SIAP+MICROS p099 PalB10 Guide

p099 PalB10

10m height lowerable mast

Installation manual and user’s guide

User Manual Vers. 00

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.2 Vers. 00

Index

1List of materials..................................................................................................................................... 3

1.1 PalB10 .................................................................................................................................................. 3

2Preparation for installation.................................................................................................................... 5

2.1 Civil works (plinth) for PalB10............................................................................................................... 5

2.2 PalB10 .................................................................................................................................................. 5

2.3 Transducers, cables ............................................................................................................................. 6

3Mechanic parts assembly..................................................................................................................... 7

3.1 PalB10 weather mast............................................................................................................................ 7

3.2 Anemometer ....................................................................................................................................... 10

3.3 Directional antenna............................................................................................................................. 12

3.4 Ultrasonic level transducer ................................................................................................................. 12

3.5 Photovoltaic panel .............................................................................................................................. 14

3.6 Video camera...................................................................................................................................... 15

3.7 Devices on a 2m height bracket......................................................................................................... 16

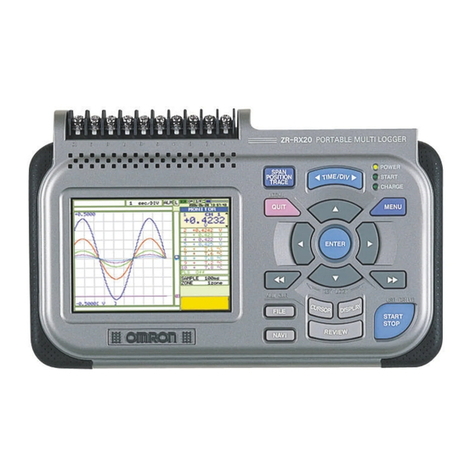

3.8 Data logger cabinet............................................................................................................................. 17

4PalB10 tilting....................................................................................................................................... 19

5Revision history .................................................................................................................................. 21

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.3 Vers. 00

1 List of materials

1.1 PalB10

PalB10 elements:

Element 1

Features: square base 300x200mm, diameter 152mm, total height 2015mm

Element 2a

Features: diameter 133mm, total height 2235mm, tiltable head

Element 2b

Features: diameter 133mm, outline 65x42x5.5mm, total height 2030mm

Element 3

Features: diameter 102mm / 89mm, total height 1970mm

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.4 Vers. 00

Element 4

Features: diameter 76mm / 60mm, total height 2250mm

Element 5

Features: diameter 48mm, total height 2250mm

Element 6

Features: cross-section 100x50x6mm, total height 1980mm

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.5 Vers. 00

2 Preparation for installation

2.1 Civil works (plinth) for PalB10

The PalB10 be installed on an adequate foundation plinth with anchor bolts. In the Annex 1 is represented

the plinth to be performed with features suitable for most type of installations.

You should execute works for the digging and burying of plinths made of concrete, joining inspection wells

and the sheath of electrical connection between the different parts of the station (meteorological pole,

pluviometric pole, nivometric pole, etc.).

In addition to the plinths, to ensure proper maintenance and management of electrical connections, will be

used for connecting underground inspection wells (minimum size of 30x30x30cm) with exposed cover (not

buried to ensure the inspection) where arrive the sheaths (made with spiral ducts made of plastic) from other

elements of the station.

The works must be made "by the rule book" to ensure the adequate support of the mechanical parts of the

station according to the type of ground on which you want to install the station.

You should choose a suitable site which has a sufficiently solid ground, so you do not have time failures that

can lead to deterioration of the foundations themselves up to possible collapse of the mechanical parts of the

station.

Siap+Micros can not therefore be held responsible for any structural failure or malfunction of the station

caused by misinterpretation and / or arbitrary choices do not conform to those indicated in this manual.

2.2 PalB10

PalB10 is composed on the whole by 7 elements made of galvanized steel.

The elements insert into each others and then secured with M10 grub screws with conic shape point,

screwed onto relative nuts, welded on the mast itself.

Since the dimensions of the mast and the significant weight of different elements, please be extremely

careful handling and installing them. Use suitable tools, like cranes with people racks and/or swinging arms

of at least 10m high lift.

Important: during any given installation of an element, check with the levelling gauge that the element itself

is perfectly in vertical position, and this kind of setting is made by acting on M10 grub screw.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.6 Vers. 00

2.3 Transducers, cables

All the sensors, or different electronic devices, directly

attached to the mast or by brackets must be wired putting

the cables into the right holes already placed onto the mast

and making them getting off at the base of the mast itself,

next to the three ø38mm holes just below the data logger in

the inner of a conduit.

