gENERAL sAFETY

WARNING

Improper use can cause breakage.

• Read instructions before operating.

• Follow manufacturer’s instructions, safety

precautions, and specifications when

operating tools.

Broken equipment can cause injury.

USERS AND BYSTANDERS SHOULD ALWAYS

WEAR EYE PROTECTION

• Flying particles can be discharged when

applying torque.

Flying particles can cause injury.

Risk of entanglement.

• Keep body parts away from rotating parts.

• Wear a protective hair covering to contain long

hair and prevent contact with moving parts.

• Do not overreach. Keep proper footing and

balance at all times.

Entanglement can cause injury.

Ac ADAPTER sAFETY

Risk of electric shock and re.

• Do not allow conductive objects to come

in contact with terminals. 120 or 220 volts

present at adapter terminals.

• For indoor use only. Do not expose adapter to

rain or snow. Do not use in damp locations.

• Replace defective cord immediately. Return to

qualified service center for replacement.

• Do not use any other type of adapter. Using an

adapter not specifically designed for this unit

may damage tester.

• Do not use an extension cord with adapter.

• Do not use a damaged adapter.

• Do not disassemble adapter.

• Do not attempt to connect two adapters

together.

• Do not operate adapter with damaged cord or

plug. Replace immediately.

• Do not operate adapter after it is dropped,

receives a sharp blow or damaged. Take the

adapter to an Authorized Service Center.

• Unplug adapter from outlet before

maintenance or cleaning. Turning off tester is

not adequate to avoid hazard.

• Read all instructions and safety messages on

battery and adapter before use.

Electric shock or fire can cause injury.

• Fully engage the direction lever in the correct

position when using ratchets. Never attempt

to test an impact tool or pulse type tool on this

instrument.

