SICK C 4000 Series User manual

OPERATING INSTRUCTIONS

Safety Light Curtain

C 4000

Operating Instructions

C 4000

2©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

Operating Instructions

C4000

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 3

Operating Instructions

C 4000

List of contents

4©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

List of contents

1 About this document .................................................................................................................. 6

1.1 Function of this document ..................................................................................... 6

1.2 Target group ............................................................................................................ 6

1.3 Information depth ................................................................................................... 6

1.4 Abbreviations .......................................................................................................... 7

1.5 Symbols used .......................................................................................................... 7

2 On safety ........................................................................................................................................ 8

2.1 Specialist personnel ............................................................................................... 8

2.2 Range of uses of the device .................................................................................. 8

2.3 Proper use ............................................................................................................... 8

2.4 General protective notes and protective measures ............................................ 9

2.5 Protection of the environment ............................................................................... 9

3 Product description .................................................................................................................. 10

3.1 Special features .................................................................................................... 10

3.2 Mode of function of the device ............................................................................ 10

3.2.1 Components of the device ...................................................................... 10

3.2.2 The light curtain principle ........................................................................ 11

3.2.3 Cascading ................................................................................................. 11

3.3 Examples of range of use .................................................................................... 12

3.4 Configurable functions ......................................................................................... 12

3.4.1 Restart interlock ....................................................................................... 13

3.4.2 External device monitoring (EDM) .......................................................... 14

3.4.3 Beam coding ............................................................................................ 14

3.4.4 Scanning range ........................................................................................ 15

3.4.5 Fixed blanking .......................................................................................... 16

3.4.6 Floating blanking ...................................................................................... 17

3.4.7 Reduced resolution .................................................................................. 19

3.5 Indicator elements ............................................................................................... 20

3.5.1 Operation status indicators of the sender ............................................. 20

3.5.2 Indicator elements of the receiver .......................................................... 21

4 Installation and mounting ....................................................................................................... 22

4.1 Determining the safety distance ......................................................................... 22

4.1.1 Safety distance from the hazardous area .............................................. 22

4.1.2 Minimum distance from reflecting surfaces .......................................... 24

4.2 Steps for mounting the device ............................................................................ 25

4.2.1 Mounting with swivel mount bracket ...................................................... 26

4.2.2 Mounting with side bracket ..................................................................... 28

5 Electrical installation ................................................................................................................ 30

5.1 System connection M26×11 + FE ...................................................................... 30

5.2 Configuration connection

M8×4 (serial interface) ........................................................................................ 31

5.3 Extension connection M26×11 + FE .................................................................. 32

5.4 External Device Monitoring (EDM) ....................................................................... 33

5.5 Reset button/restart button ................................................................................ 34

Operating Instructions

C4000

List of contents

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 5

6 Commissioning ........................................................................................................................... 35

6.1 Display sequence during power-up ..................................................................... 35

6.2 Aligning sender and receiver ............................................................................... 35

6.3 Test notes ............................................................................................................. 36

6.3.1 Tests before the first commissioning ..................................................... 36

6.3.2 Regular inspection of the protective device by qualified personnel .... 36

6.3.3 Daily function checks of the protective device ..................................... 37

7 Configuration .............................................................................................................................. 38

7.1 Delivery status ...................................................................................................... 38

7.2 Preparing the configuration ................................................................................ 38

8 Care and maintenance ............................................................................................................. 39

9 Fault diagnosis ........................................................................................................................... 40

9.1 What to do in case of faults ................................................................................ 40

9.2 SICK Support ........................................................................................................ 40

9.3 Error displays of the LEDs ................................................................................... 40

9.4 Error displays of the 7-segment display ............................................................. 41

9.5 Extended diagnosis .............................................................................................. 42

10 Technical specifications ......................................................................................................... 43

10.1 Data sheet ............................................................................................................ 43

10.2 Response time ..................................................................................................... 45

10.3 Table of weights ................................................................................................... 47

10.4 Dimensional drawings ......................................................................................... 48

10.4.1 Standard system (not cascadable) ........................................................ 48

10.4.2 Cascadable system ................................................................................. 49

10.4.3 Swivel mount bracket .............................................................................. 50

10.4.4 Side mounting .......................................................................................... 50

10.4.5 Deflector mirror ....................................................................................... 51

11 Ordering information ................................................................................................................. 52

11.1 Delivery ................................................................................................................. 52

11.2 Standard system .................................................................................................. 53

11.2.1 Standard system without function package .......................................... 53

11.2.2 Standard system with function package B ............................................ 54

11.3 Cascadable system .............................................................................................. 55

11.3.1 Cascadable system without function package ...................................... 55

11.3.2 Cascadable system with function package B ........................................ 56

11.4 Additional front screen (welding spark guard) ................................................... 56

11.5 Deflector mirror .................................................................................................... 57

