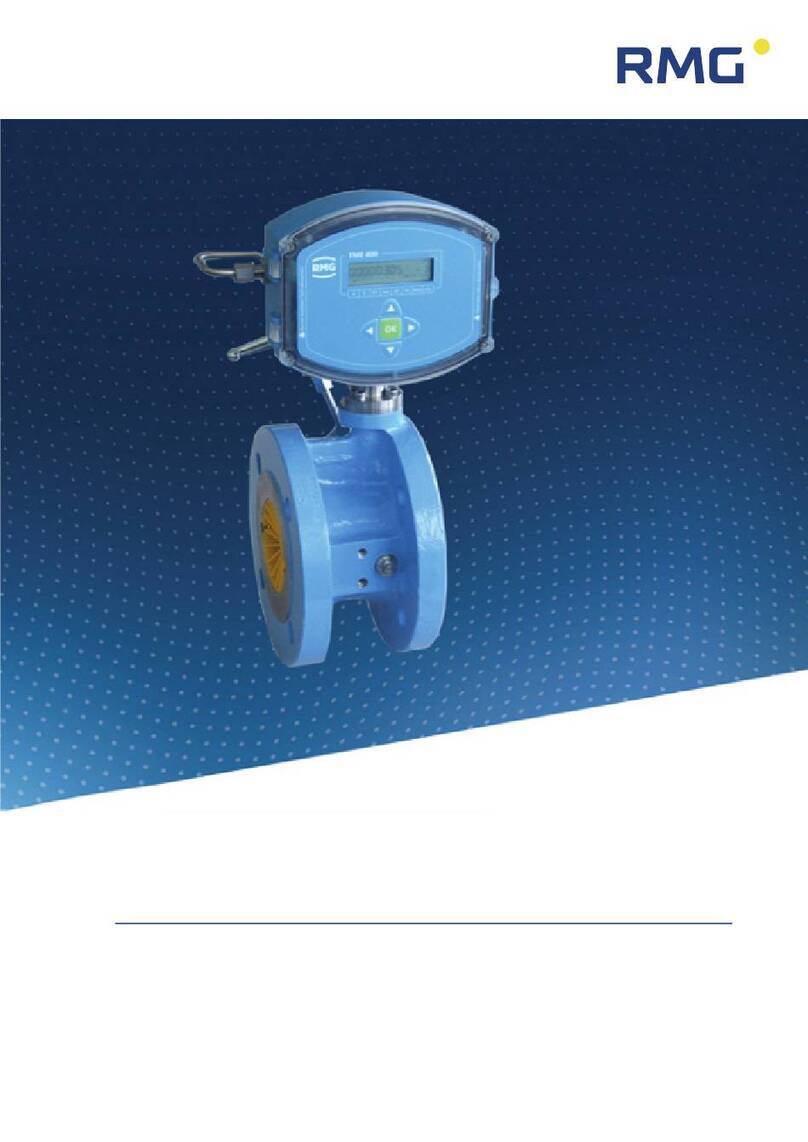

RMG USM GT400 User manual

Ultrasonic Flowmeter USM GT400

OPERATING INSTRUCTION

Reliable Measurement of Gas

Read the instructions before starting work!

IUltrasonic Flowmeter USM GT400 September, 4th 2018

Manufacturer Our customer service is available for technical queries:

Address RMG Messtechnik GmbH

Otto-Hahn-Str. 5

D-35510 Butzbach

Telephone Switchboard +49 6033 897-0

Telephone Service +49 6033 897-0

Telephone Spare Parts +49 6033 897-173

Fax +49 6033 897-130

E-Mail [email protected]

Original Document

Note

The Ultrasonic Flowmeter USM GT400

OPERATING INSTRUCTION 9/4/2018 is the original document.

This document may serve as a reference for translations into

other languages. Please use in case of any uncertainties the

German version as main reference.

Unfortunately, paper is not updated automatically, whereas

technical development continuously advances. Therefore, we

reserve the right to make technical changes in regard to the

representations and specifications of these operating

instructions. The latest version of this manual (and other devices)

can be downloaded at your convenience from our Internet home-

page:

