ShopBot ATC User manual

© Copyright 2016 ShopBot Tools, Inc. page 1

ShopBotTools.com888-680-4466 •

Automatic Tool Changer (ATC)

Installation Manual

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 2

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 3

Table of Contents

Introduction .............................................................................................................................................................................................. 5

Safety Note ................................................................................................................................................................................................ 5

ATC Installation (Mechanical).............................................................................................................................................................. 7

Mounting the Spindle............................................................................................................................................................................ 7

Mount Dust Collection Bracket .......................................................................................................................................................... 8

Mount Upper Y-Axis E-Chain Bracket............................................................................................................................................... 9

Mount Tool Bar ......................................................................................................................................................................................... 9

Mount Tool Chuck .................................................................................................................................................................................10

Mount Main Air Assembly..................................................................................................................................................................10

Mount ATC Dust Skirt...........................................................................................................................................................................11

Table Drawing.........................................................................................................................................................................................12

ATC Installation (Pneumatic) .............................................................................................................................................................13

Supplied Tubing.....................................................................................................................................................................................13

Main Air Supply......................................................................................................................................................................................13

ATC Installation (Electrical).................................................................................................................................................................16

ATC Software Setup and Tool Calibration.....................................................................................................................................16

Installing ATC Software .......................................................................................................................................................................16

USB Cable.................................................................................................................................................................................................17

Software Inputs and Outputs Check..............................................................................................................................................17

ShopBot Setup (TS)...............................................................................................................................................................................22

Home Machine (C3)..............................................................................................................................................................................25

Calibration Routine (CN74)................................................................................................................................................................25

Set Fixed Z Zero Plate Location........................................................................................................................................................28

Set Up Tool Holders ..............................................................................................................................................................................29

Zero Tools in Rack (CN72)...................................................................................................................................................................31

Change Tools (C1)..................................................................................................................................................................................32

Get Plate Oset (CN73)........................................................................................................................................................................32

Zero Various Z Heights (C2) ...............................................................................................................................................................33

Regularly Used ATC Files.....................................................................................................................................................................34

Create a Tool Change File ...................................................................................................................................................................34

Spindle Warmup Routine (C5) ..........................................................................................................................................................35

Run File......................................................................................................................................................................................................35

If Something Goes Wrong..................................................................................................................................................................35

