SIAP+MICROS t021 TLU Guide

t021 TLU

Ultrasonic Level

User Manual and maintenance

User manual and maintenance

t021-di TLU.docx

26/10/2023 2Vers.: 1.0

Summary

1Introduction ................................................................................................................................................ 3

2Technical specificaion ................................................................................................................................ 4

2.1 Operation scheme ............................................................................................................................. 5

3Installation and maintenance ..................................................................................................................... 6

3.1 Installation.......................................................................................................................................... 6

3.2 Maintenance ...................................................................................................................................... 6

4Electrical connection .................................................................................................................................. 7

4.1 Pinout del connettore ......................................................................................................................... 7

4.2 Connection cable ............................................................................................................................... 7

4.3 Data readinding in serial (RS485 Modbus)........................................................................................ 7

4.3.1 RS485 Modbus mode .................................................................................................................... 7

5Generic information ................................................................................................................................... 8

5.1 Safety................................................................................................................................................. 8

5.2 Appropriate use of the equipment ..................................................................................................... 9

5.3 Storage .............................................................................................................................................. 9

5.4 Moving ............................................................................................................................................... 9

5.5 Disposal information .......................................................................................................................... 9

6Revision history ....................................................................................................................................... 10

User manual and maintenance

t021-di TLU.docx

26/10/2023 3Vers.: 1.0

1Introduction

Water level monitoring represents a fundamental issue when it comes to deal with the assessment of

hydrological risks and the management of water resources. TLU ultrasonic hydrometric sensor is undoubtly an

effective, affordable and reliable solution. It ensures excellent accuracy standards, thanks to a self-correction

system of the hydrometric measurement. Indeed, by means of an integrated temperature sensor, it can easily

take into account the variation of the speed of sound as a function of the density of the air. The measurement

principle is based on the emission of an ultrasonic frequency impulse towards the surface to measure and on

the subsequent reception of the reflected signal. TLU is a non-contact instrument. Furthermore, it allows to

speed up and simplify the installation and maintenance steps. The sensor is supplied with power and signal

cable (12m).

Ordering Codes:

Range 0÷8 m: ..........................................................t021g-TLU08-IVS

Range 0÷16 m: ........................................................t021h-TLU16-IVS

User manual and maintenance

t021-di TLU.docx

26/10/2023 4Vers.: 1.0

2Technical specificaion

Measurement performance

Measurement range (TLU08)

0.6 ÷ 8m

Measurement range (TLU16)

0.8 ÷ 16m

Accuracy

±1 cm

Sensibility

0.5 cm

Beam width (3dB)

12° ± 2°

Operating conditions

Temperature

-20 ÷ +65 °C

Humidity

0 ÷ 100 RH%

Outputs

TLU08

Tension

0 ÷ 2 V ↔0 ÷ 10 m

Current

4 ÷ 20 mA ↔0 ÷ 10 m

RS485 MODBUS

Temperature, Water levell

TLU16

Tension

0 ÷ 2 V ↔0 ÷ 20 m

Current

4 ÷ 20 mA ↔0 ÷ 20 m

RS485 MODBUS

Temperature, Water levell

Power supply and Consumption

Voltage supply (non-natural output versions)

10 ÷ 16 Vdc

Power consumption

Min

Typical

Max

4 ÷ 20 mA

7

30

0 ÷2 V / RS485 MODBUS (TLU08)

1

0 ÷2 V / RS485 MODBUS (TLU16)

1.5

Potenza pilotaggio capsula (di picco)

