Siemens-Allis LA-3200A User manual

WAHRANTY

I

NS

T

AL

LATION

ANO

I

NSPECT

IO

N

ln

tr

oduc;t1o n .

R

ecc

1vino tHHi

ln

sp1

?c

taon

fq

t Dn

n,

nqe

l

ns

ta

ll

<J

lion

.

Sw

r:.i

g

•~

.

Ma

i

11t

en.ince .

OPERAT

ION

D

es

cri

pti

on

Ma

nua

llv ·

Op

er3

rerl

Br

e

ak

er

El

ect

r

ic

ally-Opera

ted

Br

ea

ke

r .

Drawout

I

nt

er

l

ock

.

Racking

Mecha

n

ism.

Lift

i

ng

Bar

&

Ra

il

Ext

e

nsions

.

Sp

r

ing

Disc

harge

Int

er

lock

.

M

AINTENANCE

AND

ADJ

U

STMENTS

Mai

n

te

nan

ce . .

Lub

ri

cation

.

Maintenance

Cl

osing

Handli

ng

Instruc

ti

on

Fig.

1

Fig.

2

Fig.

3

Fig.

4

T

yp

ical L

A-3000A

Breaker

Outli

ne.

Typ

ical

LA·30

00A

-

4000A

Opera

t

or

Typi

cal

Wiri

ng

Diag

r

am

- El

ectr

i

cally

Operated

Br

eakers

....

Typical

Rack

ing

Mec

h

anism

and

Drawout

I

nterlock

Fig. 5

Main

t

enance

Closing

Table

1

Oper

ating

Procedure

- Ma

nu

ally

·

Operated

Breakers

. .

..

...

.

Table

2

Operat

i

ng

P

rocedure

-

Electrical

Iy ·

Operated

Breakers

.

"

. 2 ·

L2

3

3

4

4

4

8

5

6

6.

21

6

.17

13

14

15

16

18

3

4

A<l1t

1S

t

!T

Wr\

t$

Tr

1p -

L11

t

ch

Enci;

t

CJl~f

nt-!

n

t

Mn

1n

Co

11t

:1cr

Mnke

.

Arc

1

r1q

Con

1;

1c1

Mnk

".

Contac:t R

t!

p lttCf!rTit!

nt

.

M.1

in C

on

t;

1cr

F1

nuers .

Srn

11

on

:

11

v A 1c1ng

Con

ta

ct

H 1

nge

Con

tact

F

1ng

ers .

Mo

v

11H

JArr.1n

<J

and

Mai

n Co

nt

a

ct

Tr

1pp1nq A

ctuntor.

Motor

Cu

roff

Sw

it

ch

Sec

onda

ry D isc.

Opt

ion .

Aux

i

liary

Sw

i

tc

h

Option

.

Shunt

Tr

ip

Op

t

ion

TRIP

PING

TRANSFORMERS

Curr

ent

Se

nso

rs

Trippi

ng

Transformer

Tab

le

Bell

A larm

Sw

i

tc

h

Option

St

at

ic

Tr

ip

Opt

io

n .

Lim

iT ri

p.

Undervo

ltage

Trip

Dev

ice

Opt

i

on.

L

ubr

ica

ti

ng

In

structions

I

nstruct

ion

Boo

k

Ref

.

Fig. 6 T y pical P

anel

Assembly

F

ig

. 7

Secondary

Disconnect

Fig. 8

Auxil

i

ary

Sw

i

tc

h

Fi

g.

9

Shunt

Tr

ip

.

Fi

g. 10

Unde

r

voltage

Tr

ip.

Fig

. 11

Bell

Alarm.

Tab

le 3

Ma

i

ntena

nce

Cl

osing

Table

4

Tr

ip

Rat

in

g

Ta

b le -

Amperes

Static

Tr

ip

II

.

T

ab

le 5

Tr

ip R

at

i

ng

Table

Li

mi

Tr

ip

.

. .

7

7

7

8

8

8

8

8

8

8

9.

10

. 11

. 1 1

.11

. 11

11

. 12

. 11

. 12

12

11

21

22

19

19

19

19

.

20

.

20

i

12

i 2

T

he

i

nfo

r

mation

contained

w i

thi

n is in

tende

c

~

o

assist

opera

tin g

pe

rsonne

l

by

p

rovid

i

ng

in

formation

on

th

e

genera

l

ch

arac

te

ri

stics

o f

equ

i

pment

o f th

is

type.

I t

does

not

reliev e

th

e user

of

r

espo

nsi

bi

li

ty

t0

use

sound

engineeri

ng

practice

-s in

the

i

nsta

ll

ation,

application

,

operation

and

main

tenance

of

t

he

part

icu

lar

equ

i

oment

pu

rchased

.

If

draw

i

ng

s

or

o t

her

supplemen

t

ary

i

nst

ru

ctio

ns

for

specific

app

l

ications

are

forwarded

w

it

h

th

is

rnanua

l

or

separately,

they

ta

ke

p

recede

nc

e

over

any

co

n

flicti

n g

or

i

ncom

p

lete

info

r

mat

i

on

in

this

manua

l.

Courtesy of NationalSwitchgear.com

WARRAN

TY

. ·Sicm<'ns-Allis

"LA"

air

circuit

lm

•akPrs ar

l'

warrant1·d

lo

lw

fn

•c ,

>f

(kft'<'Ls

in

mat.

nial

and

workma

nship

for

a pe

ri

od

of

one

year

from

datl'

of

in

iti

al

<>pnation

hut

not

mon

•

than

1·ighl1'c1

1

11\(>rlLhs

from

date·

of

s

hipml'nl

hy

company

.

This

warranty

is l

imited

to

Lhl'

furnish

ing

of

any

part. w

hi

ch

to

our

s;\l

i

~l'<ldinn

has h!'('ll pro»·

c·n

dPfPcti\'l'. Si('tnl'ns-J\llis

will

not

in

any casl' assunw

r<'

spons

ibil

ity

for

alliPd 1·quiprn

l'nt

1if

any

kind.

(S<'E'

S

i1

:nH'ns-

Alli

s

Warranty

Form

20160).

Typic

al

Shipping

Methods

Used

With

"LA"

Breakers

II

Courtesy of NationalSwitchgear.com

INSTALLATION

AND

INSPECT

IO

N

INTRODUCTION

The

type

"LA"

air

circu

it breakers may be fu

rn

ished

for

mou

nt

ing in

either

of

two

ways.

They

may

be

use

d in metal·enclosed switchgear

of

the

drawout

type,

or

in

individual

enclosures

(drawo

ut

type).

All

"LA"

breakers are

co

mpl

ete

ly

asse

mbled, tested, and

ca

libr

ated

at

the

factory

in a vertical

position

and

must be

so

installed

to

operate proper

ly.

Customer's

prim

ary connections

sh

oul

d be adeq

uately

braced

aga

inst the effects

of

sh

ort

circ

uit

currents

to

prevent overstressing the breaker terminals.

RECEIV

IN

G

AND

INSPE

CTION

FOR

DAMAGE

Immedia

tely

upon

receipt

of

this

equipm

ent,

caref

ully

remove all packing traces and examine parts, check-

ing

th

em

against the packing list

an

d

noting

any damages i

nc

urr

ed in transit.

If

such

is

disclosed, carrier in-

spection

must

be arranged

for

by

consignee

within

15 days

of

receipt

of

equipment

.

If

equipment

sh

ipped

F

.0

.B.

Shipping

Point,

consignee

must

fi

le a

claim

with

the carrier.

If

equipment

is

sh

ipped F.O.

B.

Destina-

tion,

the

con

signee

mu

st

obt

ain

th

e original

of

th

e carrier inspection

report

and

notify

Siemens-

Allis

imm

e-

diately.

Two

ship

pin

g

methods

are

us

ed

with

"LA"

breakers:

1.

Individually

skidded

with

pro

t

ec

tive covering

for

domestic shipments.

2.

Within

a cubicle

on

exp

ort

orders

when

part

of

a swi

tchg

ear lineup. Breakers shipp

ed

in

their

cubicl

es

are bl

ock

ed

to

prevent acciden

ta

l

tripping

duri

ng shi

pm

ent.

