Shurco Donovan Quick-Flip II User manual

Quick-Flip II™ - Electric

P/N 1808554 Rev. D

Shur-Co®, LLC Terms & Conditions

SHIPPING. Orders are shipped F.O.B.

from the Shur-Co®, LLC sites listed below. No full freight is

allowed or prepaid shipment accepted unless quoted and approved in writ-

ing prior to acceptance of the order. All shipments are made by the most rea-

sonable means in accordance with size and weight of order, unless specifi ed

routing instructions are furnished by the customer. Shipments are made daily

via U.P.S. and common carrier. Claims for shortages must be made within 10

days. All claims for damages or loss in transit must be made with the carrier.

No collect calls will be accepted. To ensure delivery of orders, we need your full

street address and phone number. When you receive your shipment, examine

it carefully. Be sure all cartons listed on the delivery sheet are accounted for.

Large items may be packaged separately. If a carton is damaged, open it and

inspect the contents before signing for delivery. If merchandise is damaged,

describe damage on the delivery receipt. Failure on your part to document

damaged or missing merchandise on the delivery receipt releases the carrier

of all liability; repair or replacement will be the customer’s responsibility.

WARRANTY. We warrant all new products are free of defects in materials and

workmanship.* This warranty is effective if products are properly installed and

used for the purpose for which they were intended and applies to the original

buyer only. Except as set forth above or in any product-specifi c warranty docu-

mentation, we make no other warranties, express or implied, including but not

limited to warranties of merchantability of fi tness for a particular use.

Returns of a product for warranty must be accompanied by a Return Merchan-

dise Authorization number (RMA#), obtained by by calling Customer Service

at 866-748-7435, and sent, with freight paid by us, to Shur-Co®, LLC, 2309

Shur-Lok St., PO Box 713, Yankton, SD 57078. All products returned without

an RMA# will be refused. When we issue the RMA#, we will also issue a call

tag to have UPS (or other freight company) pick up the product. C.O.D. returns

not accepted. We will pay no storage fees for a warranty product return prior to

pick by us or the freight company. If a warranty product return is scheduled to

be picked up by us, we will pick up the product at our earliest convenience.

If a product returned is found, in our judgement, to be defective in material

or workmanship, our obligation under this warranty is limited to the repair or

replacement of the product, which will be made by us. Repair or replacement

will be at our discretion, with replacements being made using current products

performing in the equivalent function. Labor charges, other than those incurred

at our factory, including, but not limited to, any labor to install a repaired or re-

placement product, are not covered under this warranty. All expenses associ-

ated with delivering defective products to our factory and delivering repaired or

replacement products from our factory to the owner will be paid by us.

If the product returned is found, in our judgement, to be non-warrantable, the

owner will be contacted to authorize repair work, purchase of a replacement

product or return of the product, all of which will be at the owner’s expense.

Payment authorization must be received by us before any non-warrantable

product is repaired, replaced or returned. All expenses associated with deliver-

ing the repaired non-warrantable product, a replacement product or the non-

warrantable product from our factory to the owner will be paid by the owner.

In no event will we be liable for any damages of any kind to person, product or

property, including but not limited to indirect, incidental, special, consequential

or punitive damages, or damages for loss of profi ts or revenue, even if we

have been advised of the possibility of such damages. There are no warran-

ties for used products or products that have been repaired, altered, modifi ed

or subjected to misuse, negligence or accident. We will not repair or replace

products that fail or malfunction due to ordinary wear and tear, except as ex-

pressly noted in a product-specifi c warranty. Use of non-Shur-Co®, LLC parts

in conjuction with Shur-Co®, LLC products will void this product warranty.

*Certain products have specifi c warranties that differ from this warranty, for example motors and elec-

tronics. Product-specifi c warranty documentation is available for these items. In the event of a confl ict

between this warranty and a product-specifi c warranty, the product-specifi c warranty will govern.

RETURN POLICY. All sales fi nal. See WARRANTY above for return details.

OTHER. All prices, product listings, sizes, weights and manufacturing details

are subject to change without notice. No person is authorized to modify the

foregoing conditions of sale whatsoever.

SHUR-CO® of NORTH DAKOTA

1746 4th Ave. NW

West Fargo, ND 58078

Ph 877.868.4488 | Fax 701.277.1283

SHUR-CO® of OHIO

1100 N. Freedom, St. Rt. 88 & 14

Ravenna, OH 44266

Ph 866.356.0242 | Fax 330.297.5599

SHUR-CO® of TEXAS

34505 I-10 West, S. Frontage Rd.

Brookshire, TX 77423

Ph 866.689.0039 | Fax 281.934.3311

SHUR-CO® UK, Ltd.

Unit 41 Rochester Airport Estates

Laker Rd., Rochester, Kent ME1 3QX

Ph +44 (0)1795.473499

Fax +44 (0)871.272.8278

For more info, log on to our website:

www.shurco.com

Corporate HQ and Outlet Store

SHUR-CO® of SOUTH DAKOTA

2309 Shur-Lok St., PO Box 713

Yankton, SD 57078-0713

Ph 800.474.8756 | Fax 605.665.0501

ShurTite™ Service Centers

SHUR-CO® of CANADA

490 Elgin St., Unit #1

Brantford, Ontario N3S 7P8

Ph 800.265.0823 | Fax 519.751.3997

SHUR-CO® of SIOUX FALLS

47184 258th St., Suite B

Sioux Falls, SD 57107

Ph 844.573.9322 | Fax 605.543.5469

SHUR-CO® of ILLINOIS

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO® of OHIO

Ph 866.356.0242 | Fax 330.297.5599

SHUR-CO® of COLORADO

10220 Brighton Rd., Unit #1

Henderson, CO 80640

Ph 866.355.9173 | Fax 303.289.2298

SHUR-CO® of FLORIDA

3353 SE Gran Park Way

Stuart, FL 34997

Ph 800.327.8287 | Fax 772.287.0431

SHUR-CO® of ILLINOIS

3993 E. Mueller Ave.

Decatur, IL 62526

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO® of IOWA

3839 Midway Blvd.

Ft. Dodge, IA 50501

Ph 866.356.0245 | Fax 515.576.5578

SHUR-CO® of MICHIGAN

5100 Lakeshore Dr.

Lexington, MI 48450

Ph 800.327.8287 | Fax 772.287.0431

SHUR-CO®, LLC SERVICE AND DISTRIBUTION CENTERS

P/N 1808554 Rev. D

Thank you for buying this tarping system from Shur-Co®. We appreci-

ate your condence in our products. Please read and thoroughly un-

derstand this manual before installing and/or operating this system.

Pay particular attention to important safety and operating instructions,

as well as warnings and cautions. The hazard symbol is used to

alert users to potentially hazardous conditions and is followed by cau-

tion, warning or danger messages.

Failure to READ AND FOLLOW INSTRUCTIONS could result in fail-

ure of your tarping system and/or personal injury. Your trailer require-

ments may, however, call for minor variations to these instructions.

Please inspect your tarping system periodically and repair or replace

worn or damaged parts.

QUESTIONS? CALL OUR FL HELP LINE:

1-800-327-8287

MON-FRI 8 AM-5 PM EASTERN TIME

We at Shur-Co® are concerned with your safety and the safety of all

those operating this system. Therefore, we have provided safety de-

cals at various locations on your tarping system. Keep decals as clean

as possible at all times. Replace any decal that has become worn

or damaged, painted over or otherwise difcult to read. Replacement

decals are available through Shur-Co® dealers.

To prevent rust, paint all exposed metal, such as weld seams and/or

metal exposed by grinding or cutting, with corrosion-resistant paint.

Quick-Flip™ II EL

P/N 1808554 Rev. D

!