11.5.1 Deflector mirror PNS 80 for protective field width 0 … 4 m (total) ...... 57

11.5.2 Deflector mirror PNS 120 for protective field width 4 … 15 m (total) . 57

11.6 Accessories .......................................................................................................... 58

12 Annex ............................................................................................................................................ 59

12.1 Declaration of conformity .................................................................................... 59

12.2 Checklist for the manufacturer ........................................................................... 60

12.3 List of tables ......................................................................................................... 61

12.4 List of illustrations ............................................................................................... 62

Operating Instructions Chapter 1

C 4000

6©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

About this document

1About this document

Please read this chapter carefully before working with this documentation and the C 4000.

1.1 Function of this document

These operating instructions are designed to address the technical personnel of the

machine manufacturer or the machine operator in regards to safe mounting, installation,

parameterisation, electrical installation, commissioning, operation and maintenance of the

Safety Light Curtain C 4000.

These operating instructions do not provide instructions for operating machines in which

the safety light curtain is, or will be, integrated. Information on these items is found in the

appropriate operating instructions of the machine.

1.2 Target group

These operating instructions addresses planning engineers, developers and the operators

of plants and systems which are to be secured by one or several safety light curtains

C 4000. It also addresses persons who integrate the C 4000 into a machine, initialize its

use, or who are in charge of servicing and maintaining the unit.

1.3 Information depth

These operating instructions contain information on:

of the safety light curtain C 4000.

Planning and using safety devices such as the C 4000 also require specific technical skills

which are not conveyed in this documentation.

When operating the C 4000, the national, local and statutory rules and regulations must

be observed.

General information on health and safety at work and accident prevention using opto-elec-

tronic safety devices is found in the brochure “Safe machinery with opto-electronic protec-

tion”.

Note We also refer you to the C 4000 homepage in the Internet at

www.c4000.com

Here you will find information on:

·Sample applications

·A list of frequently asked questions on the C 4000

·These operating instructions in different languages for viewing and printing

·Installation and mounting

·Electrical installation

·Commissioning and parameterisation

·Care and maintenance

·Fault and error diagnosis and

troubleshooting

·Part numbers

·Conformity and approval

Operating Instructions Chapter 1

C4000

About this document

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 7

1.4 Abbreviations

ESPE Electro-sensitive protective equipment (e.g. C 4000)

CDS SICK Configuration & Diagnostic Software = software for the configuration of your safety

light curtain C 4000

EDM External device monitoring

OSSD Output signal switching device

1.5 Symbols used

Recommendation Recommendations are designed to give you some assistance in your decision-making proc-

ess with respect to a certain function or a technical measure.

Note Refer to notes for special features of the device.

lL@! Display indicators show the status of the 7-segment display of sender or receiver:

fConstant display of the letter F

FFlashing display of the letter F

f@2 Alternating display of F and 2

{[]}LED symbols denote a flashing LED (upright orientation, 7-segment display, bottom)

>Take action … Instructions for taking action are shown by an arrow. Carefully read and follow the instruc-

tions for action.

WARNING

Warning notice!

A warning notice indicates an actual or potential risk or health hazard. They are designed

to help you to prevent accidents.

Carefully read and follow the warning notices!

nSoftware notes show the location in the CDS (Configuration & Diagnosis Software) where

you can make the appropriate settings and adjustments. Go to the menu View,Dialogue

windows of the CDS and activate the item File Cards to view the named dialogue fields as

needed. Alternatively, the Software Assistant will guide you through the appropriate setting.

IHSender and receiver

In drawings and diagrams, the symbol sdenotes the sender and the symbol rdenotes

the receiver.

The term “dangerous state”

The dangerous state (standard term) of the machine is always shown in the drawings and

diagrams of this document as a movement of a machine part. In practical operation, there

may be a number of different dangerous states:

·Machine movements

·Electrical current carrying parts

·Visible or invisible radiation

·A combination of several risks and hazards

Operating Instructions Chapter 2

C 4000

8©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

On safety

2On safety

This chapter deals with your own safety and the safety of the equipment operators.

>Please read this chapter carefully before working with the C 4000 or with the machine

protected by the C 4000.

2.1 Specialist personnel

The safety light curtain C 4000 must be installed, commissioned and serviced only by spe-

cialist personnel. Specialist personnel is defined as persons who

·have undergone the appropriate technical training

and

·who have been instructed by the responsible machine operator in the operation of the

machine and the currently valid safety guidelines

and

·who have access to these operating instructions

2.2 Range of uses of the device

The safety light curtain C 4000 is an electro-sensitive protective equipment (ESPE). The

physical resolution is 14, 20, 30 or 40 mm with a maximum protective field width of 19 me-

ters (resolution 20 mm and higher). The realisable protective field height is between 300

and 1,800 mm.