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 4

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 5

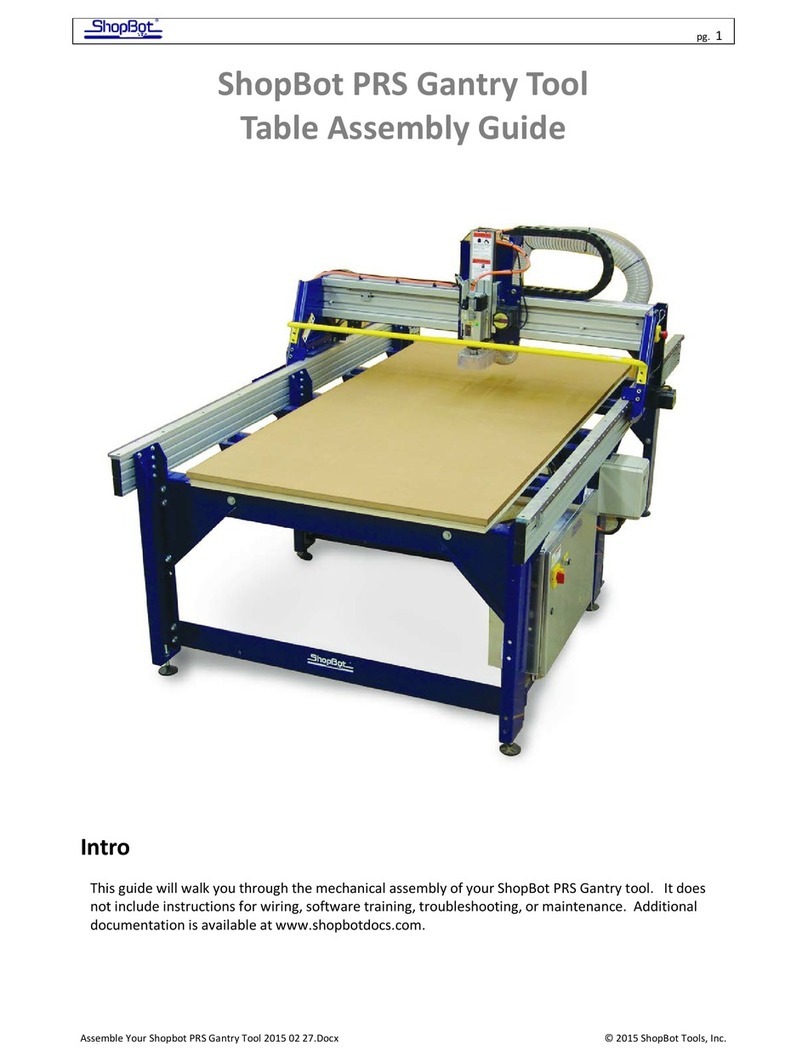

Introduction

The ShopBot Automatic Tool Changer (ATC) automates the bit changing process during projects that

require multiple tool changes. The ATC system includes a 5HP HSD spindle, a pneumatically-assisted

Z-axis, six-position tool bank standard, up to eight tool positions for our four foot wide tool (10 for a

ve foot and 12 for a six foot), xed-position Z zero plate, chuck holder, pneumatically operated dust

skirt, and ATC interface card.

The ATC reduces the time a project must remain on the machine by automatically changing cutting

bits between cuts, thus eliminating the need to change and calibrate tools by hand. The ATC allows

the PRSalpha to cut complete projects where tool changes are required without additional inputs.

The 5HP HSD spindle assembly is fan cooled - in the lower part it has air cooled bearings. The ATC

requires 6-7 cfm @ 90 psi of compressed air; PORTABLE AIR COMPRESSORS ARE NOT RECOM-

MENDED as they can have trouble keeping this pressure reliably and have a reduced service life.

The ShopBot ATC is available in the following voltages:

(#12520) HSD ATC 5HP 220V 1PH

(#12521) HSD ATC 5HP 380/460V 3PH

(#12540) HSD ATC 5HP 230V 3PH

The ShopBot ATC can be an upgrade to the E series (aluminum table sides) PRTalpha machines with

the addition of a retro Z-axis. The E series table allows for crucial table positioning without a complete

rebuild of the table. See ATC table plans before installation.

Safety Note

While running the ATC, ensure the compressed air is connected prior to turning o the power. If the

compressed air is NOT connected, and the power is turned o, the spindle will crash to the table.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 6

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 7

ATC Installation (Mechanical)

This section assumes that, except for the table assembly (a drawing for this is provided under “Table

drawing”), the ShopBot has been assembled using the instructions provided in the ShopBot assembly

manual. This means that the ShopBot is at a point in which it is able to connect and move under the

control of a computer. Wire/cable management may be left until the ATC installation has been com-

pleted.

VERY IMPORTANT! For New Table Setups

The location of the table bed is extremely critical for ATC. Excess overages in the X dimension could

mean tooling collisions, insucient cutting area, and dropped tooling. At the end of this section there

is a table drawing that shows how the table should be set up. Pay close attention to the relationship

between table sides and the table surface.

For Previously Assembled Tables

Loosen the bolts that are attached to the table side extrusions and slide table sides in the positive X

direction until the table is in the position called out in the table drawings at the end of this section.

