sSINAMICS G120 PM240-2 Power ModuleGetting Started Guide

Warning

This equipment contains dangerous voltages and controls potentially dangerous

rotating mechanical parts.

The terminals can carry hazardous voltages even after the inverter has been switched

off. After disconnecting the line supply, wait at least 5 minutes until the drive unit has

discharged itself. Only then, carry out any installation work.

Read the instructions in the associated manuals under:

http://support.automation.siemens.com. Non-compliance or failure to follow the

instructions can result in loss of life, severe personal injury or serious damage to

property.

Only suitable qualified personnel should work on this equipment. Qualified persons are

defined as persons who are authorized to commission, ground and label systems and

circuits in accordance with established safety practices and standards.

The successful and safe operation of this equipment is dependent upon its proper

handling, installation, operation and maintenance.

Warnung

Das vorliegende Gerät führt gefährliche Spannungen und steuert rotierende

mechanische Teile, die gegebenenfalls gefährlich sind.

Die Klemmen können auch dann gefährliche Spannungen führen, wenn der Umrichter

außer Betrieb ist. Warten Sie nach dem Unterbrechen der Netzversorgung mindestens

5 Minuten, bis sich das Gerät entladen hat. Führen Sie erst dann Montagearbeiten aus.

Beachten Sie die Hinweise in den zugehörigen Betriebsanleitungen unter:

http://support.automation.siemens.com. Bei Missachtung oder Nichtbefolgen der

Hinweise können Tod, schwere Körperverletzungen oder erheblicher Sachschaden

eintreten.

Inbetriebsetzung und Betrieb dieses Geräts dürfen nur von qualifiziertem Personal

vorgenommen werden. Qualifiziertes Personal sind Personen, welche die Berechtigung

haben, Systeme und Stromkreise gemäß den Standards der Sicherheitstechnik in

Betrieb zu nehmen, zu erden und zu kennzeichnen.

Der einwandfreie und sichere Betrieb des Gerätes setzt sachgemäßen Transport,

ordnungsgemäße Installation, Bedienung und Instandhaltung voraus.

Attention

L' appareil présente des tensions dangereuses et contrôle des pièces mécaniques

rotation potentiellement dangereuses.

Les bornes peuvent présenter des tensions dangereuses, même lorsque le variateur est

à l'arrêt. Après coupure de la tension du réseau, il convient d'attendre au moins 5

minutes pour permettre la décharge de l'appareil. Procéder à une intervention

seulement après écoulement de ce délai.

Respecter les consignes figurant dans les instructions de service correspondantes et

disponibles sous le lien suivant : http://support.automation.siemens.com. Le non-respect

des consignes peut entraîner la mort, des blessures graves ou des dégâts matériels

importants.

La mise en service et l'utilisation de cette machine ne doivent être effectuées que par

des personnes qualifiées. Par personnes qualifiées on entend des personnes autorisées

à mettre en service, mettre à la terre et repérer les systèmes et les circuits électriques

dans le respect des règles de l'art en matière de sécurité.

L'exploitation sûre et sans défaut de l'appareil suppose un transport, un entreposage,

une installation, une conduite et une maintenance dans les règles de l'art.

Avvertenza

Questo apparecchio conduce tensioni pericolose ed aziona parti meccaniche rotanti

potenzialmente pericolose.

I morsetti possono condurre tensioni pericolose anche quando il convertitore è stato

spento. Dopo avere interrotto l’alimentazione di rete, attendere almeno 5 minuti finché

l’apparecchio non si è scaricato. Solo allora si possono eseguire interventi

sull’apparecchio.

Leggere le istruzioni riportate nei rispettivi manuali all’indirizzo:

http://support.automation.siemens.com. In caso di non osservanza o di mancata

applicazione delle istruzioni sussiste la possibilità di morte, gravi lesioni fisiche o ingenti

danni materiali.

Solo personale qualificato può essere addetto alla messa in servizio e al funzionamento

di questo apparecchio. Per personale qualificato si intendono persone autorizzate a

mettere in servizio, mettere a terra e contrassegnare sistemi e circuiti elettrici in

conformità agli standard della tecnica di sicurezza.

Il funzionamento corretto e sicuro dell'apparecchio presuppone un trasporto,

un’installazione, un utilizzo e una manutenzione appropriati.

Advertencia

El presente equipo está sometido a tensiones peligrosas y controla piezas mecánicas

rotación que también pueden ser peligrosas.

Los bornes o terminales de conexión pueden estar también bajo tensión eléctrica

peligrosa incluso aunque el convertidor o variador no esté funcionando. Tras

desconectar la alimentación de red, espere al menos 5 minutos para que el equipo

pueda descargarse. Sólo entonces proceda a realizar los trabajos de montaje.

Respete las indicaciones que se especifican en las instrucciones de servicio asociadas,

y que pueden consultarse en: http://support.automation.siemens.com. Si no se

observan las advertencias o no se siguen las indicaciones de las instrucciones, existe

peligro de muerte, graves lesiones corporales o considerables daños materiales

La puesta en marcha y el funcionamiento de este equipo debe encomendarse

exclusivamente a personal cualificado. Personal cualificado son personas autorizadas

para poner en servicio, conectar a tierra e identificar sistemas y circuitos eléctricos

conforme a las normas en materia de seguridad.

El funcionamiento correcto y seguro del equipo presupone un transporte, instalación,

montaje y puesta en marcha adecuados, así como un manejo y un mantenimiento

rigurosos.

