Contents

Warnings ........................................................... 3

Important Isocyanate Information......................... 7

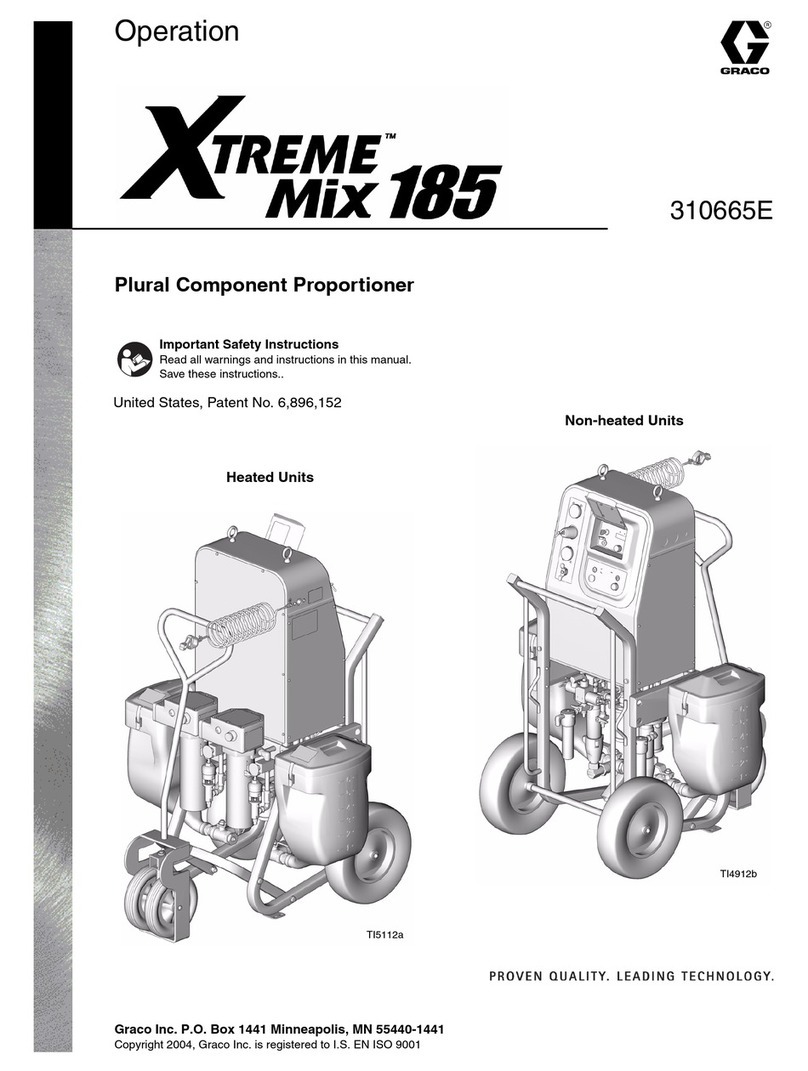

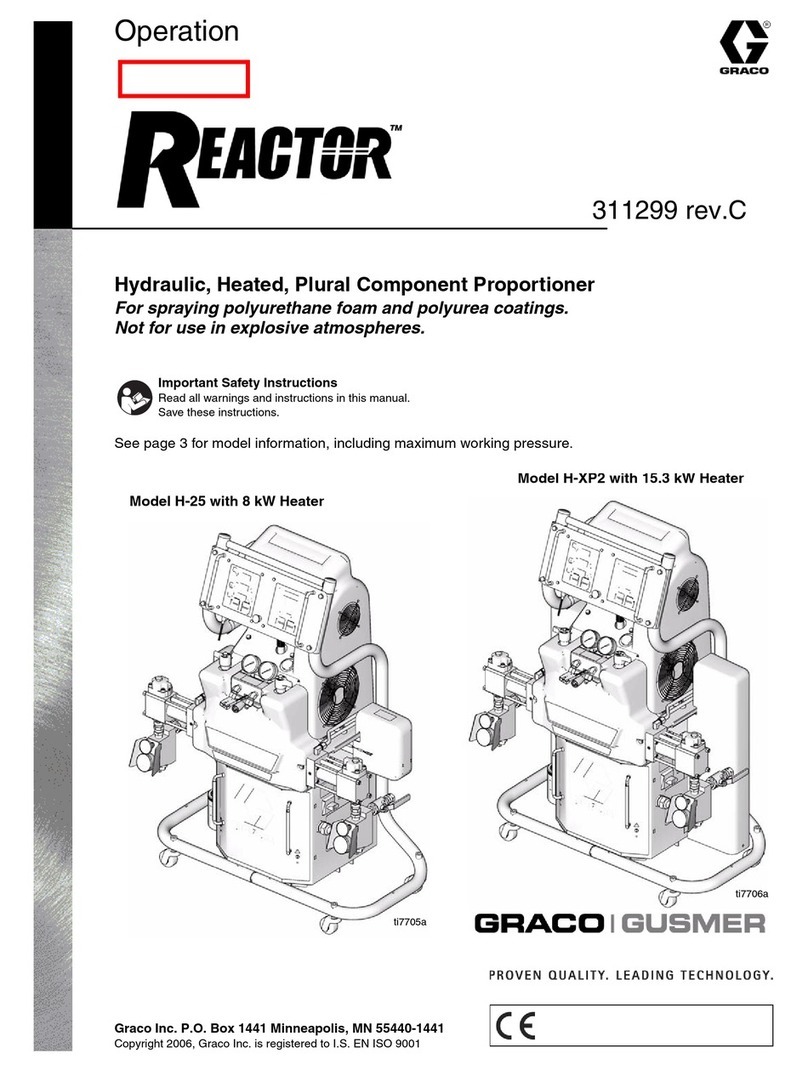

Models............................................................... 9

Approvals........................................................... 11

Accessories........................................................ 11