Cables of devices sited on the bracket at 2m height should

come out from the upper hole; cables of other devices

(sited beyond the junction) should come out from the

central hole. Cables coming from the pole base (devices

not directly fixed to the pole, power supply 230Vac and LAN

cable) should come out from the lower hole.

Pay attention to the cables coming from the devices located

beyond the junction, in the mast tilting phase the cable must

be long enough not to tear when the mast is come to a

complete tilt; leave about a piece of cable 50cm long.

Pay attention to the cables coming from the well at mast base: they must be passed into the conduits and

inserted into the first element of the pole; they have to come out from the lower hole ø38mm before mast

installation.

At shown in the previous picture, insert the conduit into the mast making it bend downwards (that is useful

not to create water residual which could freeze and consequently break the conduit).

In the execution of wiring among the devices and the mast, is

a good rule, once you do the electric connection, to secure the

cable to the mast itself or to the brackets with some straps.

Then, before entering the cables into the fixation points

already placed on the mast, is warmly suggested letting the

cable be bended in order to avoid accumulation that could

drain up in mast base (see the picture by side).

Moreover, in order not to compromise the good working of the

electric connections, in the installation’s phases please be

careful to avoid every act which could damage cables and/or

connectors: don’t yank and don’t pinch the cables, don’t leave

the connectors at extended and direct contact with water, don’t

trample them and don’t roughly hit them.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.7 Vers. 00

3 Mechanic parts assembly

Indication of the phases for mechanic and electric mounting of the different parts of the station

3.1 PalB10 weather mast

Materials :

-

Tools:

size 27 wrench for M18 hexagonal head

Act :

unscrew M18 eight nuts used for clogging the upper spacer

plate. Remove eight ø18 upper washer and the plate.

Materials :

-

Tools :

-

Act :

before installation of the element 1, insert the wires coming

out of the sheath on the top of the plinth inside in the pole

base and get them out of the bottom hole, ø38mm, of the

three present in the element 1.

Materials :

element 1 of PalB10

n° 8 M18 nuts

Tools :

spanner size 27 for M18 hexagonal head, levelling gauge

Act :

put the base of the mast (element n°1) pointing it correctly:

the three ø38 holes side is the frontal one, that has to be

pointed Southwards.

Place once again the eight ø18 washers and the eight M18

nuts previously removed. Check the shaft is perfectly in

vertical position using the levelling gauge and if it is not, have

some setting acting on nuts which stand below the base.

Cable coming out

from the conduit sited

in the center of the

plinth

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.8 Vers. 00

Once you do this, then strongly tighten up the upper nuts. Screw also the remaining eight M18 nuts

(counterlock).

Materials:

PalB10 element 2 (2a and 2b)

n° 6 M10x20 grub screws

Tools:

size 5 Allen key for M10 grub screws, levelling gauge

Act :

put element 2 (2a and 2b elements are already assembled)

into the base. Point it so that the ø30mm holes in both two

elements can match. Fasten it screwing the six M10 grub

screws, paying attention to check the right vertical position,

acting on the grub screws themselves.

Materials :

PalB10 element 2a and 2b

TE M20x110mm screw, M20 elastic washer, split pin

TE M16x40 screw, M16 flat washer per M16

Tools:

spanner size 30 for M20 hexagonal screws,

spanner size 24 for M16 hexagonal screws

Act :

elements 2a and 2b are already pre-assembled following

this instructions:

Put element 2b into 2a as shown in the picture, put the M20 screw as a kingpin and tighten up with an elastic

washer and a M20 nut. Insert the safety split-pin in the M20 screw hole.

Fasten element 2b by the M16 safety screw, and relative washer.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.9 Vers. 00

Materials :

TE M16x230 screw with hole, M16 nut and M1 flat washer,

safety lock

Tools :

spanner size 24 for M16 hexagonal screw

Act :

for a safe tiltable mast phase, in the provision you’ll find a

screw (M16x230) with a hole for the key lock.

Once the mast is assembled, insert the M16x230 screw in the

hole placed at the base of the balancing arm and tighten up

with M16 nut and secure the whole system by the lock.

The two ring which are welded both on the balancing arm and,

immediately under, on mast need to hook a rope or similar

system (like a pulley) used as a servo-system to ease the

mast tilting.

Additionally, as a further safety locking, you can use the screw

placed higher, already inserted in element 2b.

Materials :

PalB10 elements 3, 4 and 5

M10x20 n° 18 grub screws

Tools :

allen key size 5 for M10 grub screws, levelling gauge

Act :

insert in this very order elements n°3, n°4 and n°5 (all with a

circular section of different diameters).