Hardware Identication....................................................................... 1

Clearance Requirements.................................................................... 2

Base Assembly Installation................................................................. 2

Housing Assembly Installation............................................................ 3

Spring Box Installation........................................................................ 4

Pivot Arm Installation.......................................................................... 5

Tarp Installation .................................................................................. 6

Electric Hook-Up............................................................................7-10

Spring Box Cover Installation ........................................................... 11

Upper Arm Rest Installation.............................................................. 12

Replacement Parts......................................................................13-16

1. Wrenches - 1/2", 5/16", 9/16", 5/8", 3/4", 7/8"

2. Ratcheting Socket Wrench

3. Sockets - 1/2", 9/16", 3/4"

4. Allen Wrenches - 1/8", 5/32", 3/16"

5. Drill Bits (metal cutting) - 5/16", 3/8", 1/2", 3/16"

6. Center Punch

7. Hammer

8. Tape Measure

9. Flat Head or Phillips Screwdriver

10. Grinder

11. Air or Electric Impact Driver w/9/16" Socket

12. Metal Saw

13. Steel Welder

14. Hex Driver Bit - 5/16"

15. Phillips Driver Bit - #2

• Spray all bearings and drive chain with penetrating oil as needed.

• Brush springs with steel brush weekly to remove dirt and spray with

penetrating oil.

• Tighten any loose bolts.

• Replace damaged/bent parts.

• Replace worn or broken springs.

• Replace/repair worn or damaged tarps.

TOOLS REQUIRED

TABLE OF CONTENTS

MAINTENANCE

RUST PREVENTION

SAFETY

MESSAGE TO OWNERS

1. Always wear safety glasses during installa-

tion and operation.

2. Stay clear of moving parts.

3. Do not operate under low-hung power lines.

Always check for overhead obstructions be-

fore opening or closing.

4. Open and close tarp only at job site.

5. Place safety decals in visible locations. Re-

place worn or damaged decals.

6. No other use of this system is authorized,

except as designed.

SAFETY INSTRUCTIONS

P/N 1808554 Rev. D

Hardware Identication

1

A

B

D

E

F

C

Tarp length: Measure tarp length with slight tension applied. Compare

actual tarp length with length stated on sheet attached to tarp. If actual

tarp length does not match length on sheet, do not proceed. Call your

local dealer or Shur-Co® FL Customer Service at 1-800-327-8287.

TARP INSPECTION

PIVOT ARM REST HARDWARE

Item Part # Description Qty.

M. 1800998

Cap Screw - 5/16" x 1"

2

J. 1800990 Lock Nut - 5/16" 2

H. 1800989 Flat Washer - 5/16" 2

SPRING BOX HARDWARE

Item Part # Description Qty.

D. 1801629 Carriage Bolt -

5/8" x 2 1/2" 8

E. 1801555 Flat Washer - 5/8" 8

F. 1801554 Lock Nut - 5/8" 8

PIVOT ARM HARDWARE

Item Part # Description Qty.

G. 1800561 Pan Hd. Cap Screw -

5/16" x 2 1/4" 20

H. 1800989 Flat Washer - 5/16" 20

J. 1800990 Lock Nut - 5/16" 20

SPRING BOX COVER HARDWARE

Item Part # Description Qty.

K. 1801439 Pan Hd. Cap Screw -

5/16" x 3/4" - SS 4

L. 1800900 Flat Washer -

5/16" - SS 4

HOUSING HARDWARE

Item Part # Description Qty.

A. 1801024 Cap Screw - 1/2" x 4" 1

B. 1800996 Flat Washer - 1/2" 6

C. 1800995 Lock Nut - 1/2" 5

G

H

K

J

M

L

1800996 Flat Washer - 1/2"

1800995 Lock Nut - 1/2"

1801024 Cap Screw - 1/2" x 4"

1801629 Carriage Bolt - 5/8" x 2 1/2"

1801554 Lock Nut - 5/8"

1801555 Flat Washer - 5/8"

1800561 Pan Hd. Cap Screw - 5/16" x 2 1/4"

1800990 Lock Nut - 5/16"

1800989 Flat Washer - 5/16"

1801439 Pan Hd. Cap Screw - 5/16" x 3/4" - SS

1800900 Flat Washer - 5/16" - SS

1800998 Cap Screw - 5/16" x 1"

ELECTRIC/HYDRAULIC HARDWARE

Item Part # Description Qty.

N. 1800790

Cap Screw - 3/8" x 1 1/2"

2

P. 1800991 Lock Washer - 3/8" 2

N

1800790 Cap Screw - 3/8" x 1 1/2"

P

1800991 Lock Washer - 3/8"

ELECTRIC HARDWARE

Item Part # Description Qty.

Q. 1800783 Cap Screw - 1/4" x 1 1/2" 2

R. 1800442 Flat Washer - 1/4" SAE 6

S. 1800699 Lock Nut - 1/4" 2

T. 1800802 Sheet Metal Screw - #10 x 1" 4

U. 1800787 Lock Washer - 5/16" 4

V. 1800431 Hex Nut - 5/16" 4

U

T

S

R

Q

V

1800442 Flat Washer - 1/4"

1800802 Sheet Metal Screw - #10 x 1"

1800783 Cap Screw - 1/4" x 1 1/2"

1800787 Lock Washer - 5/16"

1800699 Lock Nut - 1/4"

1800431 Hex Nut - 5/16"

P/N 1808554 Rev. D

2

There must be at least 6" clearance between components and

tilt frame. If existing exhaust system or hydraulic system compo-

nents are located between tilt frame and cab, adjust component

locations as needed to achieve 6" of clearance.

If existing components interfere with base assembly installation,

and if moving existing components is not practical, fabricate

brackets as needed to prevent interference.

