Smitec HELCON 10 Series Quick start guide

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 1

Smitec S.p.A., viale Vittorio Veneto 4, 24016 San Pellegrino Terme (BG), Italy, www.smitec.it

Installation, use and maintenance manual

CONTROL MODULE IR LAMPS

HELCON 11XX SERIES

BEFORE USING THE MODULES OF THE HELCON 11XX SERIES, YOU MUST READ

THIS INSTALLATION AND USE MANUAL CAREFULLY AND FOLLOW ALL THE INDI-

CATIONS TO GUARANTEE THE MAXIMUM SAFETY

The technical data and the drawings in this manual might have been modified later; always

refer to the latest version.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 2

Summary

1 Preface ....................................................................................................................................................... 3

1.1 Main differences between the HELCON 10XX and HELCON 11XX series ........................................ 3

2 General warnings ...................................................................................................................................... 4

3 Safety instructions .................................................................................................................................... 6

3.1 General information ............................................................................................................................ 6

3.2 Precautions during handling and assembly ........................................................................................ 6

3.3 Precautions against the risk of electrocution ...................................................................................... 7

3.4 Precautions against contact with hot parts ......................................................................................... 7

3.5 Residual risks ...................................................................................................................................... 7

4 Technical data ........................................................................................................................................... 8

4.1 Environmental characteristics ............................................................................................................. 8

4.2 Electrical characteristics ..................................................................................................................... 9

4.2.1 Lamp pilot outputs ....................................................................................................................... 9

4.3 Mechanical specifications ................................................................................................................. 10

4.3.1 Weight ....................................................................................................................................... 10

4.3.2 Dimensions ............................................................................................................................... 10

4.4 Order codes ...................................................................................................................................... 11

4.5 Accessories ....................................................................................................................................... 11

5 Installation and commissioning ............................................................................................................ 12

5.1 Preliminary operations ...................................................................................................................... 12

5.2 Mechanical assembly ........................................................................................................................ 13

5.2.1 Positioning and fixing ................................................................................................................ 13

5.3 Connections ...................................................................................................................................... 16

5.3.1 Power supply - J1 ..................................................................................................................... 17

5.3.1.1 Connection scheme ........................................................................................................... 18

5.3.1.2 Electromagnetic compatibility ............................................................................................ 20

5.3.2 Fieldbus - Connector J2 and J3 ................................................................................................ 20

5.3.3 24VDC input power supply - J4 connector ................................................................................ 22

5.3.4 24VDC power supply - J5 connector ........................................................................................ 23

5.4 LEDs ................................................................................................................................................. 24

5.4.1 Fieldbus status .......................................................................................................................... 24

5.4.2 Auxiliary power supply status .................................................................................................... 25

5.5 Addressing ........................................................................................................................................ 25

5.5.1 Manual addressing .................................................................................................................... 26

5.5.2 Automatic addressing ............................................................................................................... 27

5.6 Power output ..................................................................................................................................... 28

5.6.1 HELCON 1108 .......................................................................................................................... 28

5.6.2 HELCON 1110 .......................................................................................................................... 29

6 Operation and diagnostics ..................................................................................................................... 30

6.1 Theory of operation ........................................................................................................................... 30

7 Storage ..................................................................................................................................................... 33

8 Firmware upgrade ................................................................................................................................... 34

9 Maintenance ............................................................................................................................................ 35

9.1 Fuse replacement ............................................................................................................................. 36

9.2 Replacement of the SSR module ...................................................................................................... 36

9.3 Periodic maintenance - Tightening of the fuse holder terminals and power dividers ........................ 38

10 Disposal and demolition ....................................................................................................................... 40

11 Analytical index ..................................................................................................................................... 41

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 3

1 Preface

This manual provides all necessary information for the installation, use and maintenance of the control module

IR lamps HELCON 11XX series.

The instructions included in this manual are addressed to the following professionals:

The present instructions must be made available to all the above individuals.

1.1 Main differences between the HELCON 10XX and HELCON 11XX series

The substantial difference is an improvement in the lighting technology of the lamp outputs which works opti-

mally even with power supply with distorted sinusoidal voltage. To obtain this functional improvement of the

device, the SSR modules of the HELCON 10XX series and of the HELCON 11XX series are not interchange-

able with each other.