Supplied Manuals............................................... 1

Related Manuals ................................................ 1

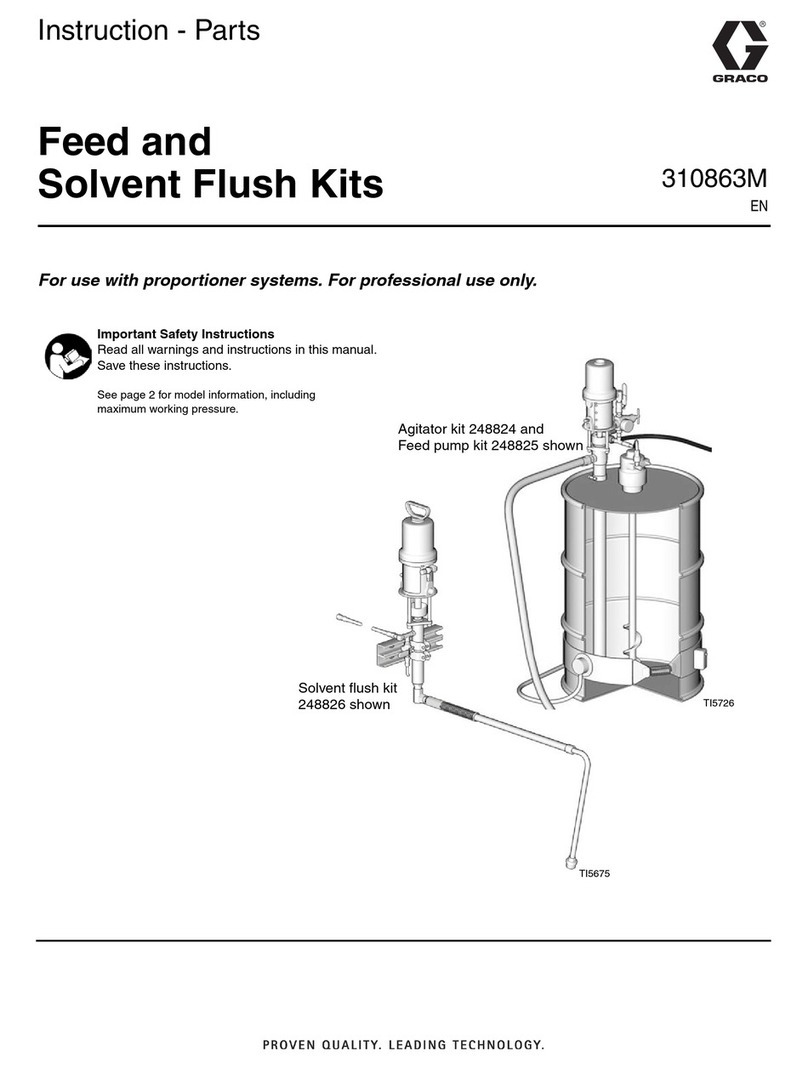

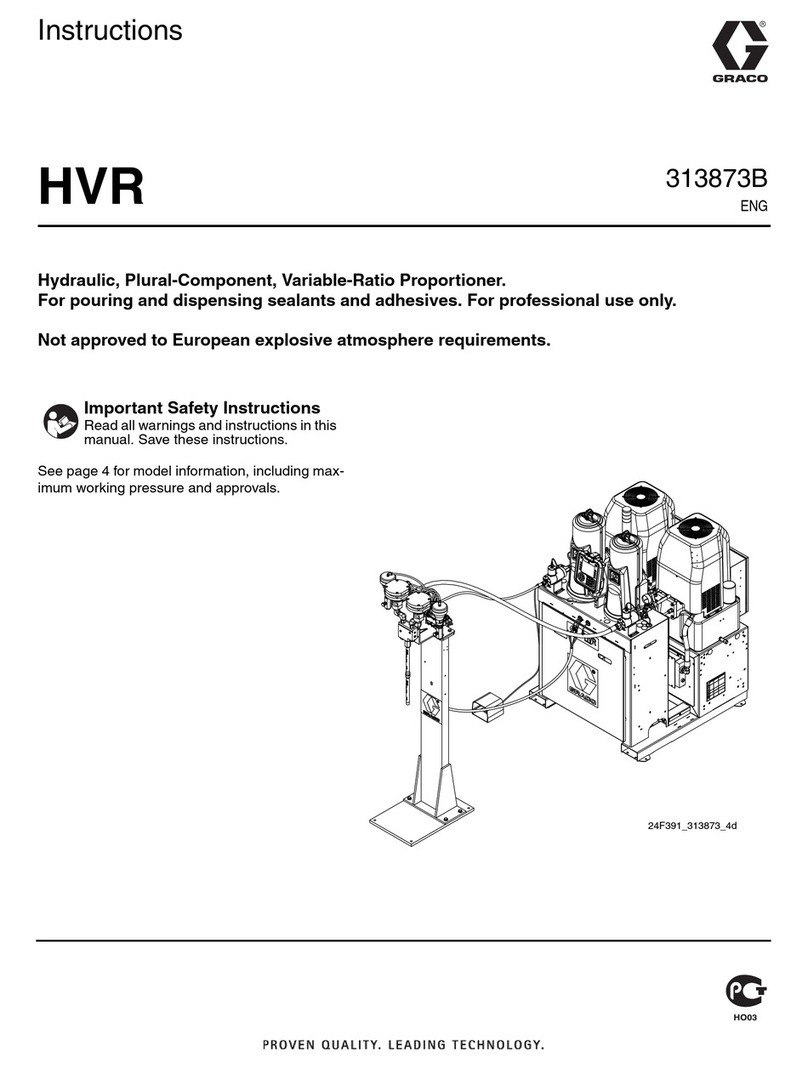

Typical Installation, without circulation.................. 13

Typical Installation, with system fluid manifold

to drum circulation................................. 14

Typical Installation, with gun fluid manifold to