Note

all

caution

tags,

remove

blocking

bolts, and open breaker

con

tacts b

efor

e insta

llati

on.

STORAG

E

Wh

en

breakers

ar

e

to

be

put

into

stora

ge,

they

should be wrapped or covered

with

a

non

-absorbent

material

to

provide

protection

from

pl

aster, concrete dust, moisture

or

other

foreign matter_ Breakers

sh

ould n

ot

be exposed

to

the

acti

on

of

cor

rosive

gase

s

or

moisture. In a

r.eas

of

hi

gh

humidity

or

tempera-

ture

fluctuations,

sp

ace

heate

rs

or

the equivale

nt

should be provided_

I

NSTAL

LA

TI

ON

The"

LA"

air

cir

c

uit

breaker

is

com

ple

tely

adjusted, tested, and inspected

befo

re shipment,

but

a care

ful

ch

ec

k

sh

ould

be made

to

be

cert

ain

th

at

shipment or storage has

not

resu

lted

in damage

or

change

of

ad

-

justm

e

nt

.

Circuit

breakers should be install

ed

in a clean,

dry,

well-ven

ti

lated ar

ea

in

which

the

atmo

sp

here

is

free

from

destructive acid

or

alkali fumes. Before insta

lling

, make certain

tha

t the breaker

contacts

are in

th

e open pos

itio

n, and

primary

discon

nect

fin

gers are l

ubr

icated

with

Siemens-Allis ele

ct

rical

contact

lubr

i-

cant

supplied

with

accessories.

1. Befo

re

the

breaker is install

ed

in

position,

make sure racking clevis' (Fig.

4)

are in test

or

con

nect

posi

tion,

then

cl

ose

it

manually

by

the

maintenance closing me

thod

(see

MAINTENANC

E

AND

ADJUSTMENTS

, page 6)

to

check

proper

functioning

of

the mechanism and contacts.

During

the

clos

ing

operation,

observe

that

the

c

ontact

s move freely

without

interference

or

rubbing

between movable arcing contacts and parts

of

the arc chutes. Then r

efer

to

OP

E

RATION,

page 3

for

a

detailed

description

of

the

circ

uit

breaker operating chara

ct

eristics

befo

re

putting

the breaker in

service.

2_

Trip

units

and accessory devices

sh

ould

receive a

thorough

check

prior

to

placing the b

re

aker in service

to

be certain

that

adjustments are

proper

and

pa

rts are

not

dama

ged

. Refer

to

Stat

ic

Trip

Devi

ce

In

-

struction

Book

18X

4

827

supplied

with

this

equipment

or

to

LimiTrip

Book

18X

10107_

3. Breakers are equ

ipp

ed

with

a

drawou

t int

er

lock

to

prevent

movement

of

a clos

ed

breaker

into

or

out

of

the

connected

position.

See

SPRING

DISCHARGE

INTERLOCK,

page 5

for

a description

of

the

interlock

. I

ts

operation

should

be

checked before the breaker

is

energized.

4.

Upon

complet

ion

of

the installation inspection,

the

c

on

trol

wiring,

if

any,

is

check

ed

and

the

insula-

t

~

on

t

es

ted,

then

the

breaker

is

ready

to

be energiz

ed

.

- 1 -

Courtesy of NationalSwitchgear.com

CAUTIONS

TO

BE

OBSERVED

IN

THE

'

STA

LLATIO

N

AND

OPERATION

OF

"LA"

CIRCUIT

BREAKERS

1.

Never

try

to

remo

ve

the

breaker

from

the

compartment

or

reinsert

into

the

compartment

without

using the guide rail extensions supplied.

See

page 17.

2. Read the

Instruction

Book

before

installing

or

making

any

changes

or

adjustments on the breaker.

3. As the closing springs

on

stored-energy breakers

may

be charged

with

the breaker

contacts

in

either

the

open

or

closed

position,

extreme

care should be taken

to

discharge the springs before

working

on

the

breaker.

4.

When charging manually-operated breakers, always

hold

handle

firm

ly

unt

il

it

is

returned

to

the

nor

mal

vertical

position

.

5. Check

current

ratings against single line diagram

to

assure

that

breakers are

properly

located in switch·

gear at instal

lation.

6. Check the

alignment

of

the

secondary disconnect fingers

to

ensure against

misalignment

due

to

possible

distor

t

ion

of

fingers

during

shipment

and handling.

7. Once the breaker

is

energized,

it

should

not

be touched,

except

for

operating, since

most

of

the com-

ponent

parts are also energized.

MAINTENANCE

Occasional chec

king

and cleaning

of

the

breaker

will

promote

long and

trouble

-free service. A

periodic

in-

spection and servicing on an annual basis should be

included

in the breaker maintenance

routine

or

at

c:horter intervals

if

necessary

due

to

environmental

or

operating conditions.

the

circuit

breaker

is

not

operated

auring

extended periods,

the

breaker should

not

remain in

either

the

closed

or

open

position

any

longer than six

months.

Maintenance opening and closing operations sho

uld

be

made

to

ensure freedom

of

mo

vement

of

all parts.

. 2 -

Courtesy of NationalSwitchgear.com

..

OPERATION

DESCRIPTION

The

LA

-

3200

air

circuit

breaker

has

a

maximum

continuous

current

rating

of

3,200

ampere

s,

and

an

interruption

rating

of

65,000

amperes

at

254,

508,

or

635

volts

60

Hz., when used

with

the

short

time

delay trip device.

With

instantaneo

us

trip

device, the

interruption

rating

is

85,000

ampe

res

at

254

vol

ts,

65,000 ampe

res

at

508

volts,

an

d 65,000 amperes

at

635

volts.

The

LA-4000A

and B

air

circu

it

breakers have a

continuous

cur

rent

rating

of

4,000

ampe

res

and

an

int

er-

ruption

rating

of

85,0

00

amperes when used

with

the

short

time

delay

trip

device. The inter

ruption

rating

with

instantaneous

trip

device is 130,000 amperes at

254

volt

s,

85,000

amperes

at

508

volt

s, and

85,000

amperes

at

635

vo

!ts. All

currents

are

symmetrical amperes and

vol

tages are

maximum.

Th

ree

configur

at

ions

of

the

operator

are availab

le

for

charging the closing springs. These are:

(

A.

) manual charging,

(B.)

electrical charg

ing

(C.)

combina

t

ion

manual-electrical charging

All operato

rs

are

identical

except

for

the means

of

supp

lying

energy

to

the closing springs.

A

double-to

ggle,

tr

ip-free mechanism is

use

d;

that

is,

the

breaker contacts are free

to

open

at

any

time,

if

required, regardless

of

the

position

of

the

mechanism.

