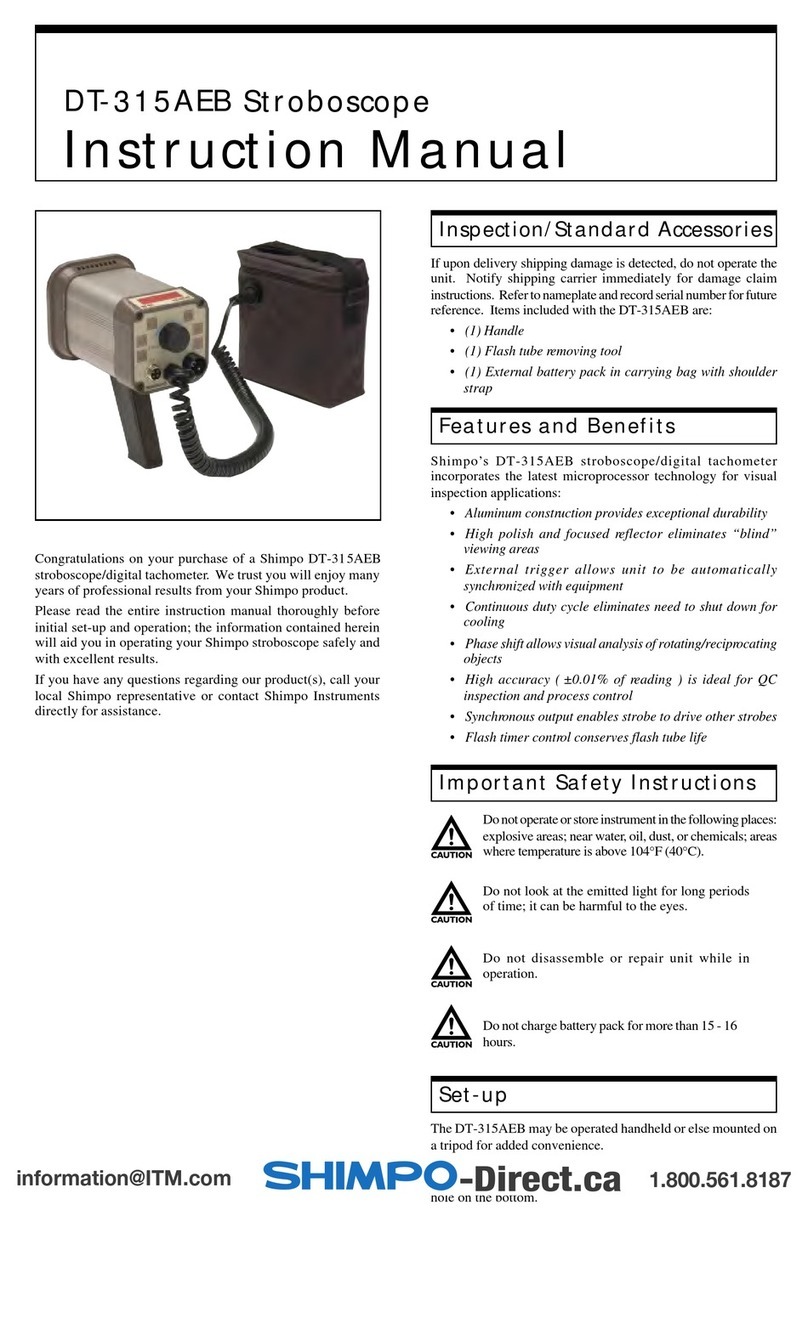

When FPM reading is displayed but unit is not flashing,

flash tube may need to be replaced.

1. Unplug line cord from power line. Turn power switch

OFF. Wait a few minutes until stroboscope is cool

before replacing flash tube.

2. Remove protective window by removing the 4 screws.

3. Use a rag and pull the tube out of its socket by rocking

it slightly up and down. Do not use bare hands to

remove tube, it may break and cause injury.

