sieger Drain-Jet S User manual

READ THIS MANUAL BEFORE USING THIS MACHINE

EN

Sieger Drain-Jet S

Sieger Drain-Jet HS

Sieger Drain-Jet WR

www.sieger-machinery.com

USER MANUAL

2112202RE101_A_M

EN

Sieger

Handelsstraat 36 b

7482GW Haaksbergen

The Netherlands

(+31 (0)53 – 303 12 65

@ info@sieger-machinery.com

ü www.sieger-machinery.com

Copyright ©

All rights reserved. No part of this publication may be duplicated, stored in an automated retrieval

system, or published in any form or by any means, be it electronic, mechanical, photocopying,

photography, recording or otherwise, without the prior written permission of Sieger.

Changes

This publication is based on the most recent information available at the time of publication.

Because Sieger pursues a policy of continuous product improvement, this publication may be

changed without prior notice.

Liability

This publication has been prepared with the greatest possible care. Nevertheless, it may not

be entirely accurate. Sieger accepts no liability for any errors in this publication or the possible

consequences thereof.

Language

Original manual.

Translation of the original manual.

Sieger is a registered trademark of Modulen & Engineering Menzing B.V. located in Haaksbergen (NL)..

3

112202RE101_A_M

PREFACE

EN

PREFACE

Dear customer, Congratulations on choosing a Sieger Drain-Jet drain cleaner.

Thanks to this quality machine from Sieger, you can look forward to years of low maintenance

drain pipe cleaning. To ensure trouble-free operation the Drain-Jet is standard equipped with four

driven rollers for driving the ushing hose. Moreover, the combination of a powerful high pressure

pump and the standard 500 metre hose provide tremendous cleaning capacity. The hydraulic

arm, which is a standard feature, makes the Drain-Jet drain cleaner ergonomic in use. The simple

control enables you to work safely and eciently.

For your safety it is important that the machine is operated maintained correctly. Read this manual

before using the machine. Follow the instructions to avoid injury and property damage. Do not

hesitate to contact Sieger if you have questions.

4112202RE101_A_M

TABLE OF CONTENTS

EN

1 INTRODUCTION............................................................................................................................................ 5

2 SAFETY............................................................................................................................................................. 9

3 GENERAL DESCRIPTION...........................................................................................................................11

4 COMMISSIONING.......................................................................................................................................13

5 OPERATION ..................................................................................................................................................14

5A Sieger ABS.....................................................................................................................................................24

6 MAINTENANCE ...........................................................................................................................................25

7 TROUBLESHOOTING .................................................................................................................................32

8 ENVIRONMENT ...........................................................................................................................................33

9 DISPOSAL......................................................................................................................................................33

10 TECHNICAL SPECIFICATIONS.................................................................................................................35

11 OPTIONS........................................................................................................................................................37

TABLE OF CONTENTS

5

112202RE101_A_M

1 INTRODUCTION

EN

1 INTRODUCTION

Intended use

The drain cleaner is intended for cleaning drain pipes. Do not use the drain cleaner for any other

purpose.

Intended audience

Only adequately trained people who have read and understood this manual may use and maintain

the drain cleaner.

About this manual

This manual pertains to the operation and maintenance of the Sieger Drain-Jet drain cleaner.

This document is applicable to the following models:

Sieger Drain-Jet S (112202AS600)

Sieger Drain-Jet HS (112202AS700)

Sieger Drain-Jet WR with ABS (112202AS900)

Supplied documentation

The drain cleaner is accompanied by the following documentation:

• User manual

• Manual for the cardan shaft

Availability

The user manual must always be present in the cab. If the manual is lost, you can request a new

copy from Sieger or download it from www.sieger-machinery.com.

Conventions used in this document

• This symbol indicates a summary of information.

1. Preceding numbers indicate the order in which steps must be performed.

[1] Numbers inside square brackets are references to parts in an illustration.

Left, right, front and rear

The designations‘left’, ‘right’, ‘front’, and ‘rear’ are to be interpreted from the perspective of a

person sitting in the driver's seat, facing the forward driving direction.

