

All

functions

are

easily

set

via

front

panel

keys.

@Easy

mounting,

no

brackets

or

screws

are

required.

e

Any

AC

voltage

between

85

and

264V

will

power

to

DT-5TG.

{DC

powered

DT-5TG-DC:DC9

~35

V)

*

Thank

you

for

your

purchase

of

SHIMPO

new

Digital

Tachometer/

Speedometer

DT-5TG.

IMPORTANT:Read

rule

for

safe

installation,

operation

and

instruction

manual

carefully

and

SAVE

THIS

INSTRUCTION

MANUAL.

(POWER)

Make

sure

AC

voltage

is

between

85

and

264V.

(DC

powered

DT-5TG-DC:DC9

~35

V)

When

installing

unit,

keep

power

and

sensor

wires

separate.

(INPUT

SIGNAL

WIRE)

Connection

wiring

from

sensors

shall

not

be

kept

in

the

same

or

parallel

conduit

or

cable

as

the

power

source,

power

or

high

voltage

cables

to

avoid

noise

which

may

cause

mulfunction.

Use

shielded

wire

for

input

power

connections

in

the

shortest

possible

metal

conduit.

(TERMINAL)

After

inserting

wires

tighten

terminals

securely.

(ENVIRONMENT)

Protect

instrument

from

water,

oil

and

corrosive

materials.

Do

not

use

it

in

the

place

of

vibration

or

shock.

Use

it

in

the

place

of

normal

temperature

and

no

dew.

In

case

of

using

the

instrument

near

motor

including

servo

motor,

inverter,

solenoid

contact

switches,

avoid

noise

by

static

electricity,

etc.

Do

not

use

it

in

the

hazardous

area.

HOUUUUUUUUUUY

0 O

:

010-

51662244

Arete

00000000

D-5

O

:

http:

//

ww

1718veb.

net

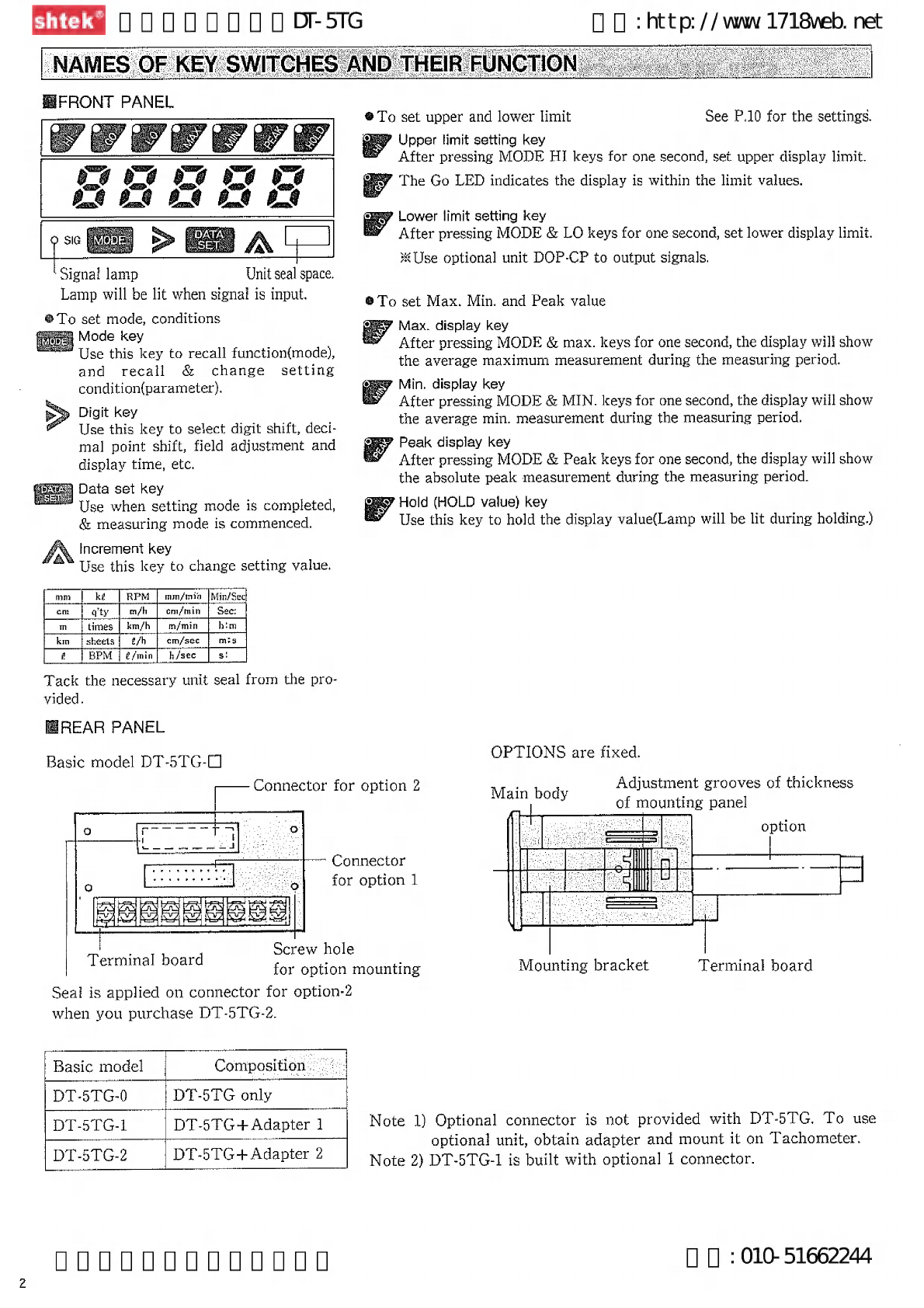

‘Signal

lamp

Unit

seal

space.

Lamp

will

be

lit

when

signal

is

input.

®

To

set

mode,

conditions

Mode

key

Use

this

key

to

recall

function{mode),

and

recall

&

change

setting

condition{parametetr).

»

Digit

key

Use

this

key

to

select

digit

shift,

dect-

mal

point

shift,

field

adjustment

and

display

time,

etc.

Data

set

key

Use

when

setting

mode

is

completed,

&

measuring

mode

is

commenced.