4. Insert new tube using the technique mentioned above.

Make sure that the tube is placed properly in the socket

otherwise it will touch the reflector. Tube should be set

symetrically within the neck of the reflector.

5. Replace protective window.

Flash Tube Replacement

MODELMODEL

MODELMODEL

MODEL DTDT

DTDT

DT- 725(DC)- 725(DC)

- 725(DC)- 725(DC)

- 725(DC)

FLASHING RANGEFLASHING RANGE

FLASHING RANGEFLASHING RANGE

FLASHING RANGE 40 — 12,500 FPM (Flashes Per Minute)

ACCURACYACCURACY

ACCURACYACCURACY

ACCURACY ±0.02% of reading

RESOLRESOL

RESOLRESOL

RESOLUTIONUTION

UTIONUTION

UTION 0.1 , 40.0 – 4,999.9 FPM

0.2 , 5,000.0 – 7,999.8 FPM

0.5 , 8,000.0 – 9,999.5 FPM

1.0 , 10,000.0 – 12,500.0FPM

DISPLDISPL

DISPLDISPL

DISPLAA

AA

AYY

YY

Y 5-Digit LED, 0.3" (8 mm) height

RR

RR

RAA

AA

ATETE

TETE

TE Divide by 2, Multiply by 2

UPDAUPDA

UPDAUPDA

UPDATE TIMETE TIME

TE TIMETE TIME

TE TIME Ext. mode: varies with flashing rate

OPEROPER

OPEROPER

OPERAA

AA

ATING TIMETING TIME

TING TIMETING TIME

TING TIME 1 hour when fully charged

FLASH TUBE POWER/LIFEFLASH TUBE POWER/LIFE

FLASH TUBE POWER/LIFEFLASH TUBE POWER/LIFE

FLASH TUBE POWER/LIFE Xenon, 10 W, 100 million flashes

FLFL

FLFL

FLASH DURASH DUR

ASH DURASH DUR

ASH DURAA

AA

ATIONTION

TIONTION

TION 10 - 15 µs

SIGNAL OUTPUTSIGNAL OUTPUT

SIGNAL OUTPUTSIGNAL OUTPUT

SIGNAL OUTPUT NPN Open Collector (24 VDC max.,

50 mA) 150 µs typical

PHASE SHIFPHASE SHIF

PHASE SHIFPHASE SHIF

PHASE SHIFTT

TT

T Internal mode only by using the “+”

and “–” switches

EXTEXT

EXTEXT

EXT. TRIGGER. TRIGGER

. TRIGGER. TRIGGER

. TRIGGER a) 12-24 VDC thru a 3-wire NPN output

sensor (requires external power supply)

INPUT SIGNALINPUT SIGNAL

INPUT SIGNALINPUT SIGNAL

INPUT SIGNAL b) 12 VDC thru a 2-wire proximity

sensor (leakage current 1 mA max.,

Load current 8 mA min.)

c) Switch or Relay contact

LL

LL

LOW BAOW BA

OW BAOW BA

OW BATT

TT

TTERY INDICATERY INDICA

TERY INDICATERY INDICA

TERY INDICATORTOR

TORTOR

TOR Yes

OPEROPER

OPEROPER

OPERAA

AA

ATING TEMPERTING TEMPER

TING TEMPERTING TEMPER

TING TEMPERAA

AA

ATURETURE

TURETURE

TURE 32° – 104° F (0 – 40° C)

DIMENSIONSDIMENSIONS

DIMENSIONSDIMENSIONS

DIMENSIONS 9" L x 4.3" W x 8.5" H

(Height includes handle)

WEIGHTWEIGHT

WEIGHTWEIGHT

WEIGHT 2.75 lbs (1.25 Kgs)

ACCESSORIES AVAILABLEACCESSORIES AVAILABLE

ACCESSORIES AVAILABLEACCESSORIES AVAILABLE

ACCESSORIES AVAILABLE Carrying Case

Specifications