drum circulation..................................... 15

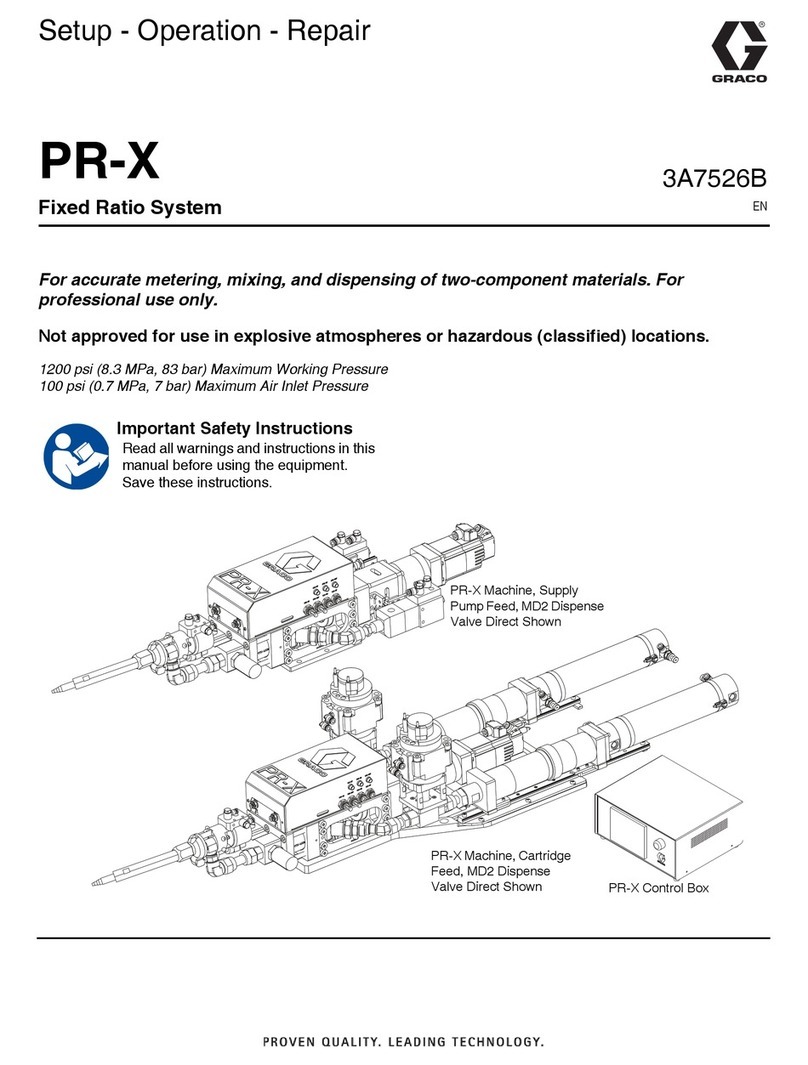

Component Identification..................................... 16

Advanced Display Module (ADM) ........................ 18

ADM Display Details .................................... 1

Navigating the Screens ................................ 1

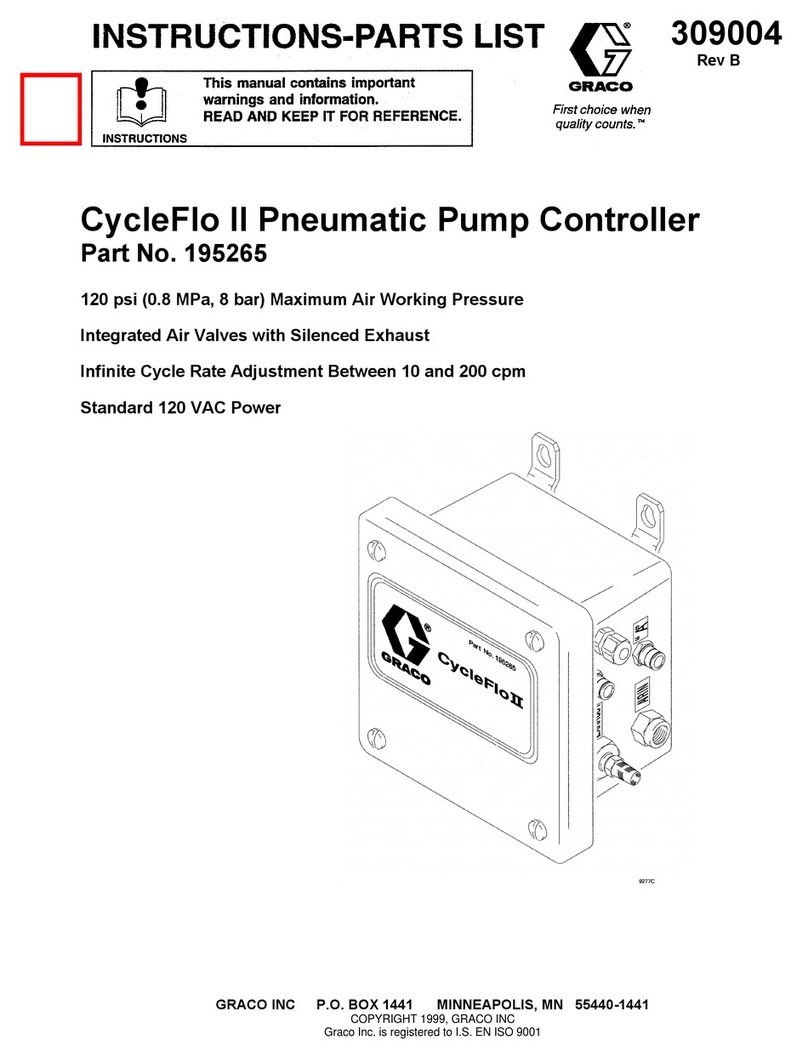

Electrical Enclosure ............................................ 3