6112202RE101_A_M

1 INTRODUCTION

EN

Customer service

If you have questions about the Sieger Drain-Jet that are not answered in this user manual, please

do not hesitate to contact Sieger.

For other instructions you can naturally always consult our website

www.sieger-machinery.com.

Warranty

You are, of course, entitled to warranty coverage if a defect develops despite correct operation

and completion of the prescribed maintenance. The warranty does not cover the following:

• Normal wear

• Failure to heed instructions on the drain cleaner

• Ignoring the instructions in this manual

• Inadequate maintenance

• The use of non-OEM parts

• Abnormal external inuences

• A modication not authorized by Sieger

Sieger honours the warranty conditions laid down in the METAALUNIE terms and conditions. A

summary of the Sieger general terms and conditions is available online, on our website.

7

112202RE101_A_M

1 INTRODUCTION

EN

Machine identication

Fill in the identication data for the machine.

These data can be found on the type plate.

The type plate is located on the tube beside the

attachment point of the upper link of the three-

point linkage. Also ll in the delivery date.

Type

Serial no.

Year

Weight kg

Delivery date

You can also register the machine online at www.sieger-machinery.com. By registering your

product, you make it possible for us to optimize your experience. Registration is benecial to you

in a number of ways, one of which is that we will keep you up to date on the latest developments

concerning technical improvements and use of the Drain-Jet drain cleaner. You will also receive

news about the latest developments at Sieger.

8112202RE101_A_M

1 INTRODUCTION

EN

EC declaration of conformity (only valid for Europe)

Manufacturer: Modulen & Engineering Menzing B.V.

Address: Handelsstraat 36b

Postal code: 7482 GW

Product identication:

Description of the product: Drain cleaner

Type or model: Drain-Jet S

Drain-Jet HS

Drain-Jet WR

Serial number: Pxxxxxx/xx

Meets the requirements:

EU Guideline: 2006/42/EC relating to machinery

Haaksbergen, April 2021

E. Jansen

Director

Modulen & Engineering Menzing B.V.

9

112202RE101_A_M

2 SAFETY

EN

2 SAFETY

Introduction

Read this manual before using the machine. Follow the instructions to avoid injury and property

damage. Do not hesitate to contact Sieger if you have questions.

REMAIN ALERT! YOUR SAFETY AND THE SAFETY OF OTHERS DEPENDS ON IT!

Symbols in this manual

The following symbols are used in this manual:

WARNING

Indicates a risky situation which, if not avoided, may result in severe

bodily injury or death.

This symbol indicates additional information and tips. This symbol is

not used to indicate a risky situation.

Indicates a risky situation which, if not avoided, may result in property

damage.

ATTENTION

10 112202RE101_A_M

2 SAFETY

EN

Safety warnings (stickers)

Various symbols can be found on the drain cleaner, the purpose of which is to alert you to a

potentially hazardous situation, remind you to use personal protective equipment or refer you to a

prescribed operation explained in this manual.

Safety glasses sticker

Sticker indicating that safety glasses must be worn.

User manual sticker

Refers to a prescribed operation.

Rotating parts sticker

Warning for mechanical danger/danger of being pulled in by moving parts.

Trapping sticker

Warning for mechanical danger/danger of crushing by moving parts.

11

112202RE101_A_M

3 GENERAL DESCRIPTION

EN

3 GENERAL DESCRIPTION

Introduction

The drain cleaner consists of the following parts:

• Frame

• Cardan shaft

• Hydraulic system

• Reel

• Side arm with hose drive

• Distance indicator

• Guide arm

• Diaphragm pump

• Pressure regulator

• Filters

• Flexible hose section

• Cleaner nozzle

Frame

The frame has attachment points for transport with a forklift. The frame is designed for attachment

to your tractor's three-point linkage.

Cardan shaft

The drain cleaner is delivered complete with a cardan shaft. This may need to be shortened. The

cardan shaft is driven by the tractor PTO shaft.

Hydraulic system

The hydraulic system is connected to the tractor's double-acting valve or a single-acting valve

with pressure-free return. The machine is operated through use of the 4-way valve block. The

wind-out and wind-up speed is controlled by the speed control valve next to the valve block.