www.rmg.com

Date created 1/31/2014

1st revision date 5/12/2014

2nd revision date 9/18/2015

3rd revision date 9/29/2017

4th revision date 2/16/2018

5th revision date 09/04/2018

Document version and language Document version Ultrasonic Flowmeter USM GT400

September, 4th 2018

Language EN

Contents

September, 4th 2018 Ultrasonic Flowmeter USM GT400 II

1 About this manual

1.1 Objective of the manual ........................... 1

1.2 Specialized knowledge required .............. 2

1.3 Abbreviations ........................................... 2

1.4 Symbols ................................................... 3

1.5 Validity of the manual .............................. 3

2 Brief instructions

2.1 Mechanical connection ............................ 5

2.2 Electrical connection................................ 6

2.3 Start Up.................................................... 7

2.4 Earthing ................................................... 7

2.5 Parameter setting .................................... 8

3 Device overview

3.1 Main components .................................... 9

3.2 Ultrasonic electronics............................. 11

3.3 Arrangement of the

ultrasonic transducers............................ 15

4 Functional principle - Ultrasonic flow

measurement

4.1 General description................................ 17

4.2 Correction of the base line..................... 21

4.3 Diagnostic function Speed of Sound...... 24

4.4 Import of gas composition data.............. 27

4.5 Batch mode............................................ 36

5 Safety

5.1 Intended use .......................................... 37

5.2 Layout of instructions............................. 38

5.3 Qualification of the personnel ................ 39

5.4 Safety instructions ................................. 39

5.5 Responsibilities of the operator ............. 46

6 Transport and storage

6.1 Transport ............................................... 47

6.2 Packing the device for transportation .... 55

6.3 Storage .................................................. 62

7 Construction and Planning

7.1 Connection flanges ................................ 65

7.2 Seals...................................................... 66

7.3 Screws ................................................... 70

7.4 Installation possibilities .......................... 71

7.5 Flow computer ....................................... 75

8 Installation

8.1 Assembly work preparations ................. 78

8.2 Installation of the device........................ 80

8.3 Connecting the device electrically ......... 84

8.4 Installing the pressure connection ....... 112

8.5 Outdoor installation.............................. 114

9Start Up

9.1 Comparing meter parameters.............. 115

9.2 Checking functions of the USM ........... 115

9.3 Reading out speed of sound................ 116

10 Operation

10.1 Measuring values and parameters ...... 118

10.2 Calling up and changing the parameters

via the ultrasonic electronics ............... 121

10.3 Parameterize the USM interface ......... 131

10.4 Modbus communication in detail ......... 141

10.5 List of the measurement values and

parameters .......................................... 143

11 Maintenance

11.1 Maintenance schedule......................... 146

11.2 Checking the device for leaks.............. 146

11.3 Checking the device for any signs of

damage................................................ 147

11.4 Changing the battery ........................... 147

11.5 Changing the transducer ..................... 147

11.6 Changing the ultrasonic electronics..... 148

11.7 Cleaning the device ............................. 148

11.8 Check the official seal.......................... 149

11.9 Decommissioning and disposal ........... 149

12 Alarm and warning messages

12.1 Alarm messages.................................. 151

12.2 Warning messages.............................. 154

12.3 Notes ................................................... 157

12.4 Troubleshooting................................... 157

13 Technical specifications

13.1 Performance data................................ 160

13.2 Approved gas types ............................ 160

13.3 Approved measuring range according

to MID.................................................. 161

13.4 Type plate............................................ 162

13.5 Weights and dimensions ..................... 163

Contents

III Ultrasonic Flowmeter USM GT400 September, 4th 2018

13.6 Inner diameter of connecting

spool pieces......................................... 168

13.7 Official seal diagram ............................ 169

13.8 Transducer types ................................. 175

14 USM GT400 Approval

14.1 Metrological approvals......................... 177

14.2 Pressure devices approval .................. 177

14.3 Electromagnetic compatibility ..............177

14.4 Explosion protection approval.............. 177

14.5 Standards, directives and guidelines ... 178

15 Index

16 USM GT400 Glossary

17 USM GT400 Attachment

18 Lists of parameters and measured

values

September, 4th 2018 Ultrasonic Flowmeter USM GT400 1

1 About this manual

1

About this manual

In this chapter you will be given information on this manual.

Contents 1.

1.1 Objective of the manual ...................................... 1

1.2 Specialized knowledge required ........................ 2

1.3 Abbreviations ....................................................... 2

1.4 Symbols ................................................................ 3

1.5 Validity of the manual .......................................... 3

1.1

Objective of the manual

The manual provides you with the information that is designed for

trouble-free and safe operation.

The ultrasonic gas meter is state of the art and conceived and

manufactured according to the recognized safety standards and

guidelines.

However, risks may arise during use that can be easily avoided

by observing this manual..

For this reason, you may only use the device as intended and in

technically sound condition.

If the ultrasonic gas meter is not used for its intended purpose,

warranty claims will be void.