Furthermore, for the purposes of electrical safety, the LED indicators and the rotary switch for setting the ad-

dress are accessible from the outside without the need to open the protective casing.

User User is a person, a company or an institution that buys the equipment and

uses it for the purposes it was designed for.

User/operator User or operator is a person authorized by the user to operate on the equip-

ment.

Specialized personnel It refers to all persons with specific competence, able to recognize and avoid

the dangers deriving from the use of the equipment.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 4

2 General warnings

These assembly instructions are an integral part of the equipment, and must be kept for future reference until

it decomissioned.

The user should be informed that the present instructions reflect the state of the art at the moment when the

equipment was sold; they will remain fully acceptable despite subsequent upgrades based on new technical

update.

In order to make the manual consultation easier, the following symbols have been adopted:

DO NOT USE THE EQUIPMENT, NOR MAKE ANY INTERVENTION BEFORE INTE-

GRALLY READING AND UNDERSTANDING THIS MANUAL.

IN PARTICULAR, ADOPT ALL SAFETY PRECAUTIONS AND PRESCRIPTIONS INDICATED IN THIS

MANUAL.

THE EQUIPMENT MUST BE USED FOR PURPOSES DIFFERENT THAN THE ONES DESCRIBED IN

THIS MANUAL; SMITEC S.p.A. SHALL NOT BE HELD RESPONSIBLE FOR ANY DAMAGES, INCON-

VENIENCES OR ACCIDENTS DUE TO THE NON-COMPLIANCE WITH THESE PRESCRIPTIONS.

Indication of “PROHIBITED ACTION”.

The symbol “DANGER” is used when non-compliance with the prescriptions or misuse may

cause serious injuries.

The symbol “DANGER FROM HOT SURFACES” is used when non-compliance with the

prescriptions or misuse may cause serious injuries.

The symbol “DANGER FROM ELECTRICAL SHOCK” is used when non-compliance with

the prescriptions or misuse may cause serious injuries.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 5

The safety prescriptions aim at establishing a series of behaviors and obligations to be complied with, while

performing the activities described later on in this manual.

These prescriptions constitute the prescribed method of operating the device, in a way that is safe for person-

nel, equipments and environment.

The symbol “USE OF INDIVIDUAL PROTECTIONS” means that protective gloves must be

worn.

The symbol “USE OF INDIVIDUAL PROTECTIONS” means that protective glasses must be

worn.

Indication of “INFORMATION OF PARTICULAR RELEVANCE”.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 6

3 Safety instructions

3.1 General information

3.2 Precautions during handling and assembly

Do not install or use the equipment before integrally reading and understanding this manual.

In case of difficulties of interpretation, contact SMITEC technical service.

It is absolutely forbidden to use the equipment for different purposes than the ones de-

scribed in this manual. The technical data and the drawings in this manual might have been

modified later; always refer to the latest version. All upgrades can be requested to SMITEC

S.p.A. directly.

Make sure that the personnel is qualified and adequately informed about the risks he may

run and how to avoid them.

The use of the HELCON 11XX series IR lamp control modules is authorized only after clas-

sification of the operating area of the final machinery and verification of safety levels, which

must be congruent with the safety levels of the unit.

Metal components and sharp surfaces may cause cuts and tears. In case of contact, be very

careful and wear the personal protection equipment.

Use adequate tools during the assembly, in order to avoid crushing or abrasions.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 7

3.3 Precautions against the risk of electrocution

3.4 Precautions against contact with hot parts

3.5 Residual risks

The main power connector is subjected to high voltages during module operation; pay at-

tention (danger of electrocution).

During all phases of installation and maintenance of the equipment, disconnect it safely from

the power supply network. Electrolocution risk.

Some components of the apparatus (for example: the aluminum heatsink) are made of con-

ductive materials. They must be connected securely to the protective conductor (PE) using

the appropriate terminals, to avoid risk of electrolocution.

Never use the device partially or totally disassembled. Danger of electric shock and / or

damage to persons and property.

The parts of the apparatus can reach an extremely high temperature in operating mode or

post-operation; take particular care not to touch the parts of the equipment in these cases,

or use special protections and precautions during handling: HOT SURFACE, RISK OF

BURNS.

By using the device in the construction of a machine, the manufacturer must take all pre-

cautions to avoid the operator's contact with the hot parts, to avoid the risk of burns.