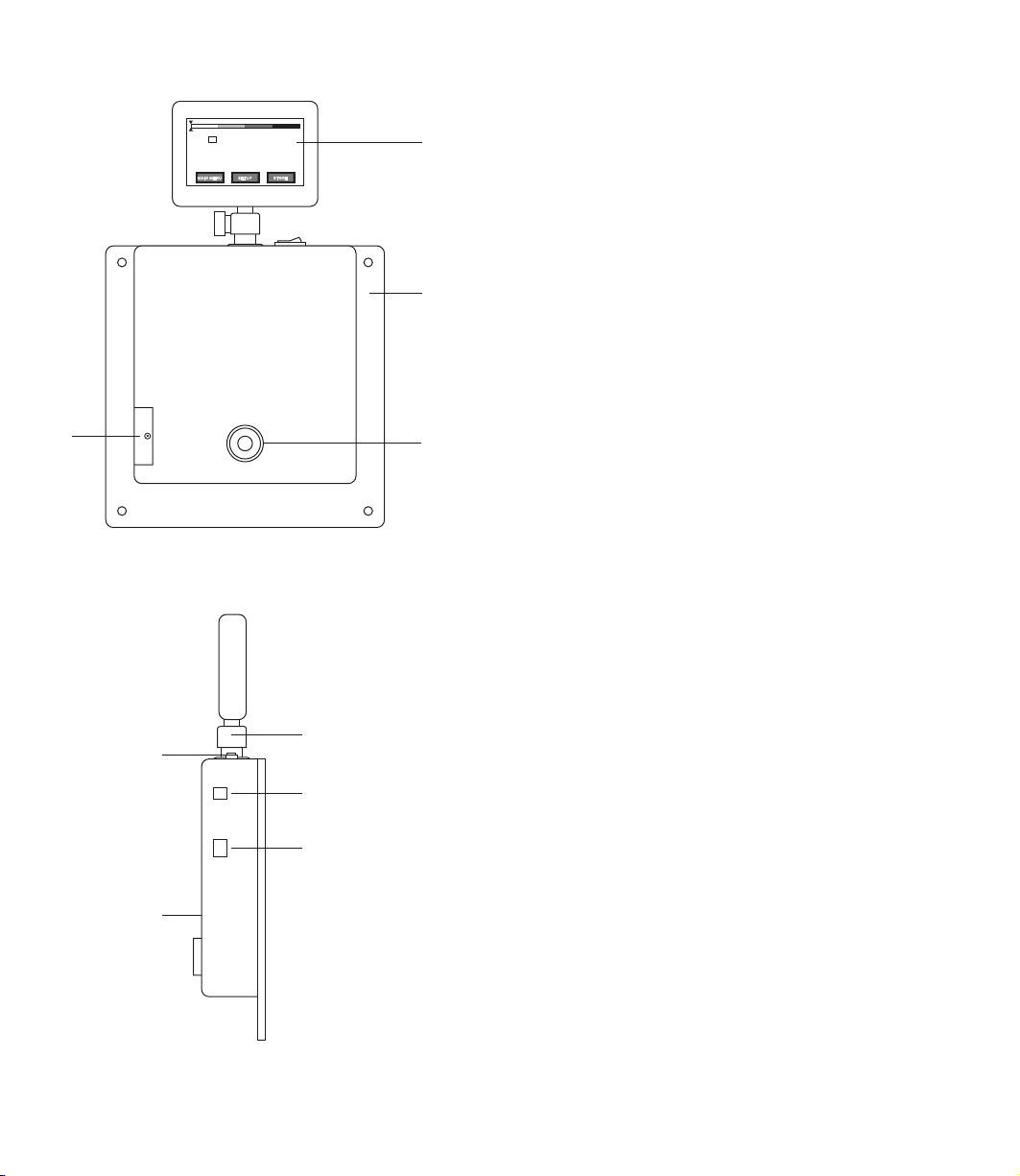

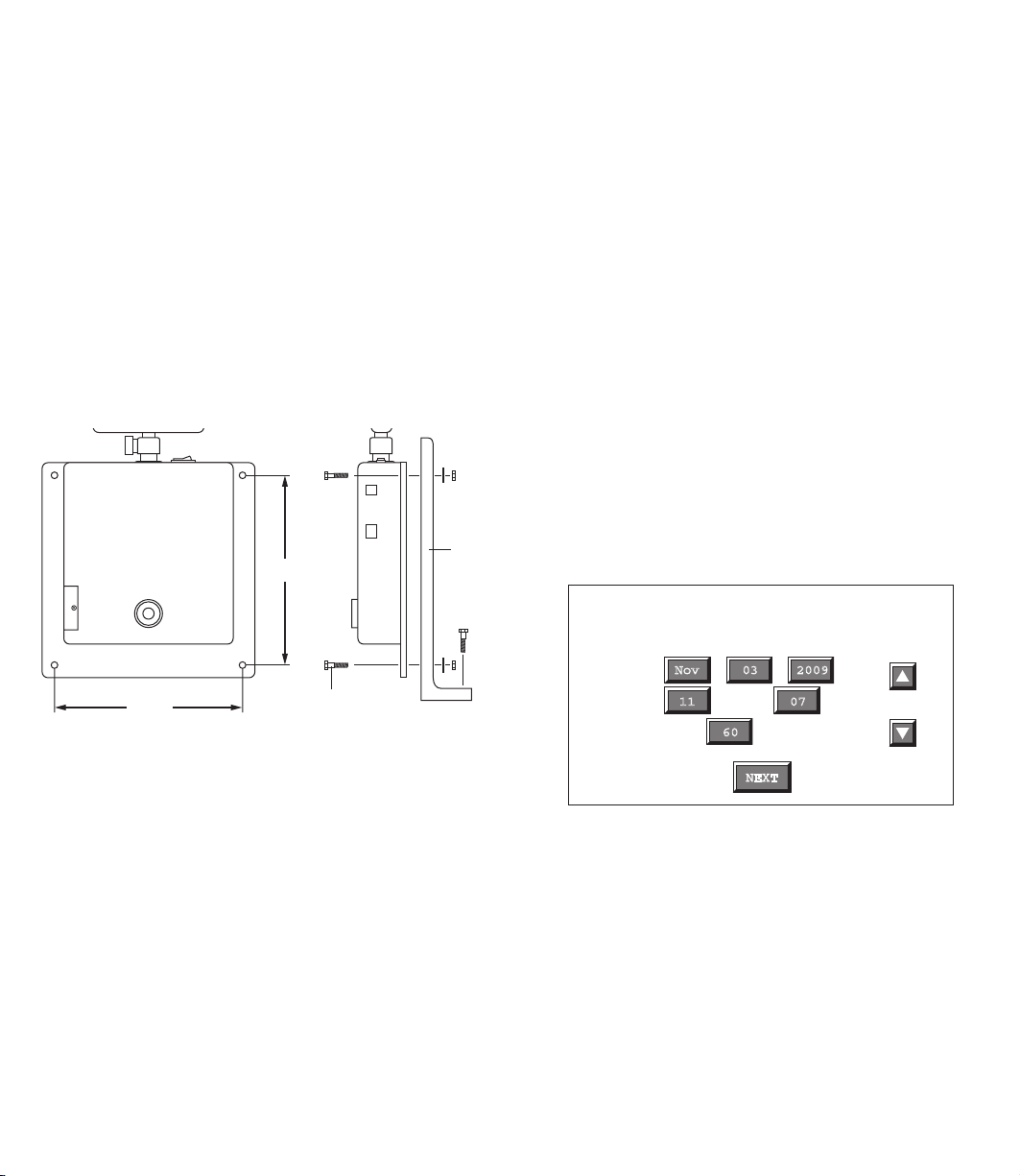

• Mount the DTI securely to a heavy bench, wall

or other support structure before applying

torque.

• Do not use the DTT if it makes unusual noises,

has loose parts, or shows any other sign

of damage. Have repairs performed at an

Authorized Service Center before use.

• Do not use chipped, cracked, or damaged

sockets and accessories.

• Do not remove any labels. Replace any

damaged label.

TORqUE TEsTER sAFETY

TORqUE TEsTER sAFETY

WARNING

• Be sure ratings for all components, including,

adaptors, extensions, drivers and sockets,

match or exceed the torque being applied.

• Do not use this instrument with power switch

OFF. Always turn power switch ON so torque

values are displayed.

• Do not turn the power switch ON with a torque

instrument engaged to tester transducer.

• Be sure the capacity of the DTT matches or

exceeds each application before performing a

procedure.

• Pull on a wrench handle—do not push—when

tester is mounted horizontally. Adjust stance

