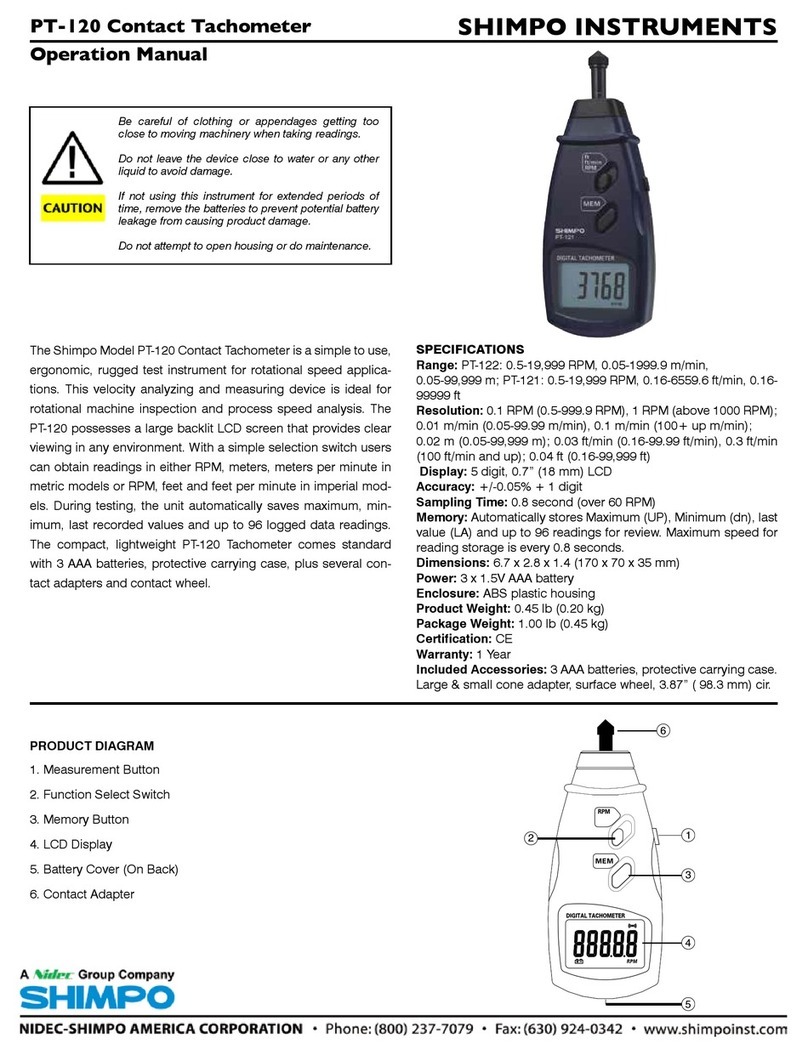

CONTROL PANEL

Revolutionsper

minute

0

OPERATING

PROCEDURES

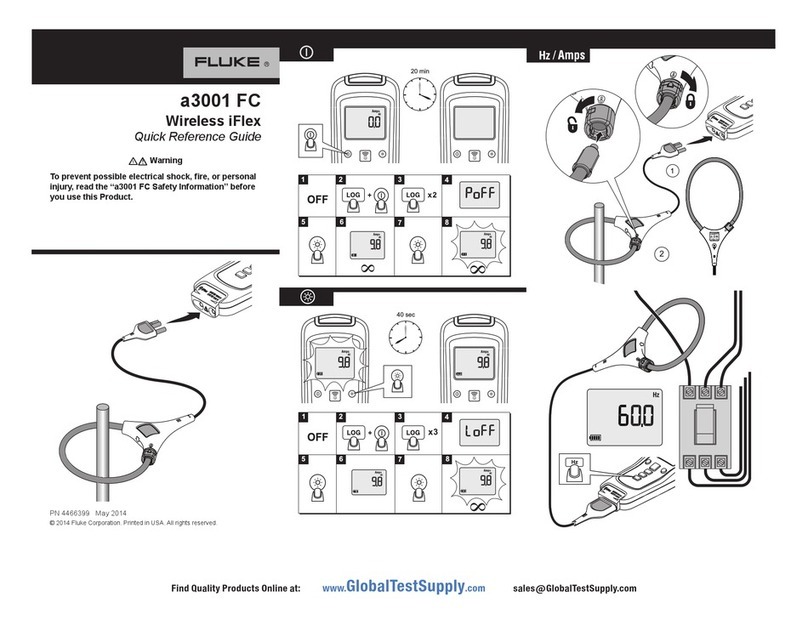

Non-Contact Measurement

2.