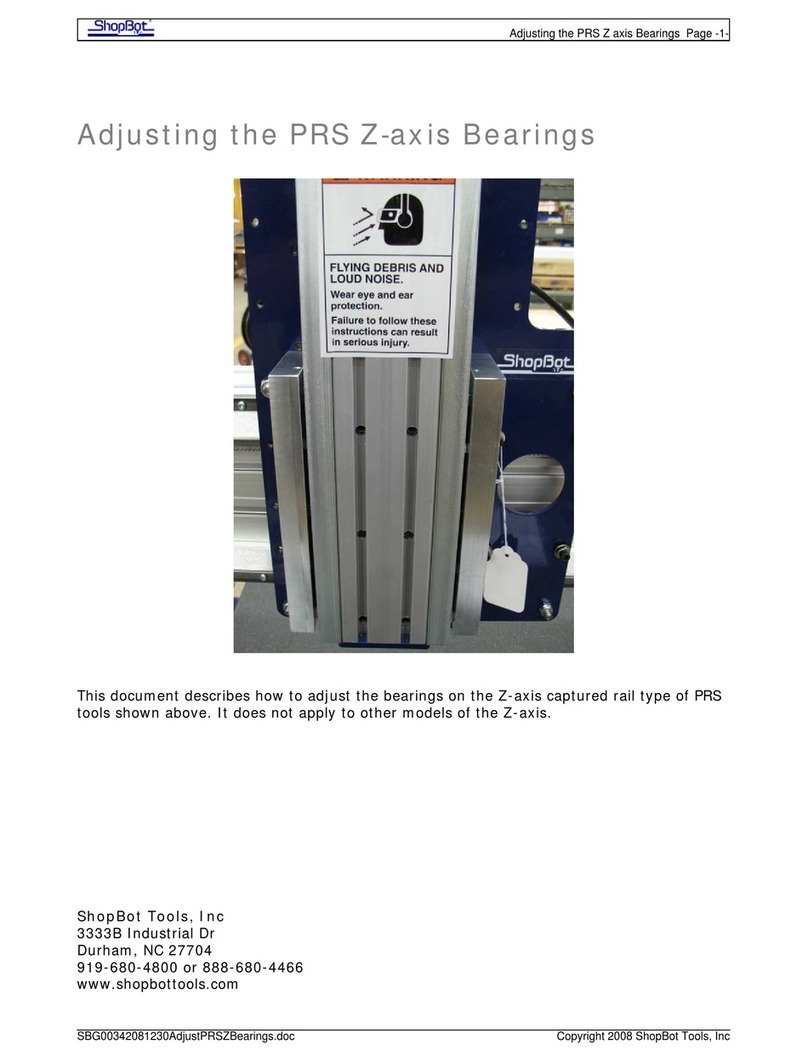

Mounting the Spindle

The ShopBot ATC is equipped with a 5HP HSD spindle. The spindle

is cooled by an electric fan, but also has air-cooled lower bearings.

The air required for cooling the lower bearings is 60 psi (4 bar).

The spindle also has an internal drawbar that holds the tool cones in

place during cutting; this requires 90-100 psi (6-7 bar).

Power up the ShopBot and position the YZ car so that it is in a

location where the front and back of the Z-axis may be reached.

Use the keypad mode (K) on the computer to move the Z-axis to a

height close to the table’s surface.

Rest the spindle on its end as seen to the left. Position the Z-axis

up or down using the keypad mode again until the holes in the

Z-axis align with the mounting holes in the spindle plate.

Tighten spindle securely to Z-axis with six 5/16”x 1 1/2” socket

head screws.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 8

Mount Dust Collection Bracket

Pry black plastic cap from top of Z-axis with a at

head screwdriver. Pre-assemble two 1/4-20x1/2”

button head screws and two 1/4-20 T-nuts through the

dust hose guide bracket. It may be necessary to slit

the top sticker down the left side of the Z-axis extru-

sion. Slide the bracket down into the extrusion and

tighten the bolts. Replace black plastic cap.

Use hose clamps to run a 4”dust collection hose to

the dust skirt from an overhead dust system. Do not

connect hose until the end, due to possible inter-

ference through the rest of the installation.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 9

Mount Upper Y-Axis E-Chain Bracket

The pneumatic assist regulator and manifold are pre-mounted on the upper Y-axis E-chain bracket.

Align holes in bracket with tapped holes on the back left side. Secure bracket with two 1/4-20x1/2”

socket head screws, 1/4” lock washers and at washers. Tighten screws securely.

Mount Tool Bar

Pre-assemble tool bar mounting bracket with four 5/16x3/4” button

head screws, 5/16” at washers, and 5/16”T-nuts.

Insert pre-assembled tool bar mounting brackets into the T-slot grooves

on the bottom of the tool bar (tab facing up).

Slide nuts into the bottom slot of the table side, as shown in the

photo. Position the tool bar o the end of the table based on the table

drawing provided.