Motor Control Module (MCM) .............................. 4

Temperature Control Module (TCM) Cable

Connections.......................................... 5

Installation.......................................................... 6

Setup................................................................. 7

Grounding ................................................... 7

Close gun fluid manifold valves A and

B ................................................... 7

General Equipment Guidelines ..................... 7

Connect Power............................................ 8

Supply Wet Cups With Throat Seal Liquid

(TSL) ............................................. 9

Install Fluid Temperature Sensor .................. 9

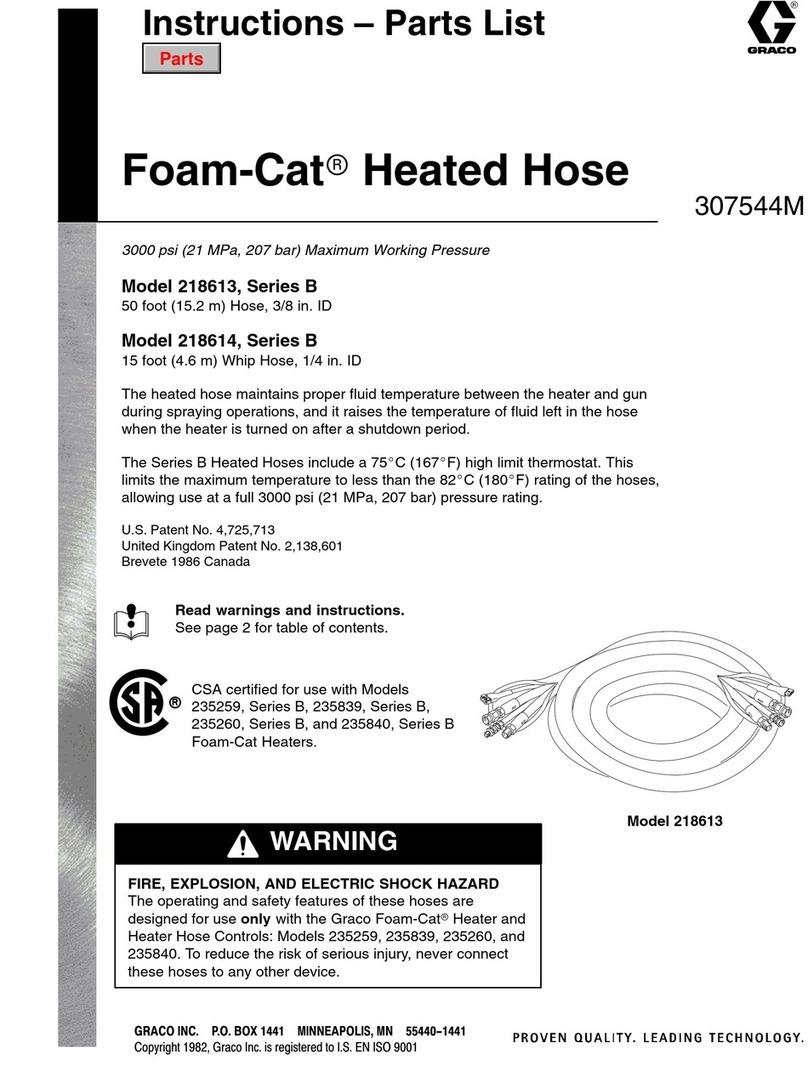

Connect Heated Hose to Proportioner........... 30

Register and Activate the Graco InSite........... 30

Advanced Display Module (ADM)