The device is a Type 4 ESPE as defined by IEC 61496-1 and -2 and is therefore allowed for

use with controls in safety category 4 in compliance with EN 954. The device is suitable for

·Hazardous point protection (finger and hand protection)

·Hazardous area protection

·Access protection

Access to the hazardous area must be allowed only through the protective field. The plant/

system is not allowed to start as long as personnel are within the hazardous area. Refer to

chapter 3.3 “Examples of range of use” on page 12 for an illustration of the protection

modes.

Depending on the application, mechanical protection devices may be required in addition

to the safety light curtain.

Note The safety light curtain C 4000 operates as standalone system, comprising a sender and

receiver, or in combination with other cascadable C 4000 systems. This means that the

protective field can be adapted to suit individual safety requirements.

2.3 Proper use

The safety light curtain C 4000 must be used only as defined in the chapter 2.2 “Range of

uses of the device”. It must be used only by qualified personnel and only on the machine

where it has been installed and initialized by qualified personnel.

If the device is used for any other purposes or modified in any way – also during mounting

and installation – any warranty claim against SICK AG shall become void.

Operating Instructions Chapter 2

C4000

On safety

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 9

2.4 General protective notes and protective measures

WARNING

Safety notes

Please observe the following items in order to ensure the proper and safe use of the safety

light curtain C 4000.

·The national/international rules and regulations apply to the installation, use and recur-

ring technical inspections of the safety light curtain, in particular:

– Machine Directive 98/37 EG

– Equipment Usage Directive 89/655 EWG

– the work safety regulations/safety rules

– other relevant health and safety regulations

Manufacturers and users of the machine by which the safety light curtain is used are re-

sponsible for obtaining and observing all applicable safety regulations and rules.

·The notices, in particular the test regulations (see “Test notes” on page 36) of these op-

erating instructions (e.g. on use, mounting, installation or integration into the existing ma-

chine controller) must be observed.

·The tests must be carried out by specialist personnel or specially qualified and authorized

personnel and must be recorded and documented to ensure that the tests can be recon-

structed and retraced at any time.

·The operating instructions must be made available to the user of the machine where the

safety light curtain C 4000 is fitted. The machine operator is to be instructed in the use

of the device by specialist personnel and must be instructed to read the operating in-

structions.

·The external voltage supply of the device must be capable of buffering brief mains fail-

ures of 20 ms as specified in EN 60204. Suitable power supplies are available as acces-

sories from SICK (Siemens type series 6 EP 1).

2.5 Protection of the environment

The safety light curtain C 4000 has been designed to minimize environmental impact. It

uses only a minimum of power and natural resources.

At work, always act in an environmentally responsible manner. For this reason please note

the following information on disposal.

Disposal

>Always dispose of unserviceable or irreparable units in compliance with local/national

rules and regulations with respect to waste disposal.

>Remove the plastic panel and dispose of the aluminium housing of the light curtain as

recyclable waste.

>Dispose all electronic assemblies as special or hazardous waste. The electronic assem-

blies are easy to dismantle.

Note SICK AG will not accept unserviceable or irreparable units returned to the company.

Operating Instructions Chapter 3

C 4000

10 ©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

Product description

3Product description

This chapter provides information on the special feature and properties of the safety light

curtain C 4000. It describes the structure and the mode of function of the unit, in particular

the different operating modes.

>Please read this chapter before mounting, installing and commissioning the unit.

3.1 Special features

·Protective operation, optionally with internal or external machine-integrated restart

interlock

·Connecting options for the reset button

·External device monitoring (EDM)