Reel

Due to its large diameter the reel can wind up a ushing hose with a maximum length of

500metres. The drain cleaner is equipped standard with a ushing hose of this length.

Side arm with hose drive

The side arm is operated with hydraulic cylinders to position the guide arm in front of the drain

pipe. The hose drive consists of four driven rubber rollers.

Distance indicator

The distance indicator is located behind the drive rollers. The indicator measures the rolled out

hose length and can indicate the location of the blockage.

Guide arm

For road transport the guide arm must be folded in and secured, in accordance with the

instructions in this manual.

12 112202RE101_A_M

3 GENERAL DESCRIPTION

EN

Diaphragm pump

The water pump is a suction diaphragm pump, driven by the tractor PTO. The recommended

pump speed is 350 to 370 rpm. The maximum allowable speed of the pump is 540 rpm.

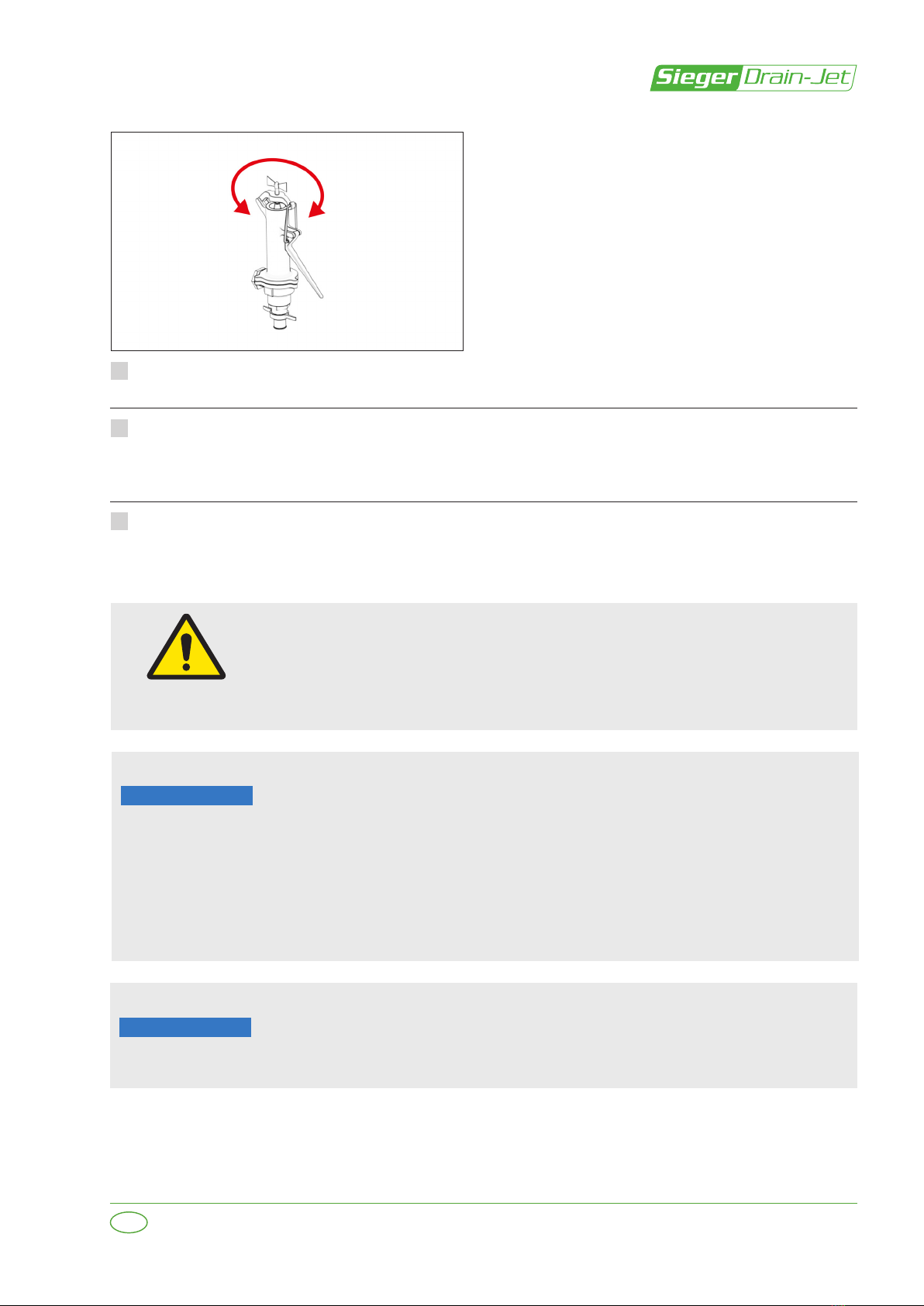

Pressure regulator

You can adjust the water pressure with the pressure regulator. A handle on the pressure regulator

enables you to depressurize the pump, which may be desirable, for example, when positioning

the guide arm in line with the drain pipe. The optimum operating pressure is 30 - 35 bar.

Pump pressure (bar) Cleaner nozzle pressure

(bar)

L/min at 500 metres

20 3.8 45

25 6.1 50

30 6.7 55.5

35 9.9 58.3

40 11 65

50 12.8 68.7

The return hose for the pressure regulator is connected to the top of the guide arm. The water

‘lubricates’and cleans the ushing hose.

Filters

The suction hose is tted with a suction strainer. The suction strainer is located upstream of the

diaphragm pump.

Flexible hose section

The exible hose section between the ushing hose and cleaner nozzle ensures that the cleaner

nozzle remains in the middle of the drain pipe.

Cleaner nozzle

The standard cleaner nozzle has 13 holes: 1 forward-pointing hose and 12 backward-pointing

holes at a 15° angle.

• Before the arm can be retracted, it is necessary to ensure that the

ushing hose is not located in the folding part of the arm.

• Position the drain-shaft arch before the machine is folded in

(otherwise the drain-shaft arch will contact the reel).

