Installation Instructions

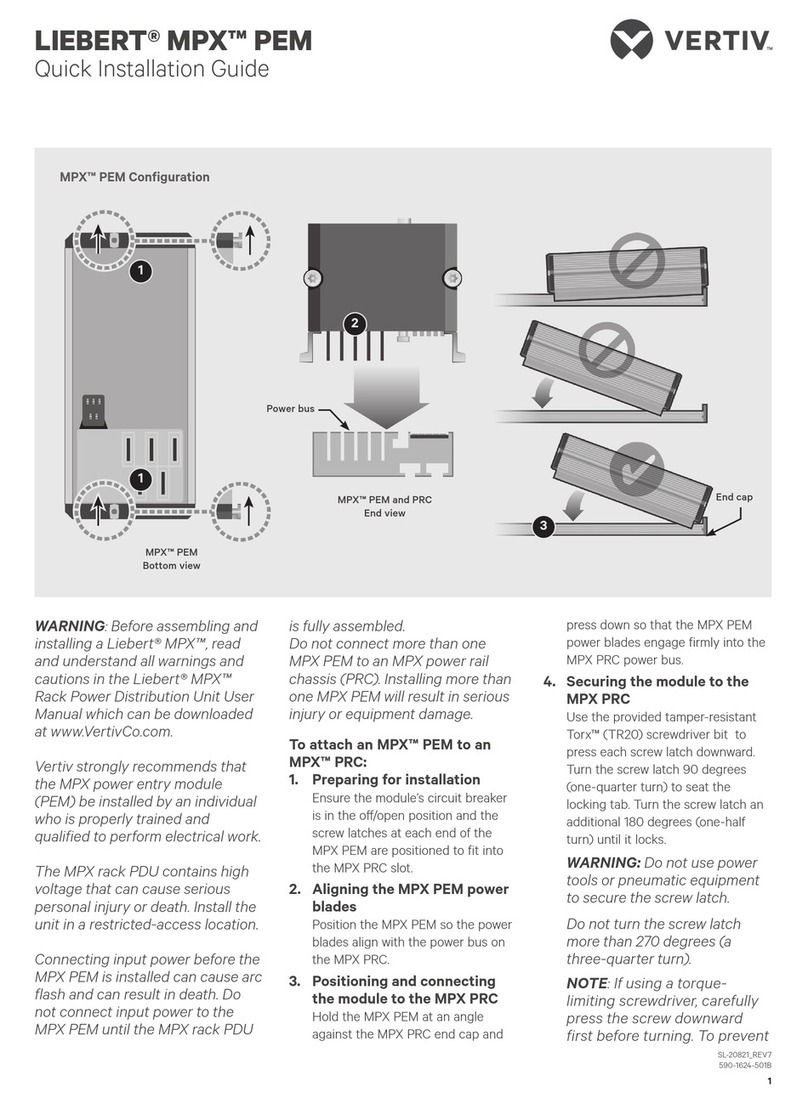

1. Locate the Arrow Mark

2. Position the check valve in place in accordance with

point upward.

3. Connect the check valve with two rigid couplings like

the SHURJOINT model 7771 or similar products of other

-

lation instructions for the couplings being used.