·Beam coding

·Status display with 7-segment display

·Optional: Function package B

–Blankingseveralareas

– Blanking with tolerance of up to 2 beams

– Floating blanking

– Reduced resolution

– Monitoring the blanked area

3.2 Mode of function of the device

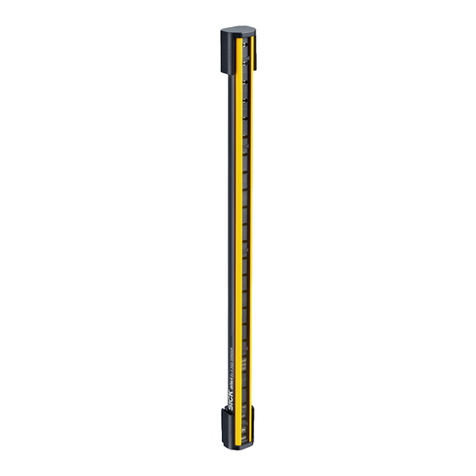

3.2.1 Components of the device

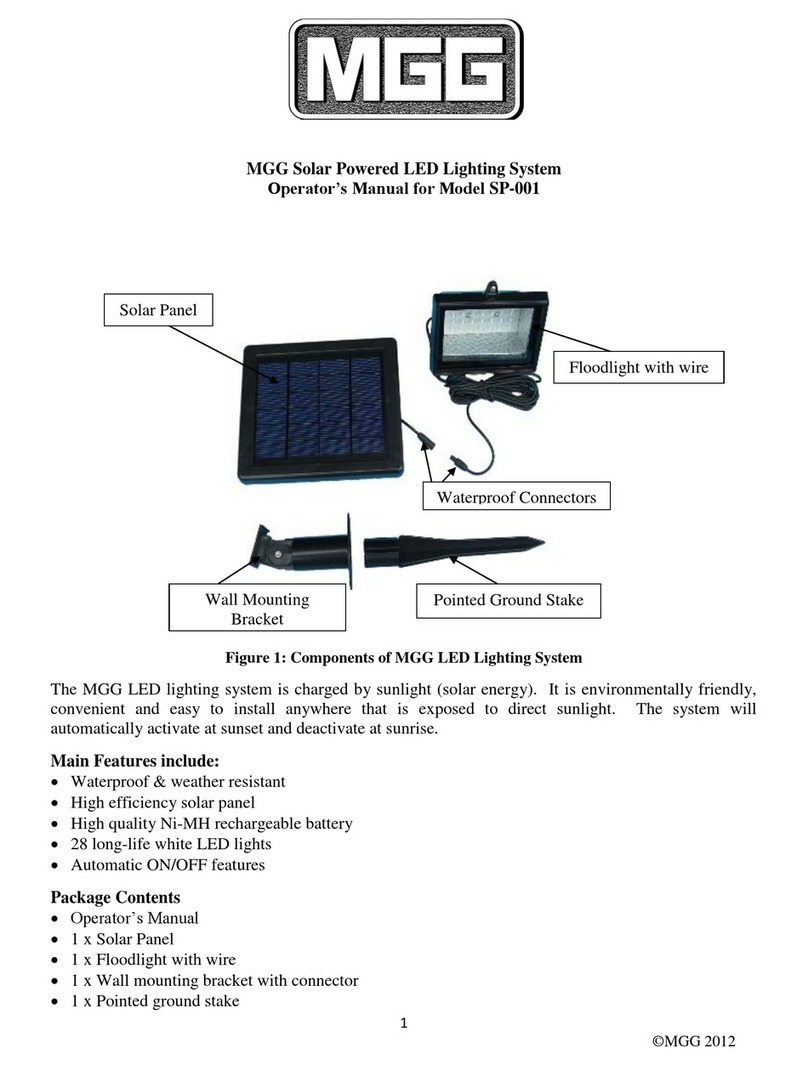

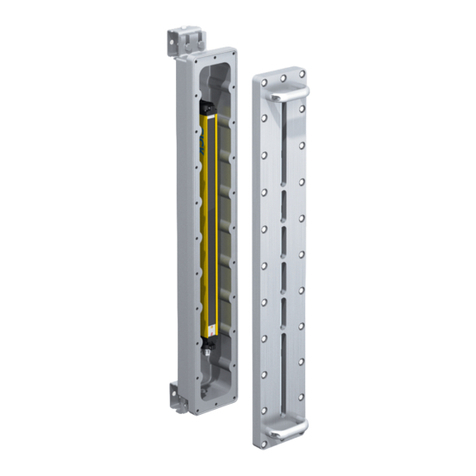

Fig. 1: Components

of the C 4000

Please refer to chapter 10 “Technical specifications” on page 43 for the data sheet.

Please refer to pages 48 ff. for the dimensional drawings.

Host (standard system, or

–with Guest 1 connected–

cascadable system)

Optional: 1. Guest system

(standard system, or

–with Guest 2 connected–

cascadable system)

Optional: 2. Guest system

(standard system)

Operating Instructions Chapter 3

C4000

Product description

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 11

3.2.2 The light curtain principle

The safety light curtain C 4000 consists of a sender and a receiver (figure 1). Between

these two units is the protective field, defined as the protective field height and the protec-

tive field width.

The construction size height determines the height of the protective field of the appropriate

system. The upper and lower limit of the protective field is shown by markings on the profile

sections.

The width of the protective field is derived from the length of the light path between sender

and receiver and must not exceed the maximum rated width of the protective field (see

“Technical specifications” on page 43).