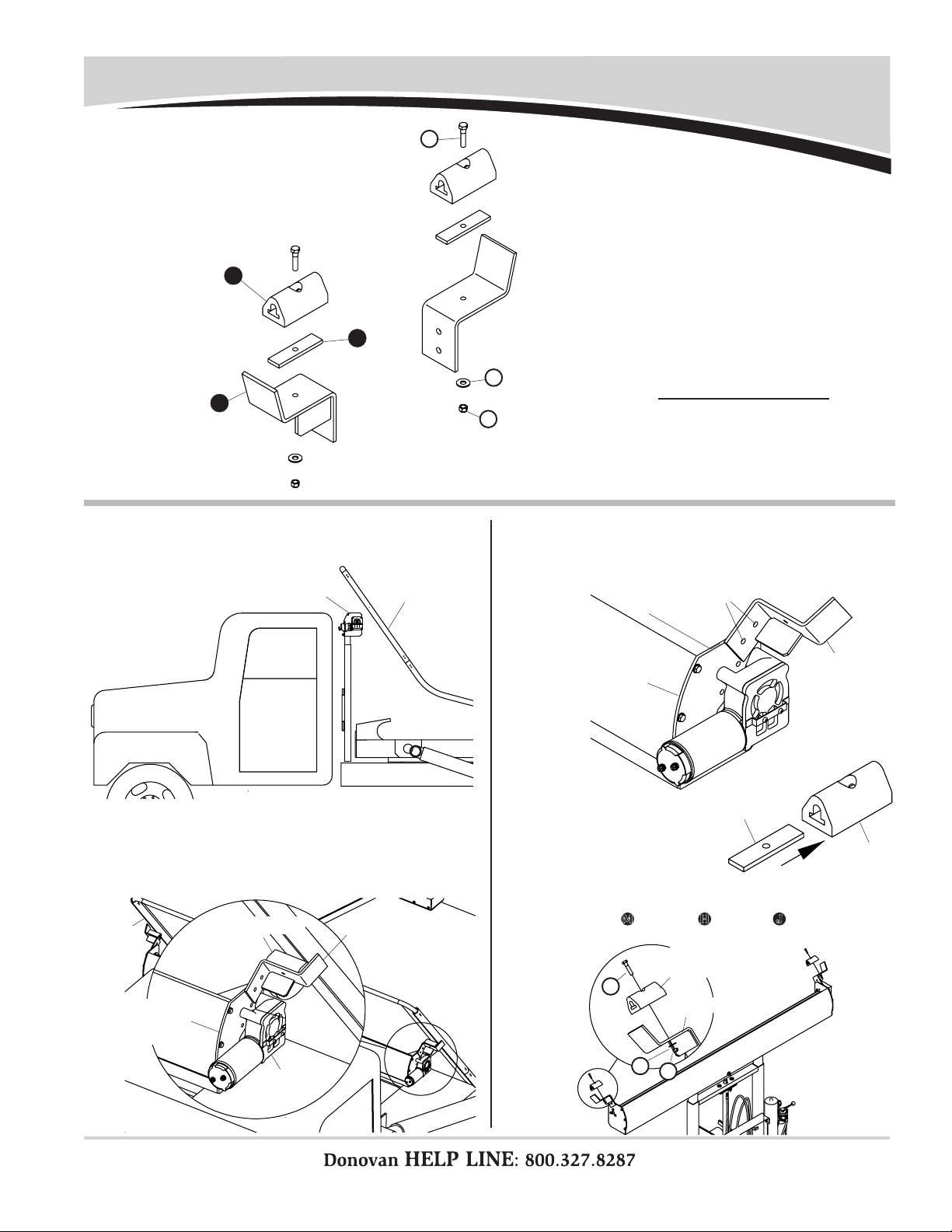

STEP 1: Locate mounting angles on both sides of truck frame,

centering brackets between cab and tilt frame. Align

angles on frame, mark and drill 5/8" holes and fasten

with 5/8" x 2" cap screws, at washers and lock nuts

(supplied by customer) or weld in place (see caution).

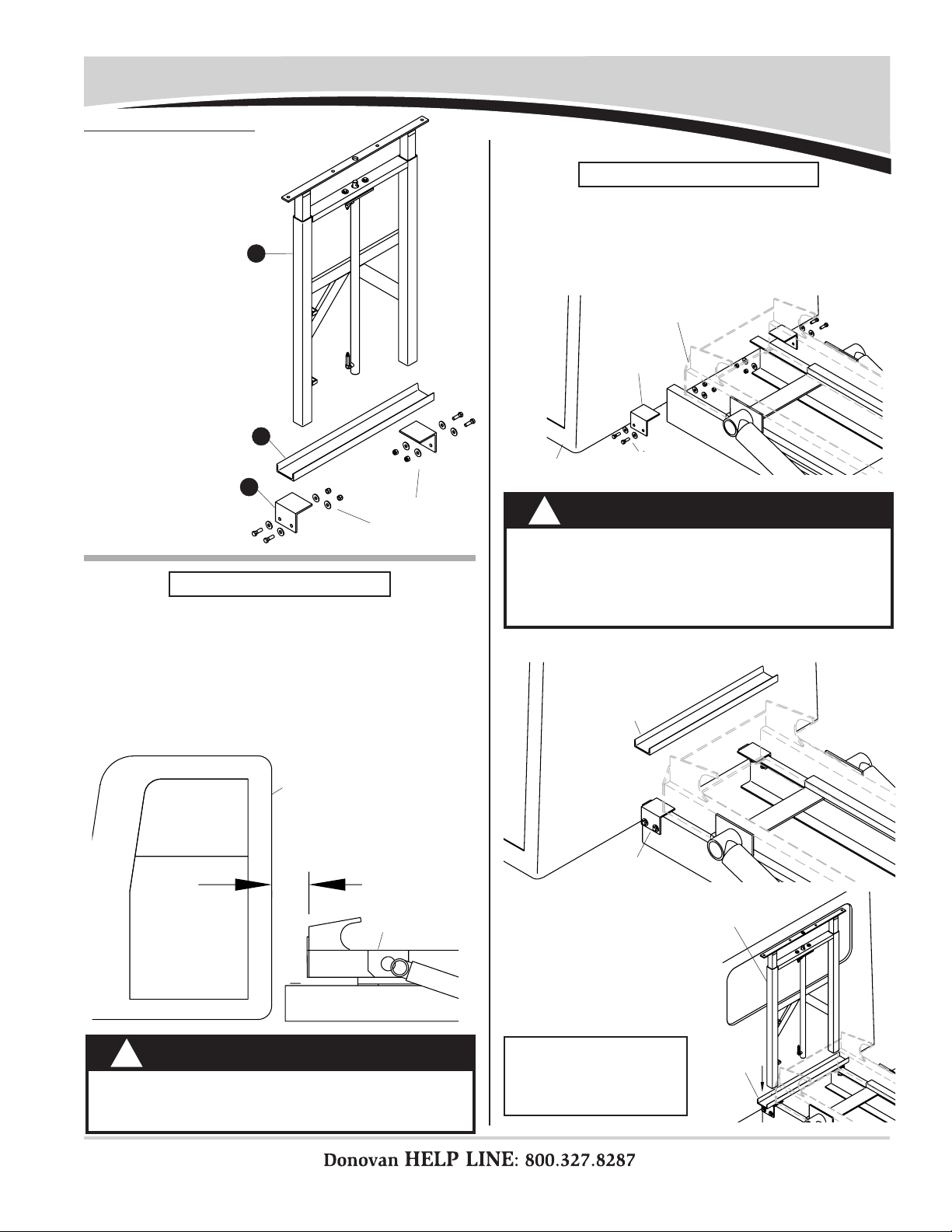

Base Assembly Installation

CLEARANCE REQUIREMENTS

BASE ASSEMBLY INSTALLATION

CAUTION

Welding components to truck frame may weaken

frame and will void warranty on truck. Weld angle

brackets to existing brackets on frame when pos-

sible. When not possible, drill holes in frame and bolt

brackets in place.

!

CAUTION

To prevent damage to and ensure proper operation

of Quick Flip II™ system, center base assembly be-

tween cab and hoist with at least 6" of clearance.

!

6" minimum

cab

tilt frame

STEP 2: Align and center mounting channel on mounting

angles and weld in place.

mounting

channel

mounting

angle

Item Part # Description

1. 1801622 Base Assembly

2. 1800726 Mounting Channel

3. 1801966 Mounting Angle

hardware

supplied by

customer

supplied by

customer

tilt frame

cab

mounting

angle

2

1

3

STEP 3: Square and center

base assembly on

mounting channel.

Weld legs to mount-

ing channel.

NOTE: If needed, fabricate

additional bracing to

stabilize base assembly

and mounting channel.