The apparatus generates an electromagnetic field during operation. Danger for people with

pacemakers, metal prostheses or hearing aids.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 8

4 Technical data

4.1 Environmental characteristics

All the technical information reported in this section are consistent with the hardware con-

figuration of the HELCON module produced at the date of writing of this document. With the

aim of technologically improving or updating the product, SMITEC S.p.A. reserves the right

to change the technical characteristics of the HELCON module without prior notice.

Operating temperature

Model: HELCON 1110

Code: KZ010605

0°C ÷ +45°C

Operating temperature

Model: HELCON 1108

Code: KZ010604

0°C ÷ +50°C

Storage temperature -20°C ÷ +70°C

Maximum altitude

1000 m a.s.l. at nominal output current

2000 m a.s.l. with current derating

Output current derating as a function of

altitude

Degree of protection of the enclosure IP65

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 9

4.2 Electrical characteristics

4.2.1 Lamp pilot outputs

Main power supply voltage 400VAC -10% ÷ 480VAC +5%

Type of power supply 2PH 50/60 HZ

Maximum short-circuit current 5 kA at the point of installation

Current main power consumption

Model: HELCON 1110

Code: KZ010605

63.8A

Current main power consumption

Model: HELCON 1108

Code: KZ010604

60.0A

Power input main power

Model: HELCON 1110

Code: KZ010605

25.5kW

Power input main power

Model: HELCON 1108

Code: KZ010604

24.0kW

Auxiliary power supply voltage 24V DC -15 ÷ +20%

Current consumption of auxiliary power supply 0.5A

The input current strongly depends on the impedance of the network; the values shown refer

to a perfectly sinusoidal network with zero generator impedance. In real cases there is a re-

duction in the input current value which can exceed 30%.

Type of electric load Halogen infrared lamps

Utilization category AC-55b (according to EN 60947-4-3)

Current max. deliverable on a single output 7.5A RMS

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 10

4.3 Mechanical specifications

4.3.1 Weight

The following table shows the weight of the various models:

4.3.2 Dimensions

External measurements of the only device:

Type Weight (kg)

KZ010604 14.1 kg

KZ010605 15.0 kg

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 11

4.4 Order codes

4.5 Accessories

Below is the list of order codes:

Order code Model Description

KZ010604 HELCON 1108 IR 400V single-phase lamps control module with 8ch x 3kW, max

24kW total.

KZ010605 HELCON 1110 IR 400V single-phase lamps control module with 10ch x 3kW,

max 25.5kW total.

Order code Article

EE500170 Spare fuse (class gG, 12A 500V RAPID, 10,3x38 mm)

EE500232 Spare fuse (class gG, 1A 500V, 10,3x38 mm)

KS011436 Electronic board static relay module for replacement (SSR)

KM030002 Non-silicone thermal conducting paste for mounting SSR modules.

It is supplied in a 35ml syringe.

KF131326 Connector with termination resistor for FLxIO bus, type M12 male

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 12

5 Installation and commissioning

5.1 Preliminary operations

Before putting the device into service, check the following:

• verify the perfect integrity of the unit and its components

• check that all the documentation necessary for the installation is present

• read and understand the following manual in its entirety

During the installation of the HELCON module, it is necessary to avoid falls and violent im-

pacts which could compromise its regular operation.

Avoid directly touching the input/output connectors located on the underside of the HEL-

CON module unless you are equipped with suitable protective equipment for static electric-

ity; any discharges on the connectors could in fact damage the device.

Always make all electrical connections with the equipment off: this will avoid damage to the

computer and danger to the operator.

Use suitable tools when assembling the equipment, to avoid the risk of injury, crushing,

abrasion, etc...

The metal parts and all the "live" parts can under certain conditions cause cuts and tears.

Pay particular attention in case of contact and use suitable personal protective equipment

(PPE).

Do not position the device in such a way that it is difficult to disconnect the wiring connected

to it.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 13

5.2 Mechanical assembly

5.2.1 Positioning and fixing

The HELCON series modules are suitable for “exposed” mounting; to ensure effective heat dissipation, it is

necessary to mount them in a vertical position, using the fixing holes provided for this purpose.