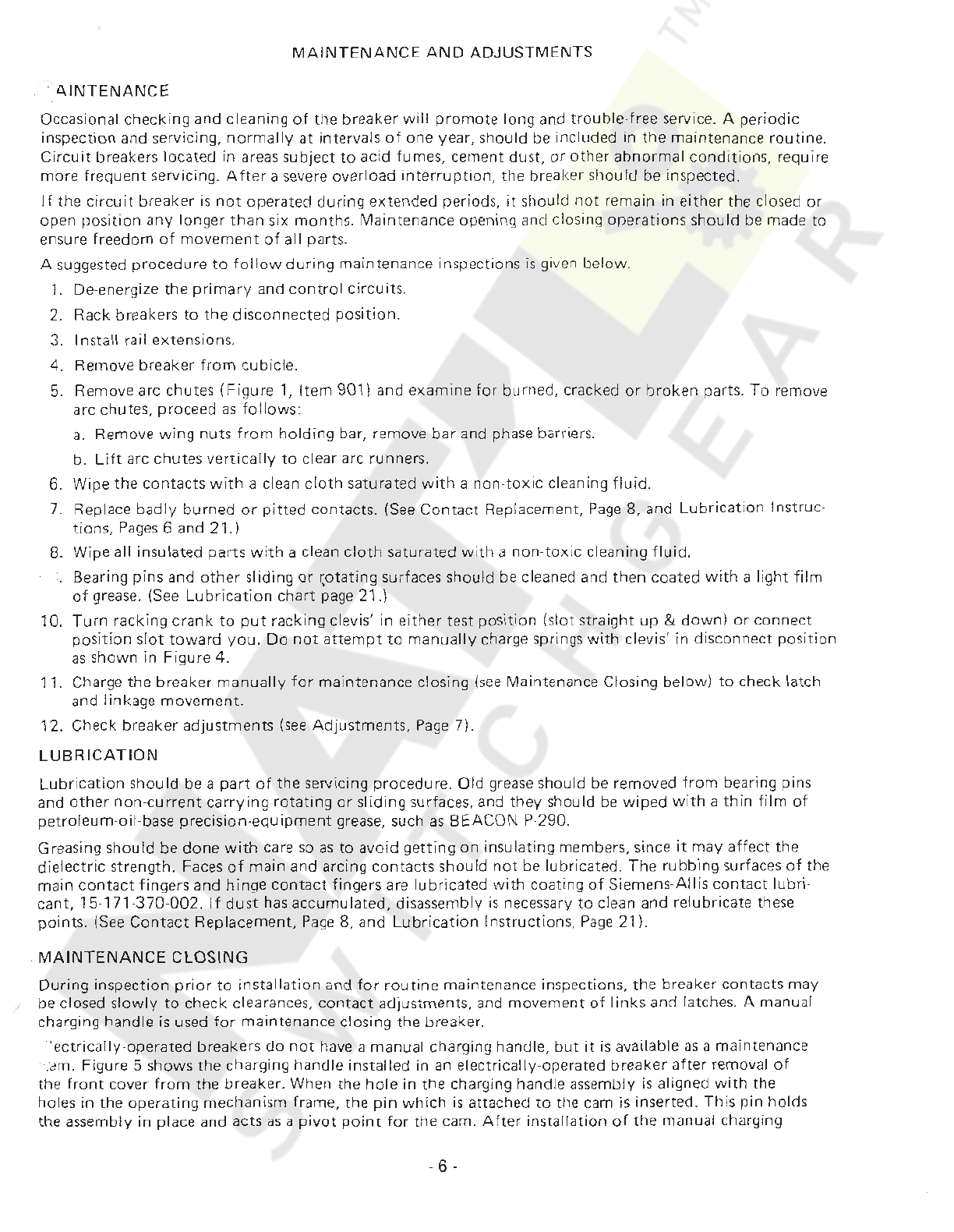

(A.)

Manually-Operated Breaker (Refer

to

F

ig

ure 2 a

nd

Table

1)

The breaker has a

center

-

mounted

frame so

many

of

the

latches and

li

nks

are arranged in pairs;

for

descrip-

tive purposes

they

wil

l be referred

to

as

single items. Detail

"A"

s

how

s

the

position

of

the

trip

latch and

toggle linkage

when

the breaker

is

open and

the

closing springs are discharged.

Movement

of

the

charging

handle

downw

ard rotates closing cam (

204

) against

roller

(168),

thus

pivoting

closing cam (

159

)

about

pin

(215) and

extending

t

he

closing springs

thru

l

ink

(163) and spring hanger (157).

Rotation

of

cam (159)

allows

ro

ller (181) in

to

gg

le linkage

to

be moved in

to

position

shown in Det

ai

l

"B".

Kickoff

springs (199)

move rolle

rs

away

from

stop

bloc

k

(1

71

),

then the toggle linkage

is

moved

by

torsion

spring

unti

l latch

(175) clear

trip

la

tch

(153A).

Spring (155) causes

trip

latch

(15

3A

)

to

reset

under

lat

ch (175).

Trip

flap

(1538)

should

normally

stop against the

front

surface

of

latch (175).

When the closing springs are

fully

charged,

ro

ll

er

(

168

) engages latch (

148).

Charging cam (

204

)

engages

pawl (146) in such a

manner

that

the charging cam

must

complete

the

charging stroke

before

it

can return

to

its

normal

position.

With

the

charging handle in

its

normal

upright

posi

tion,

the

breaker can

be

closed. By pressing

firmly

on

hood

(149), latch

(148)

will di

sengage

roller

(168) and closing springs

cau

se

closing cam (159)

to

rot

ate

aga

inst

the

toggle rollers (181 )

movi

ng

the

togg

le

into

its

upright

pos

it

ion, shown in detail

"C"

. T

he

closing

cycle can be in

terrupt

ed

at

any

po

int

by

operation

of

one

of

the

tripping

means,

which

cause

rotat

ion

of

trip

latch (

153A

)

to

a

position

that

rele

ases

latch (175)

allowing

toggle linkage

to

collapse

to

the

position

shown in detail

"A".

Manual opening

of

the

breaker

is

accomplished

by

pressing in manual

trip

bar

(

188

).

This

bar

engages

the

top

of

trip

flap

(1

538

)

which

is in tu

rn

arranged

to

disengage the

tr

ip latch

(175).

TABLE

1 -

OPERAT

I

NG

PROCEDUR

E -

MANUALLY

-

OPERATED

BREAKERS

Operation

Charging Springs

Closing

Tripping

Procedure

Make

su

re

that

th

e racking clevis' are in

either

test

or

connect

po

sition.

Never pull

charging handle

down

with

clevis' in disconnect

position

as

shown in Fig. 4.

Pull charging handle

down

all

the

way

(approximately

120

°) and

return

to

normal

vertical

position.

(Engagement

of

paw

l

with

the ratchet teeth prevents handle

re·

versal

until

the

downward

stroke is completed.)

Push

down

firmly

on

spring-release

latch

hood

(149)

after

handle

is

returned

to

normal

vertical

position.

Push

in

manual

tr

ip

bar

(

188

),

OR

If

shunt

trip

is

provided, operate r

emo

te

trip

control

switch

(CST).

(See

Figure 3.)

- 3 -

Courtesy of NationalSwitchgear.com

(B.)

Electrically

-

Op

erated Breaker (Refer

to

Figure 1

-2

and

4)

:

The

mechanism

of

the

electrically

operated breaker

is

th

e same

as

the manually

oper

ated breaker

except

th

at

the

manual cha

rg

i

ng

handle

is

replaced

by

a

motor

and gear system.

With

power

ava

ilable

to

the con-

trol

ci

rcuit,

closing the

motor

con

trol

switch

(Ml)

wil

l

sta

rt

the

automat

ic charging cycle.

The

motor

gear

box

pinion

rotate

s gear (

224

) co

unterclockwis

e, cam

follower

(233)

engages

an

arm

of

wind

and close

ca

m (

223

) which rotates

the

cams in the

sam

e manner

as

for

the manually charged breaker. When the

wind

and close earn (223) reaches its charged pos

ition

, the back

of

t

he

cam

eng

ages

switch lever

(229)

rotating

t

he

lever away

from

the

switch

operator.

Gea

r switch lever

(23

1) will still

be

holding

th

e

switch

in the operate posi

tion,

and

the

motor

will

continue

to

run

until

the

roll

pin

s on the side

of

gear (

224)

lifts

lever (231) clear,

re

leasing

the

motor

cutoff

switch

{M

CO

).

When the MCO switch op

en

s,

th

e

motor

sto

ps,

and the closi

ng

coil

circuit

is

set

up

through

one side

of

the

MCO swi

tc

h.

The

bre

aker can

now

be closed

by

depressing the latch

hood

(

149

)

or

by

energizing the closing

co

il

(CC)

throu

gh

the external close

control

switch

(CSC). When

the

close

circuit

is

energized, the

"Y

" relay

is

energi

ze

d and opens

the

"Y"

contact

in

the

mo

tor

circuit,

thus p

re

venting

"pu

mp

i

ng"

or

repeated at-

tempts

to

charge the

clo

sing springs.

If the close

circuit

CSC

switch

is

open

ed

,

the

motor

will

au

tom

atically

recharge the closing springs,

if

power

is

ava

ilable

for

the

motor

circuit.