ATTENTION

13

112202RE101_A_M

4 COMMISSIONING

EN

4 COMMISSIONING

Introduction

• Check the drain cleaner for possible transport damage at the time of delivery. Report transport

damage to the carrier or Sieger immediately.

Cardan shaft

It may be necessary to shorten the cardan shaft (the inner and outer telescoping shaft sections

and both protective sleeves). See the instructions in the manual supplied with the cardan shaft.

Commissioning after winter storage

• Diaphragm pump: drain the antifreeze (if applicable). Dispose of the antifreeze in accordance

with national regulations.

Do not allow the pump to run longer than two minutes without a supply

of water.

ATTENTION

14 112202RE101_A_M

5 OPERATION

EN

5 OPERATION

Introduction

The chapter provides information about operating the drain cleaner.

There is a danger of crushing and bodily injury in the machine's guide

arm zone. Never stand under the guide arm when it is raised.

Safety

• Never leave the tractor engine running in an enclosed area (not

even if the doors and windows are open) due to the risk of carbon

monoxide poisoning!

• The guide arm must never be used as a hoist.

• Always wear eye protection (safety glasses). Due to the high

pressure, small, hard objects can be ejected at high speed.

• Make the machine roadworthy prior to transport on public roads.

• Check the lighting. Have an assistant help you check the brake lights.

• Adjust the tractor mirrors if necessary.

15

112202RE101_A_M

5 OPERATION

EN

Connecting to the tractor

1. Ensure that the work area is adequately

lighted.

2. Hitch the drain cleaner to the tractor.

3. Disengage the PTO shaft and shut down

the engine on the tractor, and take the

ignition key with you.

4. Fit the cardan shaft (adapted to length if

necessary) to the tractor PTO shaft.

5. Secure the tractor end of the protective

sleeve to the tractor with the attachment

chain to prevent it from rotating with the

shaft.

6. Ensure that the protective sleeve on the

drain cleaner side is secured against

rotation with the other attachment chain.

7. Attach the hydraulic hoses; the connection

for the pump side is marked in red.