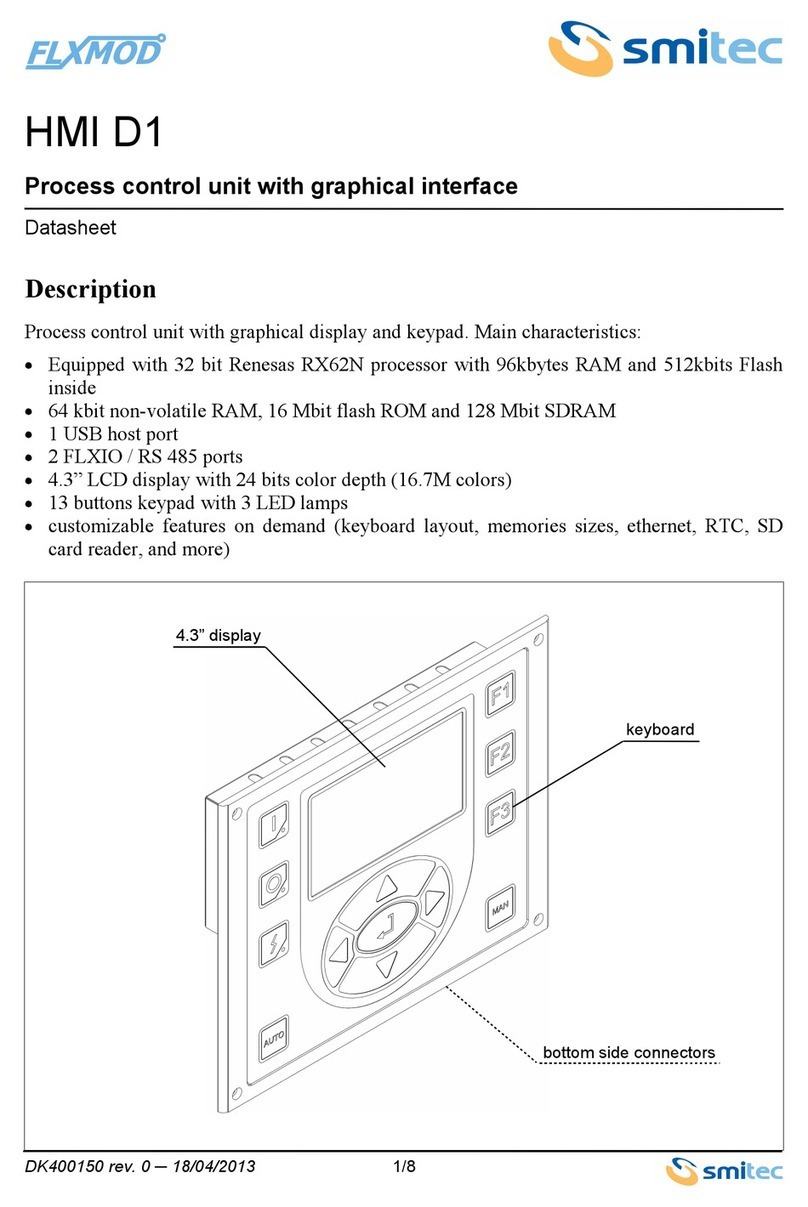

The following image shows the dislocation of the upper fixing holes, which is realized by means of a metal insert

with metric thread M6 (MA pitch). The stem portion of the screw entering the insert must not exceed 14 mm

(recommended value 12 mm). Use screws with a strength class of 8.8 or higher; the recommended tightening

torque is 10 Nm ± 10%. In the presence of vibrations, we recommend the use of anti-unscrew washers (for

example Grover or Belleville), or use medium braid compound (Loctite 243 or equivalent).