For every insertion, check the right vertical position of the

element, acting on the six M10 fasting grub screws. Once it’s

put vertical, fasten permanently the element, tightening up the

grub screws, making sure verticality is not altered.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.10 Vers. 00

Materials :

PalB10 element 6

TE M10x35 n° 6 screws, M10 flat washer

Tools :

spanner size 17 for M10 hexagonal screw

Act :

fasten element n°6 on the extension of the previously

installed rocker arm (element 2b) with six M10 screws and

relative washers.

Pay attention to the hole placed in the bottom: it must match

with the ø18 hole placed on mast.

3.2 Anemometer

On the top of PalB10, on the last element of 48 mm diameter, brackets for anemometer transducer and for

transducers themselves are placed.

Materials :

bracket fitting two transducers, equipped with clevises

Tools :

spanner size 13 for M8 hexagonal screw

Act :

insert and fasten bracket as shown in the picture

(perpendicular to the capturing antenna’s brackets on the

North-South direction and close to holes placed on the top

of the mast). Fastening is made acting on two M8 nuts

placed in the opposite side from the clevis.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.11 Vers. 00

Materials :

anemometer transducer for wind speed and direction

Tools :

spanner size 13 for M8 hexagonal screw

Act :

insert and fasten transducers to the brackets, as shown in

the picture. Fastening operation is made acting on two M8

nuts, placed in the opposite side from the clevis.

IMPORTANT: since the transducer must show wind

direction, install wind direction transducer TDVR with label

wording “NORTH” pointing to “NORTH”.

Materials :

connecting cables for anemometer transducer

Tools :

-

Act :

make the anemometer transducers connection with the

relative cables screwing the connectors.

Insert the other end of the cables into the holes placed in

the mast and make the cable go down to the three ø38mm

holes at the base of the mast.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.12 Vers. 00

3.3 Directional antenna

Depending on the type of the antenna to install, ensure his correct orientation at the suitable height to avoid

any obstacles near the station.

The antenna can be installed in the last 3 meters of the pole (items 4 and 5) in the vicinity of one of the holes

used for the passage of the cable inside the pole.

Performing the antenna installation as described below:

Materials :

directional antenna and antenna extension cable

Tools :

spanner size 13 for M8 hexagonal screw

Act:

it’s possible fastening antenna in the last 3m of mast

(elements 4 or 5). Connecting the TNC coaxial connector

cable that comes out from antenna with the extension

cable. Make the latter entering the hole placed on mast and

then make it going down to mast’s base next to the three

ø38mm holes.

Once the antenna is in the right position, secure the cable

to the mast with some straps.

3.4 Ultrasonic level transducer

Ultrasonic snow level transducer must be fixed with the proper bracket on the opposite side from the

lightning rod system. This is because the measurement must be taken in a zone where people passing is

almost denied, thus there’s no many chance that snow level can be varied.

Make bracket’s and transducer’s installations as follow.

Materials :

TNU08 transducer’s bracket with screws

Tools :

spanner size 13 for M8 hexagonal screw

Act :

mount TNU08 transducer’s bracket at about 6m height from

round (element 4) on the section ø76mm shaft mast.

Close the clamp on bracket with M8 screws and relative

washers and nuts.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.13 Vers. 00

Materials :

connecting cable for transducer TNU08

Tools :

-

Act :

make the cable pass through the inside of the bracket, leaving

the end with screw connector on the opposite side of the

mast.

Insert the opposite side of the cable in the right hole on mast

and make it going down next to the three ø38mm holes in the

base.

Materials :

ultrasonic snow level transducer

Tools :

spanner size 13 for M8 hexagonal screw

Act :

fasten the snow level transducer (TNU08) to the bracket by

the clevis placed on the end of the bracket itself.

Connecting cable to the transducer by screw connector.

Once bracket and transducer are placed, secure the possible

surplus cable with some strips.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.14 Vers. 00

3.5 Photovoltaic panel

Photovoltaic panel orientation must be executed towards sun direction, towards South in the northern

hemisphere, North in the southern one.

Photovoltaic panel must be fasten to the mast on element 3, at about 5,5m height.

Materials :

photovoltaic panel complete with cable

Tools :

spanner size 13 for M8 hexagonal screw

Act :

unloose the four side screws fastening photovoltaic panel

brackets. Lean brackets to the mast and fasten it with the

equipped clevises.

Fasten then using M8 nuts and close blocking screws of

photovoltaic panel brackets.