.

Increment

key

Use

this

key

to

change

setting

value.

[Can

[Ee

RP

[mr

le

qty

|

m/h

|

em/min

times

|

km/h

m/min

him

sheets}

g/h

em/sec

s

Tack

the

necessary

unit

seal

from

the

pro-

vided.

HREAR

PANEL

Basic

model

DT-5TG-0

‘

Pad

peed

Dead

Ged

peel

ee

=

=

j

Terminal

board

Seal

is

applied

on

connector

for

option-2

when

you

purchase

DT-5TG-2.

Connector

for

option

2

Connector

for

option

1

Screw

hole

for

option

mounting

HOUUUUUUUUUUY

Basic

model

Composition

ee

Ee

DT-5TG

only

DT-5TG-1

DT-5TG+

Adapter

1

—

DT-5TG-2

DT-5TG+

Adapter

2

See

P.10

for

the

settings.

Upper

limit

setting

key

After

pressing

MODE

HI

keys

for

one

second,

set

upper

display

limit.

The

Go

LED

indicates

the

display

is

within

the

limit

values.

t

Lower

limit

setting

key

After

pressing

MODE

&

LO

keys

for

one

second,

set

lower

display

limit.

Use

optional

unit

DOP-CP

to

output

signals.

®To

set

Max.

Min.

and

Peak

value

F

Max.

display

key

After

pressing

MODE

&

max.

keys

for

one

second,

the

display

wili

show

the

average

maximum

measurement

during

the

measuring

period.

Min.

display

key

After

pressing

MODE

&

MIN.

keys

for

one

second,

the

display

will

show

the

average

min.

measurement

during

the

measuring

period.

?

Peak

display

key

After

pressing

MODE

&

Peak

keys

for

one

second,

the

display

will

show

the

absolute

peak

measurement

during

the

measuring

period.

7

Hold

(HOLD

value)

key

Use

this

key

to

hold

the

display

value(Lamp

will

be

lit

during

holding.)

OPTIONS

are

fixed.

Adjustment

grooves

of

thickness

pal

ROSY

of

mounting

panel

option

Sila]

aM

Mounting

bracket

Terminal

board

Note

1)

Optional

connector

is

not

provided

with

DT-5TG.

To

use

optional

unit,

obtain

adapter

and

mount

it

on

Tachometer.

Note

2)

DT-5TG-1

is

built

with

optional

1

connector.

O O

:

010-

51662244

ATEI

OOOOOOOO

-5T

MOUNTING

O O

:http://ww

1718veb.

net

DIMENSIONS

a

soma

ea

This

instrument

features

easy

“Touch-in-

mount

method”.

Adjust

mounting

bracket

to

meet

with

the

thickness

of

mounting

panel.

1l.

Insert

the

provided

adjusting

tool

into

position

adjusting

hole.

(See

fig.)

2.

Lift

adjusting

tool

slightly

and

move

mounting

bracket

left

and

right.

3.

Set

the

hook

of

the

mounting

bracket

into

groove

of

panel

thickness

adjustment.

X

Please

be

careful

not

to

warp

the

instrument

body

by

mounting

too

strongly.

Mounting

Bracket

Adjustment

groove

The

instrument

is

set

to

5th

groove

at

factory.

#1f

the

mounting

is

too

loose,

proceed

to

the

next

groove

to

tighten

the

mounting.

CONNECTIONS

-

x

Connect

power

with

sensor

on

the

terminals

located

in

the

rear

of

tachometer.

X

Signai

wire

from

sensor

shail

be

shielded

separately

from

power

line.

#

Connecting

wires

from

sensor

shal!

not

be

in

the

same

meta!

conduit

of

high

power

line

such

as

electric

source,

power

high

pressure

line

to

immune

©

noise

and

to

avoid

mulfunction.

How

to

insert

wires

to

terminals.

(For

safety,

turn

power

OFF

for

sure.)

SSEERISIZe

Loosen

screws

with

screwdriver.

Fasten

solderless

terminals

onto

wires

and

insert

them

into

the

loosened

screws

as

shown

in

fig.

on

left.

X

Tighten

the

screws

with

the

screwdriver.

HOUUUUUUUUUUU

Thickness

of

panel

(1.2-~5mm)

BE

Thickness

of

panel

|

Panel

thickness

adjusting

groove

Mounting

1.2~

1.6%

bracket

OPTIONAL

UNIT

“Option

1

(EXAMPLE:

DOP-BC,

SD,

PO)

14g

E

a0.

|

5

I

E

H

mpieg

*Option

2

(EXAMPLE:

DOP-FV,

VF)

To

mount/remove

into/from

panel

1.

Insert

DT-5TG

into

panel

cutaway

as

the

mounting

bracket

in

level

position.

PULL

DT-5TG

straight

out

to

remove.

(it

DT-5TG

is

loose

i

in

the

panel

Cutaway,

t

reset

2.

From

the

rear,

alternately

push

unit

to

left

and

right.

This

will

free

unit

from

bracket

for

easy

removal.

See

instruction

manual

for

the

optional

unit

mount-

ing.

5th

groove

lst

groove

B

Panel

thickness

adjusting

groove

Adjusting

tool

Use

the

following

shield

wires

Shield

wire

Sensors

Rotary

pulse

generator

RE1-O1C

SE-P12

SE-R

SE-G

Proximity

switch

Retro-reflective

sensor 3

wires

0.3sq.

=

sensor

2

wires

Magnetic

pick

up

sensor

SE-M

When

output

voltage

10Hz.,

0.3Vp-p

or

more

is

required.

When

output

voltagel00Hz.,

0.3Vp-p

or

more

is

required.

When

output

voltage

1000Hz.,

15Vp-p

or

more

is

required.

When

output

voltage

10000Hz.,

6.0Vp-p

or

more

is

required.