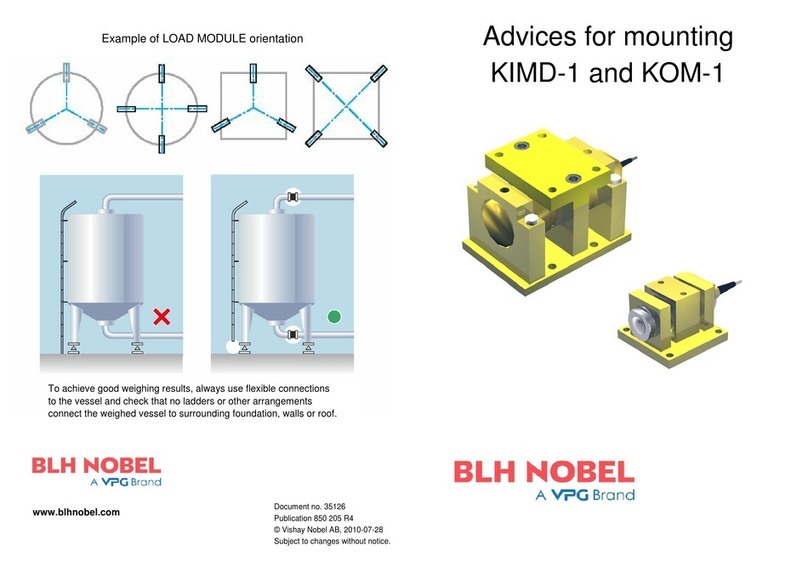

The following image shows the dislocation of the lower fixing holes, made within two metal support ears. The

fixation of the device to the support can be carried out by means of through screws fitted with a locknut. As

regards the choice of suitable screws, please refer to the above.

Upper side view (TOP)

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 14

In some installations, the support may be subject to considerable vibration, which could damage the device. In

this case, it is recommended to use dampers (“silentblock”) made of elastomeric material, whose characteris-

tics must be determined on the basis of the magnitude and frequency of the vibrations themselves. For how to

assemble the same, refer to the manufacturer's instructions.

Bottom side view (BOTTOM)

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 15

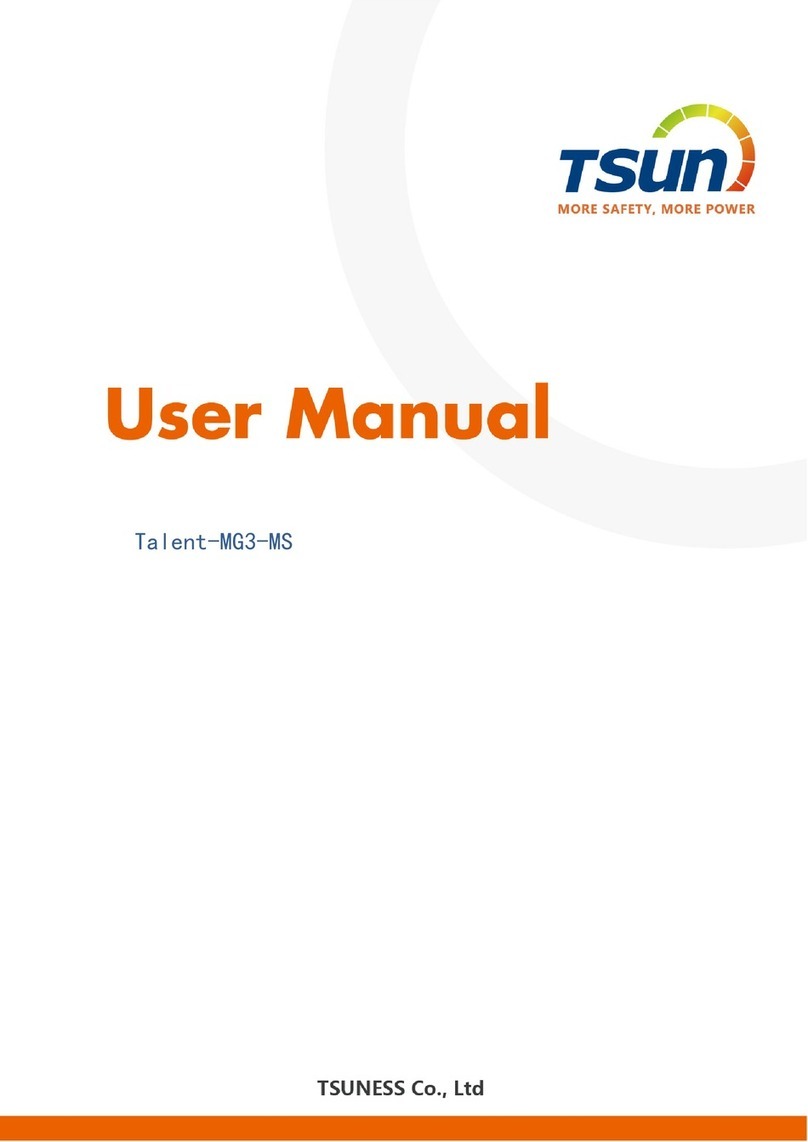

The HELCON 11XX series modules entrust the heat dissipation to an aluminum heatsink mounted on the back

of the same. To ensure optimal performance of the same, it is necessary to keep minimum distances during

assembly, both from the mounting wall and from nearby objects.