Bringconeinto contactwiththe shaft. Apply onlyenough

1. Placeasmall pieceof reflectivetape pressureto avoid slippage.

(included) on the shaft or moving

3.

Press and hold the power switch. During engagement

element (disc, pulley, etc.) whose the displaywill reflecttheproperRPM while the unit RPM

speed is to be measured. If the will be flashing abovethe display digits.

element'ssurfaceis highlyreflective

it may need to be painted a darker

color in, order to ensure reliable

results. Ifthedistancetotheobject

is less than

5"

(127 mm), reflectivetabs (optional)should

be used instead of reflectivetape.

2.

Aimthe tachometer at the reflectivetape fromadistance

of

5"

(127 mm)to 14' (4.3 m).

3.

Press and hold the power switch for several seconds

(when power

button

is depressed, laser is

active) to observe the display

as

it changes according

to thespeed of theshaft or rotating element (as soon as

the laser hits the reflective tape, the unit will start to

indicate thespeed). Ifthe beam is "on target" a red dot

will flash inthe upper right corner of the display. If the

red dot is not flashing, the beam is "offtarget", and the

aim needs to be adjusted.

4. After observation is completed, retain the reading by

releasing the power switch (to turn off laser) before

removing the tachometer from its position. The last

reading is displayedfor a period of 10seconds and can

be extended any number of additional

5

minute

increments by pressingthe memory switch.

NOTE:

Whenswitchingfromthecontacttothenon-contactmode,

the unit RPM will show on the display and also

5

dashes

(---).

Pressthepower switch tocancelthedashes.

Contact Measurement

For bothRPM measurementsand non-RPM

measurements, screw the 200L adapter

(included)intothefront of thetachometer.

NOTE:

Hand tighteningis sufficient;

do

not

use excessivetorque when mounting

RPM

Measurement

1. Place rubber conetip onthe shaft of

theZOOLadapter. Make certainthat

the pin on the shaft is properly

aligned with the slot on the cone's

sleeve.

4. Releasethe power switch priortoremoval of tachometer

from rotating object to capturethe last reading.

5.

After release of the powerswitch, the last reading (with

a non-flashing RPM unit) will remain on the display and

in memory for

5

minutes, and can be extended any

number of additional

5

minute periods by pressingthe

memory switch.

Rate

(I

Length Measurement

1.

Attach

6"

masterwheel and select the

desired function using the selector

switch located just below the

LED

display.

2.

Press and hold the power switch;

while the wheel is turning and the

tachometer is measuringtheselected

function, the red dot in the upper

right corner of the display will beflashing.

3.

Release the power switch before disengaging the

tachometer in order to capturethe last reading.

4. After release of the power switch, the last, maximum,

and minimum readingswill be stored in memory for

5

minutes and can be extended any number of additional

5

minute periods by pressingthe memory switch.

NOTE:

Thememory will clear in

5

minutes after the release of

thepower switch.

For steps 1-4describedabove,

it

was assumed that theselector

switch was in the rate mode region. If the selector switch is

moved from the rate mode to the count mode (length), the

displaywill showtheselected function (m, ft, yd, or in) and also

5

dashes

(-----).

Press the power switch to cancel the dashes

andstart measuringthesamewayas wasdescribed above. Once

inthecounting mode, themeasurementcan bestopped at any

timeandthe last readingwill be retainedfor

5

minutes. There is

no maximum or minimum readingwhen inthe count (length)

mode.

1

I

LASER RAOIATI~IN

I

-

.

-

-

.. ..

.

.

-

.

.

..

,

-

.

.

1

DO

NOT STARE INTO BEAM

-.

A&

OUTPUT

c

lrn~

I

1

1'

WAVELENGTH

670nm

I

CLASS

I1

LASER PROllCT

2

INSTRUMENTS 11701 GlenlakeAvenue Itasca,IL 60143

.

phone: (800)237-7079.fax: (630) 924-0342 .www.shimpoinst.com