mounting

channel

base assembly

P/N 1808554 Rev. D

3

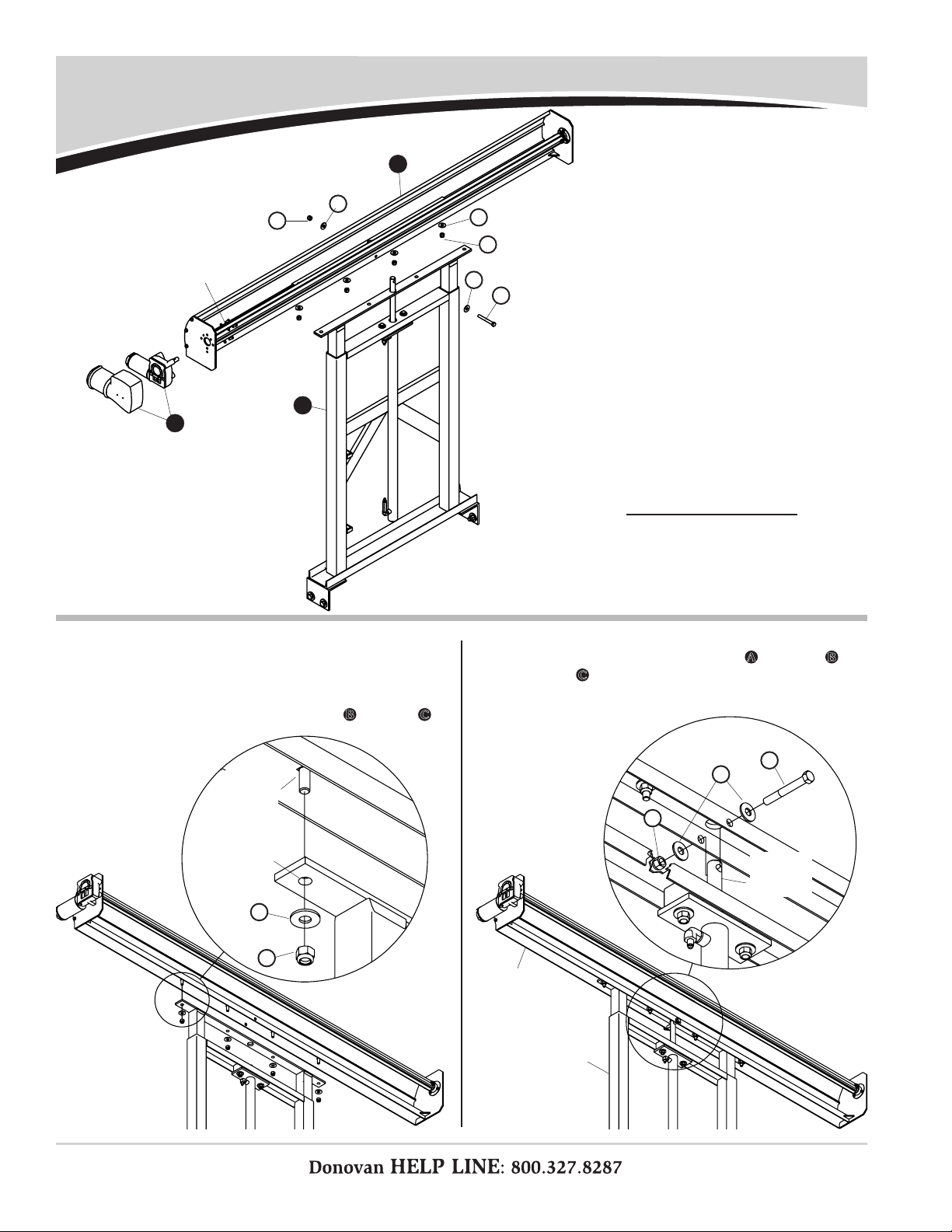

Housing Assembly Installation

STEP 2: Insert studs on housing assembly into holes in base

assembly and fasten with washers B and nuts C.

STEP 3: Fasten hydraulic cylinder rod on base assembly to

housing assembly with screws A, washers B and

nuts C.

Item Part # Description

1. 1800492 Housing Assembly

2. 1801622 Base Assembly

3. 1704878 Durabuilt Motor w/Cover

A. 1801024 Cap Screw - 1/2" x 4"

B. 1800996 Flat Washer - 1/2"

C. 1800995 Lock Nut - 1/2"

hole in base

assembly

stud on

housing

assembly

hydraulic

cylinder

rod

housing

assembly

base assembly

1

2

A

B

B

C

B

C

B

A

C

C

B

3

STEP 1: Fasten motor to housing assembly with supplied

fasteners as shown above.

fasteners

supplied

w/motor

P/N 1808554 Rev. D

4

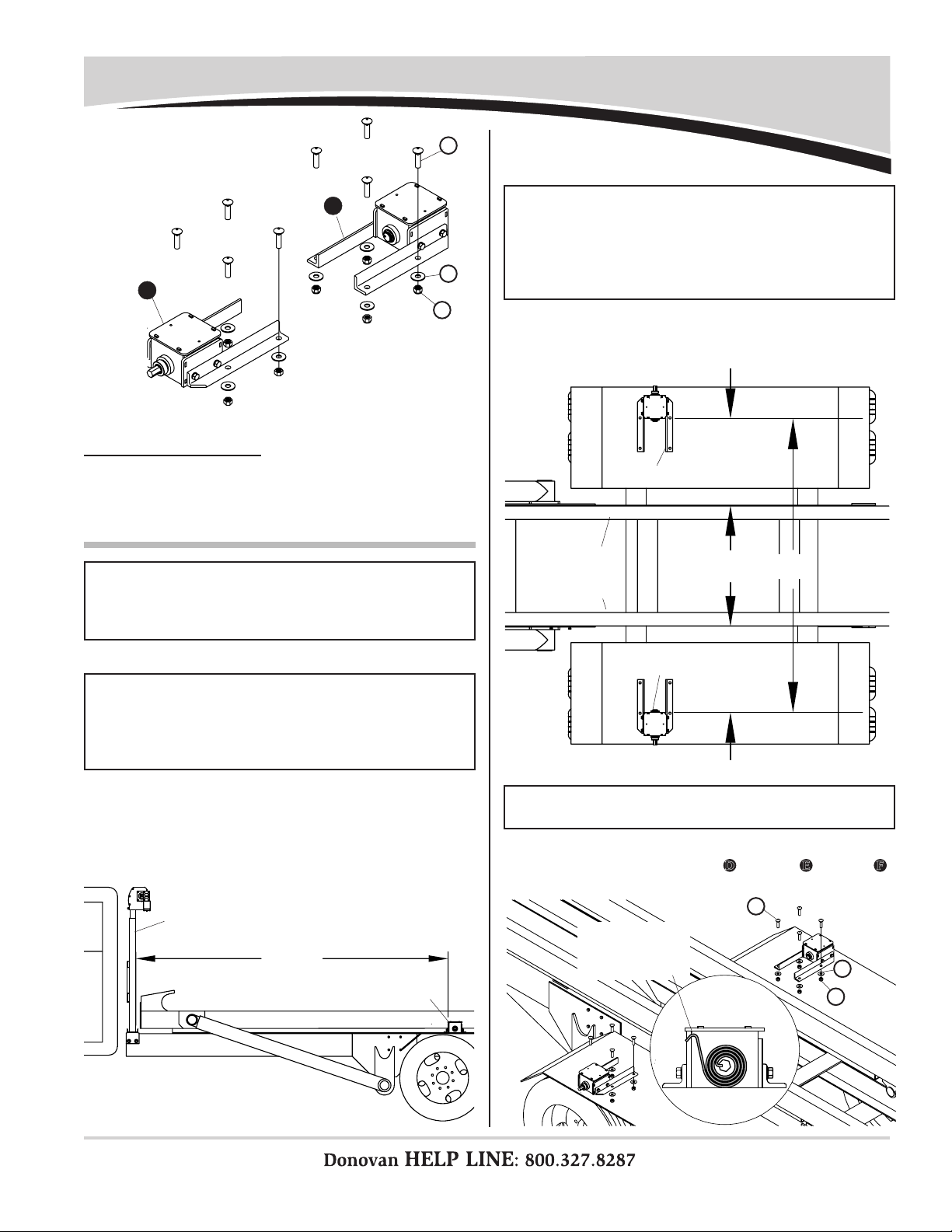

Spring Box Installation

NOTE: Fenders on most stock trucks are not strong enough to

support spring boxes. To support weight and torsion of spring

box, a support frame must be fabricated. In order for system

to operate correctly, fenders must be square and level.

NOTE: Recommended distance needed for spring boxes

to support arms for a 40-yard container is 144" from base

assembly to spring box. To assure containers are covered

and arms do not extend past rear of container, move container

onto truck and center spring boxes between base assembly

and back of container.

STEP 1: Locate spring boxes on truck fenders or on support

frame, with 144" between base assembly and front

of spring boxes.

STEP 2: Space spring boxes 87" apart (see note below). Sys-

tem must be centered on truck, with an equal distance

between truck rails to spring boxes.

IMPORTANT: Locate spring box as low on truck frame as

possible to allow clearance between roll-off container and

spring box. Top of spring box must be less than 5" above

rollers used to support container. If needed, pull container

onto truck and check for clearance.

NOTE: Spring boxes may be welded in place if fenders are

strong enough or customer-fabricated supports are used.

STEP 3:

Fasten spring boxes and backing plates to fenders on

truck with carriage bolts

D

, washers

E

and nuts

F

.

Item Part # Description

1. 1800555 Spring Box Assembly - Driver Side

2. 1800556 Spring Box Assembly - Passenger Side

D. 1801629 Carriage Bolt - 5/8" x 2 1/2"

E. 1801555 Flat Washer - 5/8"

F. 1801554 Lock Nut - 5/8"

1

2

F

D

E

D

E

F

144"

equal

distance

87"

equal

distance

base assembly

spring box

spring box

truck rail

spring box

truck rail

spring catch

must face

front of truck

P/N 1808554 Rev. D

5

STEP 2:

Slide lower arm onto pivot shaft on spring box as-

sembly, positioning bend in arm as shown. Fasten

lower arm to pivot shaft with screws

G

, washers

H

and nuts

J

.