O O

:

010-

51662244

Output

votiage

of

magnetic

pick

up

sensor

3

4

Arte

00000000

D-5

O

O

:

http://www

1718veb.

net

|

CONNECTIONS

-

EICONNECTION

DIAGRAM

a

t

Signal

Type

of

input

According

to

sensors,

connections

are

different

as

follows;

Model

(Shimpo)

Sensor

Input

,

Connection

Power

Sensors

Terminals

Earth

i

7

N

1513

|

5]

5

Blo

|

Contact

signals|

Relay

switch

5~9

oe

i

-

tput

from

SHIMPO

Open

Reatro-reflective

:

es

e

puse

ma

J

sj

è|

2/88]

z

collector

sensor

SE-R2

|

4~6~8

ee

ll

gst

eae

ae

be

s|

$|

#82

wi

erminals.

a

z|

2

A

Se

Rectangular

miy

pulse

generator

aaa

2\Sensors

shail

be

connected

with

ACBS~264V

zy

elegis

wave

gar

sensor

2

4-79

specified

terminals

and

other

For

DT-STG-0G

D09~38¥

g

&@a

t

Proximity

switch

terminals

shall

be

blank.

Multple

Connect

to

10n

plus

a

Sine

wave

Magnetic

sensors

can

not

be

connecied

&

Zon

minus

Sensor

connections

pick-up

sensor

simultaneously,

|

MODE

AND

PARAMETER

—

This

instrument

can

be

used

as

1.

Speedometer

and

2.

Elapse

time

counter.

Before

shipment,

this

instrument

has

been

adjusted

as

rotational

tachometer

which

has

the

PERIODIC

MULTIPLICATION

function

(Mode

1)

of

the

condi-

tions

in

the

chart

below.

You

may

use

this

instrument

without

any

resetting

if

your

requirement

is

within

the

preset

condition.

Setting

items

Mode

No.

Setting

Mode

Parameter

1

Nos.

of

input

pulse

Parameter

2

Preset

rpm{Sensor)

50000

rpm

Primary

setting

value

Mode

1

Periodic

multiplication

Display

value

when

reaches

|

50000

rpm

the

preset

value.

Parameter

3

Parameter

4

Decimal

point

20

rpm

Min.

rpm(Sensor)}

Parameter

5

l

second

Display

cycle

Parameter

6

O(No

function)

Pre-multiplication

function

|

Parameter

7

BEFORE

OPERATION

SET

AS

FOLLOWS.

1.

Mode

selection

1.

To

confirm

actual

rotational

speed

es

Mode

1:

Periodic

multiplication

2.

To

set

various

display

conditions

3.

To

set

various

display

conditions

Mode

2:

Elapse

time

counter

Self

circuit

test

Mode

5:

Test

mode

|

FUNCTION

(Mode)

selection

Select

mode

according

to

the

requirement.

multiplied

and

displayed.

Mode

No.

|

Mode

name

Applications

Main

purpose

Mode

1

|

Periodic

Nos.

of

pulse

and

pulse

|

Rotational

speed

flow

rate,

Multiplication

period

can

be

measured

and

|

and

peripheral

speed

Mode

2

|

Elapse

Process

time

will

be

dis-

time

played

from

process

length

counter

and

process

speed.

|

Mode

5

|

Test

mode

To

self-check

the

circuit

[FIELD

ADJUSTMENT

FUNCTION

To

measure

actual

rotational

speeds,

the

following

Field

adjustment

function

may

be

set.

Complicated

calculation

is

not

necessary

to

set

the

measuring

value.

If

DT-5TG

shows

900

rpm,

but

nos.

of

pulses

of

sensor

and

speed

reduction

ratio

is

not

known,

you

can

simply

input

the

actual

rpm

measured

with

handheld

digital

tachometer

as

the

set

rotational

speed

without

setting

parameter.

HOUUUUUUUUUUY

Elapse

time

Troubleshooting

Mode

3:Voltage

input

tachometer

Mode

4:To

use

ratiometer,

couple

optional

unit

DOP-RM

with

main

body.

HOW

TO

SET

2.

Adjust

Digit

&

Inc.

to

set

values.

E>

A

gi

a

To

shift

digit,

use

this

key

switch.

A

eee

To

increase/decrease

fig.,

use

this

key.

*

Every

time

press

this

key,

the

fig

shifts

0>

1>

2

s

reune

8

—

9-

periodically.

DATAN

r

rm

a

x

F

Uf

fs

Aa

~

Start

measuring

—

O O

:

010-

51662244

PETENTE

S

SEYE

ERE

AS

ARTO

3.

Press

Date

set

key.

RETANA

RARE

EES

00000000

-5TG

0

‘SETTING

MODE

——

[O

:

http://www

1718veb.

net

Operation

L

Display

Remarks

1.

Input

power

i

ER

voltage

power

is

input,

00000

will

be

dis-

(AC85-264V)

played

and

change

to

0.

|2

Press

MODE

and

T

Set

mode

will

be

displayed.

DATA

SET

key

at

#éWhen

purchased,

periodic

multiplication

mode

ime

for

5

sec.

CE]

Mode

primarily

set

will

be

displayed.

Measuring

mode

will

be

changed

to

setting

|

mode.

3,

Press

inc.

key

and

select

|

Mode

3

&

4

will

be

displayed

at

the

time

optional

:

the

required

mode.

Mode

1

|

nit

will

be

coupled.

Mode

1:

To

measure

Rotational,

A

TE]

mode

2

|

At

each

touch

of

inc.

key,

ohh}

Peripheral,

&

Flow

rate,

select

A

-$r

Mode

5

will

be

periodically

changed.)

periodic

multiplication

mode,

MODE.{

:.To

measure

rotational

speed,

peripheral

speed,

flow

rate,

select

PERIODIC

MULTIPLICATION

FUNCTION.

|

Set

Parameter

in

the

following

procedures

to

set

various

display

conditions.

SET

ITEM

RIEXAMPLE

OF

SETTING

—

Peripheral

speed

—

Setting

item

Primary

set

value

=i

CONDITION

Mode

No.

Mode

1:

Periodic

multiplication

RPM

of

variator:

1000rpm

***Parameter

2

|

method

i

:

(MGS

is

built

in

60P/r)

-*+*Parameter

1

Parameter

1

~[

Nos.

of

input

pulses

|i

p/r

With

Reduction

gear

1/10

Parameter

2

Set

rpm

(sensor)

50000

rom

i

Pulley

ratio

1/2

|

Parameter

3

E

value

50000

rpm

Rol!

dia.

