2

Table of Contents

1Safety Precautions.................................................................................................... 5

2Before Use................................................................................................................. 8

2-1 About This Operation Manual............................................................................................8

2-2 Product Contents...............................................................................................................8

2-3 Optional and Replacement Parts.......................................................................................9

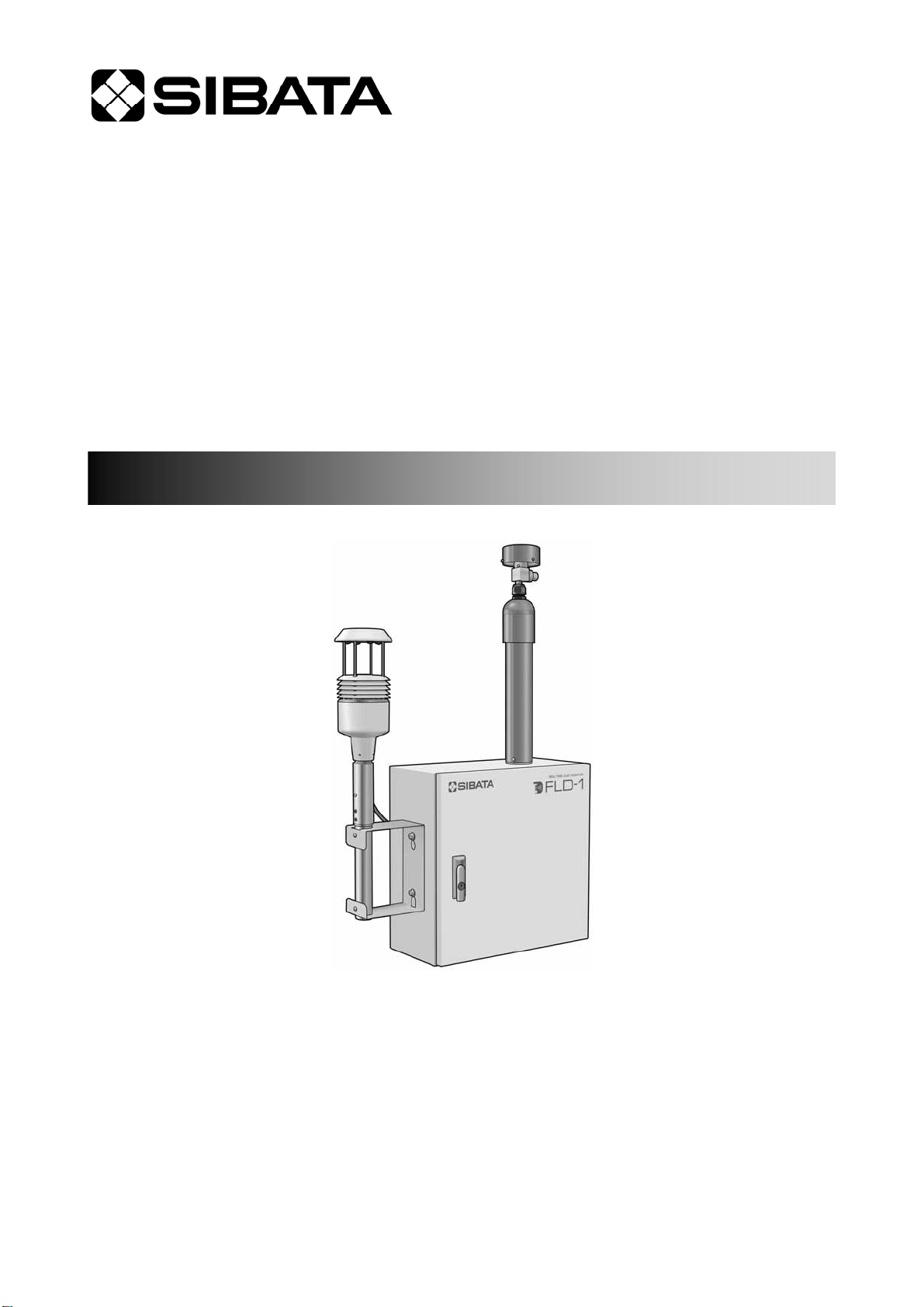

3About This Product................................................................................................. 11

3-1 Overview..........................................................................................................................11

3-2 Names of Parts ................................................................................................................12

3-3 Main Display Screens......................................................................................................16

4Preparation.............................................................................................................. 19

4-1 Installation........................................................................................................................19

4-1-1 Fastening the Instrument to a Single Pipe (Optional).............................................................19

4-1-2 Installing the Instrument on a Stand (Available by special order)...........................................21

4-1-3 Other Installation Methods ......................................................................................................21

4-2 Connecting the AC Power Supply....................................................................................22

4-3 Connecting the Weather Sensor (Optional).....................................................................23

4-4 Installing the PM2.5 Cyclone Selector (Optional)............................................................27

4-5 Connecting an External DC Power Supply (Available by special order).........................28

5Output Functions.................................................................................................... 30

5-1 Analog andAlarm Outputs...............................................................................................30

5-2 RS-485 Outputs ...............................................................................................................31

6Logging Functions.................................................................................................. 32

6-1 Logging Functions............................................................................................................32

6-2 Viewing Log Data.............................................................................................................33

7Alarm Functions...................................................................................................... 34

7-1 Alarm Functions...............................................................................................................34

7-2 Viewing theAlarm Log.....................................................................................................35

7-3 Alarm Types.....................................................................................................................36

8Measuring................................................................................................................ 37

8-1 Before Measuring.............................................................................................................37

8-1-1 Background (BG) Measurement.............................................................................................37

8-1-2 Adjusting the Sensitivity Level.................................................................................................39

8-2 Continuous Measurements..............................................................................................42

8-3 Timed Measurements ......................................................................................................44

8-4 Measuring in Parallel with the Mass Concentration Measurement Method....................50

8-4-1 Installing Filters........................................................................................................................50

8-4-2 Concurrent Measurements......................................................................................................52

8-4-3 Determining the Mass Concentration Conversion Factor.......................................................53

8-5 Optional Display...............................................................................................................54