8. Connect the 7-pole connector for the brake

lights and direction indicators to the tractor

socket.

9. WR model: connect the plug for the

electrical circuit (black - / white +).

The maximum permissible speed of the tractor PTO shaft is 540 rpm.

Do not exceed this speed.

Do not use the chains to hang up the cardan shaft.

Do not stand on the cardan shaft.

The cardan shaft can become very hot during use. Do not touch the

cardan shaft during or soon after use.

• Rotating parts (cardan shaft).

• Only use the cardan shaft with the protective sleeve and protective

guards in place and in good condition.

• Maintain a safe distance from the rotating cardan shaft.

• Prior to maintenance on the cardan shaft:

• Disengage the PTO shaft and shut down the engine on the tractor.

• Remove the ignition key from the ignition lock cylinder.

ATTENTION

ATTENTION

16 112202RE101_A_M

5 OPERATION

EN

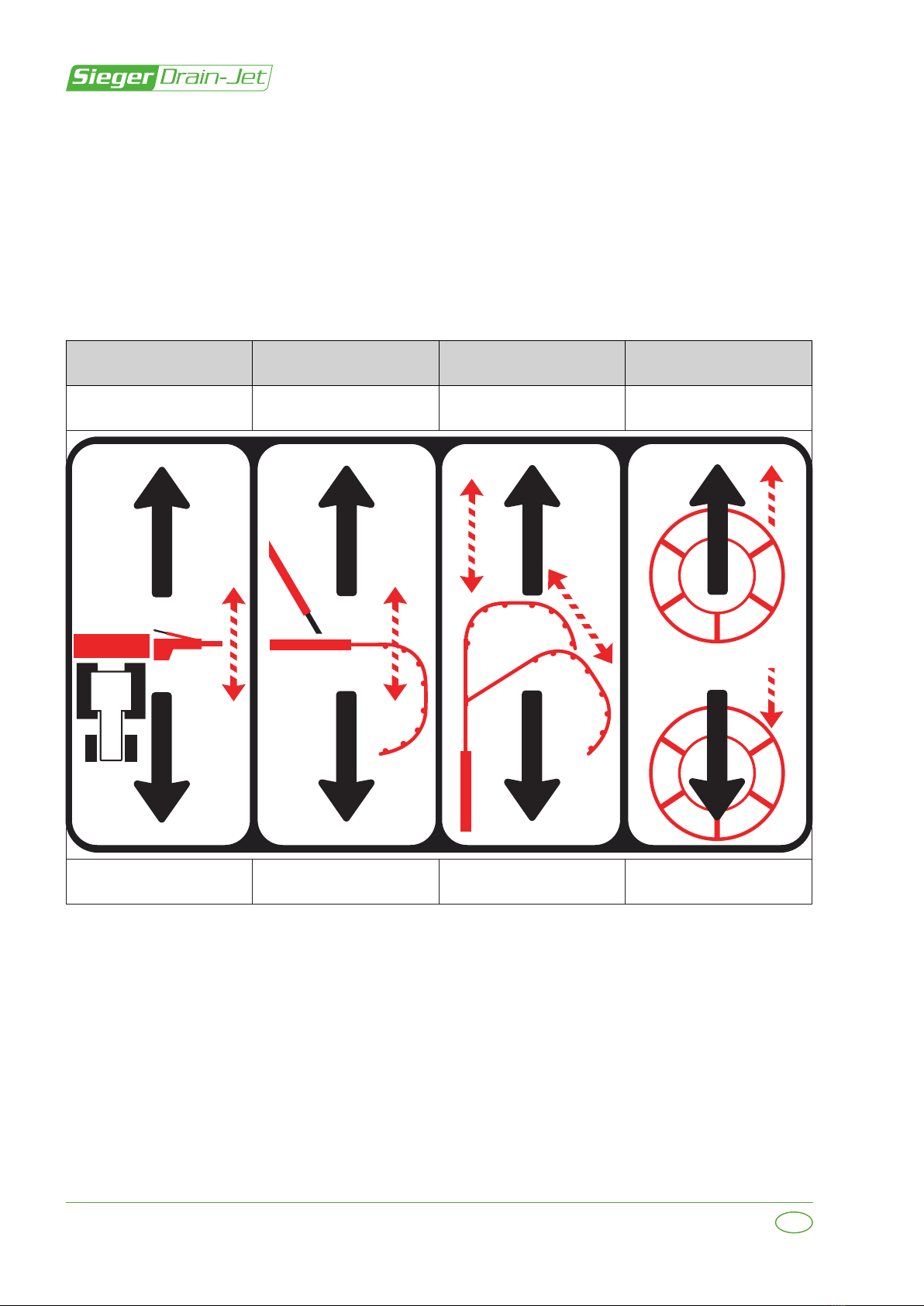

Lever 4

(HS/WR model)

Lever 3 Lever 2 Lever 1

Swing backwards Raise arm Extend arm

Fold arm out

Reel out

Swing forwards Lower arm Retract arm

Fold arm in

Reel in

Hydraulic system operation

The machine is operated through use of the 4-way valve block. The wind-out and wind-up speed

is controlled with the speed control valve next to the valve block.

The sticker on the control panel graphically indicates the various functions of the levers.

Note: Lever 4 is only present on the HS and WR model.