Check at regular intervals, the cleaning of the heatsink fins. The dirt accumulated between

them prevents the disposal of heat, causing overheating of the module and a possible re-

duction of its operating life.

Rear side view (REAR)

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 16

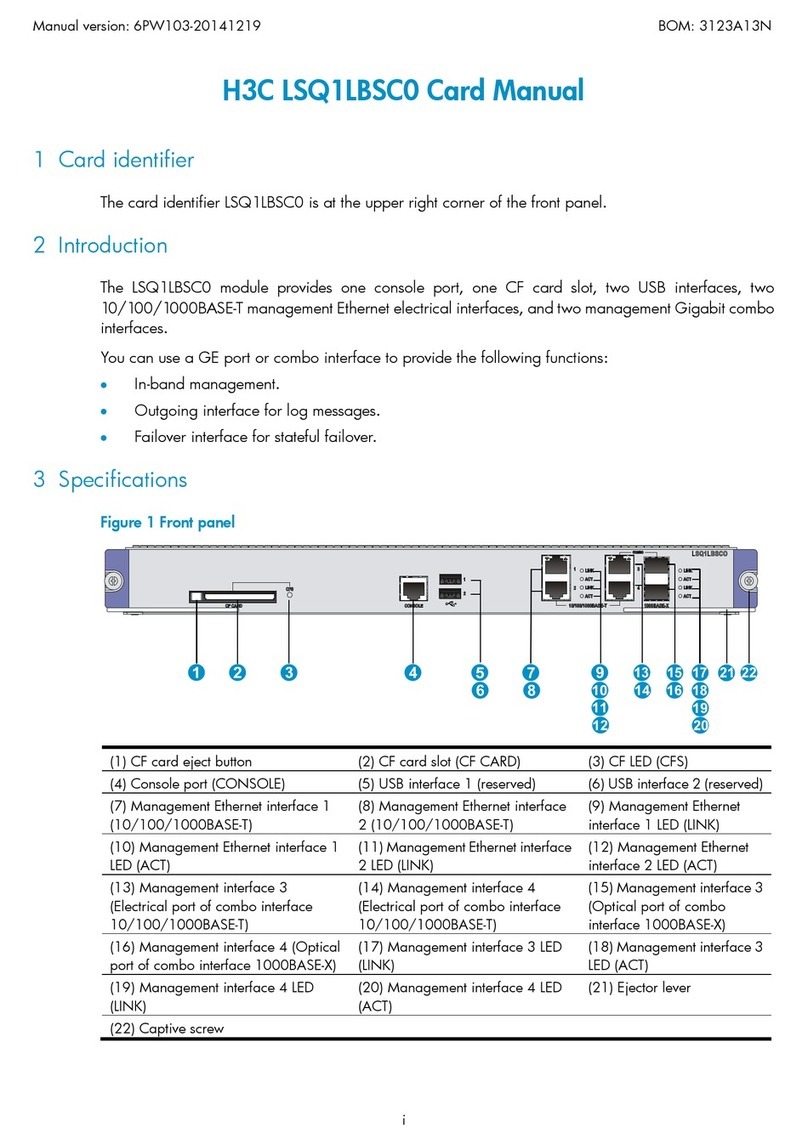

5.3 Connections

The connectors are located at the bottom.

The following image shows the connections available on the bottom of the equipment:

J3

J1 J4 J5

J2

Connections

Marker Description

J1 Main power supply

J2 Field bus - input -

J3 Field bus - output -

J4 24V DC - input -

J5 24V DC - output -

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 17

5.3.1 Power supply - J1

This is the mains supply (2 PH), using the J1 connector (2-pole 1000V 100A male; manufacturer: Ilme, code

CX 02 GM). The image and the pinout of the connector are shown below:

The following paragraphs describe in detail how the connections are to be made.