2Ultrasonic Flowmeter USM GT400 September, 4th 2018

1 About this manual

1.2

Specialized knowledge required

Persons working with or on the device must have the following

knowledge:

•training / education for working in potentially explosive

environments.

•the ability to correctly assess dangers and risks when using

the device. Possible dangers are, e.g., components under

pressure or the result of incorrect installation.

•recognize dangers that could be caused by the used flow

medium.

•training / education by RMG for working with gas measuring

instruments.

•education / instruction in all country-specific standards and

directives to be observed for work that is to be carried out on

the device.

Further information can be found under:

Chapter 5.3, „Qualification of the personnel“ on page 39

1.3

Abbreviations

The following abbreviations are used:

AGC Automatic Gain Control

ca. circa, approximately

as app. as applicable

max. maximum

MC Measurement Canada

MID Measurement Instruments Directive

min. minimum

SNR Signal to Noise Ratio

SoS Speed of Sound

TD Transducer (ultrasonic transmitter and

receiver)

TNG Transducer of a certain production type.

USE Ultrasonic electronics

USM Ultrasonic gas meter

e.g. For example

September, 4th 2018 Ultrasonic Flowmeter USM GT400 3

1 About this manual

1.4

Symbols

The following symbols are used:

1, 2, ... Marks steps within a work operation.

Marks steps in an illustration that are

described in the text.

(A) Reference to a component (element) marked

with a letter in an illustration.

Marks elements in an illustration. The arrow

points to the element being described.

Marks a cross-reference that refers to

another part in this manual or in another doc-

ument.

Print Screen Marks switches, regulators, slides, buttons

and other terms from the software are

marked by bold text.

1.5

Validity of the manual

This manual describes the Ultrasonic Flowmeter USM GT400.

The Ultrasonic Flowmeter USM GT400 device is only a part of a

complete on site system. Observe also the instructions of other

components of the site system.

If you find contradicting instructions, please contact RMG.

4Ultrasonic Flowmeter USM GT400 September, 4th 2018

1 About this manual

September, 4th 2018 Ultrasonic Flowmeter USM GT400 5

2 Brief instructions

2

Brief instructions

This chapter does not replace the rest of the operating instruc-

tions. It shows only a brief section of the steps necessary in order

to make the device ready for operation.

The chapter is only directed at experienced users.

•Observe the chapter safety.

Section 5, "Safety" on page 37

Detailed information for this content can be found under:

Section 7, "Construction and Planning" on page 65

Section 8, "Installation" on page 77

Section 9, "Start Up" on page 115

Section 12.4, "Troubleshooting" on page 157

2.1

Mechanical connection

2.1.1

Connection flanges

1Make sure that the device and the connection flange have

the same pressure rating / flange standards.

2Make sure that the device is sealed with the appropriate

seals.