Sender and receiver automatically synchronize themselves optically. An electrical connec-

tion between both these components is not required.

The C 4000 is modular in structure. All optical and electronic components and assemblies

are housed in a slim and torsionally rigid housing.

3.2.3 Cascading

To provide an effective point-of-operation guard, a maximum of three C 4000 can be con-

nected in series for cascading configuration. The device connected to the control cabinet

is the main sensor, called Host. The subsequent sensors are called Guests (cf. figure 1 on

page 10).

Benefits of cascading

·No additional external circuitry required

·Resolution and protective field height may differ among the individual systems

Limits of cascading

·The maximum protective field width must be guaranteed for each individual system!

·The maximum total number of beams must be 480 beams in non-coded operation,

and a maximum of 405 beams in coded operation.

·The maximum cable length between two cascaded systems must not exceed 3 meters.

Operating Instructions Chapter 3

C 4000

12 ©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

Product description

3.3 Examples of range of use

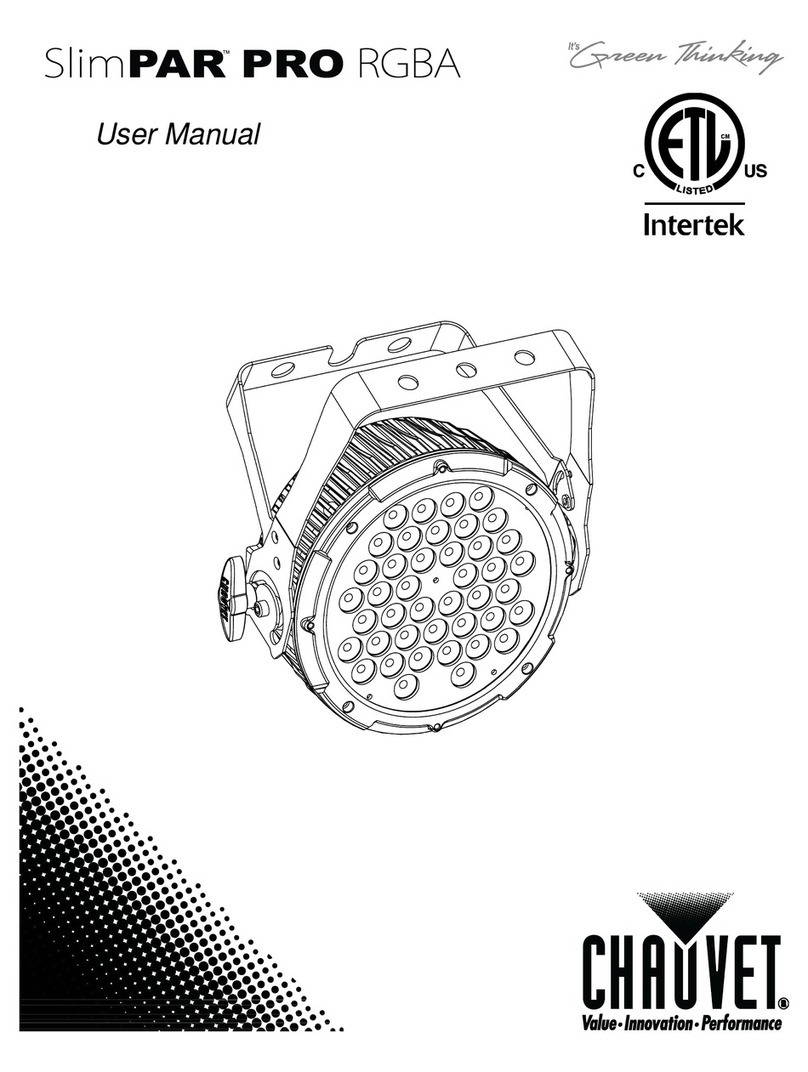

Fig. 4: Access guarding using a

safety light curtain C 4000

The safety light curtain C 4000 operates as a proper protective device only if the following

conditions are met:

·The control of the machine must be electrical.

·The dangerous state of the machine must be transferable at any time into a safe state.

·Sender and receiver unit must be so mounted that objects penetrating the hazardous

area are safely identified by the C 4000.

·The restart button must be fitted outside the hazardous area such that it cannot be

operated by a person working inside the hazardous area.

·The statutory and local rules and regulations must be observed when installing and using

the device.

3.4 Configurable functions

This chapter describes the functions of the safety light curtain C 4000 selectable via soft-

ware. Some of the functions can be combined.

WARNING

Test the protective device after any changes!

The entire protective device must be tested for proper operation after each change of the

configuration (see 6.3 on page 36).

nWhen starting to configure the device, you may save an application name with a maximum

of 22 characters. Use this function as a “memory jogger”, e.g. to describe the application

of the current device configuration.