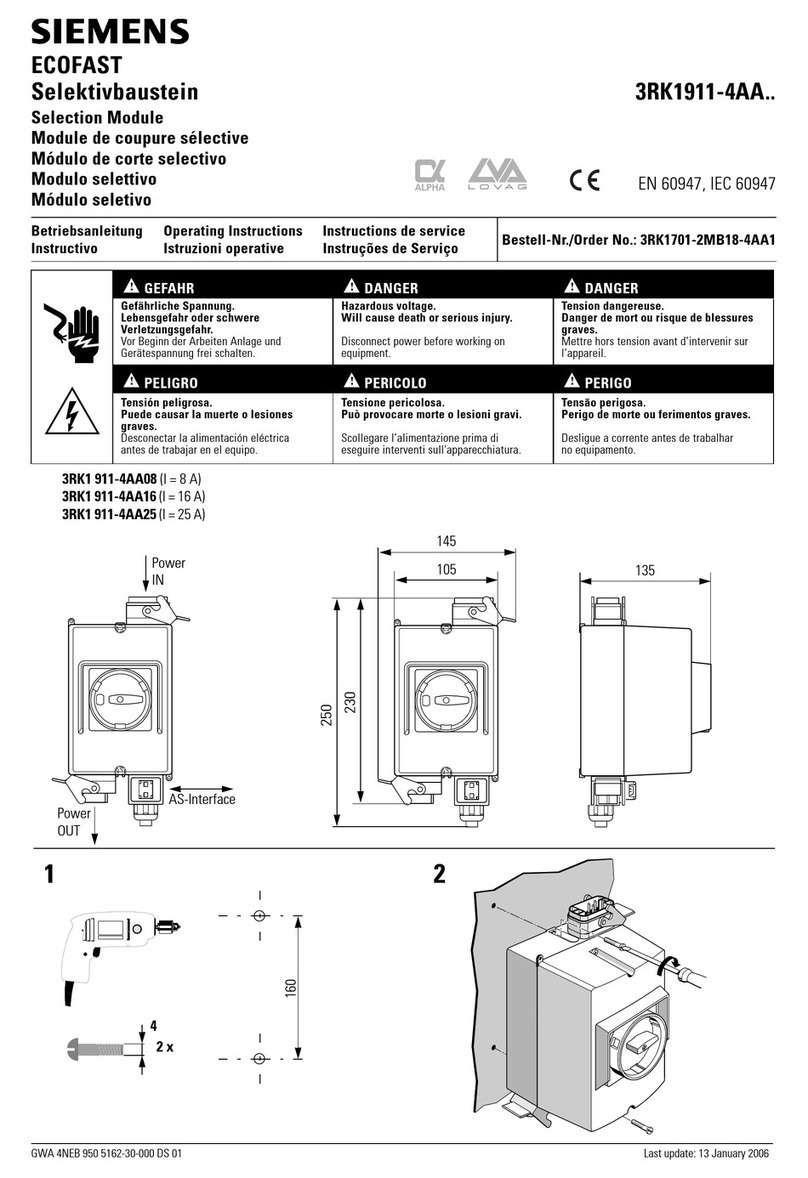

Dimensions and drill patterns PM240-2 IP20 Dimensions and drill patterns PM240-2 Push-Through*

-1-

Heated air

Heated air

Cool air Cool air

Mounting hole for mounting frame

Panel template for

mounting holes for

PT housing

Mounting hole for mounting frame

PM240-2 Push-Through mounting sequence Push-Through mounting frame

Cabinet

Seal

Mounting Frame

It is recommended that the optional mounting frame

is used to install the Push-through Power Module in

a cabinet. This optional mounting frame is designed,

in conjunction with, the supplied seal to easily

maintain an IP54 rating of the enclosure (the seal is

delivered with the Power Module). If the Power

Module is mounted without using the optional

mounting frame, it is the user's responsibility to

ensure the correct IP protection rating is reached.

Mounting Frame

Maximum cable lengths

Components for United States / Canadian installations (UL/cUL)

Using Maximum cable

length

EMI Level

Screened cables, filtered units (class A) 25 m Second Environment, C2*

Screened cables, filtered units (class A) 50 m Second Environment, C3*

Screened cables, unfiltered units, 50 m EMI Standard not fullfilled

Unscreened cables, filtered or unfiltered units 100 m EMI Standard not fullfilled

*Only if EMC compliant connections are used.

CAUTION - Cable cross-section for grounding: The earth cable must be at least as big as the power cables.

In order that the system is UL/cUL-compliant, use UL/cUL-certified J-type fuses, inverse-time circuit breakers and Type E

combination motor controllers. Use class 1 75° C copper wire only. Install the inverter with any external recommended

suppressor with the following features:

● Surge-protective devices; device shall be a Listed Surge-protective device (Category code VZCA and VZCA7)

● Rated nominal voltage 480/277 VAC, 50/60 Hz, 3-phase

● Clamping voltage VPR = 2000 V, IN = 3 kA min, MCOV = 550 VAC, SCCR = 65 kA

● Suitable for Type 1 or Type 2 SPD application

● Clamping shall be provided between phases and also between phase and ground.

*The heatsink, when fitted with the mounting frame and the seal is IP54 rated. The IP rating of the inverter side depends on the IP rating of the cabinet within which the Inverter is installed.

Tightening torque:

3 Nm (26.5 lbf.in)