English Installation and Configuration Instructions

1. Introduction to the SPCN910

The SPCN910 Communication Interface Module is an interface board that allows the SPC controller to

operate withthird party Alarm Reporting Devices (ARDs). It installs easily and neatly within SPC Grade 2

and Grade 3 cabinets.

A separate mounting kit (SPCY910) has been devised to accommodate some third party ARDs which

require extra spacing in the Siemens SPC Grade 2 cabinet.

The following ARDs have been tested for use with the SPCN910 Communication Interface Module.

ARD ARD Models Comment

DualCom GPRS

G2/G3/G4 CS2200, CS2300, CS2400

Redcare Classic 3G STU-12V 8-pin, 3G STU 11Z

11-pin

3.5G STU-12V 8-pin, 5G STU 11-

pin

Redcare GSM 5G GSM STU, GSM STU EV,

GSM STU SPCY910 Mounting Kit required

when fitting this ARD in an SPC

Grade 2 panel. See separate

installation sheet. Also requires

foam pad for mounting antenna.

Redcare Secure Secure 2, Secure 3, Secure IP Requires foam pad for mounting

antenna.

Enabling the SPCN910

To operate, the SPCN910 must be enabled. Refer

to the configuration sections of this installation

sheet for details of enabling the module.

The Status LED on the SPCN910 module will flash

regularly (once every second approx.) to indicate

that the module is functioning correctly.

4. Fitting the ARD in the Panel

The instructions in this section apply to all

types of ARD. However, some ARD models

require an additional installation kit (SPCY910

Please refer to the instruction sheet for this kit

before proceeding with the following installatio

instructions for the SPCN910.

Double-sided self-adhesive foam pads and

spacers are supplied with ARDs. Fit the adhesive

pads on either side of each of the spacers and use

the pads to attach the ARD to the back wall of

either the Grade 2 or Grade 3 panel.

¾Grade 2 - See Fig 4.

The ARD (1) should be fitted on the back wall

of the panel under the controller (2), with its

connector blocks facing down and protruding

slightly in order to facilitate the use of a

screwdriver on the connectors.

¾Grade 3 - See Fig. 5.

The ARD (1) should be fitted on the left side

of the back wall of the panel under the

hinged tray on which the controller is

mounted. The ARDs connector blocks should

be facing right in order to facilitate the

insertion of wires in the connectors.

5. Mounting the GSM Antenna (Grade 2)

The following instructions apply for mounting the

¾Redcare 5G GSM

¾Redcare GSM EV

¾Redcare GSM

¾Redcare Secure

For these units, a GSM antenna is mounted on top

of the panel and connected to the ARD. (See Fig.

6)

A double-sided self-adhesive foam pad is supplied

with SPCN910 for mounting the GSM antenna.

To attach the foam pad and mount the antenna:

¾Remove the knockout (1) for the GSM

antenna on top of the panel.

¾Attach the foam pad (2) to the GSM antenna

(3) as shown, to fit just underneath the

antenna hole (4). It is recommended that the

peeler tape (5) be removed from the section

of the antenna to which the foam pad is

attached.

¾Attach the antenna to the panel.

¾Insert the antenna cable (7) through the hole

in the panel and into the antenna connector

in the GSM module (8).

¾Ensure that the antenna is mounted so that

the panel cover can fit under it.

6. Specifications

Interfaces 1 x 16-pin socket to controller

interface

1 x channel output block with 8

terminals.

1 x signal terminal block (with 1

input and 1 output)

Status LEDs 11 operational LEDs -all green.

All outputs 0 - 5 volts CMOS, active high

All Inputs 0 - 5 volts (15 volts max.) with

internal pull-up resistor to 5 volts,

active high

Current

Consumption Min. 40 mA at 12 V DC (Status

LED blinking)

Max. 44 mA at 12 V DC (Status

LED blinking plus 8 channel

output LEDs on)

Operating

Temperature -10 to + 50 °C

Relative

Humidity Max. 90 % (no condensation)

Mounting Plug on module to SPC controlle

Dimensions

(W x H x D) 90 x 38 x 20 mm

Weight 0.025 kg

WARNING

Before starting to install and work with this

device, please read the Safety Instructions.

WARNING

Ensure that all anti-static precautions are

adhered to when handling connectors, wires,

terminals and PCBs.