17

112202RE101_A_M

5 OPERATION

EN

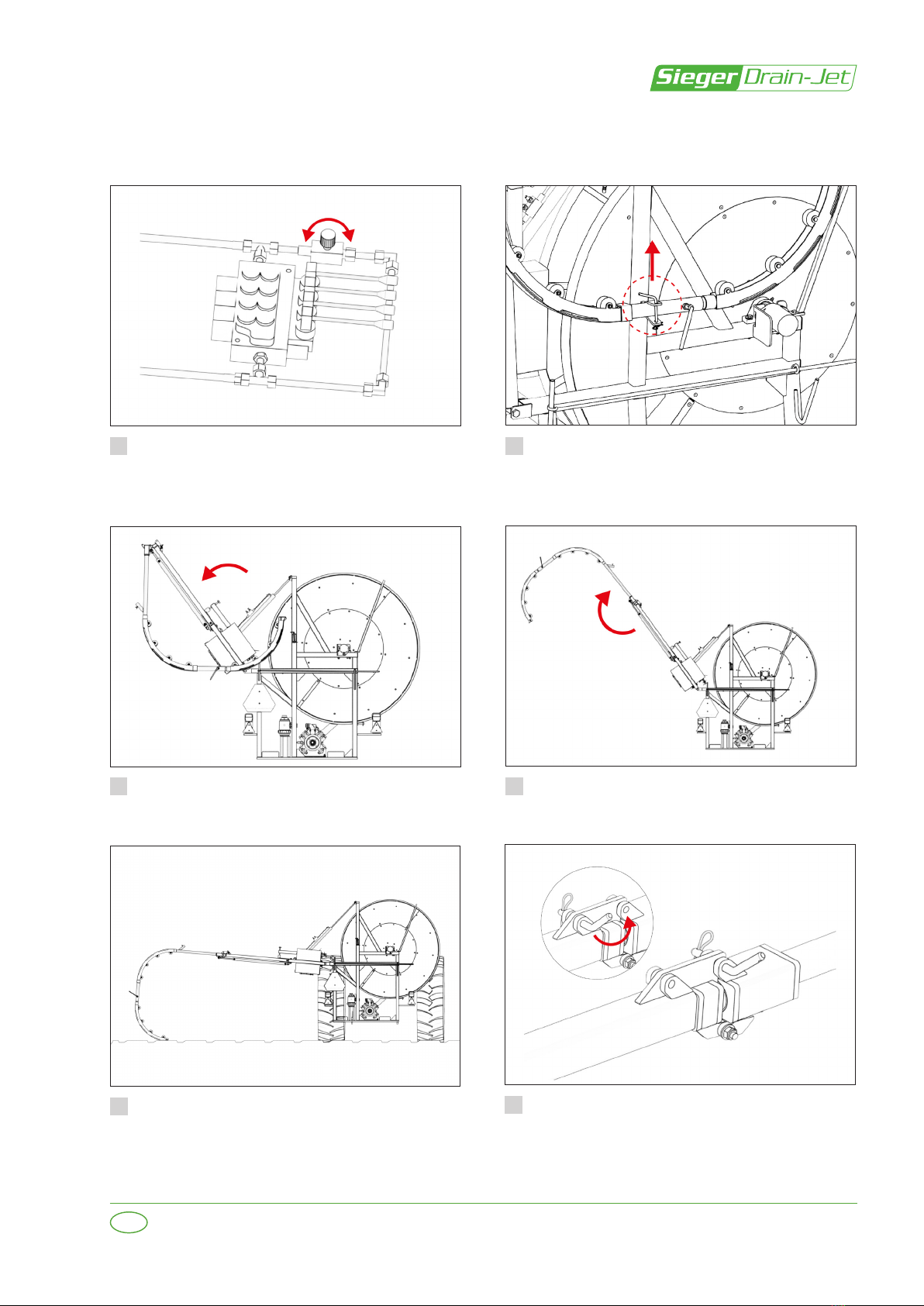

Release the arm from the road transport

retainer.

Lower the arm ±45 degrees (lever 3). Fold out the arm as far as possible

(lever2).

Pressurize the hydraulic system.

The speed can be adjusted with the speed

control valve.

1

3

2

4

Machine operation: winding out (feeding in)

Lower the arm to the ground (lever 3). From transport position to operating

position

If necessary, retract cylinder ±1 cm with

lever 2.