Note: It may be necessary to adjust this dimension so that the spin-

dle is able to reach the clips on PRTalpha models. Before tightening

the mounting bolts, turn on the machine and move the axis to ensure

that it will reach the toolbar without hitting the mechanical stops.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 10

Level the tool bar by placing a level on the xed Z zero

plate (pre-attached to tool bar), then securely tighten all

5/16” button heads in tool bar mounting bracket.

Mount Tool Chuck

The tool chuck is used to hold the tool holder cone while changing

collets and bits. Use 5/16x3/4” button head screws and T-nuts to

mount the tool chuck in the second slot from the bottom of the ta-

ble extrusion. If this location is not optimal, mount the chuck where

it is most convenient.

Mount Main Air Assembly

Mount the pneumatics in the bottom extrusion slot

on the back table side. Ensure the pneumatics are

positioned as close to center of the table as possible.

Secure pneumatics with two 5/16x3/4”button head

screws and 5/16”T-nuts.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 11

Mount ATC Dust Skirt

Note: Run calibration routine without dust skirt.

Power up the ShopBot and use keypad mode (“K” in the

software mode) to move the Z-axis to a height that will allow

the ATC dust skirt to slide under the spindle.

Use the keypad mode again to move the Z-axis

down until the holes in the side of the spindle

align with the mounting slot on the ATC dust

skirt.

Securely tighten dust skirt to the side of the spindle

with four M6x10mm socket head screws.

Note: Although the dust skirt mounting plate is slot-

ted, mount the dust skirt as high as it will go and do

not lower it below this point. Otherwise, there may not

be enough clearance between the dust skirt and the

tool bar.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 12

Table Drawing

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 13

ATC Installation (Pneumatic)

This portion of the installation covers the pneumatic system routing and hook-ups.

Supplied Tubing

• Three pieces of 5/32” tubing (001349)

• Three pieces of ¼” tubing (002704)

• One piece of 3/8” tubing (001350)

Note: Lengths may have to be cut to t depending on plunge and routing paths of machine.