1.0m

a

4

Decimal

point

None

~]

ETIN

:

:

—4

-

When

variator

runs

at

1000rpm,

and

the

peripheral

speed

Parameter

5

eo

seieor

10

rpm

|

per

m/min.

is

requested,

Parameter

6

__|

Periodic

display

1

sec.

the

peripheral

speed

of

roll

dia.

1.0m

is

obtained

from

the

Parameter

7

Pre-multiplication

formula;

|

function

0

{

no

function)

_}

1000rpm

x

1/30

X

1/2

(1%

3.14)=157m/min.

“Parameter

3

SETTING

MODE

Remarks

When

voltage

power

is

input,

00000

will

be

displayed

and

change

to

0.

Operation

Display

1

Input

power

:

(AC85-264V)

lZ

Press

MODE

and

DATA

SET

key

r

[pE]

at

same

time

for

5

sec.

zia]

Mode

1

Set

mode

will

be

displayed.

#

When

purchased,

periodic

multiplication

mode

primarily

set

will

be

displayed.

3

Measuring

model

will

be

changed

to

setting

mode.

SETTING

PARAMETER

a

(1

To

set

Parameter

i

(Nos.

of

Input

pulses)

Example:

In

case

60

p/r

l.

Set

mode

1

Parameter

No.

9.

Press

mode

key.

Alternatively

flashing

Gee

digit

key

and

increment

key)

at

the

same

time

and

set

60.

Primary

set

at

1

p/r.

3,

Press

digit

key

and

the

top

fig.

flashing.

4.

Press

digit

key

to

flash

2nd

digit.

5.

Press

inc.

key

to

shift

2nd

digit

to

6.

6.

Press

digit

key

to

flash

Ist

digit.

mao

Pt

atone

fe

it

7.

Press

inc.

key

to

shift

1st

digit

to

0.

Even

after

setting

is

completed,

figures

flash.

To

shift

digit,

press

this

digit

key.

Everytime

pressing

To

inrease/decrease

figures,

press

this

key.

this

key,

the

flashing

digit

will

shift

toward

right.

The

Everytime

pressing

this

key

G-1-

2-308

-9

value

flashing

means

“Shifting”.

the

flashing

digit

will

shift

toward

right

and

back

to

|

the

beginning

figure.

HOUUUUUUUUOU.

0

O

:

010-51662244

`

EPET

ERARE

Arete

00000000

D-5

MODE:

{To

measure:

rotational

;

Speed,

peripheral

speed,

flow

2

Parameter

2

(Preset

rom)

setting

1.

Press

mode

key.

Press

digit

key

and

inc.

key

simultaneously

and

set

1000.

2.

Flash

top

digit.

3.

Change

top

digit

zero.

4.

Flash

4th

digit.

5.

Change

4th

digit

to

1.

3

Parameter

3

(The

display

value

at

the

set

rpm}

setting

1.

Press

mode

key.

2.

Press

digit

key

and

Inc.

key

to

set

157.

(See

Parameter

1

operation.)

OO

:

http:

//

ww

1718veb.

net

>

A

>

A

Example:

To

set

1000

rpm.

Eo

a

e

No,

Alternatively

flashing

Primary

setting

50000.

CERE

m

on

or

at

at

as

m

Fi

a)

ore

re

ort

Fa

ores

ka

at

ad

aor

rtm

Pt

wW

tA

Setting

is

completed.

Example:

To

set

157

Farameter

No.

L

Alternatively

flashing

a

es

BE

y

B

y

3

eras

ot

af

Primary

setting

50000.

Setting

is

completed.

4.

Parameter

4

(Decimal

point)

setting

1.

Press

mode

key.

2.

Press

mode

key

again

to

get

back

to

parameter

9.

For

example:

To

display

157.0-

set

as

1.

When

decimal

point

display

is

required

in

parameter,

set

the

figure

in

parameter

3

as

to

add

0

after

the

decimal

point.

01570

2.

After

pressing

mode

key,

set

Parameter

4.

3.

Press

digit

key

and

shift

decimal

point

to

the

desired

position.

Decimal

point

shift

everytime

pressing

digit

key.

5

Parameter

5

(Min.

rpm

of

sensing

gear)

setting

1.

Press

mode

key.

and

set

15.

(See

Parameter

1

operation.)

For

example:

When

not

to

set

decimal

point.

>

2.

Press

digit

ke

d

Inc.

|}

and

Inc.

key

simultaneousl

ress

digi

yan

c.

key

key

y

>

A

Parameter

No.

Alternatively

flashing

No

decimal

point

in

primary

setting.

Setting

is

completed.

Example:

To

set

15

rpm.

Parameter

No.

Alternatively

flashing

Primary

setting

10

rpm

Setting

is

completed.

6

Parameter

6

(Setting

display

cycle)

1.

Press

mode

key.

2.

Press

digit

key

once,

then

the

primary

setting

of

one

sec.

will

flash.

3.

Select

0.50

sec.

Select

the

best

display

cycle

from

0.25,

0.50,

1,

2,

4,

8,

16sec.

>

>

For

example:

To

set

0.5

sec.

Parameter

No.

i

Altenatively

flashing

L——

Primary

setting

is

1

sec.

ares

va

ri

h

wy

t

Display

cycle

will

be

shifted.

Setting

is

completed.

pin

24-8

16

0.25

0.505

L

*

HOUUWUUUUUUUUY

U

O

:

http:

//

ww

1718veb.

net

select

PERIODIC

MULTIPLICATION

FUNCTION.

shtek’

o

o

00000

DO

O-sIG

‘rotational

speed,

peripheral

‘speed,

flow

ra

7

Parameter

7

(Pre-multiplication)

setting

For

example:

For

the

time

of

no

function.

go

Parameter

No.

Toe

u m

t

Alternatively

Primary

setting

is

#

Note:

See

below

for

the

details

of

pre-multiplication

function.

1.

Press

mode

key.

>

LE

0

Zero

will

display.

2.

lf

the

digit

key

is

processed,

primary

setting

is 0.