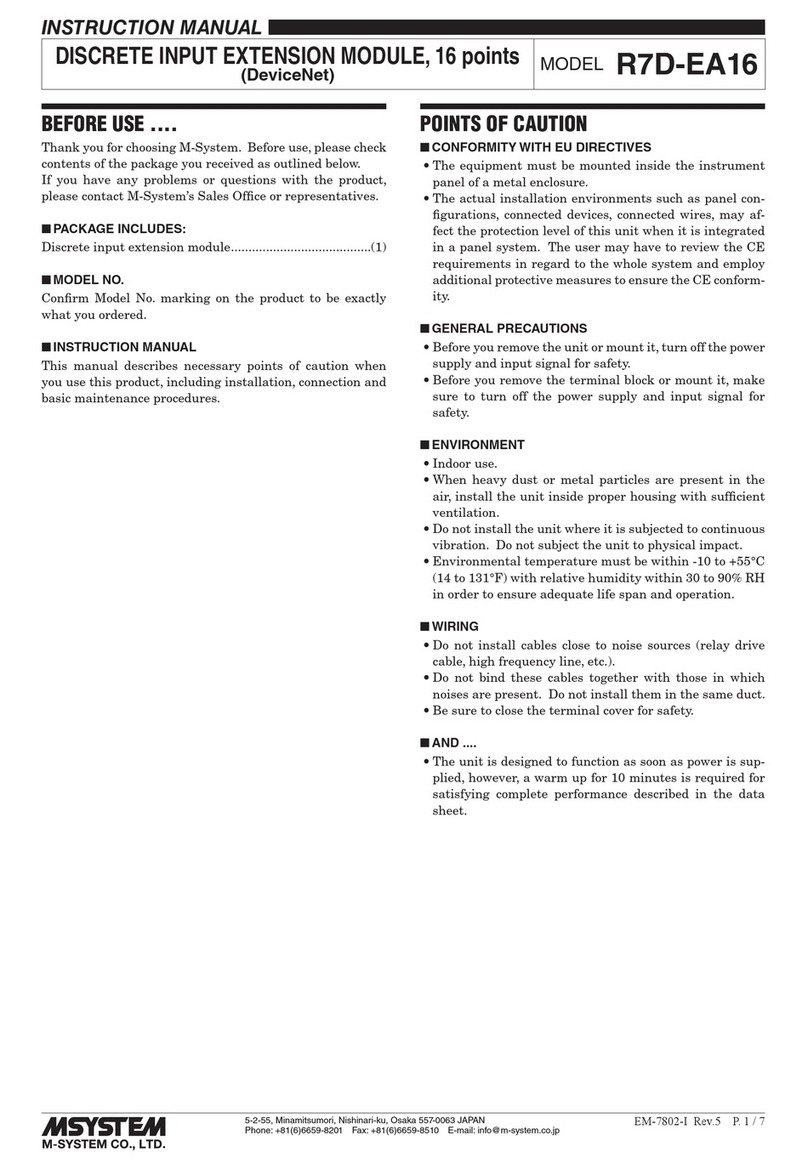

Cautions

vDo not use the Grade E EPDM gasket for petroleum or

other oil services.

v

ensure optimum gasket sealing.

v

v

SHURJOINT

Riser Check Valves

Model RCV

Installation Instructions

Product Description

The Model RCV Riser Check Valve has been designed

single clapper design features non-slamming

. T per

design provide for low friction loss. This valve can be

installed in the vertical or horizontal position and the EPDM

rubber faced clapper provides a non-stick leak-tight seal

with as little as 1.5 meters (5 feet) of head. The removable

-

two bosses on each side are provided for pressure gauges

if required. The Model RCV check valve is rated at 20 bar

(300 psi) working pressure. Check valves are supplied with

Pipe Preparation

to a different pipe O.D. with the same nominal size.

Sealing surface (pipe end to the groove) should be free

optimum sealing. Pipe ends should be cut square.

Prepare a roll or cut groove on the pipe end with a

SHURJOINT or other roll or cut grooving machine or tool in

accordance with the manufacturer’s operation manual and

C606

II 02/RCV/3

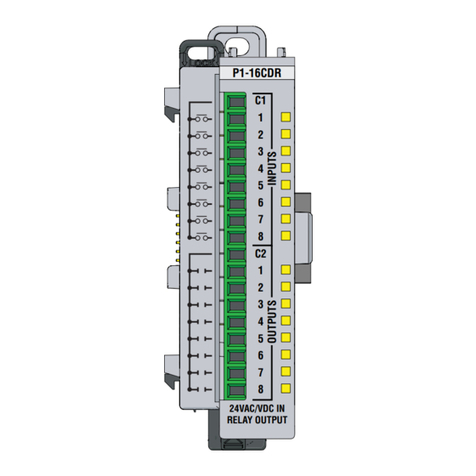

OUTLET

ARROW

INLET

Shurjoint Metals Inc.

Web Site: www.shurjoint.com