For safety reasons, the device must always operate with the PE connection inserted; danger

of electrolocution! The cross-section of the protective conductor (PE) must be not less than

that of the phase conductors.

L1

L2

PE

400 VAC power supply

Marker Signal

L1 400 VAC network - phase 1

L2 400 VAC network - phase 2

PE Earth protection

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 18

5.3.1.1 Connection scheme

The HELCON 11XX series modules are designed to operate on networks with TT or TN distribution. The op-

eration is not foreseen on IT networks, or with so-called “corner grounded” distributions. The following image

illustrates a typical usage scheme:

The protection of the device and of the power supply cables must be carried out by means of circuit breakers

of the magnetothermic type with tripping curve C complying with the EN IEC 60947-1 standard. The size of the

same must be 63A for modules with 8 outputs and 80A for those with 10 outputs. The short-circuit current pro-

vided at the point of installation must not exceed 5 kA.

In the case in which the maximum short-circuit current exceeds this limit, in order to protect the apparatus and

avoid damage to people and property, upstream of the automatic circuit-breaker use devices that are suitable

to limit the short-circuit current to a value not higher at 5 kA. Such devices could be constituted by fuses, or

switches-limiters. Contact SMITEC for information on the sizing of the same.

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 19

The sizing of the power cable depends on various factors:

• Module size (8 or 10 outputs)

• Environment temperature

• Type of cable used

• How to lay the cable

It is necessary to guarantee the protection against short circuit and overload of the cable, respecting the pre-

scriptions contained in the IEC 60204-1 standard. In case the apparatus must equip machinery that must meet

different standards, refer to them for more details.

The following table summarizes the minimum sections required for the power supply cable, using cables with

PVC insulation of 70 ° C, or XLPE / EPR from 90 ° C, assuming that the above protection devices are used

upstream of them. This table presupposes a laying of the cable in free air (similar to the installation category E

of IEC 60364-5-52).

If you intend to use cables of different types, or the way of laying cables is different from the one illustrated

above, please refer to the IEC 60364-5-52 standard for more information on the criteria for dimensioning them.

Do not install the device where the expected short-circuit current exceeds 5 kA. Danger of

fire and damage to people and property.

The use of an inadequate overcurrent protection device could cause it to fail to intervene,

with danger for people and things. Additionally, spurious protection interventions may occur.

Environment

temperature [°C]

Modules with 8 outputs

(KZ010478)

Modules with 10 outputs

(KZ010458 and KZ010488)

PVC XLPE/EPR PVC XLPE/EPR

40

16 mm²

10 mm²

16 mm²

16 mm²

45

25 mm²

50

55 25 mm²35 mm²

IR lamp control module - HELCON 11XX series - Installation, use and maintenance manual - EN

Ver. 1.02 20

In many installations multiple modules are used at the same time, in this case it is recommended to distribute

the same on the various network phases trying to equalize as much as possible the load on the various phases.

5.3.1.2 Electromagnetic compatibility

The HELCON 11XX series modules are designed to operate on industrial type electrical networks, defined as

“environment A” by the EN IEC 60947-1 norm (Class A appliance, CISPR 11).

As such, provided they are installed in accordance with this manual by skilled personnel and respecting the

rules of good technique, they do not require the installation of additional measures (eg network filters, filtering

capacitors, reactors, etc.) to obtain a installation in compliance with current directives.

In order to avoid interference and / or malfunctions of the module and other equipment, it is advisable to ensure

that the power cables are placed at a safe distance from other cables belonging to different circuits, particularly

if they transmit analog signals and / or high frequency.

5.3.2 Fieldbus - Connector J2 and J3

The HELCON 11XX modules are equipped with an interface for the FLxIO proprietary fieldbus; it is based on

an isolated RS485 electrical interface, and allows a reliable real-time control of complex applications.

Connections are made via connectors J2 and J3 (female, 4-pole, M12, shielded, D-coded, for IP65 Ethernet

connections; manufacturer: Phoenix Contact, code 1436550) on the lower panel.

The use of conductors with a section less than the recommended value could cause fire risk

and damage to people and things.

The device must always work with the PE connection inserted. In the absence of it, it may

not meet the requirements of electromagnetic compatibility, as well as being a potential dan-

ger to people and things.

This manual suits for next models

3

Table of contents

Other Smitec Control Unit manuals