Everytime

pressing

0:

Shows

no

function.

digit

key,

the

number

1:

Pre-multiplication

at

stopping.

pe

0-

1-24

2:

Pre-multiplication

at

speed

reducing.

will

shift.

Q

Setting

is

completed.

Measurement

will

be

started.

or

measurement

will

be

displayed.

1.

Press

data

det

key.

X

Setting

mode

will

be

shifted

to

measuring

mode

and

the

measurement

will

be

started.

Xu ri

Setting

values

will

be

stored

at

even

when

the

eleçtirc

power

is

off

by

accident.

Set

parameter

may

be

recommended

to

be

written

on

the

name

seal

in

the

parameter

note

for

convenience.

Set

mode

and

parameter

will

automatically

be

locked

for

no

man

to

change

the

set

data.

To

change

setting

and

release

lock,

press

mode

and

data

set

keys

at

the

same

time

for

over

5

sec.

Mode

nos.

set

initially

will

be

displayed

and

resetting

can

be

ready.

[To

use

pre-arithmetic

function

Pre-arithmetic

function

When

the

speed

of

the

rotatings

increase

or

decrease

rapidly,

the

conventional

speedometer

may

not

follow

the

display,

of

which

value

remains

at

the

time

of

the

machine

stop.

DT-5TG

will

pre-multiply

the

speed

and

absorb

the

delay

in

the

display.

1.

Pre-arithmetic

at

stopping

After

rapid

stopping,

as

the

input

pulses

disappear

(in

case

of

input

pulses

disappear

within

0.25sec.),

the

display

will

show

0

quickly

because

of

pre-

arithmatic

function.

Press

digit

key

to

select

1.

1)

Pre-arithmetic

function

will

be

available

at

speed

of

7rpm

or

faster

(at

60p/r).

Example:

To

set

the

2nd

value

from

the

decimal

point.

1.

Change

Parameter

2,5

2902

tol

28

608

|

2.

Do

not

change

Parameter

3

(Leave

it

as

it

is.)

3.

Change

Parameter4,

52292.

toj

$a

ouuu

2.

Pre-arithmetic

at

reducing

sneed.

After

reducing

speed,

as

the

input

pulses

disappear

(in

case

of

input

pulses

disappear

within

0.25sec},

the

display

will

show

nearly

by

0

reverse-iunction

of

pre-arithmatic.

Puy

Press

digit

key

to

select

2.

2}

Pre-arithmatic

will

be

stopped

at

the

pulse

input

and

cycle

arithmatic

will

be

started.

‘OVERFLOW

DISPLAY

=

If

the

display

pass

over

the|

$9

42%

|Gncluding

decimal

point),

the

display

will

be

as

O0

O

:

010-51662244

7

Aros

COOOGOOO

SIG

OO

:http://

ww

1718veb.

net

[MODE

2;

TO

MEASURE

ELAPSE

TIME.

—

oe

Mode

2:

Elapse

time

counter

Note:

DT-5TG

may

not

be

used

as

elapse

time

counter

This

mode

allows

the

operator

to

correctly

time

a

if

the

optional

unit

DOP-FV

or

DOP-VF

is

attached.

certain

process.

ET

ITEM

BExample

of

Elapse

timer

=

S

"

x

Setting

|

Setting

item

|

Primary

set

value

*

Calculate

elapse

time

(Setting

example]

Parameter

1

|

Nos.

of

input

pulses

|

1

p/r

100m

DT-5TG

|

Parameter

2

Se

rpm(sensor)

|

200

rpm

Parameter

3

|

Change

over

in

the

|

Hour

and

min.,

only.

I

r

|

Varlable

speed

drive|

unit

of

hour,

min.

ee

i

Speed

reduce

~

L

|

(Reduction

ratio

1/50)

(iddrpm)

Parameter

4

|

Display

value

at

|02=00

Magnetic

pick

up

sensor

60

pulses

o

preset

speed.

|

Calculation

time

7

Parameter

Jev

Magnetic

pick-up

sensor

60

pulses/r

Parameter

5

|

Display

cycle

_|

1

sec.

_.

Parameter

2

deepsea

enn

nee

sh

eneteeenen

meer

ne

racane

cab

Enareg

nae

100

rpm

*

The

DT-5TG

is

set

to

the

abvoe

values

primarily

before

Linear

speed

=

PSD

of

rollerX

rpm

=0.1

3.14

x

100

*

1/50=0.628m/min.

shipment

from

SHIMPO

Elapse

time

=

Length

of

process

=

100

=

159,2min.

Linear

speed

0,628

Parameter

3

Seeererererrererrrra

a

Parameter

qovvuséeuvunvtn

2

hrs

39

min,

SETTING

MODE

Į

Operation

L

Display

Remarks

li.

Input

power

(AC85-264V)

When

voltage

power

is

input,

00000

will

be

displayed

and

change

to

0.

2,

Press

MODE

and

DATA

SET

|

|

Set

mode

will

be

displayed.

|

key

at

same

time

for

5

sec.

[ee

al

Mode

1

When

purchased,

periodic

multiplication

mode

primarily

set

Š

will

be

displayed.

x

Measuring

model

will

be

changed

to

setting

mode,

%

Press

inc.

key

and

select

the

Mode

3

&

4

will

be

displayed

at

the

time

optional

unit

will

be

required

mode.

coupled.

A

-P

-

Mode

2

|

At

each

touch

of

inc.

key,

pEi

-Esh

A

4

_|

will

be

periodically

changed.

1

Parameter

1

(Nos.

of

input

pulses)

setting

Example:

To

set

60

p/

p]

-

rt

-

1.

Set

mode

2

£

p

Parameter

No.

2.

Press

mode

key

ae

(Press

digit

key

and

inc.

Key

and

set

60.)

Saree

Alternatively

flashing

Ad

ceo

ao

Primary

set

is

1

p/r.

3.

Top

figure

flashes

>

gags

4.

The

2nd

digit

flashes.

>>

Gag!

i

T

a

iai

r

|

5.

The

2nd

digit

becomes

6.

A

moe

6.

The

Ist

digit

flashes.

>

eee

ens

——

7.

The

7th

digit

become

zero.

A

gga

8

The

set

data

flashes

even

after

completion

of

setting.

