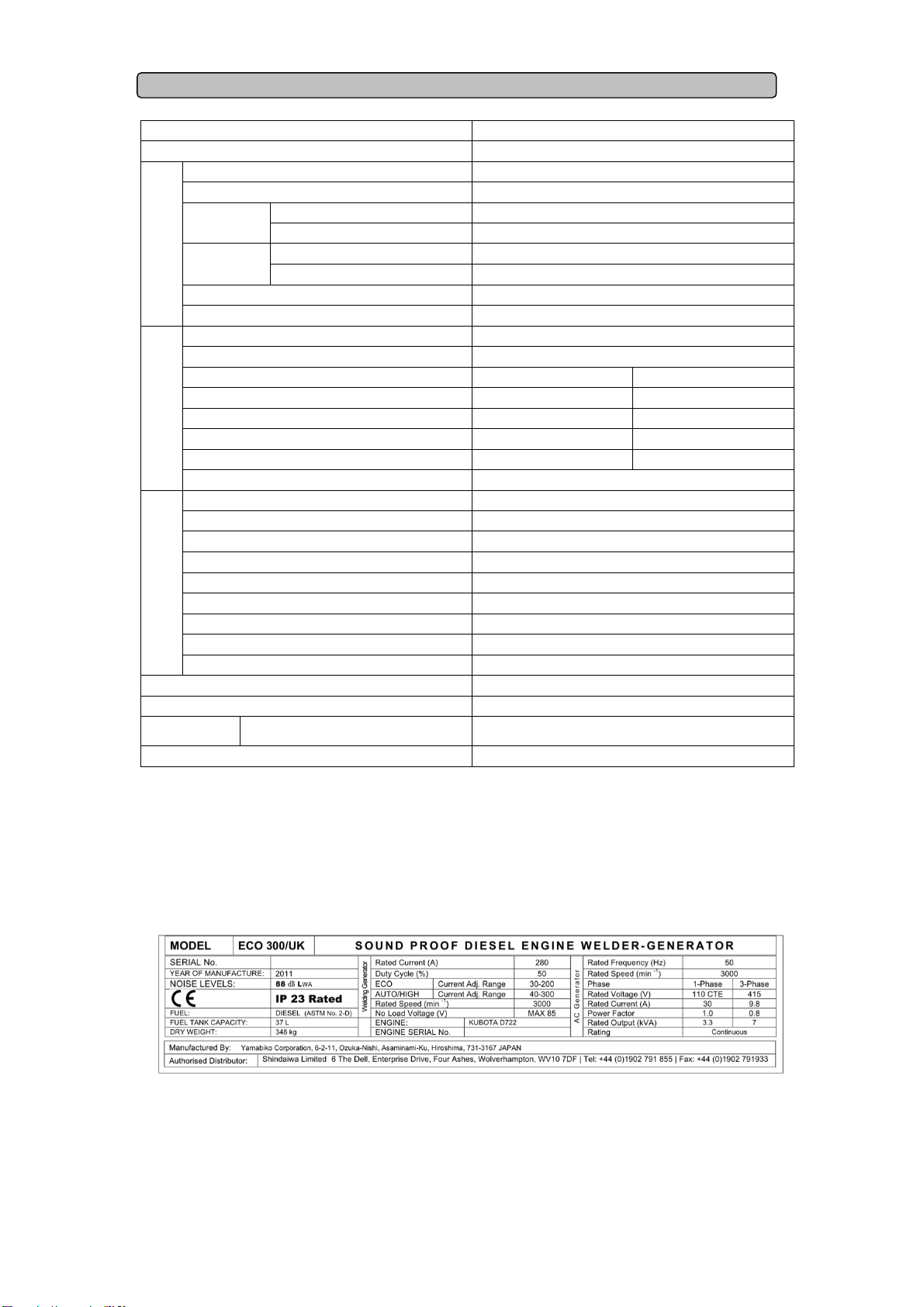

Shindaiwa Limited

Four Ashes, Wolverhampton, UK

T:

+44

0

1902

791855

- 4 -

ECO 300/UK

Series 3

OOM-300UK

Caution: Electric shock

Do not flush water onto the equipment nor operate it in the rain.

Caution: Explosion

Do not use the equipment or charge the battery, if the battery fluid level is

Below the LOWER level.

The battery may emit combustible gas, so keep it away from fire and sparks.

Caution: Fire

This equipment uses Diesel as a fuel. When inspecting the equipment or

refuelling, always stop the engine and keep away from fire, always wait until the

engine cools down before refuelling.

Always wipe away any drips of Diesel fuel or lubrication oil. Do not use this

equipment if a leak is found. Repair the equipment before use.

Temperature around muffler and exhaust can get extremely high. Keep any

inflammable items (such as fuel, gas, paint, etc.) away from the equipment.

Keep any inflammable items and combustible items away from the welding area,

as welding causes hot sparks.

Always operate this equipment on a flat surface and at least 1 metre away from

any object (wall, box, etc.).

Do not connect AC output to any indoor wiring.

Always wait until the equipment cools down before placing any covering

materials for storage.