STEP 3: Slide arm coupler into lower arm

and fasten with screws G, washers

H and nuts J.

STEP 4: Slide upper arm onto arm cou-

pler and fasten with screws G,

washers H and nuts J.

NOTES: If holes will not align well enough to insert bolts, run

5/16" drill bit through holes. Place bolt heads on inside of

arms to prevent bolts from catching on container.

STEP 5: Insert cast elbow into

upper arm and fasten

with screws G, washers

H and nuts J.

Pivot Arm Installation

Item Part # Description

1. 1800548 Upper Arm

2. 1800597 90° Cast Elbow

3. 1800547 Arm Coupler

4. 1800545 Lower Arm

5. 1801636 Hex Pivot Arm Shaft

G. 1800561 Pan Hd. Cap Screw - 5/16" x 2 1/4"

H. 1800989 Flat Washer - 5/16"

J. 1800990 Lock Nut - 5/16"

1

2

3

4

1

4

G

H

J

G

H

J

G

H

J

G

HJ

lower arm

pivot

shaft

bend in arm

spring box

H

G

J

H

G

J

H

G

J

arm coupler

lower

arm

cast elbow

upper arm

upper

arm

arm

coupler

5

5

STEP 1: Align

pivot shaft on spring box

as shown and

fasten

with supplied screws and nuts.

pivot arm

spring box

supplied

screws

& nuts

P/N 1808554 Rev. D

6

Tarp Installation

STEP 1: Thread front of tarp with plastic rod into slot in center

of roller bar. Trim ends of rod to t tarp.

STEP 2: Slide rear crosspiece into tarp pocket at rear of tarp.

STEP 3: Center tarp on roller bar and rear crosspiece.

STEP 4: Insert rear crosspiece into 90° elbows. Using holes in

90° elbow as guide, mark and drill 5/16" holes. Fasten

with screws G, washers H and nuts J.

Item Part # Description

1. _______ Tarp

2. 1800546 Rear Crosspiece

G. 1800561 Pan Hd. Cap Screw - 5/16" x 2 1/4"

H. 1800989 Flat Washer - 5/16"

J. 1800990 Lock Nut - 5/16" 1

2

H

G

J

plastic rod on

front of tarp

slot in rollerbar

tarp pocket

rear crosspiece

90° elbow

rear crosspiece

H

G

J

drill

5/16"

holes

P/N 1808554 Rev. D

Item Part # Description

1. 1800090 Hydraulic Pump - 12 Volt - M310

2. 1801623 Pump Mount Bracket

3. 1801223 Spacer - Steel Pump Bracket

4. 1800906 Hose Clamp - 5" to 7"

5. 1801125 Motor Mount Rubber Tire

6. 1801627 Hydraulic Hose - 84 OAL

7. 1800976 Cable Tie - 8"

N. 1800972 Cap Screw - 5/16" x 1 1/2"

P. 1800991 Lock Washer - 3/8"

7

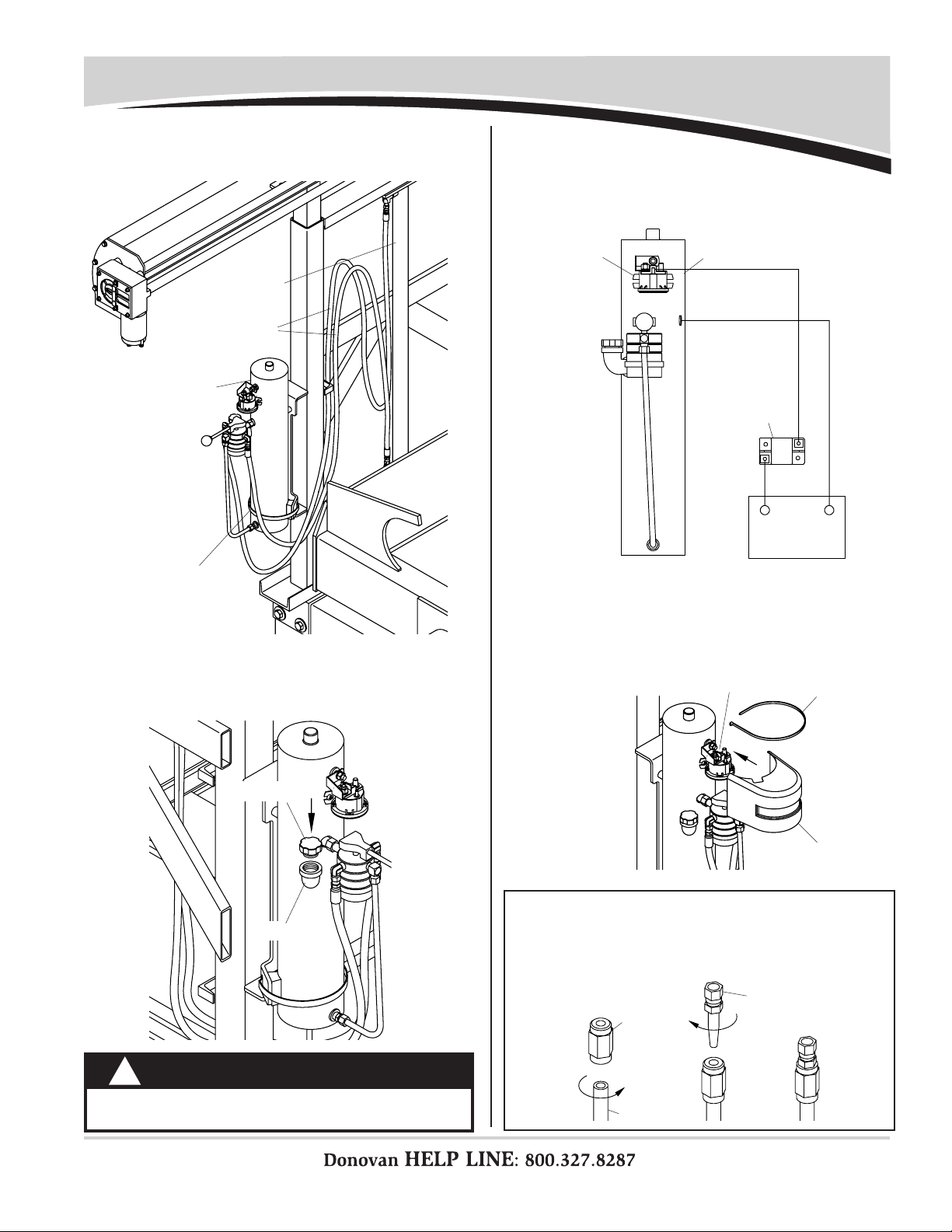

Hydraulic Pump Installation

STEP 1: Locate pump mount bracket on outside of leg or other

easily accessible location. Locate bracket so pump

will be vertical, with control valve and motor on top

and reservoir on bottom as shown.

pump and

mounting

bracket

outside of leg

weld to leg

1

2

3

4

56

N

P

STEP 2: Mark bracket location on trailer. Unfasten and remove

hydraulic pump from bracket. Weld bracket in place,

then replace and refasten pump.

solenoid

manual valve

control

reservoir

hose clamp

bracket

fill port

HYDRAULIC PUMP

solenoid

cover

7

solenoid cover

P/N 1808554 Rev. D

8

Hydraulic Pump Installation - continued

NOTE: To thread tting body onto end of hose, turn body

counterclockwise until body engages hose about 1". Thread

tting insert onto body, turning clockwise until insert is snug

against body. Fitting must be threaded completely onto

hoses to prevent leaking.

hose

reusable

fitting

body

reusable

fitting

insert

STEP 5: Connect negative wire from battery to stud on hydrau-

lic pump.

STEP 6: Connect positive wire from battery to circuit breaker

and from circuit breaker to solenoid on pump.