>

eurei

is

to

shift

the

digit.

A

puaa

is

to

be

used

to

increase/decrease

the figures.

Everytime

pressing

this

key,

the

digit

shifts

Everytime

pressing

this

key

01-238

toward

right

and

flashing

indicates

the

chang-

~—-9,

the

figure

changes.

ing

position.

|

2

Parameter

2

(Set

speed

rpm)

setting

Example:

To

set

100

rpm

Parameter

No.

1.

Press

mode

key.

eS

sa

ii

Alternatively

flashing

EERE:

-__

Primary

setting

is

200.

9.

The

top

figure

flashes.

>

gapt

3.

The

3rd

digit

flashes.

>

woe

oo

(4

Change

3rd

digit

to

1.

A

oe

raga

Setting

is

completed.

E

s0000000000000

OO

:

010-

51662244

shtek“

COOOOGOOOor5StG

MODE

2:

TO

MEASURE

ELAPSE

TIME

O O

:

http:

//

ww

1718veb.

net

E

co

4

Parameter

3

(Hr.

Min.

&

Sec.

unit)

setting

i.

Press

mode

key.

2.

Select

hour,

minute

unit.

Everytime

pressing

digit

key,

The

figure

will

be

changed

as

follows.

l-

mort

mo

ou

Note

1-Per

second

unit/For

example

99-

25

shows

99.

25

seconds

J.

Press

mode

key.

2.

Press

digit

key

to

flash

top

fig.

3.

Press

digit

key

and

inc.

key

to

set

0239.

(See

parameter

1

&

2

for

right

operation)

Note

1)

Concerning

limit

over

for

hour,

min.,

sec.,

unit.

display

range

for

hours,

mir,

sec.

is

99

=-

59,

For

example

in

case

02

=-69

is

set,

the

two

digits

show

Eferror)

when

pressing

mode

and

data

set

keys.

|

p

3

4

Parameter

4

(Display

value

at

preset

rotation/calculation

time)

setting

=>

AA

Setting

is

completed.

Example:

To

set

Hr.

Min.

setting

p

Parameter

No.

em

[z-s]

H

Alternatively

flashing

Hour

&

Min.

are

initiaily

setting.

Setting

is

completed.

Note

2--Per

hour

&

minute

unit,

min.

&

sec.

unit/For

example,

05

2.15

shows

5

hours

and

15

seconds.

xample:

To

set

2

hours

39seconds

sc

Parameter

No.

Sp

Primary

setting

is

02

1.00

Alternatively

flashing

To

remedy:

Press

digit

key

and

display

E

digit

and

reset

O~5

fig.

by

inc.

key.

5

Parameter

5

(Display

cycle)

setting

l].

Press

mode

key.

X

Select

the

best

display

cycle;

0.25,

0.50,

1, 2,

4,

8

or

16

sec.

2,

Press

digit

key

and

select

1

sec.

Everytime

pressing

display

cycle

key,

display

cycle

changes

from

p?1727

4

8-"

16

0.25-7

0.505

repeatedly-

Example:

To

set

1

sec.

Parameter

No.

fe

oe

al

a

Alternatively

flashing

i

Primary

setting

is

1

sec.

5>

o

Setting

is

completed.

6

Setting

is

over

and

start

measuring.

1.

Press

data

set

key.

Mode

will

be

changed

from

setting

mode

to

measuring

mode.

or

display

measuring

value.

x

When

power

is

off,

the

value

set

before

the

power

off

will

be

stored

in

memory.

lt

is

appropriate

to

make

notes

on

parameter

seal,

located

on

top

of

the

DT-5TG.

The

preset

mode,

parameter

set

are

locked

automati-

cally

for

protecting

from

mishandlings.

To

unlock

and

change

the

settings,

press

mode

key

and

data

set

key

simultaneously

for

over

5

seconds.

The

mode

nos.

set

initially

will

be

displayed.

Resetting

can

be

possible.

"OVERFLOW

DISPLAY

WHEN

ELAPSE

TIME

COUNTER

MODE

(MODE

2)

|

When

elapse

time

counter

mode

is

set,

if

the

input

pulse

is

nil

or

the

elapse

time

passes

99hours(or

min.)

59min.

(or

sec.),

or

99sec.

99

and,

overflow

is

displayed,

the

followings

will

be

displayed.

0000000000000

When

Hour(Min.)

Min.(Sec)

are

ear

and

if

the

input

pulse

is

and

the

measuring

value

becomes

within

the

range,

the

normal

measuring

value

will

be

resurned.

O O

:

010-

51662244.

w

When

sec.

Aros

COOOOGOOOor-5tG

0

:

http:

//

ww

1718veb.

net

|

TO

USE

EACH

FUNCTION

|

To

set

and

display

upper

and

lower

limit.

=

EY

If

the

measuring

value

exceeds

the

upper

limit,

lamp

will

be

lit.

y

H

the

measuring

value

falls

between

the

upper

and

lower

limit,

the

lamp

will

be

lit.

Ey

If

the

measuring

value

is

below

the

lower

limit,

the

lamp

will

be

lit.

Please

set

the

value

so

that

the

value

stays

between

upper

and

lower

limit.

HI

To

set

upper

value

tọ

1000.

To

set

the

upper

limit

to

1

hour(or

min.)

Lamp

is

lit

i

1.

Press

MODE

key

and

HI

The

last

display

will

flash

|

#4

Sen

m

simultaneously

for

over

I

sec.

.

and

in

a

sec.

upper

limit

can

be

set.

2.

Press

Digit

and

Inc.

keys

and

match

the

setting

value.

3.

Press

DATA

SET

key.

Lamp

will

be

off

and

display

cycle

shown

above

will

be

displayed.

LO

To

set

lower

value

to

100.

To

set

the

lower

limit

to

10

min.{or

sec.)

Lamp

is

fit

a

Gogg

8

The

last

reading

will

fash

|

HF

200

and

in

a

sec.

the

lower

limit

can

be

set.

l.

Press

MODE

and

LO

key

simultaneously

for

over

1

sec.

2.

Press

Digit

and

Inc.

keys

and

match

the

setting

value.

3.