Keep children at a safe distance from the machine at all times.

Caution: Burns

Do not touch the engine and muffler during operation and immediately after

stopping the equipment, for the temperature could reach extremely high.

When checking engine oil or changing oil, always stop the engine, and wait until

the engine cools down. If you open either the oil gauge or the oil plug during

operation, hot oil may cause some injury.

Be sure to wear leather gloves, apron, shoe covers, eye protection glasses

/mask, safety shoes, safety cap, and long sleeve shirts, to protect from sparks.

Do not open the side door during operation and immediately after stopping the

equipment, because some parts/components (flexible tube, resistors, etc.) can

reach very high temperatures inside the equipment.

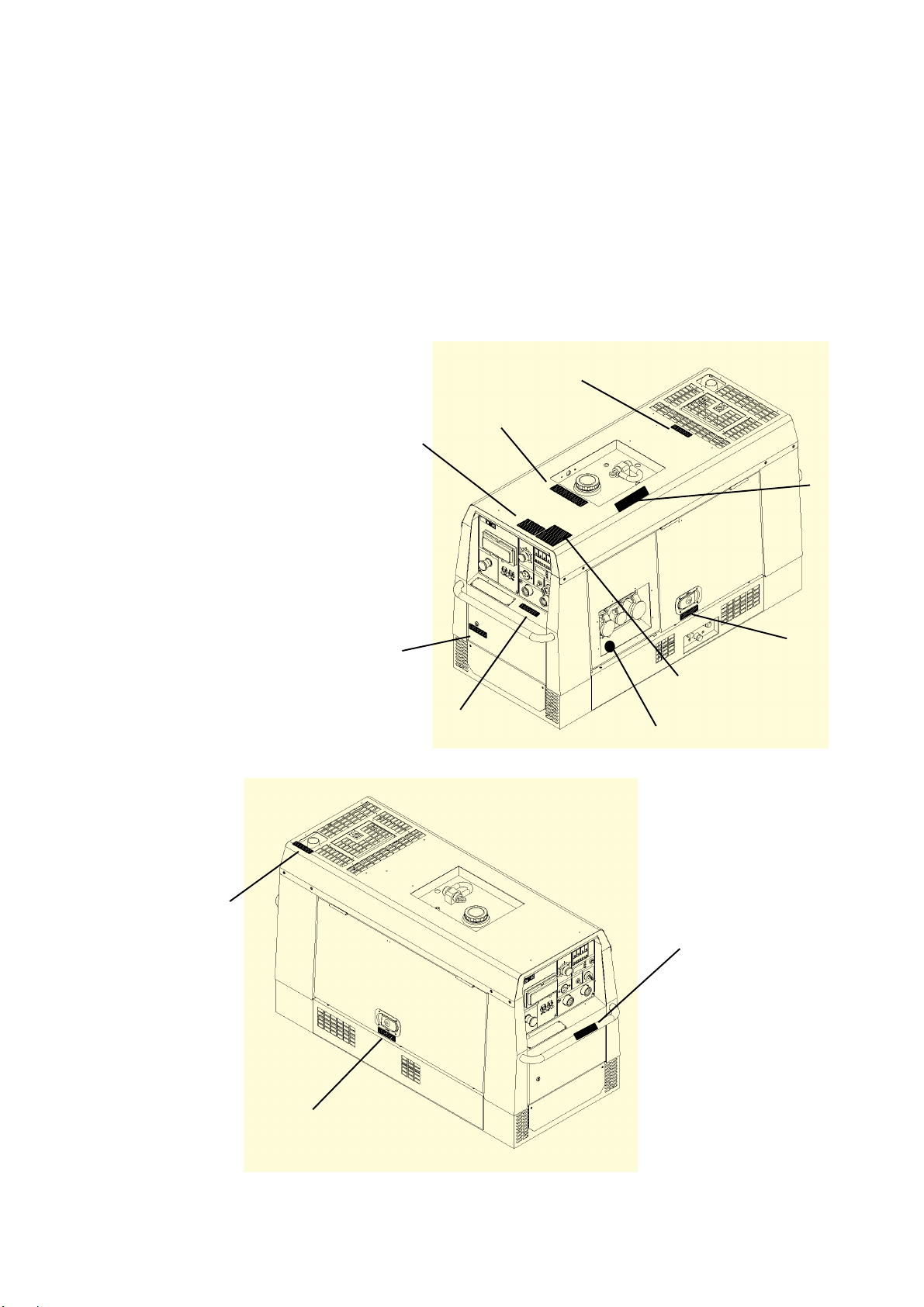

Caution: Injuries

When lifting the equipment, always use the top-mounted lifting lug. Do not lift

using the positioning handles.

Always use appropriate lifting gear & secure adequately during transportation.

Always place the equipment on a flat and stable surface and fix the wheels to

prevent equipment movement.

When starting the engine, turn off the connected equipment and set the circuit

breaker to the OFF position.

Do not move the equipment during operation.

When performing equipment checks and maintenance, always stop the engine.

Do not operate the equipment, if it is faulty or if there are missing parts.