2.1.2

Inlet / outlet piping

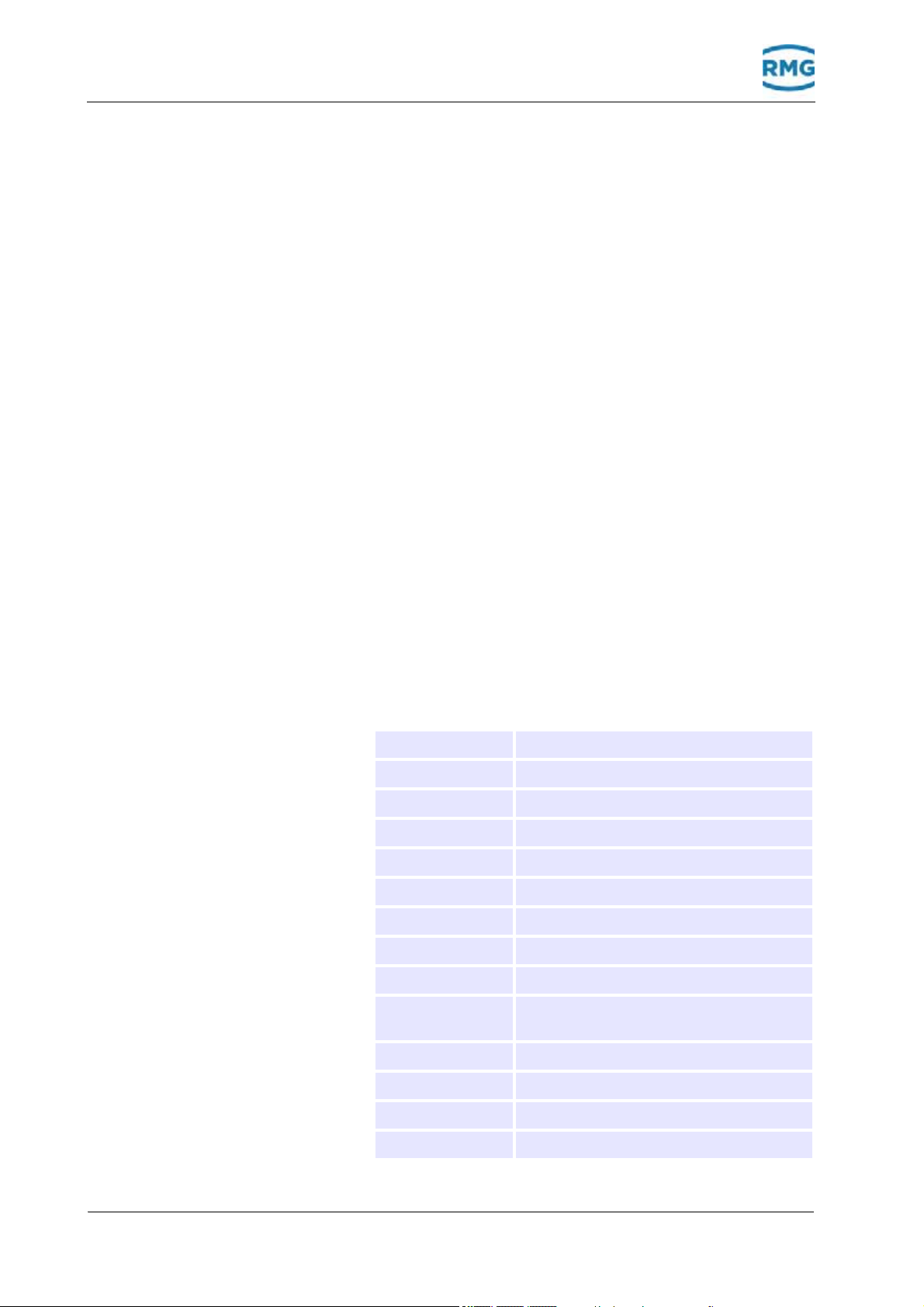

Operating mode Inlet piping Outlet piping Temperature sensor

position

Unidirectional operation 10 D (no flow conditioner) 3 D 1.5 D to 5 D

Unidirectional operation 3 / 5 D (with RMG or stan-

dardized flow conditioner)13 D 1.5 D to 5 D

Bidirectional operation 10 D (no flow conditioner) 10 D (no flow conditioner) 3 D to 5 D

Bidirectional operation 3 / 5 D (with RMG or stan-

dardized flow conditioner)13 / 5 D (with RMG or stan-

dardized flow conditioner)12 D to 5 D1

1 Depending on the nominal width.

–Seealso"Inner diameter of connecting spool pieces" on

page 168

6Ultrasonic Flowmeter USM GT400 September, 4th 2018

2 Brief instructions

2.1.3

Joining pressure connections

Establish connection with the clamping screw connec-

tion

3Unscrew the union nut of the clamping screw connection.

4Remove the blind plug.

5Push the union nut and clamping rings onto the pipe.

6Push the pipe into the clamping screw connection until the

stop.

7Tighten the union nut in order to fix and seal the pipe.

Establish connection with the female thread

8Unscrew the blind plug.

9Seal the connection in the thread.

2.2

Electrical connection

Fig. 2-1: Connection assignment on the terminal strip

10 Connect the computer to the terminals RS 485-0.

11 Allocate the terminal strips according to the applications.

Option: connect ERZ 2000 (-NG) to RS 485-1.

September, 4th 2018 Ultrasonic Flowmeter USM GT400 7

2 Brief instructions

2.3

Start Up

12 Supply the device with power supply (24 V DC) via the

system.

If the power LED illuminates green permanently, the device is

ready for operation.

If the alarm and warning LED do not flash, the device oper-

ates trouble-free.

Section 3.1, "Light emitting diodes" on page 14

The USM-GT-400 is supplied without connection box to the North

American region, the connection is made to cables that are led

through a flame arrester. The marking of the cable (numbers) is

(always) identical to the terminal assignment.