6

5

18 112202RE101_A_M

5 OPERATION

EN

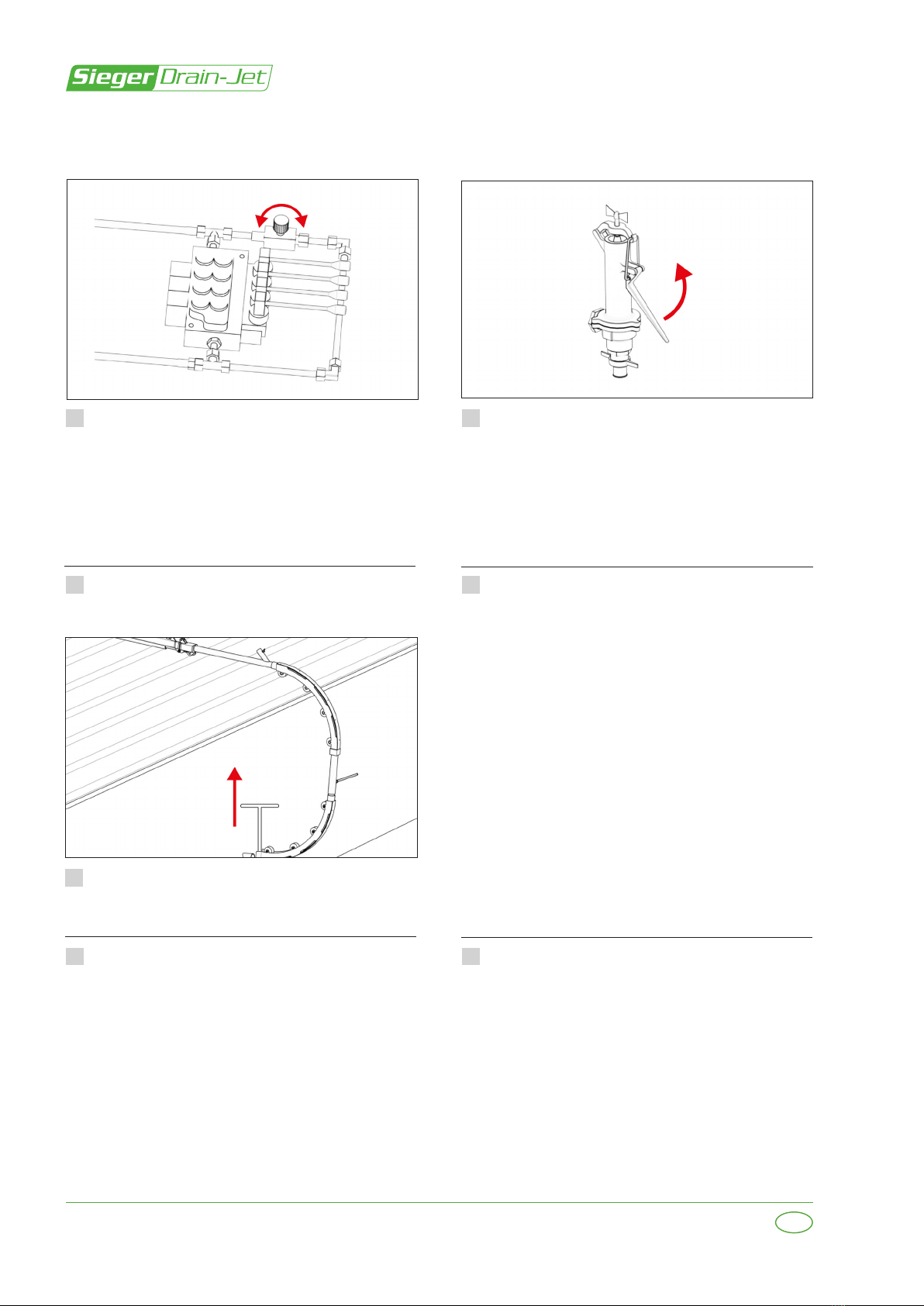

Drive the tractor to the ditch or pit.

Position the drain-shaft arch in front of the

drain.

Secure the drain-shaft arch with the

ground anchor.

Lay/place the suction hose in the pit or

water tank. Connect the return hose for

the pressure regulator to the top of the

guide arm. The water ‘lubricates’and

cleans the ushing hose.

Disengage the pressure regulator. Engage

the PTO.

Recommended speed for the pump is 350 – 370 rpm. Use the lowest possible speed necessary

to achieve the operating pressure of 30-35 bar.

Run the reel slowly to roll out the hose;

tighten the tension roller until the drive no

longer slips.

Reel out the hose carefully until the nozzle

is ±3 centimetres from the drain (lever 1).

Set the distance indicator to 0.

7

9

11

8

10

12

19

112202RE101_A_M

5 OPERATION

EN

Engage the pressure regulator and adjust it to 35 bar.

Reel out the hose at ±30 metres per minute. Retract the hose ±15 metres if the hose gets

stuck or the drive wheels slip. Then continue reeling out, assuming that the end has not yet

been reached.

If the cleaner nozzle gets stuck approximately 50 metres into the drain pipe due to heavy

deposits: retract the hose completely to ush the contamination out of the drain pipe. Repeat

to clean the next section of drain pipe.

13

14

15