to prevent a possible fall.

• Pull on a wrench handle—do not push—when

tester is mounted horizontally. Adjust stance

to prevent a possible fall.

• Do not use extensions, such as a pipe, on a

wrench handle.

WARNING

CAUTION

CLOTHING

DONOTCR DONTPULL

EARPROT

DUSTMASK

DRWSTEP EXTENDER

NO OVERTORQUE

EYEPROTEC FACESHLD FILTMASK

FIRE FALLING GEARS

HAMRON HAMMER2

WEARGLV

XPLOSION VIBRATE

TIPOVER

SHOCK

PRYING PRWDRIVR

INFO SOLID CIRCLE

TRIANGLE

DANGER

C0 MASK NEEDED

TIP OVER CHILD

WARNING

CAUTION

CLOTHING

DONOTCR DONTPULL

EARPROT

DUSTMASK

DRWSTEP EXTENDER

NO OVERTORQUE

EYEPROTEC FACESHLD FILTMASK

FIRE FALLING GEARS

HAMRON HAMMER2

WEARGLV

XPLOSION VIBRATE

TIPOVER

SHOCK

PRYING PRWDRIVR

INFO SOLID CIRCLE

TRIANGLE

DANGER

C0 MASK NEEDED

TIP OVER CHILD

WARNING

CAUTION

CLOTHING

DONOTCR DONTPULL

EARPROT

DUSTMASK

DRWSTEP EXTENDER

NO OVERTORQUE

EYEPROTEC FACESHLD FILTMASK

FIRE FALLING GEARS

HAMRON HAMMER2

WEARGLV

XPLOSION VIBRATE

TIPOVER

SHOCK

PRYING PRWDRIVR

INFO SOLID CIRCLE

TRIANGLE

DANGER

C0 MASK NEEDED

TIP OVER CHILD