2.4

Earthing

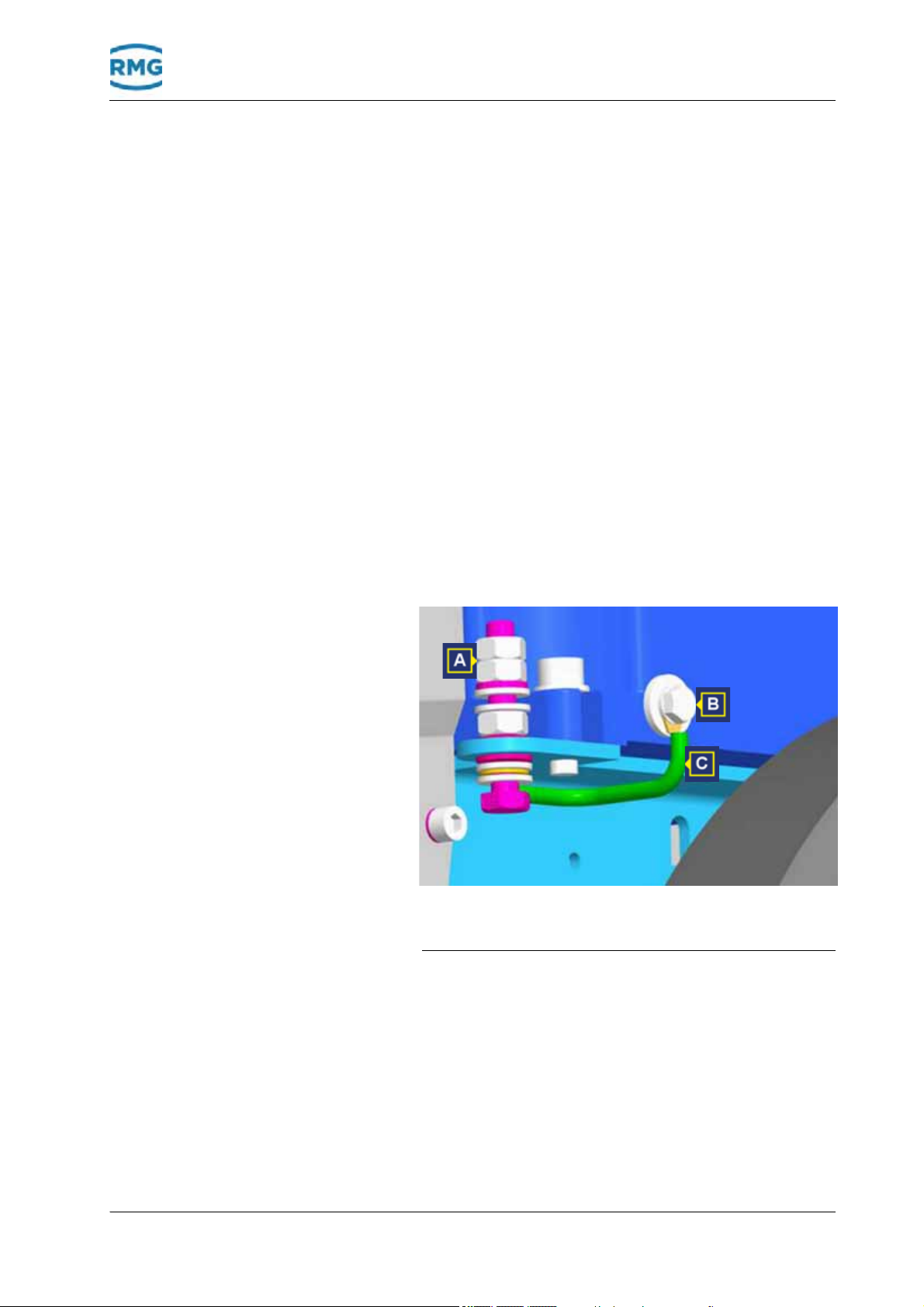

Fig. 2-2: Connect to earth - Ultrasonic gas meters DN150 (6")

and DN100 (4")

AEarthing screw M6 BEarthing screw M6

CEarthing cable

Fig. 2-3: Connect to earth - Ultrasonic gas meter

DN200 (8")

AEarthing screw M6 BEarthing screw M6

CEarthing cable

8Ultrasonic Flowmeter USM GT400 September, 4th 2018

2 Brief instructions

13 Connect the earthing cable according to the ultrasonic gas

meter version DN100 (4") to DN150 (6") or from DN200 (8").

2.5

Parameter setting

The device shall be supplied pre-assembled according to cus-

tomer agreement. Changes to the pre-assembly are more

extensive and are therefore not described in this brief instruction.

If this should be necessary, you will then find the description:

Section 10.1.3, "Calibration and Service Switch" on page 119

September, 4th 2018 Ultrasonic Flowmeter USM GT400 9

3 Device overview

3

Device overview

In this chapter you will receive information on the main compo-

nents of the ultrasonic gas meter and the arrangement of the

ultrasonic transducers in the housing of the ultrasonic gas meter.