The

cl

ose

coil circu

it

is

always

interr

upted

by

the

motor

cut-o

ff

s

witch

MC

O.

Trip

free

operation

of

the

mechanism, discharging

the

sprinQs on a closed breaker

is

pre-

vented

by

comp

leting

the

close

coil

circuit

through

an

auxiliary

contact

of

the breaker.

TABLE

2 -

OPERAT

I

NG

PROCEDURE

- E

LECT

RICA

LLY

-

OPERATED

BR

EAK

ERS

CAUTION!!

MAK

E

SURE

THAT

RACKING

CLEVIS

' (FI

G.

4)

ARE

IN

TEST OR CO

NN

ECT POSI-

TION

BEFORE

C

HARG

ING SPR INGS. DO

NO

T

CH

ARG

E SPRINGS WI

TH

CL

EV

IS'

IN

DISCONNECT

POSITION

AS

THIS

COULD

CAUSE

DAMAGE

TO

BREAKER.

Operation

Charging Springs

Closing

Tripping

Procedure

Energize

con

tro.J

circuit.

Move

motor

control

switch

on

fr

ont

of

breaker

to

"ON"

positi

on.

After

springs are cha

rg

ed, actu

at

e remote close

control

switch (CSC).

OR

Pu

sh

down

firm

ly

on

spring-r

elease

latch

hood

(149).

Actu

ate

remote

trip

control

switch

(CS

T).

OR

Push in

man

ual

trip

bar

(188).

(C.)

Combination

Operated Breaker

Th

e

combination

manually

and el

ectrically

operated

br

ea

ker

includes

both

the

moto

r-gear charging

system

as

well

as

the manual charge handl

e.

NOT

E: Manual Handle must

be

in vertical

position

during

e

lect

rical c

ha

rging.

Drawout

I

nter

l

ock

The breakers

incl

ud

e

as

integral parts

the

mechanism

to

rack

the

breaker in

or

out

of

t

he

cubicle

comp

art

-

ment, i

nterlocking

to

prev

ent

racking a closed breaker

into

or

out

of

the connect

ed

position

, and in

te

r-

locking

to

preve

nt

withdrawing

a breaker

fro

m the cubicle

while

the closing springs are charged.

Racking Mechanism

Refer

to

page 17.

With

the

breaker resting on the

cub

icle rail the fol

lowin

g

sequ

ence s

hould

be u

sed

to

rack the breaker

into

the cubicle.

CAUTION

!! N

EV

ER

IN

STALL

OR

REMOVE

A BR

EA

KER

FROM

THE

COMPARTM

ENT

WITHOUT

HAVING

RAIL

EXTENSIONS

IN

PLACE. SEE PAGE

17

.

C

AUTION!!

ON

ELECTRICALLY

OPERATED

BREA

KERS, BE SURE M

OT

OR

CO

NTR

OL

SWI

TCH

ON

THE

FRONT

OF

THE

B

REAKER

IS

OFF.

1. Push

tr

ip bar

in,

lower

interlock

slide and insert racking crank.

NOTE:

Interlock

slide

cannot

be

open-

ed

un

l

ess

manual

trip

bar

is

pressed in.

While

the

trip

bar

is

pressed in, the breaker is in the

TRIP-

FREE

position

and

cannot

be closed.

-4 -

Courtesy of NationalSwitchgear.com

2.

With

the racking crank,

rotate

the racking screw (273) u

nti

l the racking shaft is in t

he

disconne

ct

ed

position.

T

he

clevis can

now

engage the racking pins

(E

l in the cubicle. The breaker should

now

be

pu

sh

ed along the

ra

il

into

the DI

SCONNECTED

pos

ition

.

Double

check that the racking cl

ev

is

does

en-

gage

the pins in t

he

cubicl

e.

3. Check

to

see

that

the

floo

r i

nterlock

(Item

11

3)

is

clear

befor

e racking.

4.

Count

ercl

ock

wise

rotation

of

the

racking screw

will

rack the breaker in

to

the TEST posi

tio

n.

At

the

TEST

p

os

ition, the

floor

mounted

interlock

isclear and the cover slide

interlo

ck

can

be closed,

allow

-

ing the

tr

ip bar

to

ex

tend and the breaker

ca

n

be

operated. (Between the

TEST

pos

iti

on and the CON-

NECTED

position,

the slide

interlock

will

engag

e the stop

pin

and the

br

eake

r

will

be

tripp

ed

throu

gh

the

interlock

mechanism, and the cover slide

ca

nnot

be closed.)

In

the

CONNECTED

position,

the slide

interlock

will

clear

the

s

top

pin

of

the racking toggle and the

fl

oor

inter

l

ock

is

clear

allowing

the breaker

to

be

clo

sed.

Th

is prev

en

ts

mov

i

ng

a

clo

sed

breaker

int

o

or

out

of

the

CONNECTED

pos

iti

on.

5.

To

withdraw

the breaker

fro

m

the

CO

NN

ECTED

position,

the

procedure

is

the

same

only

the racking

screw

ro

ta

ti

on

is

clockwise.

6.

Befor

e

attempting

to

operate

the

breaker, the positi

on

of

the devi

ce

should

be

checked

with

reference

to

the

marking

in t

he

cubicle,

to

be certain

that

it

is

fully

connected.

Two

stop

nuts

are

provided

on

the racking screw

to

set

the

connected position.

The

se

are adjusted

by

setting the angle

of

the racking

clevis,

as

shown in detail

"D"

of

Figure

1,

and

by

tightening the

nuts

against the

"L"

link

s (281) the

two

nuts

(

278

) should be

then

locked against each other.

CAU

TION!!

TO

AVOID

DAMAGE

TO

THE

RACK

I

NG

MECHANI

SM, DO

NOT

ROTATE

THE

RAC

K-

ING

CRANK

IN

THE

COUNTERCLOCKWISE

DIRECTION

WHEN

IN

TH

E CO

NN

ECTED

POS

IT

ION.

Spring Discharge

In

te

rlock

When racking

the

breaker

out

to

the

DISCONNECTED

position,

the

closing spri

ngs

will

aut

o

matically

dis-

charge,

at

or

befo

re

reac

hing

th

e disconnect

posit

ion.

The

barrel nut engag

es

the

sp

ring i

nter

l

ock.

This in

turn

connects

to

the manual cl

ose

hood

which

releases

the

closing spring

s.

CAUTION!!

ON

MANUALLY

CHARGED

BREAKERS,

THE

CLOSE

HOOD

IS

INTERLOCKED

TO

TH

E M

ANUAL

CHARGE

CAM,

AND

MUST

BE

CLEAR

BEFORE

RACKING

THE

B

REAK

ER

TO

THE

DISCONNECT

POSITION.

NOT

E:

Manual charge handle

must

be in vertical

positio

n during

ra

cking

and

ra

cking mechani

sm

must

be returned

to

the test

position

before closing springscan be char

ged

while

breaker

is

remo

ved

from

cubic

l

e.

Note

al

so

that the spring discharge

interlock

produces a

TRIP

-

FREE

operation

in

which

all

of

the stored

energy

of

the

sprin

gs

is

dissipated in the mechanism.

It

is

preferable

to

turn

the

motor

contro

l switch

off

in

the

TEST

pos

it

ion,

clo

se

the breaker

no

rm

ally

in

that

po

sitio

n, then rack

out

in

th

e

normal

manner.

.

5.