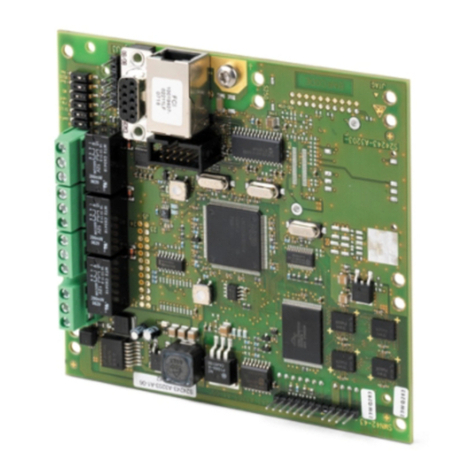

2. Description of the SPCN910

The module connects to the SPC controller board via

a 16 pin connector and is secured by four mounting

pillars. It provides 8 channel outputs, 1 signalling

input and 1 signalling output. Each I/O channel has

its own individual status LED.

The SPCN910 incorporates the following elements:

See Fig. 1

1 Mounting pillar holes

2 Channel output terminal block.

3 Channel status LEDs

4 Signalling terminal block

5 Signalling LEDs

6 Status LED

7 Programming connector

8 Controller interface connector

1. Mounting Pillar Holes (x4)

The SPCN910 contains four mounting pillar holes

which allow mounting pillars to be inserted for

securing the board to the controller PCB. For further

information see the section - Installing the

SPCN910.

2. Channel Output Terminal Block

The SPCN910 has a terminal block with 8 screw

terminals for each of the 8 on-board channel

outputs (1-8). These are connected to

corresponding terminals on the ARD.

3. Channel Status LEDs

Each channel (1- 8) has a LED to indicate the status

of the channel:

¾ON – Output on

¾OFF – Output off

4.Signalling Terminal Block

The signalling terminal block has two terminals:

¾ATS (output) - Alarm Transmission System

test. This output should be connected to the

ARD test input when BSIA Form No. 175

operation is desired.

¾LF (input) - Line Fault. Used by the ARD to

indicate a line fault to the SPCN910.

Signalling inputs should be connected to

corresponding ARD outputs and vice versa.

5. Signalling LEDs

The following two LEDs for the signalling block are

currently used and indicate the following conditions:

ATS ON – Short pulse only when active.

OFF – Normal, no activity.

LF BLINKING - Line Fault detected on a

transmission path.

ON - Line fault detected all

transmission paths.

OFF - No line fault detected.

6. Status LED

This status LED at the top of the board indicates the

current status of the SPCN910:

¾BLINKING - Normal operation.

¾ON - SPCN910 is operational but not

communicating with the controller. This usually

indicates a configuration error i.e. modem not

enabled.

¾OFF - SPCN910 is not operational or not

properly connected.

7. Programming Connector

This connector is used exclusively by engineers in

production and development.

8. Controller Interface Connector

The interface to the SPC controller is a dual in-line

socket which is mounted onto the 16 pin header on

the controller PCB. This interface is keyed to ensure

the SPCN910 is inserted onto the board in the correct

orientation. See Fig. 3.

3. Installing the SPCN910

WARNING

Do not install a SPCN910 on a powered

controller.

The SPCN910 should always be installed in

the primary modem slot on the SPC controller.

(Left hand slot – see Fig 2.)

See Fig. 2

1Primary modem slot

2Secondary modem slot

3Controller interface connectors

4Mounting pillar holes

5Wireless modem connectors

The SPCN910 is supplied with four mounting pillars

for securing the module to the controller PCB.

See Fig. 3

1Mounting pillars

2SPCN910 with mounting pillars installed.

3Controller PCB.

4Controller interface connector socket on

SPCN910.

To install the module onto the controller:

¾Power down the controller (disconnect the

battery leads from the battery if one is

connected).

¾Insert one end of each of the four mounting

pillars into the appropriate holes. Push firmly

until each is secured in place.

¾Align the SPCN910 controller interface

connector socket over the 16 pin SPC controller

interface header on the PCB (see Fig. 3).

¾Slowly but firmly push the module down onto

the controller PCB until the mounting pillars are

secured to the PCB and the interface socket is

connected.

¾Check that the module is correctly connected

and then power-up the controller again.