Contents 3.

3.1 Main components ................................................ 9

3.2 Ultrasonic electronics ....................................... 11

3.3 Arrangement of the ultrasonic transducers .... 15

3.1

Main components

Fig. 3-1: Main components of the ultrasonic gas meter

ACovers of the transducer and

transducer lines

BCovers of the transducer lines

CUltrasonic electronics DLifting eyes

EJoining flanges FTransducer

GRetaining bolts

The ultrasonic gas meter consists of the following main

components:

10 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

Covers of the transducers (A and B) The covers protect the connections and the lines of the transduc-

er (TD) against contamination and mechanical damage.

Ultrasonic electronics (C) The ultrasonic electronics is in a pressure tight, encapsulated

housing mounted on the ultrasonic gas meter. The ultrasonic

electronics evaluates the data recorded by the transducers. In

addition to the display, the parameters can be shown and evalu-

ated on a computer using the RMGViewUSM software.

Lifting eyes (D) The lifting eyes can be used to safely transport the device using

a suitable lifting gear.

Connection flange (E) The device is bolted onto the gas line using the connection

flanges.

Transducer (F) The transducers are installed in the housing of the ultrasonic gas

meter and are not visible once installed.

Retaining bolts (G) The retaining bolts are mounted when delivering the device. The

retaining bolts secure the product from tipping over or rolling

away. The bolts must be mounted to ensure for a safe installation

or de-installation.

September, 4th 2018 Ultrasonic Flowmeter USM GT400 11

3 Device overview

3.2

Ultrasonic electronics

Fig. 3-2: Ultrasonic electronics and display

AService and calibration switch BControl panel

CDisplay DMagnet for operation

ECover with viewing window FPressure tight housing

Device data (readings and parameters) can be set and evaluated

via the display and the operating elements.

Moreover, the device data (readings and parameters) can also be

shown, evaluated and set using the RMGViewUSM software.

Service and calibration switch (A) The service switch (right switch) is only for RMG service. The ser-

vice switch is, e.g., used to install new firmware.

The calibration switch (left switch) protects the parameters

against unauthorized changes. The device can be configured by

opening the calibration switch.

Control panel (B) The control field comprises buttons that are triggered by pressing

a button or magnetically. Parameters, readings, warning, alarm

and status messages are called up using the button.

Display (C) The display shows the readings, warning , alarm and status mes-

sages as well as the parameters.

Magnet for operation (D) The magnet is used to operate the control panel of the ultrasonic

electronics when the housing is closed. If the magnet is placed

above the symbol on the viewing window, this function is

activated.

12 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

Cover with viewing window and

pressure tight housing (E and F)

The cover and the pressure tight housing encapsulate the ultra-

sonic electronics against the potentially explosive atmosphere.

During operation, information can be read through the viewing

window from the display and status indicators of the LEDs.

Electrical connection

(Terminal strip)

More information on the electrical connection can be found here:

Chapter 8.3, „Connecting the device electrically“ on page 84

Display screen

Fig. 3-3: Example for a possible display

First line Shows the name of the parameter (coordinates) called-up, e.g.,

p-maximum value (maximum pressure value).

Second line Shows the value of the parameter (coordinates) called-up, e.g.,

52.00 bar a.

Third line Shows the coordinate designation, e.g., A-06, thus column A, line

06.

The calibration switch is open. The value of the parameter can be

changed.

The calibration switch is closed. The value of the parameter can-

not be changed.

Forth line Shows the warning, alarm and status messages, e.g., -01 power

failure

September, 4th 2018 Ultrasonic Flowmeter USM GT400 13

3 Device overview

Buttons

When the cover is closed, the buttons can be operated through

the glass using the magnets supplied. The cover must not be

opened.

Change to the columns. Jump, e.g., from A to B and back again.

When holding for a longer time, you can change the columns by

quickly scrolling back.

Change or scroll forwards in the lines step by step, e.g., from A-

01 to A-02.

When holding for a longer time, you can change the lines quickly

scrolling forward.

Change or scroll back in the lines step by step, e.g., from A-01 to

A-02.

When holding for a longer time, you can change the lines with

quick return.

Enter values.

Reset button

The reset button (A) is for RMG service only. If the reset button is

pressed, the ultrasonic electronics is restarted.

Switches

Calibration switch (A): Activate to change parameters.

Service switch (B): For RMG service only. For installing a new

firmware.