Press

DATA

SET

key.

Lamp

will

be

off

and

dispiay

cycle

shown

above

will

be

displayed.

TO

DISPLAY

MAXMIN.

&

PEAK

mies

1,

Pressing

MODE

and

MAX

keys

simultaneously

for

over

1

sec.

will

change

to

MAX

a”

display

mode

and

display

MAX

of

the

measurings

from

the

time

pressing

both

MODE

and

MAX.

keys

simultaneously

to

the

present.

MAX

lamp

will

be

lit

during

the

display.

2.

Pressing

MODE

and

MIN.

keys

simultaneously

for

over

1

sec.

will

change

to

MIN

display

mode

and

display

MIN

of

the

measurings

from

the

time

pressing

both

MODE

and

MIN.

keys

simultaneously

to

the

present.

MIN

lamp

will

be

lit

during

the

display.

—

se

3.

Pressing

MODE

and

PEAK

keys

simultaneously

for

over

1

sec.

will

change

to

PEAK

Eei

ES

display

mode

and

display

of

the

measurings

from

the

time

pressing

both

MODE

&

le

PEAK

keys

to

the

present.

(The

Max.

value

of

every

0.25

sec.)

PEAK

lamp

will

be

lit

during

the

display.

Press

simultaneously

for

}

sec.

psy

4

Pressing

MODE

and

HOLD

keys

simultaneously

for

over

1

sec.

will

hold

the

display

i

Ly

value.

HOLD

lamp

will

be

lit

during

the

dispiay.

VES

Press

simultaneously

for

1

sec.

Note:

MAX.

MIN.

PEAK.

&

HOLD

must

be

used

separately.

(32)

To

resume

normal

measuring

mode

Note:

The

above

mode

may

be

reset

by

interrupting

power

to

the

unit.

press

this

switch.

—.

reer

d

HUUUUUUUUUUUO

O

O

:010-

51662244

10

O O

:

http:

//

ww

1718veb.

net

ETAY

0000000

0

-5TG

ESET

TEST

MODE

(Mode

5)

Perform

testing

after

removing

wiring

of

sensors.

co

Press

Mode

and

Data

set

keys

simultaneously

simultaneously

for

over

5

sec.

The

mode

set

now

will

be

displayed.

?

Press

Inc.

key

and

select

Mode

5.

A

4

Press

Mode

key.

cs

Ry

hy

iy

iy

If

00000

up

to

99999

flash

repeatedly,

it

is

normal

function.

4

Lf

the

following

fiqures

flash

for

a

sec.,

it

is

normal.

The

last

reading

will

be

displayed

for

a

second.

Pressing

MAX

keye

eee

E

TTT,

3.8.8.8.8.

Pressing

MIN

key*

Pe

ae

ere

cree

Pressing

PEAK

keytts

tt

tse

9.3,9.9.5.

Pressing

HOLD

key“

seans

ree

ree

ree

eee

5

Press

Mode

key.

Normally

displays

the

following

figure.

=e

ar

SIG

lamp

will

flash

and

pos

ot

ut

display

1000.

3

al

If

the

DT-5TG

functions

as

the

test

mode,

it

ig

normal.

Check

the

sensor

or

others.

6

Press

data

set

key

The

test

mode

display

during

the

operation

in

elapse

time

counter

mode

is

as

follows;

1

When

normal

:

hour{min.)

min(sec)

eae

-

-

PT

of

=

WF

FF

yir

1i

When

sec.

2.3,4-+++++Operation

and

display

is

the

same

as

above.

`

1

<

Desired

value

-

<

at

99999

Display

value

of

setting

rpm

the

last

display

value

Display

value

at

set

rotational

speed

Display

value

at

set

rpm:

Value

set

at

parameter

3.

The

last

display

vaiue:

Value

set

in

Field

adjustment

Desired

value:

Field

adjustment

value

against

the

above

display

value.

Set

rotational

speed

value

at

dispatching

is

50000;

1

Desired

value

(=

99999

)

a

=

“ee

a

56000

according

to

this

formula,

the

setting

value

becomes

double.

In

case

desired

value

surpasses

the

double

set

value,

change

setting

value.

For

example,

set

the

display

value

10000

in

setting

rotational

speed.

When

99999

10000

=

9.9999

so

the

desired

value

can

be

set

not

more

than

9.9999

times.

At

this

time,

adjust

the

value

of

set

rotational

speed,

and

change

parameter

No.2

“Set

rotational

speed”.

o000000000000

0

O

:

010-

51662244

HOUOUOUUO

D-SIG

O O

:

http:

//

ww

1718veb.

net

SE

TROU

1.

Parameter

input

error

fo

MOSSE

Be

Peis

fo

contents

Troubleshootings.

1)

Press

DATA

SET

key

to

release

|

error,

PORR

Field

adjustment

settin

;

Ef-

pU

:

J

E

2)

Re-enter

parameter

according

to

the

ror

3

:

E

procedures

of

field

adjustment

range

at

P.

a

4

In

case

upper/lower

set-

1)

Press

data

set

key

to

release

error.

1

ting

in

HI/LO

condition

2)

Re-enter

the

upper

and

lower

values.

2.

Memory

error

1)

Press

DATA

SET

key

to

release

error.

2)

In

case

EE-02

is

repeatedly

displayed,

recharge

the

power.

3)

In

case

EE-03

is

displayed,

proceed

to

ee

Internal

memory

error

EE-03

troubleshooting.

|

1)

Press

DATA

SET

key

and

release

error.

2)

Press

HI,

HOLD,

INC.

&

MODE

keys

ee

+3

Memory

recall

error

in

order,

at

this

tme

display

figures

are

11111,

22222,

33333,

44444.

The

primary

setting

values

for

DT-5TG

will

be

transfered.

Ea

q

E

3.

Communication

error

(At

the

time

of

inserting

optional

unit into

DT-5TG)

Error

communication

|

1)

Confirm

connections

between

with

optional

unit

optional

unit

and

main

body.

2)

Press

DATA

SET

key

to

release

error.

Error

in

confirming

optional

unit

Display

range

“Measuring

rar

Display

‘period

*:

Display

ienten

Time:base..

Accuracy:.