Courtesy of NationalSwitchgear.com

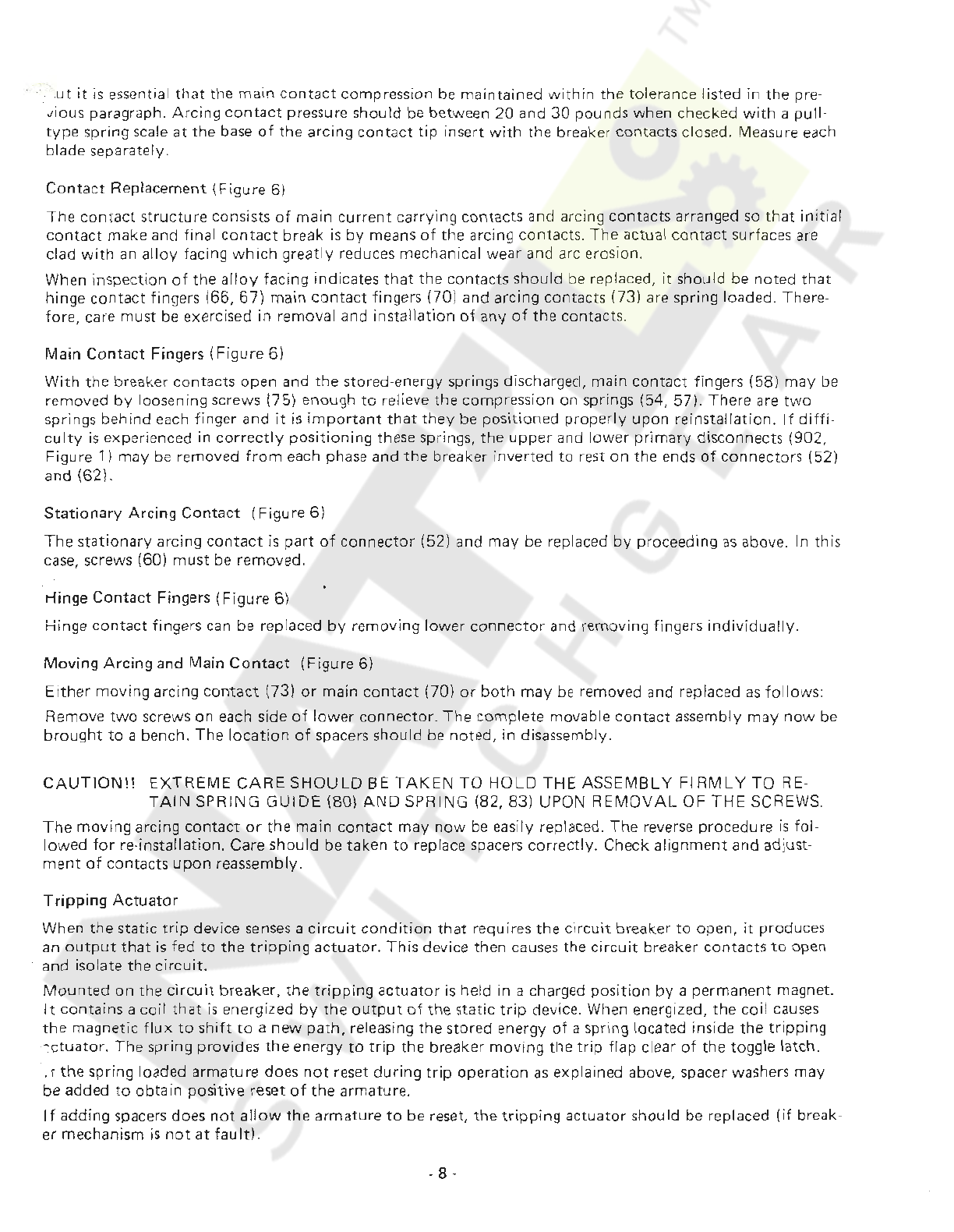

MAINTENANCE

AND

ADJUSTMEN

TS

. ·

AINTENANCE

Occasional checking and cleaning

of

the breaker

will

promote

long and

trouble

-free service. A per

iodic

inspection and servicing,

normally

at

intervals

of

one year, should

be

included in the maintenance

routine.

Circuit

breakers

lo

cated in areas subject

to

acid fumes, cement dust,

or

other

abnormal

conditions,

requir

e

mo

re

frequent servicing.

After

a severe overload

interruption,

the breaker should be inspected.

If the circu

it

breaker

is

not

operated

during

extended periods,

it

should

not

remain in

ei

ther the closed

or

open

position

any

longer than s

ix

months

. Maintenance opening and closing operations sho

uld

be

made to

ensure freedom

of

movement

of

all parts.

A suggested procedure

to

follow

during

main

te

nance inspections

is

given below.

1. De-energize the

primary

and

contro

l circuits.

2. Rack breakers

to

the

disconnected

position.

3. Install rail extensions.

4. Remove breaker from cubicle.

5. Remove arc chutes

(Figure

1, Item 901) and examine for burned, cracked

or

broken

parts.

To

remove

arc chute

s,

proceed

as

follows:

a.

Remove

wing

nuts

from

holding

bar, remove

bar

and phase barriers.

b.

Lift

arc chutes

vertically

to

clear arc runners.

6. Wipe the

contacts

with

a clean

cloth

saturated

with

a non-

toxic

cleaning

fluid.

7. Replace

badly

burned

or

pitted

contacts.

(See

Contact

Replacement,

Page

8, and

Lubrica

tion

lnstruc·

tions,

Pages

6 and

21.}

8. Wipe all insulated parts

with

a clean

cloth

saturated

with

a

non-toxic

cleaning

fluid.

Bearing pins and

other

sliding

or

~otating

surfac

es

should be cleaned and then coated

wit

h a light

fi

lm

of

grease.

(See

Lubric

ation

chart

page 21.)

10.

Turn

racking

crank

to

put

racking clevis' in

either

test

position

(s

l

ot

straight

up

&

down}

or

connect

position

slot

toward

you.

Do

not

attempt

to

manually

ch

arge

springs wi

th

clevis' in disconne

ct

position

as

shown in Figure 4.

11. Charge

the

breaker

manually

for

maintenance closing (

see

Maintenance Closing below)

to

check latch

and linkage

movement.

12. Check breaker

adjustmen

ts

(see

Adjus

tments

,

Page

7).

LUBRICATION

Lubric

atio

n should be a

part

of

the servicing procedure. Old

grease

should be removed

from

bearing pins

and

other

non-current

carry

ing

rotating

or

sliding surfaces, and

they

should

be

wiped

with

a

thin

f

ilm

of

petroleum-oil-base precision

-equipment

grease, such

as

BEACON P-290.

Greasing should be

done

with

care

so

as

to

avoid

getting

on

insulating members, since

it

may

affect

the

dielectric strength. Faces

of

main

and arcing

contacts

should

not

be lubricated.

The

rubbing

surfaces

of

the

main

contact

fingers and hinge

contact

fingers are

lubricated

with

coating

of

Siemens-

Allis

contact

lubri-

cant,

15

-

171-370-002.

If

dust

has

accumulat

ed, disassembly

is

necessary

to

clean and relubricate these

points.

(See

Contact

Replacement.

Page

8, and Lubric

ation

Instructions.

Page

21).

.

MAINT

ENA

NCE

CLOSING

During

inspection

prior

to

instal

lation

and

for

routine

maintenance inspections. the breaker contacts may

be

closed

slowly

to

check clearances,

contact

adjustments, and movement

of

links

and latches. A manual

charging handle

is

used

for

maintenance closing the breaker.

"

ectrically

-operated breakers

do

not

have a manual charging handle,

but

it

is

available

as

a maintenance

-.

~m.

Figure 5 shows the charging handle ins

ta

lled in an electrically

-o

perated breaker

after

removal

of

the

front

cover

from

the breaker. When the

hole

in the charging handle

as

s

embly

is

aligned

with

the

holes in the

operating

mechanism frame, the

pin

which

is

attach

ed

to

t

he

cam

is

inserted. This

pin

holds

the assembly in place and acts

as

a

pivot

point

for

the cam.

After

installation

of

the manual charging

. 6 .

Courtesy of NationalSwitchgear.com

handle assembly on the electrically·operated breaker, the actual maintenance closing

operation

is

the

same

for

hath

the electrically-operated breaker and the man

ually

·operated

br

eake

r.

Refer

to

Table 3

and Figure 5.

CAUTION

II

TH

E

PROCEDURE

IN T

ABL

E 3

SHOULD

BE USED FOR

MAIN

TE

NAN

CE

C

LOSING

O

NL

Y.