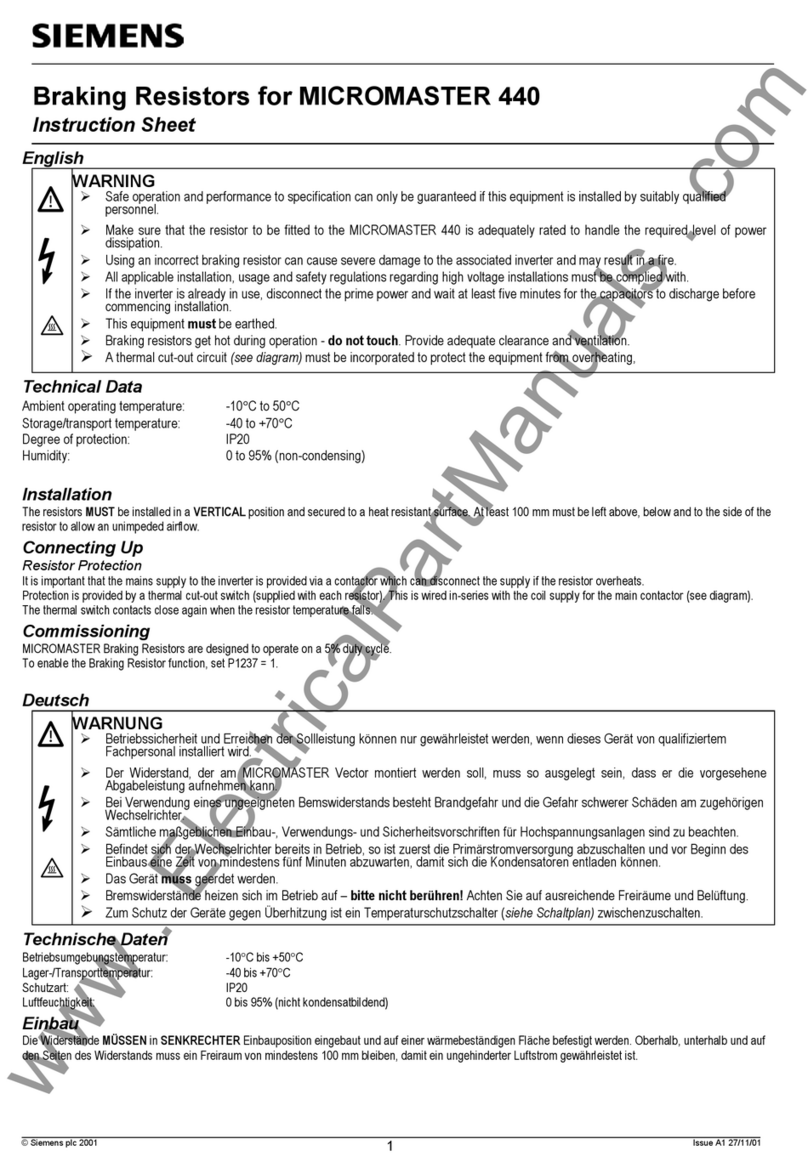

Main Air Supply

The ShopBot ATC requires 100 psi (7 bar) of air for normal operations. The main air supply should be

clean, dry, un-oiled air. It may be necessary to apply inline lters (not supplied) to achieve this require-

ment.

Caution: Do not attach a charged air line directly to the pneumatic assembly during installation.

This assembly should only be charged once all air lines are connected.

Insert one end of 3/8” tubing into the push-in tting on the

regulator side of the assembly.

Ensure shuto valve is turned to the on position (as

shown).

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 14

Route the other end of the 3/8” tubing through the X-axis E-chain,

Y-axis E-chain, and up to the YZ car. Route the 3/8” tubing to the

back right side of the spindle (as if facing the spindle). Connect the

tubing into the open push-in connection tee.

Move the Z-axis as close to

the table surface as possi-

ble to make sure that Z-axis

travel is not shortened due

to hose length.

Route ¼” and 5/32” tubing

from the output of the pre-

cision regulator (see left) to

the base of the large, verti-

cal air cylinder on the front

of the YZ car (see right).

Trim tubing to proper length

and push it into the connectors.

Connect two pieces of 1/4” tubing to the top two push-in

connectors on the manifold.

Route the other end of the tubing to the front side of the

spindle. Trim tubing to length.

Connect the 1/4” tubing from the top manifold connection to

left connection in front of the spindle (identied as 6-7 bar).

Connect the 1/4” tubing from the second manifold connec-

tion to right connection in front of the spindle (identied as 4

bar).

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 15

Connect two pieces of 5/32” tubing to the bottom

two push-in connectors on the manifold.

Route the other end of the tubing to the front side of

the spindle. Trim tubing to length.

Connect the 5/32” tubing from the left hand manifold

connection (as facing the back of the machine) to the

rear dust skirt connection (as facing the front of the ma-

chine).

Connect the 5/32” tubing from the right hand manifold

connection (as facing the back of the machine) to the

front dust skirt connection (as facing the front of the

machine).

Connect the main air supply to the lter and regulator assembly

with a standard air line that has a 1/4”female quick disconnect

(not supplied).

Attach the air hose to the male end of the disconnect, located on

the left of assembly.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 16

ATC Installation (Electrical)

This portion of the installation will cover the electrical system, wire routing, and the hook-up requirements.

Emergency Stop Switch and Three-Button Pendant Install

The three-button pendant and the separate emergency stop are bundled together for shipping. Both must be

attached for either one to function.

The ShopBot three button pendant allows the operator

to locate the reset, start, and extra emergency stop but-

tons in a convenient location away from the control box.

Control boxes may dier slightly from pictures shown,

depending on which model is present.

The separate emergen-

cy stop switch also comes tted with a Wago connector that plugs into the

control board. Power for the router or spindle is routed through the control

box safety controls so that activating the emergency stop, by hitting the red

“STOP” button, will stop the movement of the carriages and power down the

router or spindle. This stop button should be mounted to the gantry in an

easy-to-access location. There are pre-drilled holes on the top of each end

plate for easy attachment.

Note: Input #4 will ash red on the computer screen and the ShopBot control

software will not allow the ShopBot to move if the emergency stop is not

connected.