Materials :

-

Tools :

-

Act :

secure connecting cable to mast, making it pass inside the

hole present on mast down to the three ø38mm close to the

mast’s base.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.15 Vers. 00

3.6 Video camera

Video camera is equipped with a swivel that allows it to rotate on two axis, and then to easily frame the

involved zone. For any other information concerning installation, please refer to the proper user’s guide of

device.

Installing the video camera as below:

Materials :

video camera equipped with mast bracket and connecting

cable

Tools :

-

Act :

placing the video camera complete with bracket next to hole

placed at about 900mm over the junction. Make the cable

going down next to the three ø38mm on the mast’s base.

Materials :

-

Tools:

-

Act :

fasten video camera with equipped straps.

Pointing camera lens towards the desired direction, secure

video camera’s blocking screws as shown in the proper

user’s guide.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.16 Vers. 00

3.7 Devices on a 2m height bracket

At 2m height, mast presents a bracket for transducers and devices.

Each device has its own fixed position with rings or M8 screws.

Fastening of brackets and devices, must be done in the correct order shown below.

Materials:

transducer bracket placed at 2m height

Tools :

spanner size 13 for M8 hexagonal screw

Act :

prepare bracket as shown in the picture, with the two

clevises on the recommended positions.

Materials :

air temperature transducer,

relative humidity transducer

Tools :

spanner size 13 for M8 hexagonal screw

Act :

fasten two transducers on the clevises, tighten up the M8

nuts. The relative humidity transducer (TRH) places close

to the PalB10 mast while temperature transducer (TTEP)

towards the end of the bracket.

Materials :

connector cables for transducers

Tools :

-

Act :

connect all two of the devices with relative cables. Make the

cable pass in the bracket, entering in the hole placed in the

lower part of it. Going out from the hole placed in central

plate..

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.17 Vers. 00

Materials :

transducers’ bracket at 2m height complete with cables and

transducers

screws and M8 nuts with washers

Tools :

spanner size 13 for M8hexagonal screw

Act :

insert cables in the right entry hole placed in PalB10, paying

attention to make them going down towards the three holes in

the lower position. Guiding the cables, draw up the bracket to

the plate and then fasten with M8 nuts.

3.8 Data logger cabinet

Data logger cabinet must be installed at the PalB10 base with the right brackets. It’s provided with 3

cableglands that allow the cables passing from upper devices and from outer devices (rain gauge, snow

level transducer, power supply, earthing,…).

Materials :

plate for brackets used on data logger box’ brackets

Tools :

spanner size 17 for M10 hexagonal screw

Act :

mount plate as shown in the picture, inserting the three

fixing screws.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.18 Vers. 00

Materials :

data logger cabinet complete with brackets

Tools :

spanner size 13 for M8 hexagonal screw

Act :

secure data logger cabinet to the plate using four M8 nuts.

Materials :

conduits

Tools :

-

Act :

pass the cables coming out from ø38 holes at the mast

base into the conduits and insert them in relative cable

glands placed on the bottom of the data logger box. Tight

the cable glands lock nut so to firmly secure the conduits.

ATTENTION:

to prevent tearing of the cables of the devices installed

above the articulation when lowering of the mast, leave an

excess cable length inside the pole itself

The conduits must be routed in the mast facing down, in

order to let possible condensation drain.

The cables shall prolong at least 50 cm. inside the mast.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.19 Vers. 00

4 PalB10 tilting

PalB10 is a mast 10m height equipped with junction at 4m height that allows its tilting to make easier

reaching transducers and/or devices placed at different height.

In the picture below (1:100 scaling) you can see the schema for distances and overall dimensions of moving

parts during tilting phase.

ATTENTION: during the tilting phase of the mast pay extreme attention; execute slowly the different

operations, keep safe distance from moving parts. Stay away from the path of the upper end mast as well as

the path of the mast balance arm.

Perform the lowering pole steps according to the instructions below.

User’s Manual

p099-di PalB10.docx

27/02/2023 Pag.20 Vers. 00

Materials :

snap-hook rope

Tools :

-

Act :

secure snap-hook to ring “1”. Make the rope pass in ring “2”

bundling it to mast.

Materials :

-

Tools :

-

Act :

remove safety screws installed on mast (see chapter 3.1).

ATTENTION: from this very moment the tilting part of the

mast is held in position and controlled only by the rope.

Materials :

-

Tools :

-

Act :

Release rope until you reach requested tilting point; secure

rope in order to block mast and execute maintenance

operations.

Lift up the mast pulling rope and accompanying the balance

arm down to the vertical rest position.

Tie up the rope to the mast and secure the balance arm to

the Mast base with the safety screws, then place the safety

lock. At last remove the rope.

1

2

Table of contents

Other SIAP+MICROS Data Logger manuals