MAIN

TA IN A FIRM

GRIP

ON THE

MANUAL

CHARGING

HANDL

E

DURING

TH

E

CLO

S

ING

STROKE

-

TH

E

BREAKER

MAY

SUDDEN

LY

LATCH

F

ULLY

CLOSED

AN

D APPLY

UNEXP

EC

TED

FOR

CE

TO

THE

CHARGIN

G

HANDLE

.

TA

BLE

3 -

MA

I

NTENANCE

CLOSIN

G (

Ref

er

to

Figure 5)

CAUTION!!

TU

RN

RA

CKI

NG

CRANK

TO

PUT

RA

CKING

CLEVI

S' IN

EITHER

TEST

POSITION

(

SL

OT STR

AIGHT

UP &

DOWN)

OR

CONNECT

POSITION

SLO

T

TOWARD

YOU

.

DO

NOT

ATTEMPT

TO

M

ANUALLY

CHARG

E SPRINGS

WITH

CLEVIS'

IN DISCONNECT

PO

SITI

ON AS SHOWN IN FIG. 4.

Operation

Closing Contacts

Procedure

1.

P

ull

charging handle DOWN A

LL

TH

E

WAY

(a

ppro

x

imately

120

°)

, and

hold

handle

down.

2.

Pl

ace

blade

of

screwdriver between

ho

od and

sp

ring

release latch a

nd

hold

it

in

this

position.

T

hi

s prevents

sp

rings

from

latching in charged pos

itio

n,

or

se

e

no

te

below

.

3. S

low

ly

return handle

to

vertical position. Observe

cont

act,

touch,

mechanical

op

era·

tion,

etc.

4.

Re

move screwdriver a

nd

pull charging handle

to

the

fully

charged

posit

ion. All

ow

sp

ring release latch

to

hold

closing springs. Move chargi

ng

handle

to

th

e

verti

ca

l

po

s

it

ion.

5. C

lo

se

breaker

norm

a

lly

by

pressing

clo

se

hoo

d.

Opening Contacts Push

in

manual

trip

rod.

NOTE

:

Holding the spring rele

ase

latch

down

prevents the stored

-ene

rgy springs

from

propping in the charged posi-

tion.

Th

us

,

when

th

e handle is s

lowly

returned

to

the n

orm

al v

ert

ical

position,

th

e energy in

the

springs

is

slowly

rele

ased

against

th

e

clo

sing handle assembly cam fac

e.

•

ADJUSTMENTS

D

ur

ing maintenance inspections,

the

following

items should

be

checked

to

ensure

that

the

or

iginal

se

ttin

gs

are maintained:

Trip

Latch

Engagement

(Figur

e 2)

Togg

le

latch (

175)

should eng

age

th

e fu

II

wi

dth

of

tr

ip

l

atc

h (1

53A

)

when

the

breaker is closed in the

nor·

mal manner.

The

tension

on

spring (

155

) can be increased if required

by

bending spring tab on

tr

ip

flap

to

·

wards the

front

of

the breaker.

Too

much tension

will

interfere

with

the

cap

ab

ili

ty

of

the

tripping

actuator

to

move the

trip

flap,

so

over-bending s

houl

d be avoided.

Main

Contact

Make (

Figur

e 6)

Compression

of

cont

act

fingers (58) should be between

.093

inch

es

and

.12

5 inches.

This

is

the difference

in

the

measurement

from

the

breaker b

ase

to

the

tip

of

the

fin

ger

contact

surface

when

the breaker is open

a

nd

the

measurement in

th

e

sam

e pla

ce

wh

en

the

breaker

is

clo

sed.

This

is

checked

with

a normal closing

operation

-

not

maintenan

ce

clo

sing.

Adjust

me

nt

is

provided

by

positioning

screws (85)

aft

er loosening

nuts

(86).

Cou

nte

rc

loc

kwise

ro

t

ation

of

scr

ew

s (

85

) increasescompression.

Ca

re

should be tak

en

to

re

tight-

en

nuts

(86)

after

adjustment.

If

it

is

desired

to

check

contact

pressur

e,

a push·

type

spring scale

can

be

us

ed

to

compress

contact

fin

gers (

58

),

with

breaker open.

Contact

pressure should be

betw

een

20

to

30

pounds

on each finger.

Arci

ng

Contact

Make

(Figure 6)

With

movable ar

ci

ng

contact

(73) in any one phase

touching

the

mating

station

a

ry

contact

when the break-

er

is

closed

by

the

maintenance closing

method

(

See

Table

3, Fig. 5),

the

phase-to-phase variation should

not

,exceed .

062

inches.

Adjustment

may

be made

by

positioning

screws

(85)

as

in

the

pr

evious paragraph,

- 7 -

Courtesy of NationalSwitchgear.com

·

..

ut

it

is

ess

ential

that

the

main

cont

act

com

pression

be

maintained w

ithin

t

he

tolerance listed in the pre-

vious paragraph.

Arcing

conta

ct

p

re

ssure should be between 20

an

d

30

pound

s when checked

with

a pull-

type

spring

scale

at

the

base

of

the arcing

contact

tip

insert

with

the breaker contacts closed. M

eas

ure each

blade

se

parately.

Conta

ct

R

ep

l

ac

ement

(Figure 6)

The

contacl

structu

re

consists

of

main

cur

rent

carrying contacts and arcing

contac

ts arranged

so

that

initial

contact

mak

e and final

contact

break

is

by

means

of

the arci

ng

contacts. The actual

contact

surfaces are

clad wi

th

an al

loy

facing

which

greatly

redu

ces

mechanical wear and arc erosion.

When inspection

of

the all

oy

facing indicates

th

at the contacts should be replaced,

it

should

be

noted

that

hinge

cont

act fingers (

66,

67) main

contact

fingers (70) and arcing contacts (73) are spring loaded. There-

fore, care

must

be exercised in removal and install

ation

of

a

ny

of

the contacts.

Main

Cont

act Fingers

(Figure

6)

With

the breaker

contact

s open and

th

e stored-energy spri

ngs

di

sc

harged, main

contact

fingers (58)

may

be

removed

by

loosening scr

ew

s (75) enough

to

relieve

the

compr

ession on springs (54, 57).

The

re

a

re

two

springs behind each finger

and

it

is

important

that

they

be

positioned

properly

upon

reinstallation. If

diffi-

culty

is

experienced in

correctly

positioning

t

hese

springs, the

upper

and

lower

prim

ar

y disconnects (

902

,

Figure 1) may

be

removed

fr

om

each phase and the breaker

inv

erted

to

rest

on

the ends

of

connec

to

rs

(52)

and (62).

Stationary

Arcing

Cont

act

(Figure 6)

The

stat

ionary

arcing

contact

is

par

t

of

connector

(52) and

may

be

re

pl

ac

ed

by

proceeding

as

above.

In

this

case, scre

ws

(60)

must

be

rem

oved.

rlinge

Con

tact

Fingers (Fig

ure

6)

Hinge

co

ntact

fingers can be replaced

by

removing lower

co

nnector

and removing fingers

individua

lly.

Moving

Arcing

and Main

Contact

(Figure

6)

Eithe

r moving arcing

cont

ac

t (73)

or

main con

tact

(70)

or

both

may

be

re

moved and replaced

as

foll

ows:

Remove

two

screws on each side

of

lower

connector.

The

comp

lete movable

conta

ct

assembly

may

n

ow

be

bro

ught

to

a bench. The loca

tion

of

spacers s

hould

be noted, in disa

sse

mbly.

CAUTION!!

EXTREME

CARE

SHOU

LD BE

TAKEN

TO H

OLD

THE

ASSEMBLY

Fl

RMLY

TO

RE

·

TAI

N

SP

RING

GUIDE

(80)

AND

SPRING (82, 83) U

PO

N

REMOV

AL

OF

TH

E

SC

REWS.

The

moving

arcing

contac

t

or

the

main

contact

may

now

be easily replaced.

The

rev

erse

procedure

is

fol-

lowed

for

re-installation. Care should be taken

to

replace spacers corre

ct

ly. Check align

ment

and adjust·

ment

of

con

tact

s

upon

reassembly.

