Ku nst sto ffschwei ßtechn i k

Contents

02.11.11 Working instructions WIDOS 4900 Page 4 of 46

1.

DESCRIPTION OF PRODUCT ............................................................................................. 6

1.1.

pplication and prescribed use ......................................................................................6

1.2.

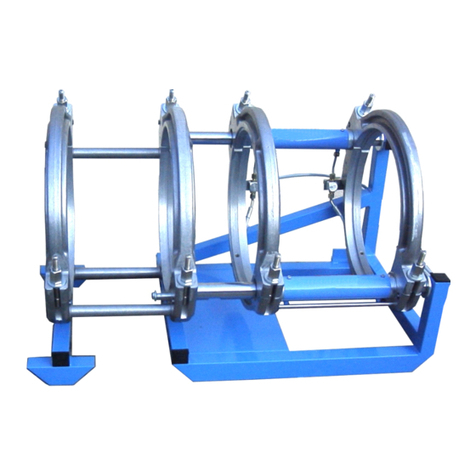

Machine overview ............................................................................................................6

1.3.

Safety measures ..............................................................................................................7

1.4.

Conformity........................................................................................................................7

1.5.

Designation of product....................................................................................................7

1.5.1

Technical Data ...............................................................................................................7

1.5.1.1

WIDOS 4900 General data..................................................................................7

1.5.1.2

Planer....................................................................................................................8

1.5.1.3

Heating ele ent.....................................................................................................8

1.5.1.4

Hydraulic aggregate...............................................................................................9

1.5.1.5

Basic fra e ...........................................................................................................9

1.6.

Equipment and accessories: ..........................................................................................9

2.

S FETY RULES................................................................................................................... 10

2.1.

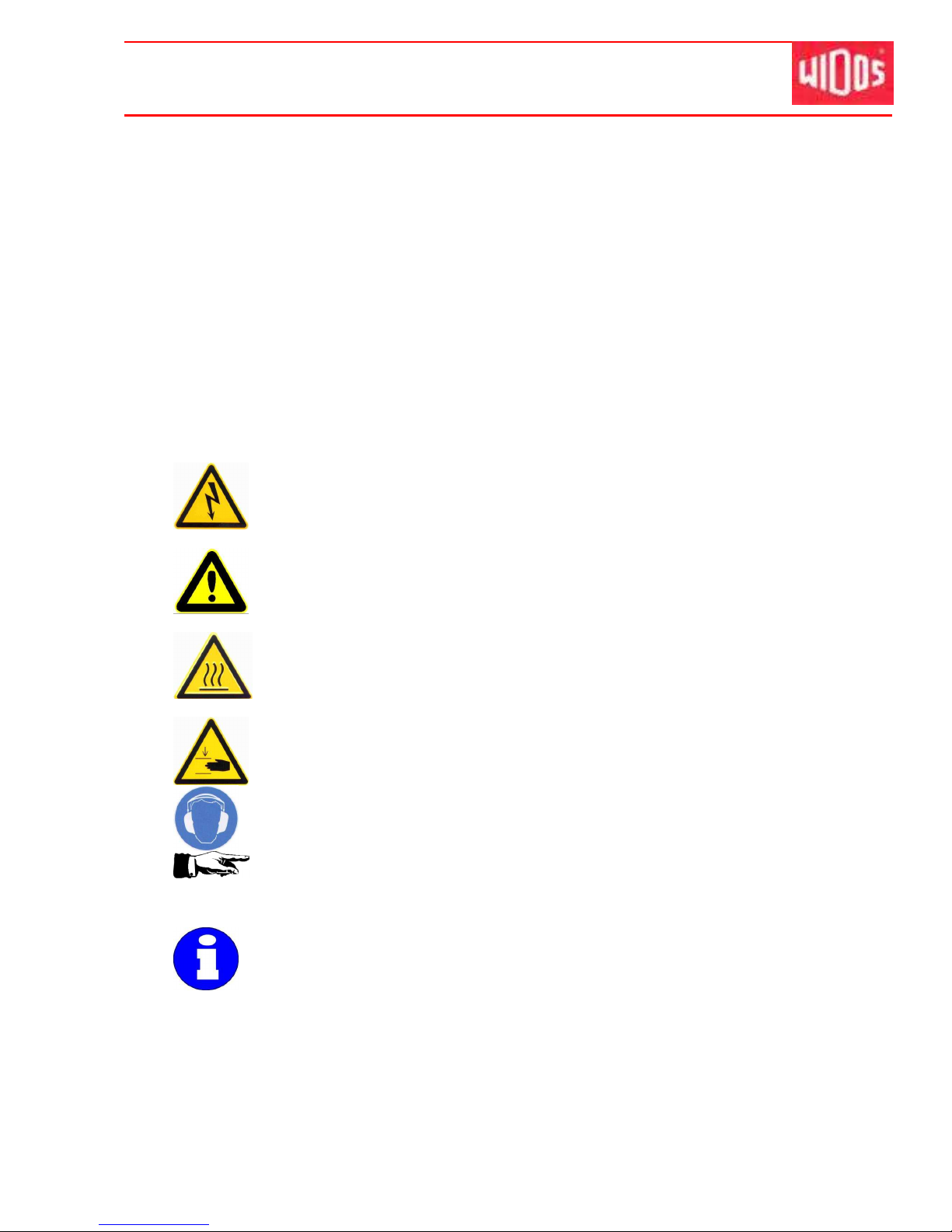

Explanation of the different symbols............................................................................10

2.2.

Obligations of the owner................................................................................................11

2.3.

Obligations of the worker ..............................................................................................11

2.4.

Organizational measures...............................................................................................11

2.5.

Informal security measures...........................................................................................11

2.6.

Instruction of the staff ...................................................................................................11

2.7.

Dangers while handling the machine............................................................................12

2.8.

Maintenance and inspection, repair..............................................................................12

2.9.

Dangers caused by electric energy ..............................................................................12

2.10.

Dangers caused by the hydraulics ...............................................................................12

2.11.

Special dangers .............................................................................................................13

2.11.1

Danger of catching clothes by the planer..................................................................13

2.11.2

Danger of noise .......................................................................................................13

2.11.3

Danger of burning at heating ele ent, heat protective box and welding area...........13

2.11.4

Danger of stu bling over hydraulic and electric wires ..............................................13

2.11.5

Danger of squeezing by cla ping tool and guideways ..............................................14

2.12.

Structural modifications on the machine .....................................................................14

2.13.

Cleaning the machine ....................................................................................................14

2.14.

Guarantee and liability ...................................................................................................14

3.

FUNCTION L DESCRIPTION............................................................................................ 15

4.

OPER TING ND INDIC TING ELEMENTS .................................................................. 16

4.1.

Elements on the hydraulic aggregate...........................................................................16

4.2.

Elements at the heating element ..................................................................................17

4.3.

Separating device for heating element.........................................................................17