STEP 7: Place solenoid cover over solenoid. Secure cover to

pump with 8" cable tie.

CAUTION

Replace shipping plug with breather cap on hydrau-

lic pump or pump will be damaged.

!

STEP 3: Connect hoses from hydraulic pump to hydraulic

cylinder, making sure hose clamps are tight around

reservoir.

battery

hydraulic pump

solenoid

reservoir

hydraulic

cylinder

hydraulic

hoses

hose clamp

breather cap

fill port

+_

solenoid

solenoid

cover

cable tie

STEP 4: Remove shipping plug from ll port and ll pump with

approximately 4 quarts Dexron automatic transmis-

sion uid. Install breather cap onto ll port. Do not

reinstall shipping plug.

150a circuit

breaker

p/n1800458

P/N 1808554 Rev. D

9

Electric Installation

Item Part # Description

1. 1800418 Solenoid

2. 1800429 Solenoid Cover

3. 1807726 Toggle Switch

4. 1801265 Toggle Switch Plate

5. 1800302 Ring Terminal - 8 Ga. x 1/4"

6. 1800158 Ring Terminal - 8 Ga. x 3/8"

7. 1800417 Circuit Breaker - 60-Amp 12V

8. 1800441 Butt Connector - 18-22 Ga.

Q. 1800783 Cap Screw - 1/4" x 1 1/2"

R. 1800442 Flat Washer - 1/4" SAE

S. 1800699 Lock Nut - 1/4"

T. 1800802 Sheet Metal Screw - #10 x 1"

U. 1800787 Lock Washer - 5/16"

V. 1800431 Hex Nut - 5/16"

NOTE: New electric motor kits include dual-conductor wire. If

not using new electric kit, use existing wire on truck.

STEP 1: Locate solenoid in sheltered location such as battery

box, cab or under cab. Using solenoid as guide, mark

and drill 1/4" holes. Loosely fasten solenoid with

screws Q, washers R and nuts S.

1

2

7

3

STEP 2:

Locate circuit breaker near battery. Fasten with

screws

T

and washers

R

.

4

5

6

8

solenoid

drill

1/4"

holes

CAUTION

Do not pull dual-strand wires apart. To separate,

cut through insulation between wires carefully with

knife. Pulling wires apart could damage wire insula-

tion and expose wire.This could result in equipment

damage and/or personal injury.

!

NOTE: Cut wires to length and strip only enough wire insulation

to install ring terminals. Insert bare

wire into ring terminals and

crimp securely.

strip wire

insulation

ring terminal crimp securely

CAUTION

Do not spray electric components with pressure

washer or hose.

!

S

T

R

R

Q

U

V

R

T

Q

S

R

T

R

60a

circuit

breaker

P/N 1808554 Rev. D

10

Electric Installation - continued

STEP 5: Divide portion of dual-conductor wire into two single-

strand wires (see caution). Cut section of single-strand

wire to run from positive terminal on battery to circuit

breaker. Crimp 3/8" ring terminal 6 onto one end of

wire and 1/4" ring terminal 5 onto other end. Connect

3/8" ring terminal to positive battery post and connect

1/4" ring terminal to post on circuit breaker marked

BAT.

STEP 8: Run three-strand jacketed toggle switch wire to sole-

noid and cut to length. Connect wire ends to solenoid,

placing ring terminal 5 on post marked BATT+ and

two quick disconnects to tabs marked T1 and T2.

STEP 9: Slide solenoid cover under bolt heads and washers

holding solenoid in place. Tighten fasteners to hold

cover and solenoid in place.

STEP 10: Operate toggle switch to verify tarp is moving in same

direction as shown on toggle. If tarp is not moving in

same direction as toggle, either swap two wires con-

nected to tabs T1 and T2 on solenoid or two wires

connected to motor.

STEP 6: Locate toggle switch

where switch can easily

be accessed by system

operator. Weld toggle

switch plate in place.

STEP 7: Fasten toggle switch to plate with screws T and

washers R.

STEP 4:

Cut section of dual-conductor wire to run from solenoid

to battery. Crimp two 3/8" ring terminals

6

on one end

of wire and connect terminals to posts on solenoid

marked Batt+ and Batt-. Crimp one 1/4" ring terminal

5

and one 3/8" ring terminal

6

on other end of wire.

Connect 1/4" ring terminal to circuit breaker post

marked AUX and connect 3/8" ring terminal to negative

battery post.

STEP 3: Cut section of dual-conductor wire to run from solenoid

to electric motor. Crimp two 3/8" ring terminals 6on

one end of wire and two 1/4" ring terminals 5on

other end. Connect 1/4" ring terminals to motor and

3/8" ring terminals to solenoid.

toggle

switch

plate

toggle

switch

plate

toggle

switch

solenoid

tighten

fasteners

solenoid cover

WIRING DIAGRAM

battery

solenoid

toggle

switch

direct-drive motor

NOTE: Refer to

wiring diagram

for steps 3, 4, 5

and 8. See note

and caution on

previous page.

NOTE: Kit includes three extra butt connectors. If excess

switch wire cannot be coiled, connectors are provided to

shorten switch wires to desired length.

+_

T

R

TEST OPERATION

60a

circuit

breaker

P/N 1808554 Rev. D

11

Spring Box Cover Installation

STEP 1: Fasten spring box covers to spring boxes with screws

K and washers L.