14.4 W

Mechanical specifications

Protective body

Plastic material (ABS), aluminium and stainless

steel screws

Electrical connections

IP67 / 7 pole male connecto

User manual and maintenance

t021-di TLU.docx

26/10/2023 5Vers.: 1.0

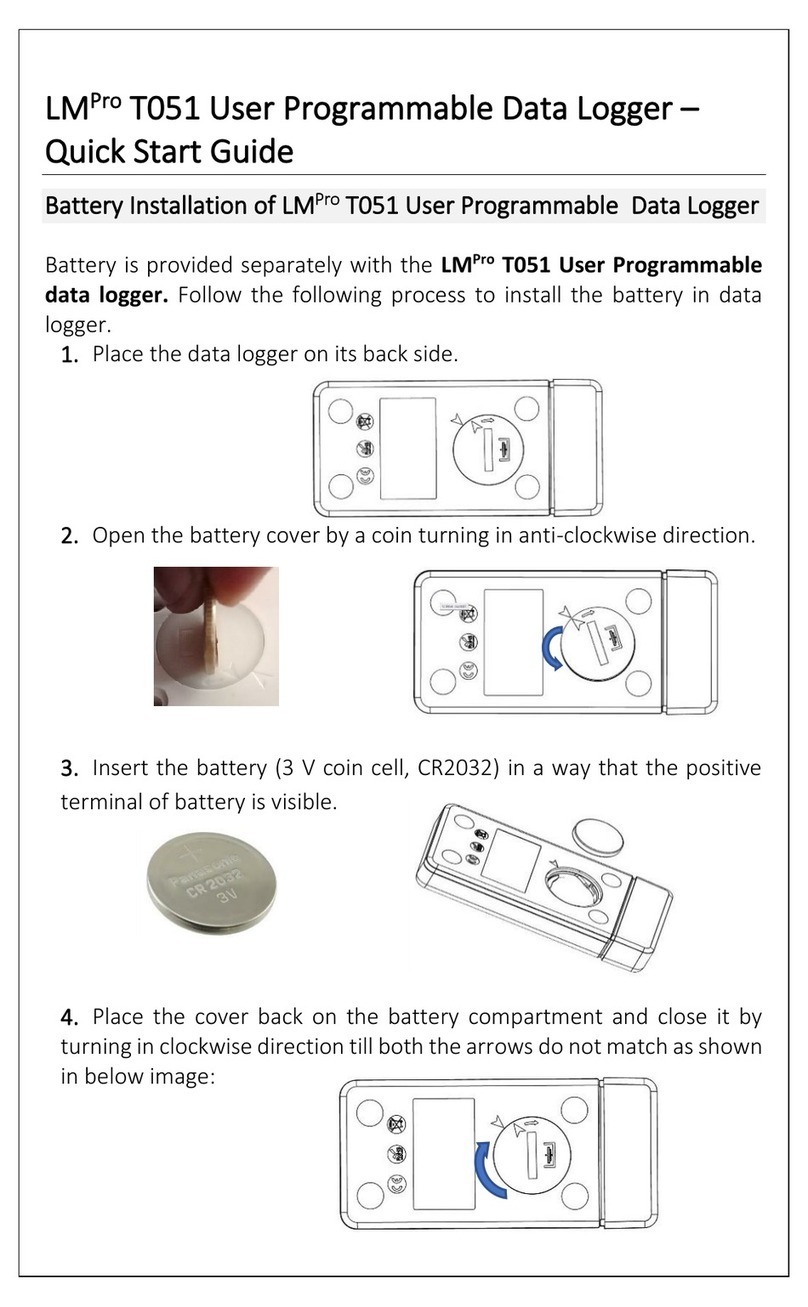

Dimension: TLU08 TLU16

H–maximum heigh 335mm 400mm

D1 –fixing diameter 40mm

D2 –maximum diameter 210mm

Elementi:

A–connector

B–support stem

C–ultrasonic capsule protection and air

temperature sensor

D–central body in aluminium

Weight:

TLU08: 1.6kg

TLU16: 2.3 kg

2.1 Operation scheme

User manual and maintenance

t021-di TLU.docx

26/10/2023 6Vers.: 1.0

3Installation and maintenance

3.1 Installation

The TLU sensor, in all its versions, can be installed

on special Siap+Micros arms equipped with a

terminal plate for the attachment of 40mm diameter

U-bolts (see the example in the image to the side).

The length of the arm used can vary according to

the measurement needs.

N.B.: the sensor has a 12° measurement cone, when choosing the site or installation method it is necessary

to take this into account, taking care not to have any obstacles inside this cone so as not to mistakenly detect

the obstacle.

3.2 Maintenance

The sensor has no particular maintenance requirements. For a correct and constant accuracy of the

measurement, the area below the sensor inside the measuring cone (12°) must be kept clean and free from

obstacles, even temporary ones.

However, it is advisable to periodically check that it is working properly in the factory with sample instruments.

User manual and maintenance

t021-di TLU.docx

26/10/2023 7Vers.: 1.0

4Electrical connection

4.1 Pinout del connettore

Pin

Signal

1

A-RS485

2

B-RS485

3

+0÷2 Vdc

4

+4÷20 mA

5

-4÷20 mA

-0÷2 Vdc

6

Vcc

7

GND

4.2 Connection cable

The connection cable supplied with the sensor is made with circular connectors with housing, 6 x 22 mmq + 2

x 2.5 mmq shielded cable and ferrules for connection to the data logger terminals. The braid is connected to

the general ground lead

Pin

1

2

3

4

5

6

7

7

Cable

Blue

White

Green

Black

Yellow

Blue

(2.5mmq)

Brown

(2.5mmq)

Red

Segnali

A-RS485

B-RS485

+0÷2 Vdc

+4÷20 mA

-4÷20 mA

-0÷2 Vdc

Vcc

GND

GND

4.3 Data readinding in serial (RS485 Modbus)

Sensors with RS485 Modbus output send data only upon specific request from the PC, data logger or PLC.

Below are the correct communication parameters of the device performing the interrogation.

4.3.1 RS485 Modbus mode

Serial port settings: 9600 baud, no parity, 8 data bits, 1 stop bit

Compatible with ModBus RTU protocol, supported functions: “03 – read Holding Registers” and “04 – Read

Input Registers”.