Fig. 2 (left): Securing danger-

ous points with a safety light

curtain C 4000

Fig. 3 (right): Securing danger-

ous areas with a safety light

curtain C 4000

Operating Instructions Chapter 3

C4000

Product description

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 13

3.4.1 Restart interlock

Fig. 5: Outline drawing of the

protective operation

The dangerous state of the machine () is interrupted if the light curtain () is disrupted

and will not be reinstated () until the user actuates the restart button.

The restart interlock can be implemented in two different ways:

·With the internal restart interlock of the C 4000:

The C 4000 controls the restart.

·With the restart interlock of the machine:

The C 4000 has no control over the restart.

The possible combinations are shown in the following table:

WARNING

Always configure the C 4000 with restart interlock!

The C 4000 is unable to verify if the restart interlock of the machine is connected. If you

deactivate both the C 4000 and the machine-internal restart interlock, the users and oper-

ators of the machine will be at an acute risk of injury.

The electrical connection of the restart button is described in the chapter “Reset button/

restart button” on page 34.

nDevice symbol C 4000 receiver, context menu Configuration draft, Edit, file card General,

option Restart interlock.

Reset

If you activate both the C 4000 and the machine-internal restart interlock, each restart

interlock will have its own button designated to it.

When actuating the button for the internal restart interlock

·the C 4000 will reset its switch outputs

·the light curtain changes to green

Restart interlock of

the C 4000

Restart interlock of

the machine

Permissible application

deactivated deactivated Only if the light curtain cannot be stood

behind. Observe EN 60204-1!

deactivated activated All

activated deactivated Only if the light curtain cannot be stood

behind. Observe EN 60204-1!

activated activated All. Restart interlock of the C 4000 handles

the reset function (see below).

T

a

b

.

1

:

P

erm

i

ss

ibl

e

configuration of the restart

interlock

Operating Instructions Chapter 3

C 4000

14 ©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

Product description

The machine-internal restart interlock prevents the machine from restarting. This is why the

button of the internal restart interlock only fulfills the reset function in this configuration

and is called Reset Button.

After activating the reset button, the user must also press the restart button. If the reset

button and the restart button are not pressed in this specified sequence, the dangerous

status remains unchanged.

Recommendation The reset button prevents the accidental and inadvertent operation of the restart button.

The user must first acknowledge the dangerous state with the reset button.

The electrical connection of the reset button is described in chapter “Reset button/restart

button” on page 34.

3.4.2 External device monitoring (EDM)

The EDM function controls the contact elements (if used) activated by both of the device out-

puts (e.g. external contacts). The machine must be allowed to restart only if both contactors

have been opened.

The C 4000 controls the contactors after every disruption of the light path and before the

machine restart. The EDM can so identify if one of the contactors has fused, for instance.

In this case

·the error message appears 8(in the 7-segment display)

·the safety light curtain changes to red

·with the internal restart interlock activated, the safety light curtain signals by flashing yel-

low LED [“Reset required”

Note If the system is unable to change to a safe operational state (e.g. after contactor failure),

the system interlocks and shuts down completely (“Lock-out”). The 7-segment display will

then show the error message (.

The electrical connection of the EDM is described in chapter “System connection

M26×11 + FE” on page 30.

nDevice symbol C 4000 receiver, context menu Configuration draft, Edit, file card General,

option EMD

3.4.3 Beam coding

If several safety light curtains operate in close proximity to each other, the sender beams

of one system may interfere with the receiver of the other system. With code 1 or 2

activated, the receiver distinguishes the beams destined for it from other beams. The fol-

lowing settings are available: non-coded, code 1 and code 2.

WARNING

Use different beam codings if the systems are located close to each other!

Systems mounted in close proximity to each other must be operated with different beam

codings (non-coded, code 1 or code 2). If this precaution is neglected, the system may be

impaired in its protective function by the beams from the neighbouring system and so

change to the unsafe state. This would mean that the user/operator is at risk.

Operating Instructions Chapter 3

C4000

Product description

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 15

Fig. 6: Schematic layout of the

beam coding

Notes ·Beam coding increases the availability of the protected machine. Beam coding also en-

hances the resistance to optical interference such as welding sparks and similar.

·In a cascaded system, host and guest can be operated only with the same beam coding.

·Beam coding will increase the response time of the system. This may also change the re-

quired safety distance. For details refer to chapter 4.1 “Determining the safety distance”

on page 22.

·After activating the system, sender and receiver will briefly display the coding.

·If operated with beam coding, the number of beams in cascaded systems must not ex-

ceed 405 beams.

nDevice symbol C 4000 receiver or sender, context menu Configuration draft, Edit, file card

General, option Beam coding.