Item Part # Description

1. 1800560 Spring Box Cover

K. 1801439 Pan Hd. Cap Screw - 5/16" x 3/4" - SS

L. 1800900 Flat Washer - 5/16" - SS

1L

K

spring box

spring box cover

K

L

P/N 1808554 Rev. D

12

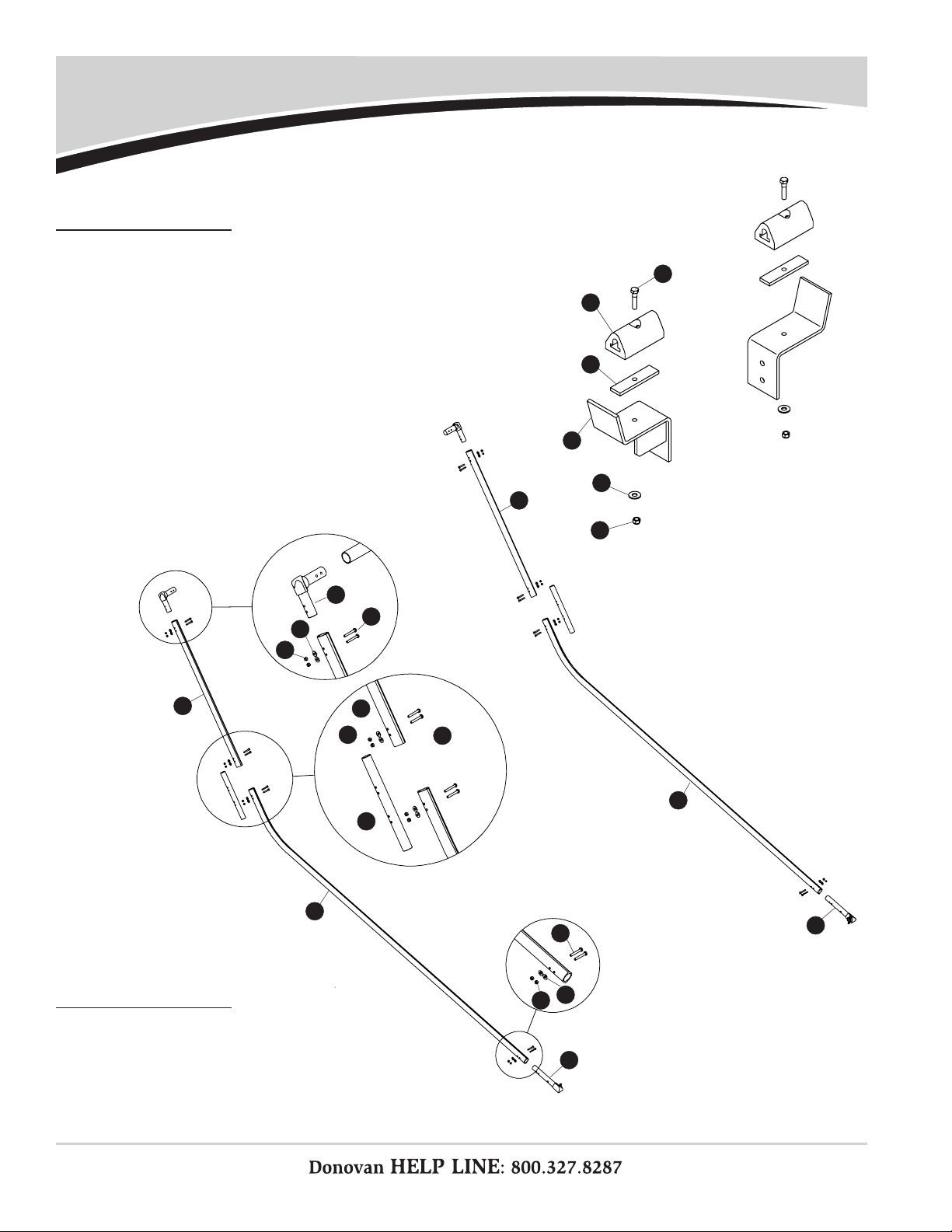

Pivot Arm Rest Installation

STEP 1: Wind tarp open until arms are completely forward,

stopping just before arms reach housing assembly.

STEP 2:

Position rubber bumpers on pivot arm rests. Align

components on housing assembly brackets, adjusting

so pivot arms rest evenly on rests and do not interfere

with motor. Clamp pivot arm rests in place.

STEP 3: Remove rubber bumpers and weld or bolt pivot arm

rests onto housing brackets (hardware not provided).

STEP 4: Insert bumper hold-

down bars into slots

in rubber bumpers.

Item Part # Description

1. 1801012 Rubber Bumper

2. 1800140 Bumper Hold-Down Bar

3. 1801324 Pivot Arm Rest

M. 1800998 Cap Screw - 5/16" x 1"

H. 1800989 Flat Washer - 5/16"

J. 1800995 Lock Nut - 5/16"

1

2

3

arms

housing assembly

housing

assembly

bracket

pivot

arm

pivot arm rest

rubber bumper

motor

housing

assembly

bracket

pivot arm

rest

weld or bolt

STEP 5: Fasten bumper assemblies to pivot arm rests with

screws M, washers H and nuts J.

bumper

hold-down

bar

rubber

bumper

pivot arm rest

bumper

assembly

M

J

H

M

HJ

P/N 1808554 Rev. D

13

Replacement Parts

2

5

8

11

14

1

4

7

9

13

3

6

10

12

15

5

6

12

11

16 17

16

18

18

19

20

21

hardware

supplied by

customer

BASE & HOUSING ASSEMBLIES

Item Part # Description

1800492 Modular Housing Assembly

1. 1800491 Modular Housing Weldment

2. 1801950 Bearing Flange - Reversed

3. 1800699 Lock Nut - 1/4"

4. 1704878 Durabuilt Motor w/Cover

5. 1800460

Self-Tapping Screw - 5/16" x 1 1/4"

6. 1800989 Flat Washer - 5/16"

7. 1800767 Cap Screw - 1/4" x 3/4"

8. 1800784 Flat Washer - 1/4"

9. 1804907 Cap Screw - 5/16" x 3/4"

10. 1800787 Hydraulic Motor Washers

11. 1800996 Flat Washer - 1/2"

12. 1800579 Lock Nut - 1/2"

13. 1801024 Cap Screw - 1/2" x 4"

14. 1800477 Modular Housing Deector

15. 1802015 Roller Bar

16. 1801187 Carriage Bolt - 5/16" x 2 1/2"

17. 1800980 Shaft Extension - 3/4" x 4"

18. 1800990 Lock Nut - 5/16"

19. 1801622 Base Assembly

20. 1800726 Mounting Channel

21. 1801966 Mounting Angle

P/N 1808554 Rev. D

14

Replacement Parts

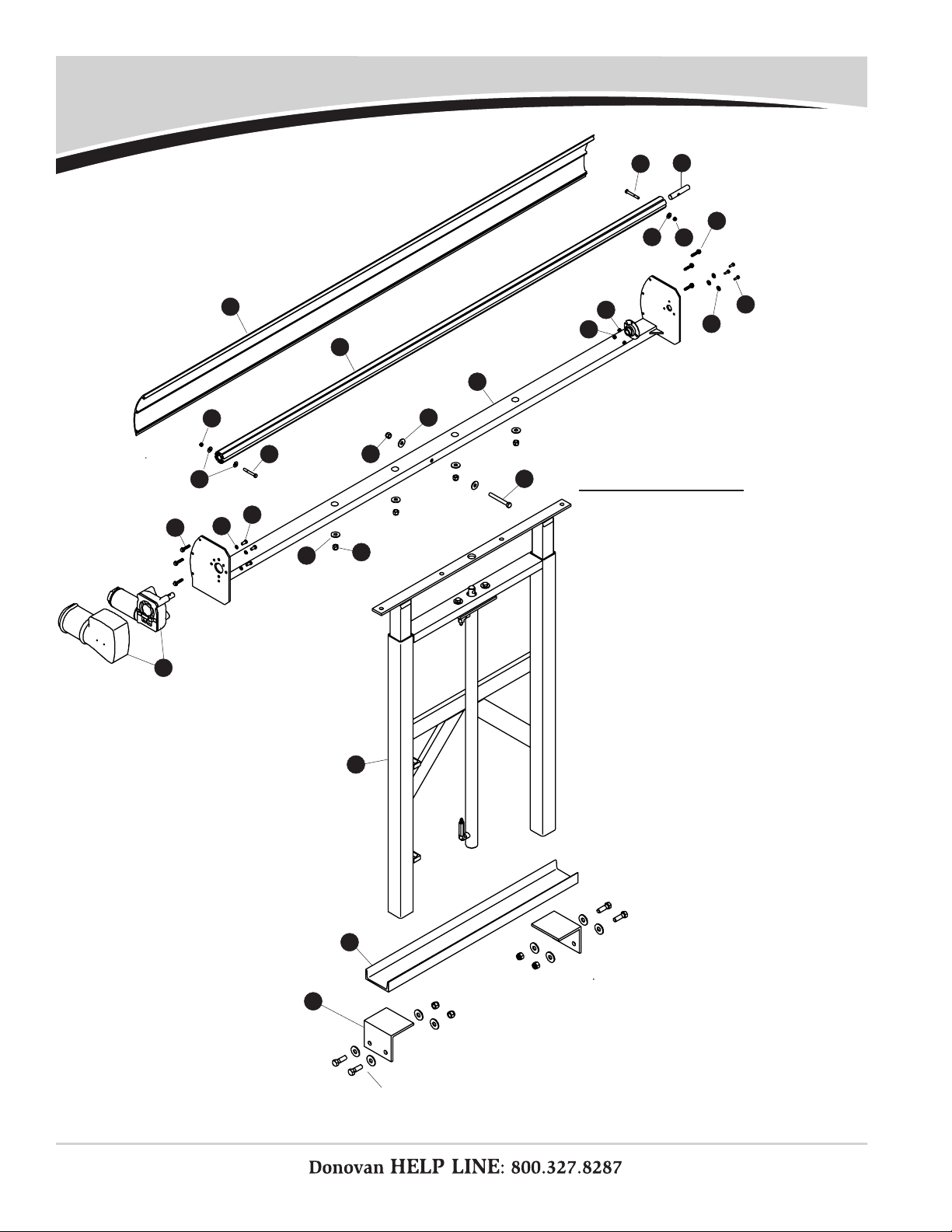

SPRING BOXES

Item Part # Description

1. 1800560 Spring Box Cover

2. 1800556 Spring Box Assembly - Pass. Side

3. 1800555 Spring Box Assembly - Driver Side

4. 1801629 Carriage Bolt - 5/8" x 2 1/2"

5. 1801555 Flat Washer - 5/8"

6. 1801554 Lock Nut - 5/8"