Measuring

system

Bees

ee

rotation

Input:

signal

wave

form

Input

:signal-

voltage...

1~9999p

JSS

Leet

tet

DEBT

Geel

i

ts

-

Rate

measurement

Elapse

time

counter

0~-99999,

0.0-~-9999.9

99

sec

99

0.00

—

999.99,

0.000

—99.999

99min.

59

sec.

0.0000

—

9.9999

99hours.

59min

10~99999rpm

(1p/r

input

Display

period

1

sec.)

E

0.2~30000rpm

(60p/r

input

Display

period

1

sec.)

0.25,

05,

1,

2,

4,

B,

16sec.

selectable

Red

LED

(Character

height

14.2mm

Crystal

oscillator

(4,194304MEH2)

0.00894

+1

digit

CPU

multiplication

ing

method)

Sine

wave

(10kHz2

MAX),

Square

wave,

open

collector

G0kHz

MAX)

Contact

@0Hz

MAX)

sine

wave

(0.3—30V

r-r)

(Nos,

of

Input

cycles),

Square

wave

L:

0~1.5V,

H:

4—30V

Input.

impedance

ooti

Sensor.

Power:

Stippiy:.

-Applicable

seso

ciii

Ambient

‘temperature:

Powėrtegquirëment

45i

Powerlines

ys!

Outside

dimension:

Weight:

ece

es

Others

."-

Approx.

10k0

Dely

+5%

50mA

max

Rotary

pulse

generator,

Magnetic

pick-up,

Gear

sensor,

Proximity

swich,

Retro-refiective

sensor

O~45C

(32°

to

113°F

LW

(5W

when

optical

unit

is

attached.)

DT-5TG-DC:3

W

(SW

when

optical

unit

is

attached.)

Operational

capacity:

AC

85~264V

(50/60Hz)

For

DT-STG-DC:DC9~35V

W956

x

H48

x

D88mm

(DIN

250g

i.

Comparator

2.

Display

mode

(MAX.

MIN.

PEAK,

HOLD)

Change-over

type.

Manufactured

by

NIDEC-SHIMPO

CORPORATION

1

Terada,Kohtari,Nagaokakyo-city,Kyoto,Japan

Phone:

(075)958-3608

Fax:

(075)958-3647

,

ftoooo0oooo0c0

O

[O

:

010-

516672%

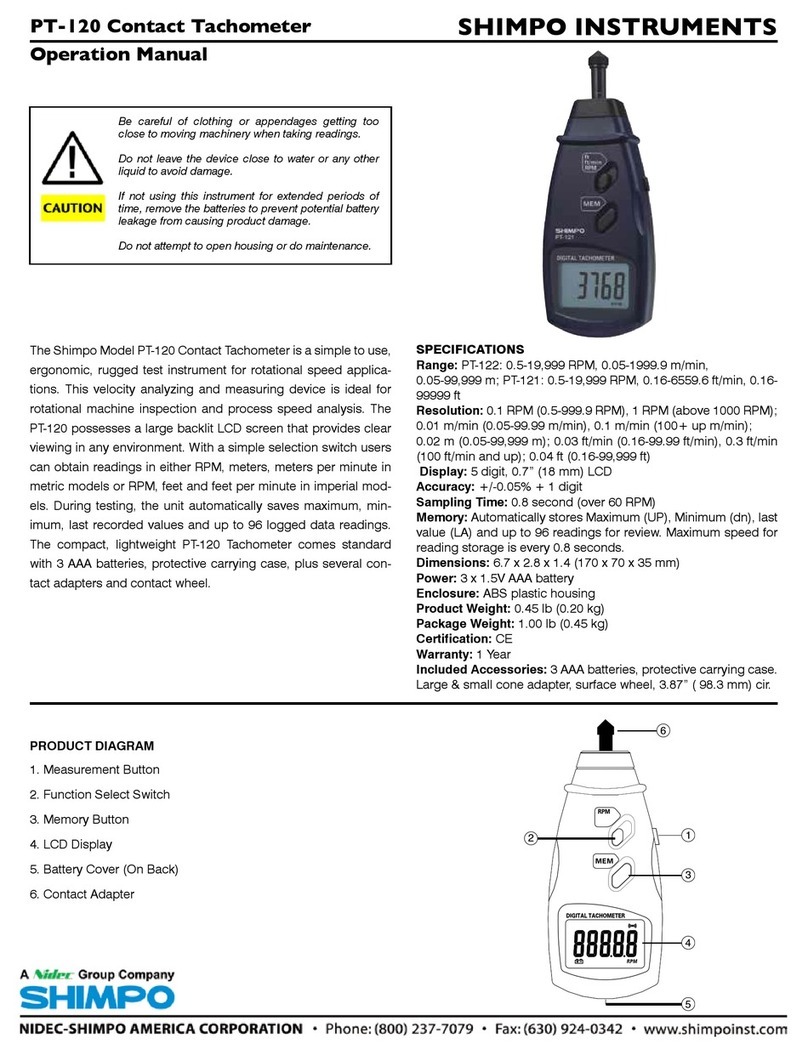

Other Shimpo Measuring Instrument manuals

Shimpo

Shimpo DT-5TS User manual

Shimpo

Shimpo DT-725 User manual

Shimpo

Shimpo FGV-0.5XY User manual

Shimpo

Shimpo DT-205L User manual

Shimpo

Shimpo FG-7000 User manual

Shimpo

Shimpo DT-365E User manual

Shimpo

Shimpo DT-107A User manual

Shimpo

Shimpo DT-5TXR User manual

Shimpo

Shimpo DT-326 User manual

Shimpo

Shimpo PT-120 User manual

Shimpo

Shimpo FG-7000L User manual

Shimpo

Shimpo FGV-0.5XY User manual

Shimpo

Shimpo DT-207L User manual

Shimpo

Shimpo DRI User manual

Shimpo

Shimpo DT-725 User manual

Shimpo

Shimpo DT-361 User manual

Shimpo

Shimpo FG-7000T User manual

Shimpo

Shimpo FG-7000L-M-100 User manual

Shimpo

Shimpo DT-721 User manual

Shimpo

Shimpo DT209X User manual