3.4.4 Scanning range

WARNING

aMatch the scanning range with the protective field width!

The scanning range of the system (host, guest 1 and guest 2) must be adapted to the width

of the protective field.

·If the scanning range is too small, the light curtain will not change to green.

·If the scanning range is too great, the light curtain may malfunction. This would mean that

the user/operator is at risk.

Note If you are using the additional front screen (see page 56) available as an accessory, the

useful scanning range will be reduced by 8% for each additional front screen.

The available settings depend on the physical resolution of the system:

nDevice symbol C 4000 receiver or sender, context menu Configuration draft, Edit, file card

General, option Scanning range.

Code 1

Code 2

Physical resolution Selectable

scanning ranges

Scanning range with

1 additional front

screen

Scanning range with

2 additional front

screens

14 mm 0-2.5 m

2-6 m

0-2.3 m

1.8-5.5 m

0-2.1 m

1.7-5 m

20 mm, 30 mm,

40 mm

0-6 m

2.5-19 m

0-5.5 m

2.3-17.4 m

0-5 m

2.1-16 m

T

a

b

.

2

:

Ph

ys

i

ca

l

reso

l

ut

i

on an

d

s

canning range

Operating Instructions Chapter 3

C 4000

16 ©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

Product description

3.4.5 Fixed blanking

Fig. 7: Schematic layout

of the fixed blanking

The light curtain C 4000 is capable of fixed-blanking one or several adjacent beams, e.g. to

allow continued operation in spite of an obstruction such as a table placed permanently in

the light path.

The blanked area will no longer be part of the protective field. Blanked objects must there-

fore be permanently located inside the blanked area (). As soon as the object is removed

from the beam path, the light curtain will send a signal to disrupt the dangerous movement

(). Protection is otherwise no longer guaranteed.

WARNING

Completely protect the blanked area!

The object must cover the entire distance between sender and receiver.

>If necessary, protect the areas to the left and right of the object against intrusion by fit-

ting mechanical barriers!

Fig. 8: Protecting a fixed blank-

ing using mechanical barriers

>Also, make sure that the object can only me removed as a whole together with the bar-

riers.

>After adapting the blanking, check the protective field with the test rod. Instructions are

found in chapter 6.3.3 on page 37.

Blanked area, sides protected by

mechanical barriers

Operating Instructions Chapter 3

C4000

Product description

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 17

Properties of fixed blanking

·The C 4000 is capable of blanking a total of four areas simultaneously. A minimum of one

beam spacing must exist between two blanked areas.

·The first beam of the light curtain (close to the 7-segment display) must not be blanked.

It is needed for the synchronisation between sender and receiver.

·For vibrating objects, you can select a position tolerance of the area of a maximum of

±2 beams.

·In addition, you can define a size tolerance of –1 beam.

Notes ·If you configure a blanked area without position and without size tolerance, the move-

ment of the object within the area is very limited before the light curtain changes to red.

·The maximum selectable tolerance values depend on the size of the blanked area: The

actual tolerance expansion in millimetres differs. It depends on the physical resolution of

the device.

·With fixed blanking, the 7-segment display indicates ras soon as sender and receiver

are aligned.

nDevice symbol C 4000 receiver, context menu Configuration draft, Edit, file card Blanking

of the appropriate system, Type of blanking = fixed. With the help of selection fields, the

size of the area and the tolerance values (in millimetres) for size and position can be

selected.

3.4.6 Floating blanking

Fig. 9: Schematic layout

of the floating blanking

The light curtain C 4000 is capable of blanking an area of two or more adjacent beams ().

In contrast to fixed blanking, the blanked area is allowed to move () without the light cur-

tain changing to red.

The blanked area will no longer be part of the protective field. Moving objects must there-

fore be permanently within the protective field (and ). As soon as the object is removed

from the protective field, the light curtain will send a signal to disrupt the dangerous move-

ment (). Protection is otherwise no longer guaranteed.

Properties of floating blanking

·The C 4000 is capable of blanking a total of four areas simultaneously.

·Fixed and floating blanking can be mixed.

·The size of the movable area must be at least equal to the effective resolution (see page

19 if you use reduced resolution).

·Areas of floating blanking must not be allowed to make contact or overlap during opera-

tion. The CDS (Configuration & Diagnostic Software) will check this automatically.

Operating Instructions Chapter 3

C 4000

18 ©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

Product description

·The first beam of the light curtain (close to the 7-segment display) cannot be blanked. It

is needed for the synchronisation between sender and receiver.