Data type: “2 registers swapped float IEEE 754 in the form CDAB where A is the most significant byte of the

float and D is the less significant byte of the float (swapped float)”.

ID

Registers

Units

Reg. 1-2

Reg. 3-4

Reg. 5-6

Reg. 7-8

Reg. 9-10

Reg. 11-12

Reg. 13-14

21

3

m

-

Distance from sensor

-

-

-

Diagnostic

Supply Voltage

User manual and maintenance

t021-di TLU.docx

26/10/2023 8Vers.: 1.0

5Generic information

The qualitative level of our instruments is the result of a continuous evolution of the product. This may cause

differences between what is reported in the manual and the instrument you have purchased.

Siap+Micros S.p.A. reserves the right to modify without notice technical specifications and dimensions to adapt

them to the needs of the product.

5.1 Safety

Please read these safety instructions carefully before using this product:

•The warranty will be void if the product is used differently from the instructions described in this manual.

•Any sign of tampering will void the warranty

•Use the devices only according to the instructions (environmental management, operation, wiring,

installation, etc.) provided in this manual

•The correct and safe operation of the device can only be guaranteed if the transport, storage, operation

and management of the device are compliant. This also applies to product maintenance.

•The device shall not be exposed to aggressive chemicals or solvents that could damage the plastic

casing and/or corrode the metal parts.

•Maintenance should only be performed by qualified and well trained personnel.

It is appropriate to carry out a careful risk assessment in relation to the context of installation and use of the

device by the installer considering the possible meteorological station in its complexity without being limited to

the sensor.

The instruments must be installed according to the rules of the trade, with equipment that complies with

applicable regulations and using supports correctly sized by qualified technicians and designed for the specific

purpose.

During installation operations, check the suitability of the surrounding environment and compliance with local

safety regulations.

The manufacturer declines all responsibility in case of failure due to negligence of the instructions, tampering,

uses not described in this manual, improper use, use by operators not trained.

Read the instructions and intended use carefully and be sure you understand before installing the device

Before starting the activities, check the integrity of the instrument to be installed, prepare the equipment

necessary for the work and wear the necessary PPE.

Take adequate measures to prevent the access of foreign personnel (untrained and uninformed) during the

installation, maintenance or replacement of the instrument.

Take precautions to avoid falling objects, both during the installation phases and during the operation of the

instrument.

Do not perform any activity in bad weather conditions.

User manual and maintenance

t021-di TLU.docx

26/10/2023 9Vers.: 1.0

During maintenance, particularly if the station is not frequented, visually check for the absence of dangerous

insects and, if not, use suitable insecticides.

Consider the presence of any animals near the station, if so, pay attention to them.

Use only SIAP+MICROS original spare parts.

The instrument is not classified suitable (according to Directive 2014/34/EU) for use in atmospheres with

potential explosion risk pursuant to Directive 99/92/EC.

SIAP+MICROS strives to minimize health and safety risks in all phases of the instrument's life, including

installation, use, maintenance, decommissioning and disposal.

5.2 Appropriate use of the equipment

Use the instrument for its intended purpose, do not use it for any other purpose or cause malfunctions and/or

damage.

5.3 Storage

If you do not plan to use the equipment for an extended period of time (at least one year) disconnect all cables

from the equipment, place it in a clear plastic bag along with a bag of desiccant salts and seal the bag with

tape. Put appropriate indication on the bag of the contents and weight of the equipment by inserting the wording

"HANDLE WITH CARE".

Store the instrument in an environment with a temperature between 0°C and 60°C with a humidity not

exceeding 80%. Make sure that the instrument is stored in a stable position and that it cannot be damaged or

moved by inexperience or carelessness. Do not stack other tools or weights. Do not place the instrument on

top of other instruments and in any case ensure the solidity and stability of the underlying support.

Non esporre, stoccare lo strumento in ambienti con presenza di vapori e/o gas corrosivi.

5.4 Moving

In order to avoid any damage to the device during transportation, please keep it in upright position without

shaking.

5.5 Disposal information

Electrical and electronic equipment marked with specific symbol in compliance with 2012/19/EU

Directive must be disposed of separately from household waste. European users can hand them

over to the dealer or to the manufacturer when purchasing a new electrical and electronic

equipment, or to a WEEE collection point designated by local authorities. Illegal disposal is

punished by law.

Disposing of electrical and electronic equipment separately from normal waste helps to preserve natural

resources and allows materials to be recycled in an environmentally friendly way without risks to human health.

User manual and maintenance

t021-di TLU.docx

26/10/2023 10 Vers.: 1.0

6Revision history

The following table shows the description of the changes made to this document.

Version

Date

Updates

1.0

05/06/2023

Current version of the document.

All the information content in this document are the current available at the printing phase. Siap+Micros S.p.A. reserve the rights to change

the specifications without any advance notice

This manual suits for next models

2

Table of contents

Other SIAP+MICROS Data Logger manuals