Tripping

Actuator

Wh

en

the static trip device

sen

ses

a

circuit

condit

ion

that

re

quires the

cir

cu

it

breaker

to

open, it

pro

duces

an

output

t

hat

is

fed

to

the

tripp

ing

actuat

or.

Th

is

device then causes the

circuit

breaker

conta

cts

to

open

and isolate the circ

uit.

Mounted

on

the c

ir

cuit

breaker,

the

tripping

actu

ator

is held in a cha

rge

d

position

by

a perman

ent

magnet.

It

contains a coil

that

is

energized

by

the

output

of

the static

trip

device. Wh

en

energized, the

coil

causes

the m

ag

netic

flu

x

to

sh

ift

to

a

new

path,

releasing

the

stor

ed

energy

of

a spring located inside the tripping

-:

c

tuator.

Th

e spring provides

the

en

ergy

to

trip

the breaker moving the

tr

ip flap clear

of

the toggle

la

tch.

.r the spring lo

ad

ed

arma

tu

re

does

not

reset

during

trip

operation

as

explain

ed

abov

e,

spacer washers may

be added

to

ob

tain positive reset

of

the arm

at

ure.

If

adding

space

rs

does

not

allow

the

armatu

re

to

be

res

et, the t

ripping

actua

tor

should be replaced

(i

f break·

er mechanism

is

not

at

fault

).

. 8 .

Courtesy of NationalSwitchgear.com

N

OT

E:

Do

not

at

t

empt

to

disassemble the

tr

ippi

ng

actuator

as th

is

may

destroy

the

magnetic fie

ld

set-

up

by

the

permanent magnet and

wil

l render

the

actuator latch inopera

ti

ve u

nt

il remagnetized.

When repl

ac

ing a

tri

ppi

ng

act

u

ator

, the coil leads must be connected to

the

ter

minal

block

of

the st

at

ic

trip

in

the

correct polarity relationsh

ip

.

The bla

ck

l

ea

d of coil

must

be co

nn

ected

to

terminal 7 (negative) a

nd

th

e

reel

lead

of

coil conn

ec

ted

to

te

rmi

nal 8 (positive)

of

the static

trip

device.

Wh

en

th

e

trip

ping actu

ator

has been rep

la

ced, the circuit bre

ak

er s

hould

be

giv

en

a FUN

CT

ION TEST to

en

su

re

proper

operat

io

n

of

all

com

pon

ents. Re

fe

r to Siemens-Allis I

nstr

uction

Book

18X4827

for

the

pr

ocedures

of

th

e F

UN

CTI

ON

TE

ST.

Motor

C

utoff

Sw

it

ch

es

The

fun

ct

ion and a

djust

me

nt

of

t

he

motor

cut

o

ff

swi

tc

hes

on elec

tr

ic

ally

-o

pe

rated

br

eakers is described on

P

age

10

.

-9 -

Courtesy of NationalSwitchgear.com

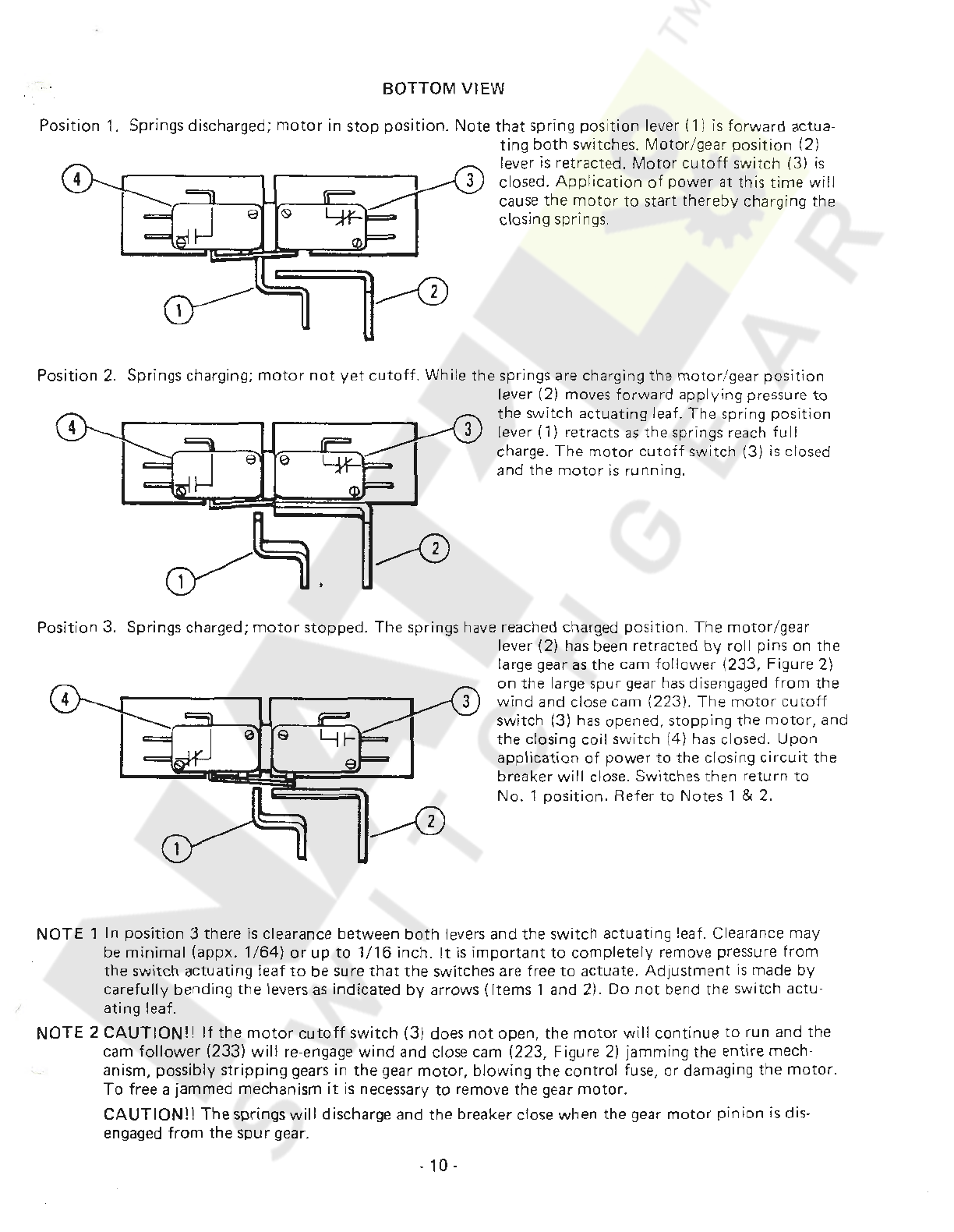

P

osition

1.

Position 2.

Posi

tio

n 3.

BOTT

OM VIEW

S

pr

in

gs

discharged; motor in s

top

po

sition.

Note

that

spring pos

it

ion lever (1) is f

or

ward actua-

ting

both

switches.

Motor

/gear

position

(2)

lever

is

retracted.

Motor

cutoff

switch (3)

is

closed.

Application

of

power

at

this

time

will

cause the

motor

to

sta

rt

thereby charging the

closing springs.

Spri

ngs

charging;

mo

to

r

not

yet

cuto

ff.

While the spri

ngs

are charging the

motor

/

gea

r

po

s

iti

on

lever (2) moves

for

ward

applying

pressure

to

the switch actuating leaf.

Th

e spring

position

lever (1) retracts

as

the springs

re

ach fu

II

charge.

The

mot

or

cutoff

switch

(3) is closed

and the

motor

is

runn

ing.

Spri

ngs

char

ged

;

mot

or

stop

ped. The

sp

rings have reached charged p

os

ition.

The

mot

o

r/

g

ea

r

l

eve

r (2) has been retracted

by

ro

ll pins on

the

la

rge

gear

as

the cam

fo

ll

ower

(233, Figure 2)

on

the large spur gear

has

disengaged

from

the

wind

and close cam (

223

).