14 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

Light emitting diodes

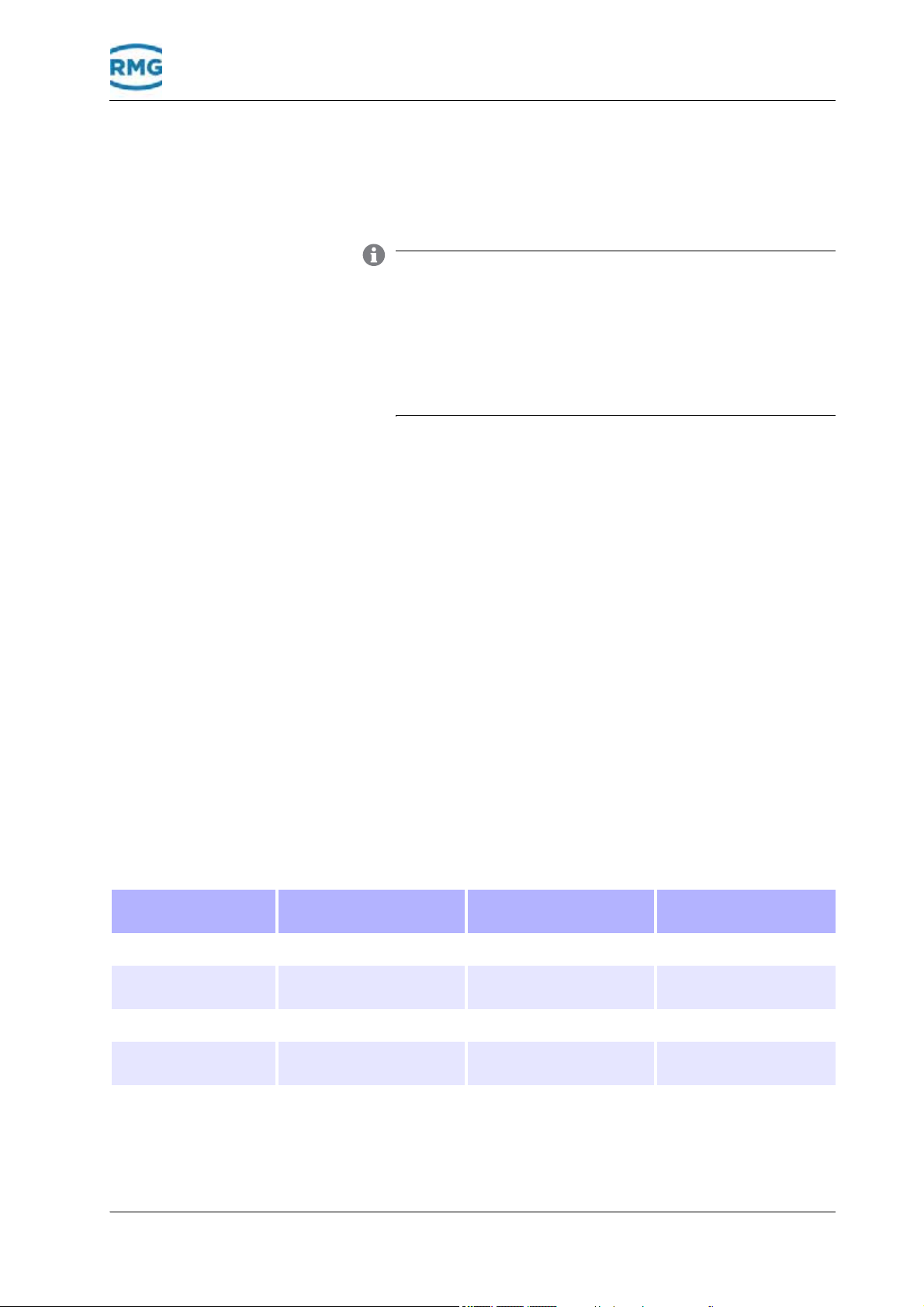

Fig. 3-4: LEDs of the electronic ultrasonic electronics

AFlow BPower (supply voltage)

CAlarm DWarning

EReset FService (service switch state)

GCalibration (calibration switch

state)

HButton states

LED Illuminates con-

tinuously

flashing

Power Voltage supply is

switched on.

—

Flow Gas flow present. —

Alarm Alarm message is

stored.

Alarm is active.

Warning Warning message is

stored.

Warning is active.

Reset Reset is running. —

Calibration Calibration switch is

open.

—

Service Service switch is

open.

—

Control panel Panel is being

pressed.