Wire Emergency Stop and Three-Button Pendant

Run cables from the three-button pen-

dant and the separate emergency stop

switch into the control box through the

Roxtec opening.

Plug in the longer Wago connector (for

the three-button pendant) into its corre-

sponding female plug on the board. Plug

in the smaller connector (for the emer-

gency stop) into the female connector

beside the longer one.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 17

Wiring the Proximity Switches and Z Zero Plate

Run cables from proximity switches and Z zero plate through the Roxtec opening into the control box.

Locate the proximity switch on the back side of the Z-axis, located

just under the Z-axis motor. Using the 90-degree proximity switch

cable, plug the cable onto the back of the proximity switch and

screw the connection tight with the thumb screw. Route the cable

through the Y-axis E-chain and into the control box. Ensure there

is proper clearance between the switch and E-chain to prevent

interference or tension during movement.

Proximity Switches

Connect the black proximity switch cable for the X-axis into input 2 (2/PX) on the blue terminal block on the

control board inside the control box. Connect the black proximity switch cable for the Y-axis into input 3 (3/PY)

on the same blue terminal block on the control board.

Connect the Z-axis proximity switch into input 5 (IN5) terminal block. The blue wires from all of the switches

can be connected to any of the grounds (GND) on the board if necessary. The brown wires from all three of the

switches will be connected to the “+24V” position on the blue output terminal block. To make wire insertion

easier, the terminal blocks can be removed by pulling them straight o the board.

When the control box is powered up, a red LED in the body of the proximity switch on the tool will stay bright

until it is triggered by coming near a target.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 18

Z Zero Plate

Plug in the Z zero plate. The black wire goes in the input #1 terminal and the green (or white) wire goes into

the ground terminal (GND) on either the input terminal block or the output block. The red wire goes to +5 (it is

only used by the digitizing probe).

USB Cable

Plug in the provided USB cable into the control box connector, and make

a loop in the cord for strain relief. Fasten the cord to the zip tie mount. Do

not plug in the USB cable to the computer at this point, the software needs

to be installed on the computer rst.

Connecting the Solenoids

Locate the row of solenoids mounted on the upper

Y-axis E-chain bracket whcih are wired into a xed

WAGO terminal. Locate the gray solenoid cable

and connect the WAGO end as shown in the yellow

circle as per the picture to the right.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 19

Route the gray cable from Wago connec-

tor through Y-Axis E-chain, through X-Axis

E-chain, under table, through the Roxtec

xture on the side of the control box, and

into the control box.

Connect the yellow, green, white and brown wires to the ATC Interdace Board inside the control box as per

the picture below. Connect the yellow wire (cooling air) to the +24V terminal at the front of the ATC Inter-

face Board. It will share this terminal with a brown wire from the z-proximity cable. Connect the green wire

(ground) to the GND terminal of the Tool Release terminal block. Connect the white wire (tool release) directly

above the green to the TR+ terminal of the Tool Re-

lease terminal block. Lastly connect the brown wire

(dust skirt) to the DS+ terminal of the Dust Skirt termi-

nal block.

Automatic Tool Changer (ATC) Installation Manual • December 1, 2016

© Copyright 2016 ShopBot Tools, Inc. page 20

Connecting Spindle

Remove the small socket head screw from the front face of the spindle plug,

using a 4mm hex wrench.

Plug the cables into the mating plug of the HSD spindle and secure the sock-

et head screw to lock the plugs in place. Route the cabling from the spindle

through the Y-axis E-chain into the control box and over to the left side of the

ATC interface board.

Connect the small blue terminal block to the location

marked “VFD Logic”. Ensure the wires are attached with red

connected to S4, black connected to S1, and green con-

nected to SC.

This manual suits for next models

3

Table of contents

Other ShopBot Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

HyQuest Solutions

HyQuest Solutions HailSens IoT user manual

Monosem

Monosem 7x7 NG Plus 4 Series Operator's & parts manual

MICRO-EPSILON

MICRO-EPSILON optoNCDT 1900-IE operating instructions

DANA

DANA SPICER Torque-Hub FBH04 Wet Series Service manual

SMC Networks

SMC Networks D-NF001 Operation manual

LPKF

LPKF ZelFlex Z4P user manual