The

m

otor

c

utoff

s

wi

tch (3)

has

opened,

stopping

the

motor,

and

the closing coil s

wi

tch (4)

has

closed.

Upon

app

lication

of

power

to

the closing c

irc

u

it

the

br

ea

ker

will

cl

os

e.

Switches

the

n retu

rn

to

No.

1

position.

R

efer

to

Notes 1 & 2.

NOTE

1

In

position

3 there isclearance betwe

en

both

levers and the

switch

actuating leaf. Clearance

may

be

minimal

(appx. 1/

64)

or

up

to

1/16

inch.

It

is

important

to

completely

remove pressure

from

the

switch

actuating

leaf

to

be sure

that

the

switches are free

to

actuate. A

djustment

is made

by

ca

ref

ully

bending

th

e levers

as

indi

cated

by

arrows

(It

ems 1 and 2).

Do

not

bend the switch actu-

a

ting

leaf.

NOTE

2

CAUTION!!

If the

motor

cu

toff

switch

(3) does n

ot

open, the

motor

will

continue

to

run and the

cam

fo

llower

(233) w

ill

re

-engage

wind

a

nd

close

ca

m (223, Figure 2)

jamm

i

ng

the entire mech-

an

is

m,

possibly str

ipping

gears in

th

e gear

motor,

bl

o

wing

the

control

fuse,

or

damaging the

motor.

To

free a jammed mechanism

it

is n

eces

sary

to

remove the gear

motor.

CAUTION!!

The springswill discharge and the breaker close when the gear

motor

pinion

is dis-

engaged

fr

om

the

spur

ge

ar.

. 10 -

Courtesy of NationalSwitchgear.com

ACCESSORIES

Tripping

Transformers

-

Static

Trip

11

There are several

tripp

ing transformer ratings available, each

with

seven

ca

li

brated

pickup

sett

in

gs

(Page

12).

The

tr

i

pping

transformers

are

mounted

on

the

lower

connector

and

mounted

with

the pol

arity

mark

facing

the breaker panel.

Current

Sensors -

LimiTrip

The

current

sensors

provided

with

the

optional

LimiTrip

device are integrated

units

containing

two

cores

with

four

terminals.

Proper

polarity

is

established when the terminals face away

from

the panel. Li

miTrip

sensors should never be subjected

to

primary

current

with

the

LimiTrip

device disconnected

from

the

sensor.

OPTIONAL

DEVICES

Secondary

Disconnect

Assembly

Option

The electrical

attachments

are

wired

to

the

termina

ls

of

a secondary

disconnect

assembly (

See

Figure 7),

which

is

mounted

on

the

left

side

of

the

breaker.

Thre

e

blocks

of

ten

terminals

each

can

be

mounted

on

the

breaker.

The

secondary

disconnect

assemb

ly

is

accessible

from

the

front

of

the

breaker and aligns

with

a

stationary

unit

in

the

cubicle.

The

stationary

contact

strips should be

lubricated

with

a l

ight

fi

lm

of

con-

tact

grease

which

is

furnished

with

the

switchgear.

Auxiliary

Switch

Option

The

auxiliary

switch

(See Figure

8)

is

of

the

rotary

type

and

functions

by

direct

connect

to

the

breaker

mechanism.

The

contacts

are

factory

set

for

"a"

(open when

the

breaker

is

open) and

"b"

(closed when

the

breaker

is

open)

position,

but

each

rotor

(955)

may

be adjusted

individually

in

steps

of

30

degrees.

This

adjustment

is

made

by

removing cover

(962)

and

lifting

the

entire

rotor

assembly

out

of

case

(950)

after

disconnecting

arm

(957)

from

the

linkage.

Cotter

pin

and bearing

(956)

are removed

to

perm

it

re-

moval

of

rotors

(955)

from

shaft

(954).

To

change

rotors

(955)

from

"a"

to

"b"

position,

the

rotor

should

be

rotated

60°

in

the

clockwise

direction

aher

removal and replaced

on

the

shaft

in this new

position.

Shunt

Trip

Option

Each el

ectrically

-operated

breaker

is

equipped

with

a

shunt

trip

attachment

for

tripping

from

a

remote

l

ocation.

(See Figure

9).

Since

the

shunt

trip

coil

is

designed

for

a

momentary

duty

cycle,

an

"a"

auxiliary

contact

switch

is

used

to

interrupt

its

circuit

immediately

after

the

breaker

is

tripped.

Energization

of

the

coil causes

the

armature

to

pick

up

and

rotate

the

trip

latch

to

trip

the

breaker. A compression spring (808)

ret

urns

the

ar

mature

to

its

norma

l

position

.

Undervoltage

Trip

Device

Option

The undervoltage

trip

device

(Figure

10)

automatically

trips

the

breaker

on l

oss

of

voltage.

Either

instan-

taneous

or

time

-

delay

operation

can

be

supplied. A

.06

inches gap

should

be maintained between

flap

ex-

tension and

pull

link

(738)

when

the

device

is

energized

with

the

breaker closed. Pick-up and

drop-out

is

set

so

that

the

device

picks

up

at

a voltage

of

85%

or

less

of

rated value and

drops

out

between 30% and

60%

of

the

rated value.

NOTE:

Pick-up and

drop-out

are

not

ind

iv

idually

adjustable.

Bell

Alarm

Switch

Option

The

bell alarm

switch

option

(See Figure 11)

functions

to

operate a

switch.

A single

pole

double

throw

or

a

double

pole

double

throw

switch

is

available.

The

switch

operator

is

connected

to

and

is

operated

by

the

tripping

actuator.

The

switch

operator

remains

tripped

even when

the

actuator

is

reset

by

the

breaker. The

switch

operator

must

be reset

either

manually,

or

by

an

additional

optional

electrical reset solenoid.

The

contacts

of

the

bell

alarm

switch

can be connected in series

with

the

breaker

closing

coil,

to

provide

a

lockout

feature

to

prevent

reclosing

after

a

fault.

-

11

-

Courtesy of NationalSwitchgear.com

-·

TABLE

4 -

TRIP

RATING

TABLE

-

AMPERES

STATIC

TRIP

II

Breaker

Tripping

Long

Time

Element

Ground

Element

Type

and

XFMR

Calibrated Pick-Up Settings Max.

Ca

lib

rated

Pick-Up

Frame

Rating

Cont

.

Setting

s

Size (Primary) A B c D E F G Rating 1

5%

25

% 50%

100

%

LA-3200A

2000

Amps

1000

1250

1500

1750

2000

2250

2500

2500

300

500

1000

2000

LA-3200A

3200

A

mp

s

1600

200

0 24

00

2800

3200

3600

4000

3200

480

800

1600

3200

LA-4000A

4000

A

mp

s

2000 2500

3000 3500

4000

4500

5000

4000

600

1000

2000

4000

&8

TABLE

5 -

TRIP

RATINGS

-

AMPERES

LIMITRIP

Breaker

Tripping

Lon

g

Time

Element

Type

and

XFMR

Calibrated Pick-Up Settings Max.

Fram

e

Rating

Co

nt

.

Size (

Primary

) A B c D E F Rating

1

.A-3

20

0A

2000

Amps

1000

1250

15

00

1750

20

00

2250

2250

_A-

3200

A

3200

Amps

16'o0

2000

2400

2800

3200 3600

3200

LA-4000A

4000

Amps

2000 2500

3000

3500

400

0

4500

4000

&8

Static

T

rip

Op

ti

on

The

opt

ional

tripping

devi

ces

are covered in detail

un

der

their

own

instruction

books which are

ref

erenced

on

the last page. Several types are available

that

provide a range

of

tripp

ing functions.

The

Stat

ic

Trip

11

device

mounts

on

to

a slide

type

bracket

on

the

circ

uit b

rea

ker.

To

remove

trip

device,

the

terminal

block

cover located above the

trip

device should be removed, exposing the

term

in

al

block

screws.

The

lower

r

ow

of screws can be

loo

sen

ed

with

a scr

ew

driv

er,

al

l

owing