·Size tolerances of 1 or 2 beams may be selected for moving areas. In case of 2 beams

(increased size tolerance), the effective resolution at the edges of the moving area will be

reduced! For this reason the moving area must always be greater than the effective res-

olution at the edges of the area (see table 3).

·The size tolerance of 2 beams can be used only in devices with a physical resolution of

14 mm and 20 mm.

WARNING

Check the safety distance S!

In case of floating blanking and increased size tolerance (2 beams), the required safety dis-

tance S will depend on the effective resolution.

>If required, recalculate the safety distance and readjust it on the machine.

Example: – Physical resolution 14 mm

– Increased size tolerance (2 beams)

– Effective resolution 22 mm

Calculate the safety distance with a resolution of 22 mm.

>Mark the effective resolution on the notice label of sender and receiver.

Fig. 10: Marking the effective

resolution on the device label

Note With floating blanking, the 7-segment display indicates ras soon as sender and receiver

are aligned.

nDevice symbol C 4000 receiver, context menu Configuration draft, Edit, file card Blanking

of the appropriate system Type of blanking = floating. With the help of the selection fields,

the size of the area can be selected (in millimetres).

Physical resolution Size

tolerance

Effective resolution at the edges

of the area with floating blanking

14 mm 1 beam 14 mm

2 beams 22 mm

20 mm 1 beam 20 mm

2 beams 30 mm

30 mm 1 beam 30 mm

2 beams Not possible

40 mm 1 beam 40 mm

2 beams Not possible

T

a

b

.

3

:

Eff

ect

i

ve reso

l

ut

i

on

i

n

floating blanking with size

tolerance

Operating Instructions Chapter 3

C4000

Product description

8 009 221/16-11-00 ©SICK AG • Safety Systems • Germany • All rights reserved 19

3.4.7 Reduced resolution

Under reduced resolution, the light curtain allows the disruption of 1, 2 or 3 adjacent

beams. Objects which are not larger then specified in table table 4 may be moved through

the light curtain without the light curtain changing to red (Fig. 11, and ).

Fig. 11: Schematic outline of

the operation with reduced res-

olution (example: reduction by

one beam)

Notes ·The function Reduced Resolution can be used only in devices with a physical resolution

of 14 mm and 20 mm.

·The first beam of the light curtain (close to the 7-segment display) must not be interrupt-

ed. Otherwise, the safety light curtain will change to red.

·The system response time does not change under reduced resolution.

·With reduced resolution, the 7-segment display indicates ras soon as sender and re-

ceiver are aligned.

WARNING

Check the safety distance S!

The safety distance S required under reduced resolution depends on the effective resolu-

tion.

>If required, recalculate the safety distance and readjust it on the machine.

Example: – Physical resolution 14 mm

– Resolution reduced by 1 beam

– Effective resolution 22 mm

Calculate the safety distance with a resolution of 22 mm.

>Mark the effective resolution on the notice label of sender and receiver.

Fig. 12: Marking the effective

resolution on the device label

Physical resolution Reduction Effective resolution Maximum size of

movable objects

14 mm 1 beam 22 mm 10 mm

2 beams 30 mm 18 mm

3 beams 37 mm 25 mm

20 mm 1 beam 30 mm 14 mm

2 beams 40 mm 24 mm

3 beams Not possible —

SS

T

a

b

.

4

:

Eff

ect

i

ve reso

l

ut

i

on an

d

maximum size of moving

objects under reduced

resolution

Operating Instructions Chapter 3

C 4000

20 ©SICK AG • Safety Systems • Germany • All rights reserved 8 009 221/16-11-00

Product description

3.5 Indicator elements

The LEDs and the 7-segment display of sender and receiver signal the operating status of

the C 4000.

3.5.1 Operation status indicators of the sender

Fig. 13: Indicator elements

of the sender

Display Meaning

[Yellow: Power supply OK

eSystem error. The device is defective. Replace the sender.

oThe device is in the test mode.

uNon-coded operation (only after switching on)

-Operation with code 1 (only after switching on)

,Operation with code 2 (only after switching on)

Other

displays

All other displays are error messages. Please refer to chapter “Fault

diagnosis” on page 40.

Yellow

7-segment display

Tab. 5: Meaning of the

operation indicator elements

of the sender

Table of contents

Other SICK Lighting Equipment manuals

SICK

SICK deTec2 Core User manual

SICK

SICK deTec4 Core User manual

SICK

SICK deTec4 Core User manual

SICK

SICK C4000 Advanced Ex User manual

SICK

SICK C4000 Select User manual

SICK

SICK C4-RD User manual

SICK

SICK C4-RD User manual

SICK

SICK deTec4 Core User manual

SICK

SICK deTem4 Core Ex User manual

SICK

SICK C 4000 User manual