• Prevent the polyethylene hose from kinking by positioning the drain-

shaft arch no more than 5 to 10 centimetres from the drain.

• Raise the drain cleaner until the angle of the PTO shaft is

approximately 10 degrees (maximum 12 degrees).

• Stop immediately when a blockage is reached.

• Stop immediately at the end of the drain pipe.

• Never allow the ushing hose to stand still in the drain pipe for more

than ten minutes.

• Retract the hose at a lower speed.

Ensure that no one is within the working zone around the machine when

the machine is in operation.

• Only remove the locking pin from the pivot point if the arm is resting

on the ground.

• Do not place your hands between the drive wheels.

When the cleaner nozzle is in the drain:

• Do not switch o the pump!

• Keep the hose under pressure!

• Never leave the machine unattended!

ATTENTION

ATTENTION

20 112202RE101_A_M

5 OPERATION

EN

Roll up the hose once the end of the

drain is reached. Reduce the speed from

20 to 25 metres per minute by adjusting

the throttling valve. Watch the distance

indicator carefully. Stop the reel once the

hose is out of the drain.

Disengage the pressure regulator.

Disengage the PTO shaft.

Raise arm slightly and drive to the next

drain.

Remove suction hose from the water.

Remove suction hose from the water.

Remove ground anchor.

Machine operation: winding up

1 2

3 4

5

67

This manual suits for next models

2

Table of contents