7. 1801439 Pan Hd. Cap Screw - 5/16" x 3/4" - SS

8. 1800900 Flat Washer - 5/16" - SS

9. 1801327 Cap Screw - 1/2" x 1"

10. 1800797 Lock Washer - 1/2"

11. 1800551 Mounting Angle #2 of 2

12. 1800763 Torsion Spring

13. 1808514 Spring Shaft - 1 1/4" OD - 7/8" Hex End

14. 1800860 Flanged Bushing - 1 1/4"

15. 1800861 Shaft Collar - 1 1/4"

16. 1800977 Shim - 1 1/4" x .047"

17. 1800542 Spring Box Weldment

18. 1800550 Mounting Angle #1 of 2

19. 1801474 Ring Retainer - 1/4" x .093"

12

7

8

12

11

10

9

17

16

13

15

14

18

19

6

3

5

4

1

18

12

19

16

14

11

10

9

12

13

14

16

15

9

10

14

16

9

10

P/N 1808554 Rev. D

Replacement Parts

15

1

2

3

4

1

4

5

5

6

6

6

7

7

7

8

8

8

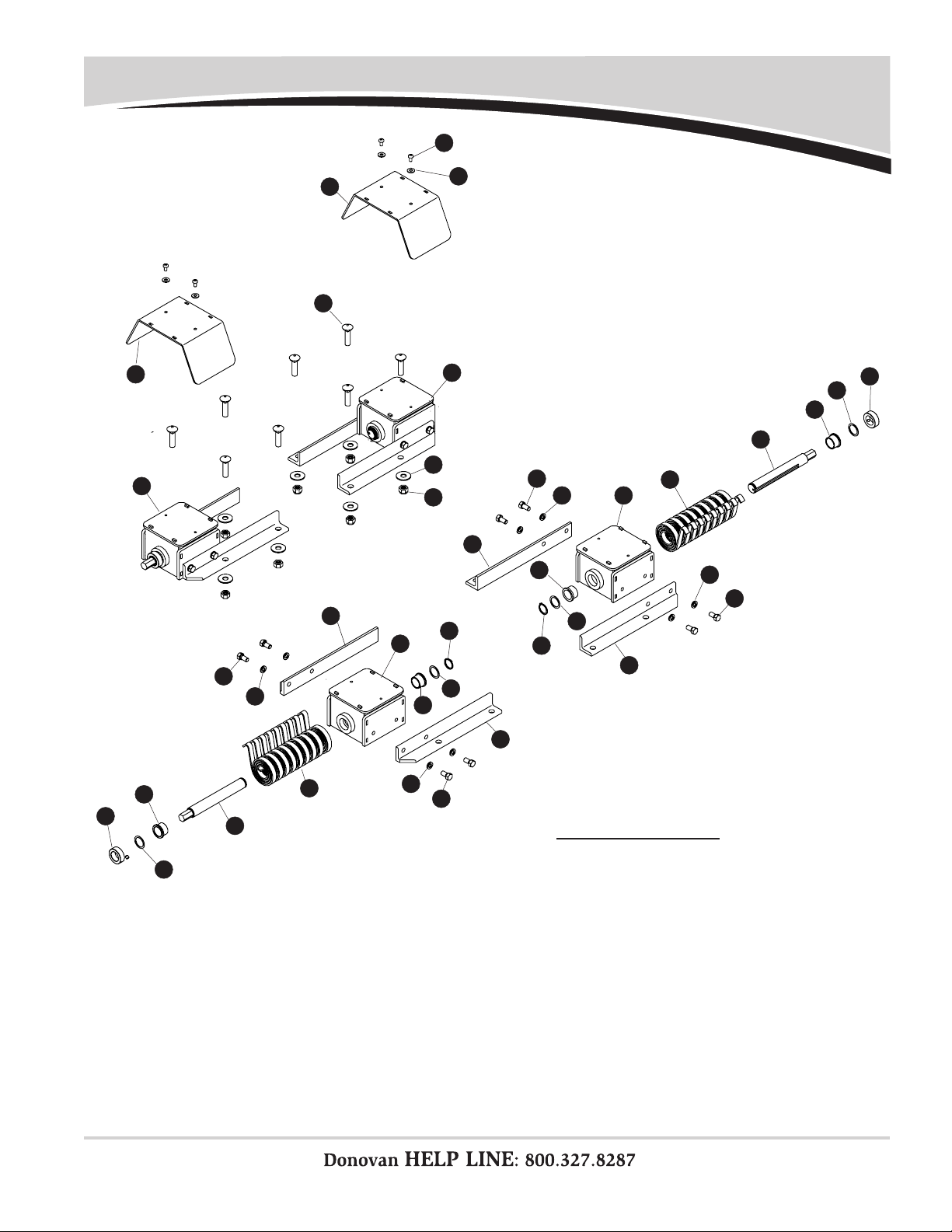

PIVOT ARM RESTS

Item Part # Description

1. 1801012 Rubber Bumper - 4" - Drilled

2. 1800140 Bumper Hold-Down Bar

3. 1801324 Pivot Arm Rest

4. 1800998 Cap Screw - 5/16" x 1"

5. 1800989 Flat Washer - 5/16"

6. 1800995 Lock Nut - 5/16"

1

2

3

4

5

6

PIVOT ARMS

Item Part # Description

1. 1800548 Upper Arm

2. 1800597 90° Cast Elbow

3. 1800547 Arm Coupler

4. 1800545 Lower Arm

5. 1801636 Hex Pivot Arm Shaft

6. 1800561 Pan Hd. Cap Screw - 5/16" x 2 1/4"

7. 1800989 Flat Washer - 5/16"

8. 1800990 Lock Nut - 5/16"

P/N 1808554 Rev. D Replacement Parts

16

TARPS

Item Part # Description

1. 1800546 Rear Crosspiece

2. _______ Tarp

3. 1800561 Pan Hd. Cap Screw - 5/16" x 2 1/4"

4. 1800989 Flat Washer - 5/16"

5. 1800990 Lock Nut - 5/16" 1

2

5

3

4

ELECTRIC COMPONENTS

Item Part # Description

1. 1800418 Solenoid

2. 1800429 Solenoid Cover

3. 1807726 Toggle Switch

4. 1801265 Toggle Switch Plate

5. 1800783 Cap Screw - 1/4" x 1 1/2"

6. 1800442 Flat Washer - 1/4" SAE

7. 1800699 Lock Nut - 1/4"

8. 1800802 Sheet Metal Screw - #10 x 1"

9. 1800787 Lock Washer - 5/16"

10. 1800431 Hex Nut - 5/16"

11. 1800302 Ring Terminal - 8 Ga. x 1/4"

12. 1800158 Ring Terminal - 8 Ga. x 3/8"

13. 1800417 Circuit Breaker - 60-Amp 12V

14. 1800441 Butt Connector - 18-22 Ga.

1

2

13

3

8

10

4

5

6

7

11

12

14

8

9

6

6

HYDRAULIC COMPONENTS

Item Part # Description

1. 1800090 Hydraulic Pump - 12 Volt - M310

2. 1801623 Pump Mount Bracket

3. 1801223 Spacer - Steel Pump Bracket

4. 1800906 Hose Clamp - 5" to 7"

5. 1801125 Motor Mount Rubber Tire

6. 1801627 Hydraulic Hose - 84 OAL

7. 1800976 Cable Tie - 8"

8. 1800972 Cap Screw - 5/16" x 1 1/2"

9. 1800991 Lock Washer - 3/8"

1

2

3

4

56

7

solenoid cover

8

9

•

Construction Products

- Arm-Matic™

- DuraPull™

- Econo-Pull™

- Turbo Tarp2™

- 2000 Series

- 5000 Series

- Hammer™

- Bullet™

- Flash™

- Long Arm™

•Waste Products

- SWAT ™

- The Ox™

- Quick-Flip III™

- Sidewinder™

- Sidewinder™ 350

- HyTower™ SL

- HyTower™ DL

- Double-Flip™

- Donovan Belt & Ratchet (DBR)

Table of contents