- 1 -

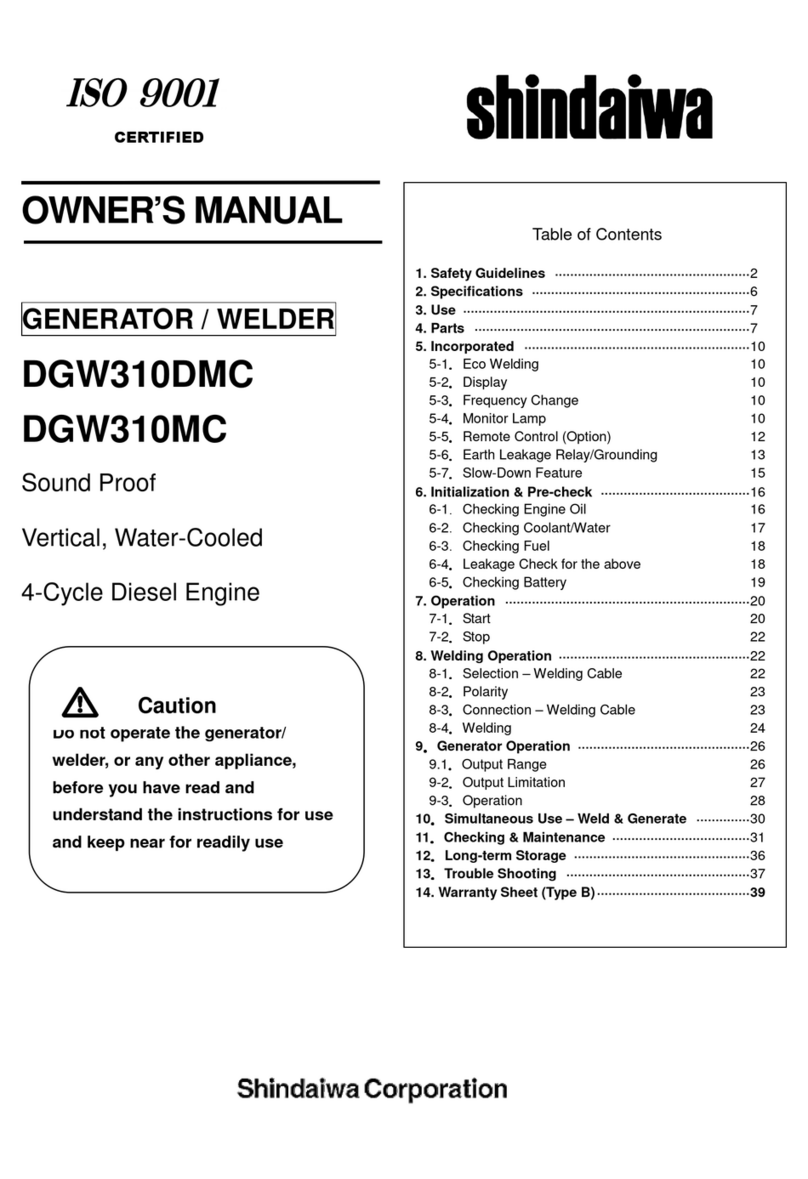

Table of Contents

1. Safety Precautions···································································· 2

2. Specifications ·········································································· 6

3. Applications············································································· 7

4. Part Names ·············································································· 7

5. Equipment ··············································································10

5-1. Automatic Switching Mode················································10

5-2. Simple Hour Meter (Tripmeter)···········································10

5-3. Spill Containment····························································10

5-4. ECO Drive ·····································································11

5-5. VRD (Voltage Reduction Device)········································12

5-6. Weld Mode Selector·························································13

5-7. Meter············································································13

5-8. Error Code Display··························································14

5-9. Frequency Selector··························································14

5-10. Monitor Lamp·································································14

5-11. VoltageAdjustment Dial····················································16

5-12. Earth Leakage Circuit Breaker and Grounding ······················16

5-13. Remote Control (Option)···················································19

6. Pre-Operation Inspection··························································19

6-1. Engine Oil Inspection·······················································20

6-2. Cooling Water Inspection··················································20

6-3. Fuel Inspection ·······························································21

6-4. Spill Containment Inspection··············································22

6-5. Inspection for Fuel/Oil/Cooling Water Leakage······················22

6-6. Battery Inspection····························································22

7. Operating Procedures······························································23

7-1. Starting the Engine··························································24

7-2. Stopping the Engine·························································25

8. Using as a Welder····································································25

8-1. Welding Cable Selection···················································25

8-2. Welding Polarity······························································26

8-3. Welding Cable Connection················································26

8-4. Welding Work·································································27

9. Using as a Generator································································29

9-1. Output Types and Ranges·················································29

9-2. Usable Device Capacities ·················································30

9-3. Operation ······································································30

10. Simultaneously Welding and as AC Power Source·····················32

11. Inspection/Maintenance··························································33

12. Long-Term Storage ································································39

13. Troubleshooting····································································40

14. Engine Wiring Diagram···························································43

15. Generator Wiring Diagram ······················································44