—

September, 4th 2018 Ultrasonic Flowmeter USM GT400 15

3 Device overview

3.3

Arrangement of the ultrasonic trans-

ducers

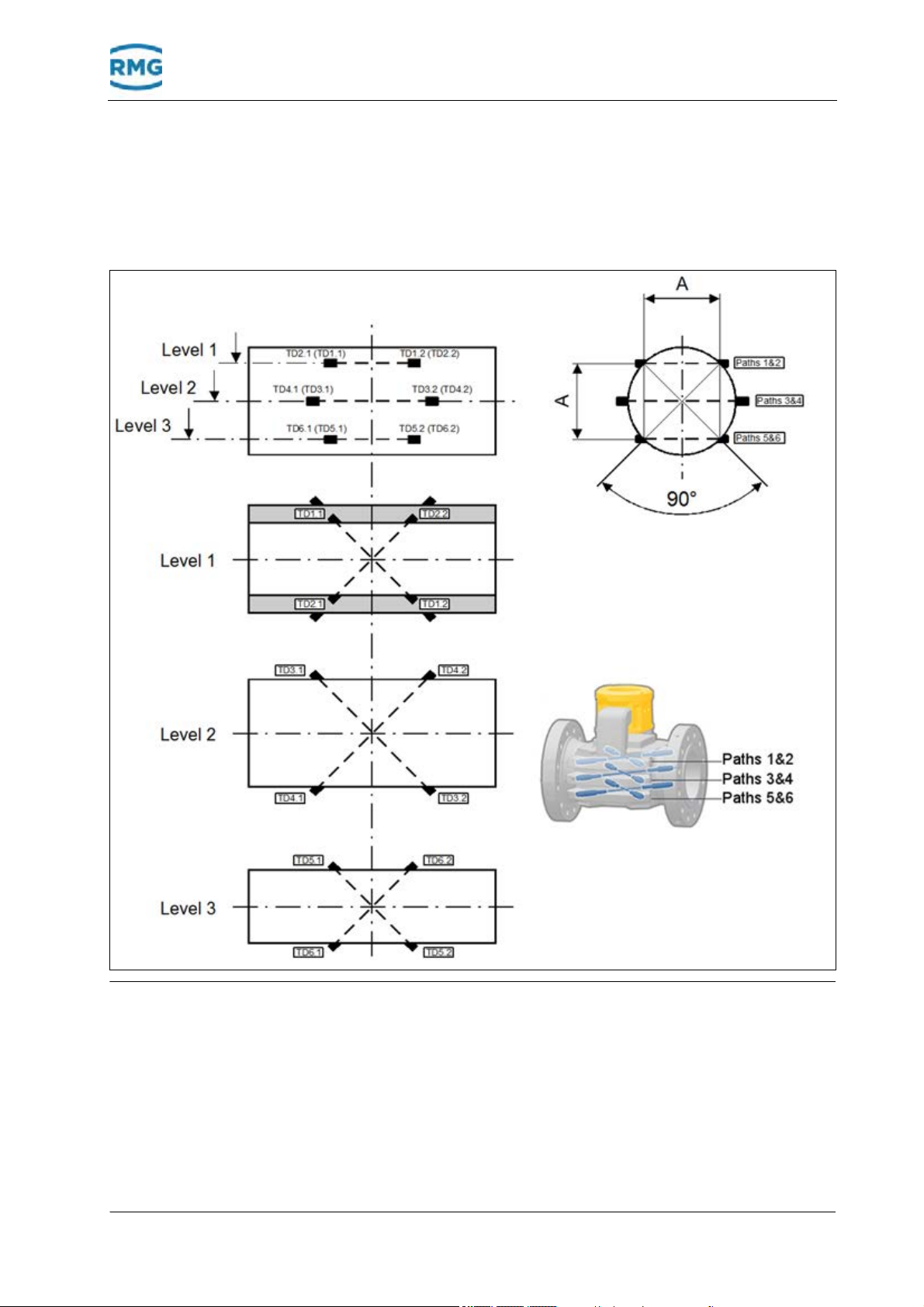

Fig. 3-5: Transducer paths and levels of the ultrasonic gas meter

The figure shows the arrangement of the transducers that are lo-

cated in the ultrasonic gas meter. The arrangement of the

transducers in the three levels is shown in three section

representations.

Four transducers are installed per level. The transducers form

two paths per level for the measurement.

16 Ultrasonic Flowmeter USM GT400 September, 4th 2018

3 Device overview

Other manuals for USM GT400

1

Table of contents

Other RMG Measuring Instrument manuals