Operation.............................................. 31

Advanced Setup Screens.................................... 34

Advanced Screen 1 — General..................... 34

Advanced Screen — Units......................... 34

Advanced Screen 3 — USB.......................... 34

Advanced Screen 4— Software .................... 34

System 1............................................................ 35

System ............................................................ 35

Recipes ............................................................. 35

Add Recipe.................................................. 35

Enable or Disable Recipes............................ 35

Run Mode .......................................................... 36

Home — System Off .................................... 37

Home — System Active................................ 37

Home — System With Error.......................... 37

Targets........................................................ 37

Maintenance................................................ 38

Cycles......................................................... 38

Events......................................................... 38

Errors.......................................................... 38

Troubleshooting........................................... 39

Diagnostic ................................................... 40

Job Data ..................................................... 40

Recipes....................................................... 40

Startup............................................................... 4

Fluid Circulation.................................................. 45

Circulation Through Reactor ......................... 45

Circulation Through Gun Manifold................. 46

Jog Mode........................................................... 46

Spraying ............................................................ 47

Spray Adjustments....................................... 48

Manual Hose Heat Mode..................................... 49

Enable Manual Hose Mode........................... 49

Disable Manual Hose Mode.......................... 50

Shutdown........................................................... 51

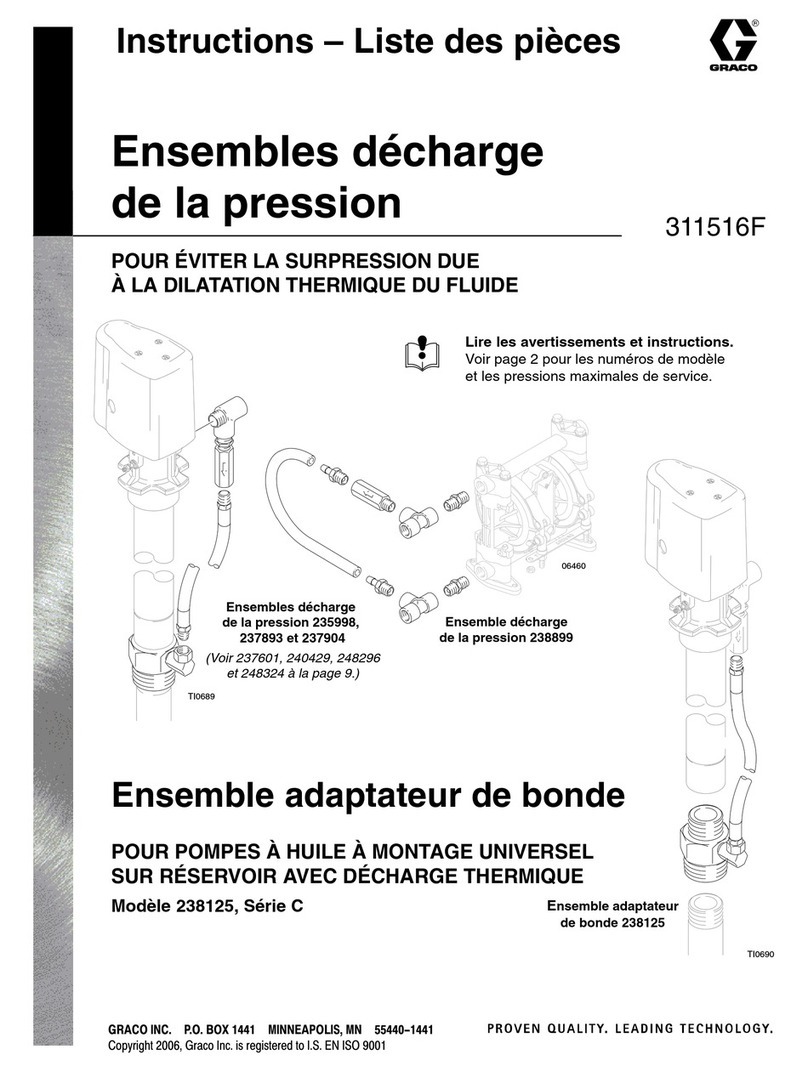

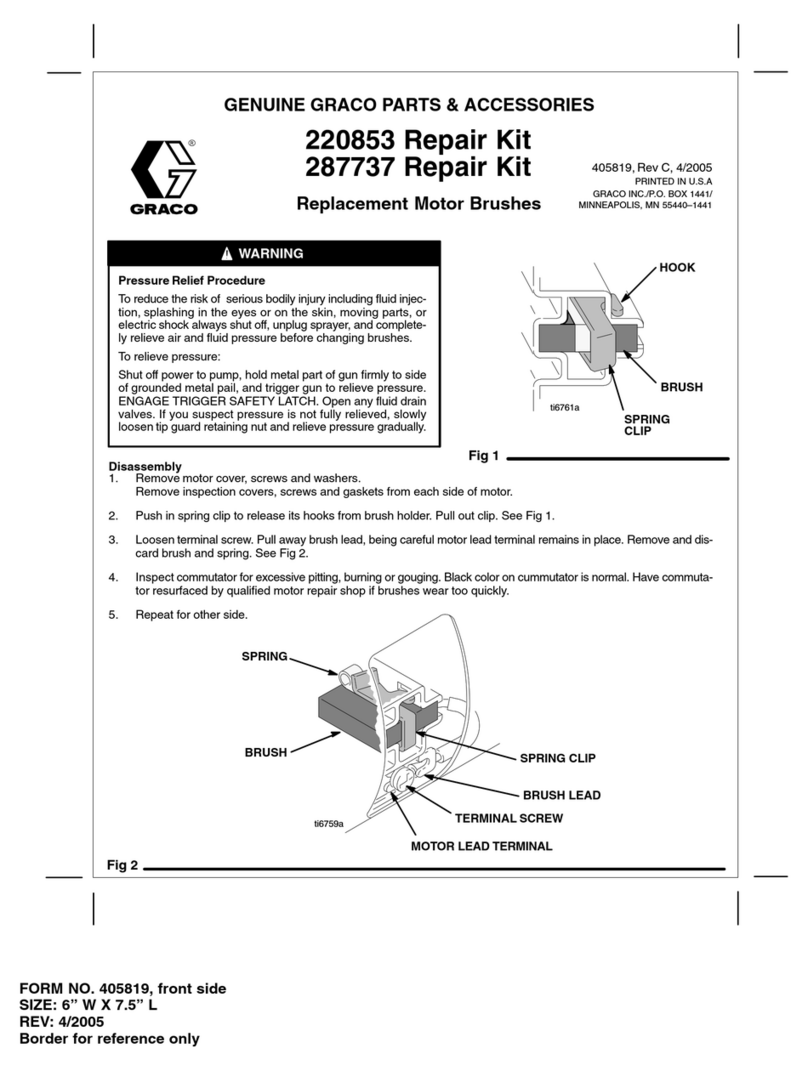

Pressure Relief Procedure .................................. 53

Flushing............................................................. 54

Maintenance ...................................................... 55

Preventative Maintenance Schedule ............. 55

Proportioner Maintenance ............................ 55

Flush Inlet Strainer Screen ........................... 56

Pump Lubrication System............................. 57

Errors ................................................................ 58

View Errors.................................................. 58

Troubleshoot Errors ..................................... 58

Troubleshooting.................................................. 59

Error Codes and Troubleshooting.................. 59

USB Data........................................................... 60

Download Procedure.................................... 60

USB Logs.................................................... 60

System Configuration Settings...................... 61

Custom Language File ................................. 6

Upload Procedure........................................ 6

Performance Charts............................................ 63

Technical Specifications...................................... 66

Notes ............................................................... 68

Graco Extended Warranty for Reactor®

Components ......................................... 69

2333023G